ASTM E2492-07(2012)

(Test Method)Standard Test Method for Evaluating Springback of Sheet Metal Using the Demeri Split Ring Test (Withdrawn 2017)

Standard Test Method for Evaluating Springback of Sheet Metal Using the Demeri Split Ring Test (Withdrawn 2017)

SIGNIFICANCE AND USE

The formability of materials is affected by springback, the difference between the final shape of a part and the shape of the die that formed it. Materials having a large amount of springback create difficulties for the die designer and make die rework much more likely and complicated. This can add months and great costs to the achievement of successful dies. While dealing with springback in traditional metals is largely overcome by experience, new metals often have so much springback that they can only be used after much trial and error. The quantification and prediction of the tendency of metals to springback is addressed by this test method.

The magnitude of the springback is a convolution of the elastic modulus, the flow stress of the metal of interest, the sheet metal thickness and the amount and type of cold work introduced by the forming process. Since the cup forming process contains features of many forming operations, the amount of springback measured by the Demeri split ring test is indicative of the behavior of the metal in many stamping operations.

The amount of springback that occurs in this test is very large compared to other approaches. This improves measurement accuracy and reduces experimental error in all types of formable metals.

This test does not require measurement fixtures or any sophisticated profiling equipment for accurate measurement of springback. Conventional length measuring instruments are all that is needed to perform the required measurements.

This test can be used to rank materials according to their tendency to springback after a forming operation (see Refs 1-3). Since springback depends on the sheet thickness, metals should be compared at the same thickness. Experience has shown that the test can also be used in conjunction with an appropriate analysis to predict quantitatively the amount of springback occurring after a forming operation (see Refs 2-9).

This test provides a method to compare springback predictions by v...

SCOPE

1.1 This test method provides a means of evaluating the springback behavior of metals in a test that simulates a stretch-draw forming process. The test method can also be used to calibrate computer simulation codes by selecting appropriate control parameters to achieve satisfactory correlation between simulation and test results.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method provides a means of evaluating the springback behavior of metals in a test that simulates a stretch-draw forming process. The test method can also be used to calibrate computer simulation codes by selecting appropriate control parameters to achieve satisfactory correlation between simulation and test results.

Formerly under the jurisdiction of Committee E28 on Mechanical Testing, this test method was withdrawn in September 2017. This standard is being withdrawn without replacement due to its limited use by industry.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2492 − 07 (Reapproved 2012)

Standard Test Method for

Evaluating Springback of Sheet Metal Using the Demeri

Split Ring Test

This standard is issued under the fixed designation E2492; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope of the die that formed it. Materials having a large amount of

springback create difficulties for the die designer and make die

1.1 This test method provides a means of evaluating the

rework much more likely and complicated. This can add

springback behavior of metals in a test that simulates a

months and great costs to the achievement of successful dies.

stretch-drawformingprocess.Thetestmethodcanalsobeused

While dealing with springback in traditional metals is largely

tocalibratecomputersimulationcodesbyselectingappropriate

overcome by experience, new metals often have so much

control parameters to achieve satisfactory correlation between

springback that they can only be used after much trial and

simulation and test results.

error. The quantification and prediction of the tendency of

1.2 The values stated in SI units are to be regarded as

metals to springback is addressed by this test method.

standard. No other units of measurement are included in this

4.2 The magnitude of the springback is a convolution of the

standard.

elastic modulus, the flow stress of the metal of interest, the

1.3 This standard does not purport to address all of the

sheet metal thickness and the amount and type of cold work

safety concerns, if any, associated with its use. It is the

introduced by the forming process. Since the cup forming

responsibility of the user of this standard to establish appro-

process contains features of many forming operations, the

priate safety and health practices and determine the applica-

amount of springback measured by the Demeri split ring test is

bility of regulatory limitations prior to use.

indicative of the behavior of the metal in many stamping

operations.

2. Terminology

4.3 The amount of springback that occurs in this test is very

2.1 Definitions:

large compared to other approaches. This improves measure-

2.1.1 springback—the difference between the final shape of

ment accuracy and reduces experimental error in all types of

a part and the shape of the forming die.

formable metals.

2.1.2 Demeri Split Ring Test—a test that measures the

4.4 This test does not require measurement fixtures or any

springback behavior of sheet metal by comparing the diameter

of a ring extracted from the wall of a flat bottom cup and the sophisticated profiling equipment for accurate measurement of

springback. Conventional length measuring instruments are all

diameter of the same ring split to release residual stresses.

that is needed to perform the required measurements.

3. Summary of Test Method

4.5 Thistestcanbeusedtorankmaterialsaccordingtotheir

3.1 The test method consists of four steps: (1) deep draw a

tendency to springback after a forming operation (see Refs

cylindrical cup from a circular blank with a constant clamp or 2

1-3). Since springback depends on the sheet thickness, metals

blankholder force, (2) cut a circular ring from the mid-section

should be compared at the same thickness. Experience has

of the drawn cup, (3) split the ring along a certain direction to

shown that the test can also be used in conjunction with an

release residual stresses caused by the stretch-draw operation,

appropriate analysis to predict quantitatively the amount of

and (4) measure the opening of the ring (springback).

springback occurring after a forming operation (see Refs 2-9).

4. Significance and Use

4.6 This test provides a method to compare springback

predictions by various numerical simulation codes.Test results

4.1 The formability of materials is affected by springback,

canbeusedtocalibratecomputersimulationcodesbyselecting

the difference between the final shape of a part and the shape

proper control parameters and appropriate material models to

achieve satisfactory correlation between simulation and test

This test method is under the jurisdiction of ASTM Committee E28 on

Mechanical Testing and is the direct responsibility of Subcommittee E28.02 on

Ductility and Formability.

