ASTM F2979-20

(Guide)Standard Guide for Characterization of Wear from the Articulating Surfaces in Retrieved Metal-on-Metal and other Hard-on-Hard Hip Prostheses

Standard Guide for Characterization of Wear from the Articulating Surfaces in Retrieved Metal-on-Metal and other Hard-on-Hard Hip Prostheses

SCOPE

1.1 This standard guide provides options and a compendium of information for measuring the bearing surface and estimating the in-vivo wear of explanted Metal-on-Metal (MoM) and other “hard” (for example, ceramic) hip components. The guide covers the measurement of acetabular cups and femoral heads using a dimensional change method and is applicable to all prosthetic hip types, including stemmed (modular) and resurfacing hip systems.

1.2 The methods specified in this guide are not applicable for measuring the in-vivo wear from non-articulating surfaces, for example modular connections (at the stem/neck, neck/head, or cup liner/shell interface) or at the acetabular cup rim.

1.3 The parameters (wear depth and volumetric wear) evaluated and reported in this guide are estimated from the assumed as-manufactured shape of the components. The wear volume is calculated using a numerical integration method and the wear depth is the difference between the assumed as-manufactured shape and the measured surface.

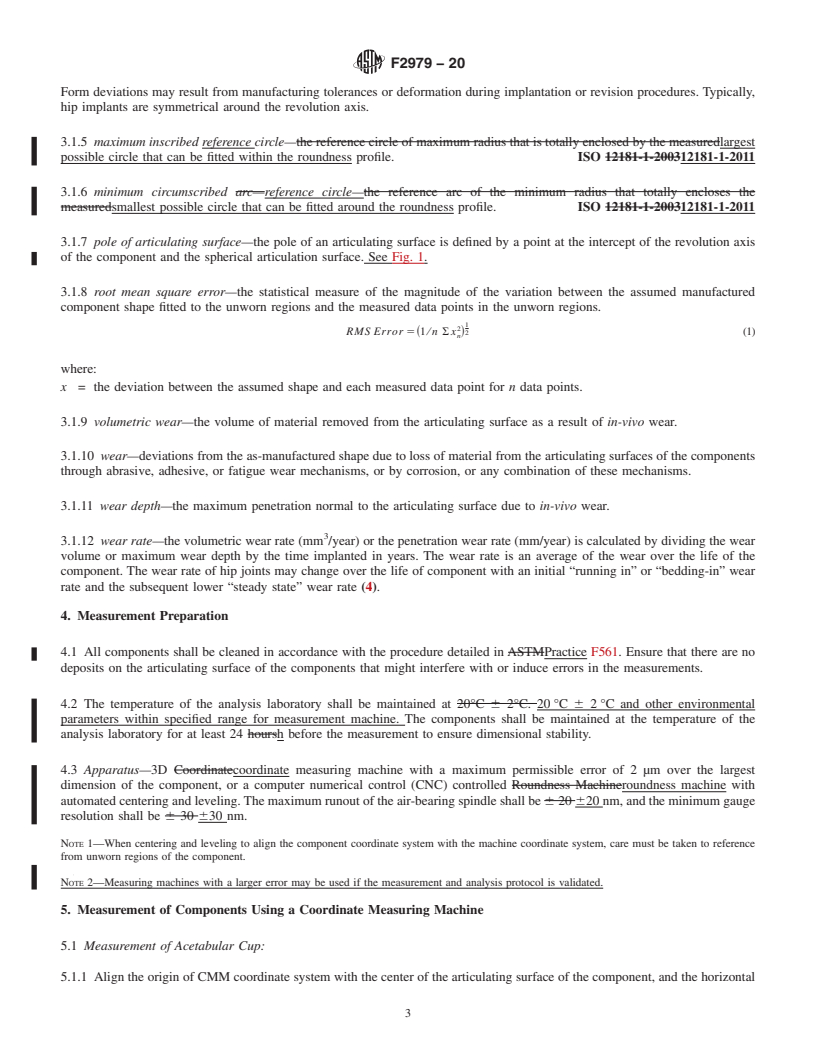

1.4 This guide covers the measurement of the depth of wear and the volumetric wear using a Coordinate Measuring Machine (CMM) and the depth of wear using an Roundness Machine. Other metrology measurement equipment may be used to measure the wear depth or volume if the resolution and accuracy of the measurements are comparable with the instruments detailed in this standard. The measurement and analysis protocols should be based on those described in this standard.

1.5 This guide is applicable to hip joints which are nominally spherical at the time of manufacture. Form deviations resulting from manufacturing or deformation may occur and may necessitate the use of a non-spherical surface to represent the unworn surface of the component. Hip joints designed with asymmetry are considered beyond the scope of this guide, although the principles and techniques may be applicable to the characterization of wear from the articulating surfaces.

1.6 This guide is intended as an extension to Practice F561 as a Stage II nondestructive test.

1.7 This standard may involve hazardous materials, operations, and equipment. As a precautionary measure, explanted devices should be sterilized or disinfected by an appropriate means that does not adversely affect the implant or the associated tissue that may be the subject of subsequent analysis. A detailed discussion of precautions to be used in handling human tissues can be found in ISO 12891-1. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2979 − 20

Standard Guide for

Characterization of Wear from the Articulating Surfaces in

Retrieved Metal-on-Metal and other Hard-on-Hard Hip

1

Prostheses

This standard is issued under the fixed designation F2979; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope althoughtheprinciplesandtechniquesmaybeapplicabletothe

characterization of wear from the articulating surfaces.

1.1 Thisstandardguideprovidesoptionsandacompendium

of information for measuring the bearing surface and estimat-

1.6 This guide is intended as an extension to Practice F561

ing the in-vivo wear of explanted Metal-on-Metal (MoM) and

as a Stage II nondestructive test.

other “hard” (for example, ceramic) hip components. The

1.7 This standard may involve hazardous materials,

guide covers the measurement of acetabular cups and femoral

operations, and equipment. As a precautionary measure, ex-

heads using a dimensional change method and is applicable to

planted devices should be sterilized or disinfected by an

all prosthetic hip types, including stemmed (modular) and

appropriate means that does not adversely affect the implant or

resurfacing hip systems.

the associated tissue that may be the subject of subsequent

1.2 The methods specified in this guide are not applicable

analysis. A detailed discussion of precautions to be used in

for measuring the in-vivo wear from non-articulating surfaces,

handling human tissues can be found in ISO 12891-1. This

forexamplemodularconnections(atthestem/neck,neck/head,

standard does not purport to address all of the safety concerns,

or cup liner/shell interface) or at the acetabular cup rim.

if any, associated with its use. It is the responsibility of the user

1.3 The parameters (wear depth and volumetric wear) of this standard to establish appropriate safety, health, and

evaluated and reported in this guide are estimated from the environmental practices and determine the applicability of

assumed as-manufactured shape of the components. The wear regulatory limitations prior to use.

volume is calculated using a numerical integration method and

1.8 This international standard was developed in accor-

the wear depth is the difference between the assumed as-

dance with internationally recognized principles on standard-

manufactured shape and the measured surface.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

1.4 This guide covers the measurement of the depth of wear

mendations issued by the World Trade Organization Technical

and the volumetric wear using a Coordinate Measuring Ma-

Barriers to Trade (TBT) Committee.

chine (CMM) and the depth of wear using an Roundness

Machine. Other metrology measurement equipment may be

2. Referenced Documents

used to measure the wear depth or volume if the resolution and

accuracy of the measurements are comparable with the instru-

2

2.1 ASTM Standards:

ments detailed in this standard. The measurement and analysis

E177 Practice for Use of the Terms Precision and Bias in

protocols should be based on those described in this standard.

ASTM Test Methods

1.5 This guide is applicable to hip joints which are nomi- E691 Practice for Conducting an Interlaboratory Study to

nally spherical at the time of manufacture. Form deviations

Determine the Precision of a Test Method

resulting from manufacturing or deformation may occur and F561 Practice for Retrieval and Analysis of Medical

may necessitate the use of a non-spherical surface to represent

Devices, and Associated Tissues and Fluids

the unworn surface of the component. Hip joints designed with F2033 Specification for Total Hip Joint Prosthesis and Hip

asymmetry are considered beyond the scope of this guide,

Endoprosthesis Bearing Surfaces Made of Metallic,

Ceramic, and Polymeric Materials

1

This guide is under the jurisdiction of ASTM Committee F04 on Medical and

Surgical Materials and Devices and is the direct responsibility of Subcommittee

2

F04.22 on Arthroplasty. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Dec. 15, 2020. Published January 2021. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2014. Last previous edition approved in 2014 as F2979 – 14. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F2979-20. the ASTM website.

Copyright © ASTM In

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2979 − 14 F2979 − 20

Standard Guide for

Characterization of Wear from the Articulating Surfaces in

Retrieved Metal-on-Metal and other Hard-on-Hard Hip

1

Prostheses

This standard is issued under the fixed designation F2979; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide specifies a method to measure the standard guide provides options and a compendium of information for measuring

the bearing surface and estimating the in-vivo wear of explanted Metal-on-Metal (MoM) and other “hard” (e.g., (for example,

ceramic) hip components. The guide covers the measurement of acetabular cups and femoral heads using a dimensional change

method and is applicable to all prosthetic hip types, including stemmed (modular) and resurfacing hip systems.

1.2 The methods specified in this guide are not applicable for measuring the in-vivo wear from non-articulating surfaces, for

example modular connections (at the stem/neck, neck/headneck/head, or cup liner/shell interface) or at the acetabular cup rim.

1.3 The parameters (wear depth and volumetric wear) evaluated and reported in this guide are estimated from the assumed

as-manufactured shape of the components. The wear volume is calculated using a numerical integration method and the wear depth

is the difference between the assumed as-manufactured shape and the measured surface.

1.4 This guide covers the measurement of the depth of wear and the volumetric wear using a Coordinate Measuring Machine

(CMM) and the depth of wear using an Roundness Machine. Other metrology measurement equipment may be used to measure

the wear depth or volume if the resolution and accuracy of the measurements are comparable with the instruments detailed in this

standard. The measurement and analysis protocols should be based on those described in this standard.

1.5 This guide is applicable to hip joints which are nominally spherical at the time of manufacture. Form deviations resulting from

manufacturing or deformation may occur and may necessitate the use of a non-spherical surface to represent the unworn surface

of the component. Hip joints designed with asymmetry are considered beyond the scope of this guide, although the principles and

techniques may be applicable to the characterization of wear from the articulating surfaces.

1.6 This guide is intended as an extension to ASTMPractice F561 as a Stage II nondestructive test.

1.7 This standard may involve hazardous materials, operations, and equipment. As a precautionary measure, explanted devices

should be sterilized or disinfected by an appropriate means that does not adversely affect the implant or the associated tissue that

may be the subject of subsequent analysis. A detailed discussion of precautions to be used in handling human tissues can be found

in ISO 12891-1. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and

determine the applicability of regulatory limitations prior to use.

1

This test method guide is under the jurisdiction of ASTM Committee F04 on Medical and Surgical Materials and Devices and is the direct responsibility of Subcommittee

F04.22 on Arthroplasty.

Current edition approved Feb. 1, 2014Dec. 15, 2020. Published April 2014January 2021. Originally approved in 2014. Last previous edition approved in 2014 as

F2979 – 14. DOI: 10.1520/F2979-14.10.1520/F2979-20.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2979 − 20

1.8 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

F561 Practice for Retrieval and Analysis of Medical

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.