Current edition approved April 1, 2012. Published May 2012. Originally

approved in 2007. Last previous edition approved in 2007 as E2492–07. DOI: The boldface numbers in parentheses refer to the list of references at the end of

10.1520/E2492-07R12. this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2492 − 07 (2012)

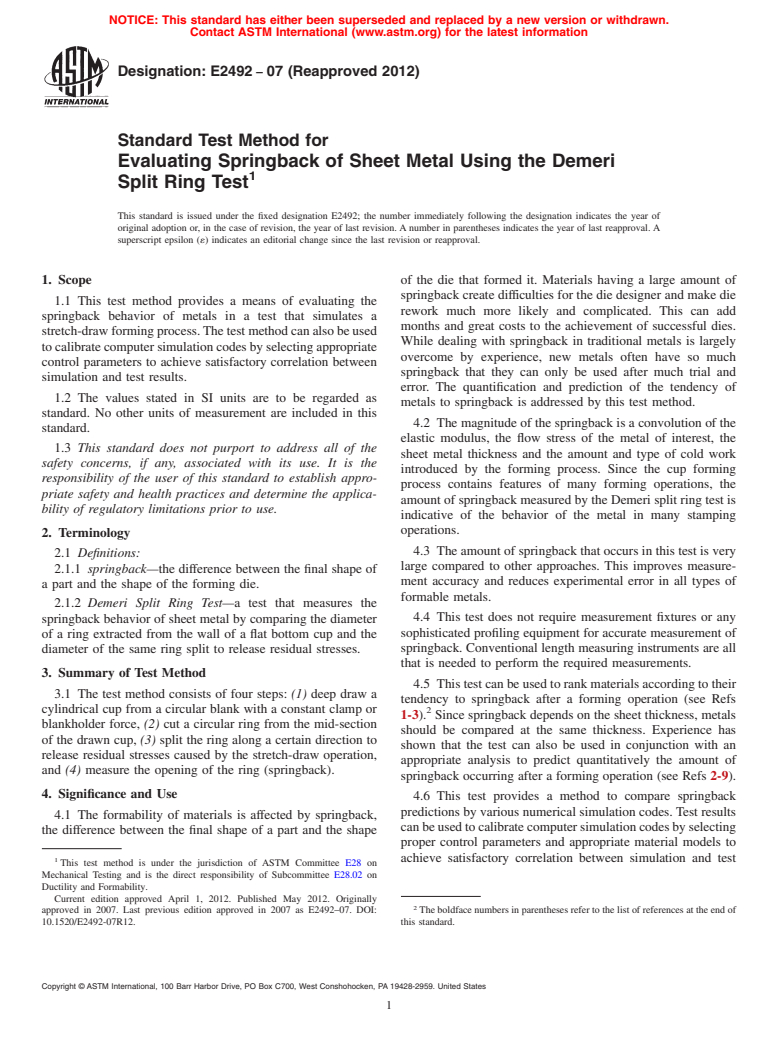

FIG. 1 Cross Section Through the Experimental Setup Used for Cup Drawing

results. Test data can be used to evaluate and improve current required accuracy and precision are acceptable for the first

forming and simulation capabilities. threemeasurements.Onlyanon-contactingmethod,suchasan

optical micrometer, traveling microscope, or comparator,

4.7 The experimental setup and test procedure are simple,

should be used for measuring the final diameter as this is very

and test results are highly repeatable.

sensitive to the presence of additional forces.

5. Apparatus

6. Hazards

5.1 Cup Forming Apparatus—A die set and punch are

6.1 Forming equipment can be dangerous. Care must be

needed to form the cup from circular sheet metal blanks for

taken to keep hands away when forming the cups.

subsequent testing. The die set consists of upper and lower

tools with centrally located circular holes. The sheet is held

6.2 Cutting and slicing equipment can also cause injury if

between these and formed into a cup by the action of a punch

care is not taken in their use.

that fits through the hole in the upper and lower dies. This

6.3 Sheet metal generally has sharp edges and burrs.

arrangement is shown in Fig. 1. The apparatus can be part of a

Precautions, such as gloves and safety glasses should be worn.

double acting press where the clamp force on the upper tool of

When the ring is split open, it is required to be restrained in

the die is generated hydraulically, followed by movement of

some way to avoid artifacts due to sudden springback. If it is

the punch to make the cup.Alternatively, the upper tool can be

not restrained, harm to the person splitting the ring may result.

held down by a combination of bolts and Belleville spring

washerstoachieveaconstantforce.Inthiscase,thecupcanbe

7. Sampling, Test Specimens, and Test Units

formed in a universal or compression testing machine.

7.1 Samples for testing shall be from the same lot or heat as

5.2 Ring SlicingApparatus—Thecuttingequipment,usedto

the material of interest except where the measurement of

slice the ring from the cup and split it, must not change the

springback is being made to rank different types of materials

worked state of the ring, as this will affect the result. Good

for future reference. In this latter case, it will suffice to use

results have been obtained with laser cutting equipment,

material typical of the specification.

electro discharge machining (EDM), and slow speed diamond

wheels. Shears have been shown to badly distort the ring and 7.2 Test units shall be in SI units.

leave burrs that affect the result. Other methods are acceptable

if they can be shown to agree with one of the successful 8. Procedure

methods.

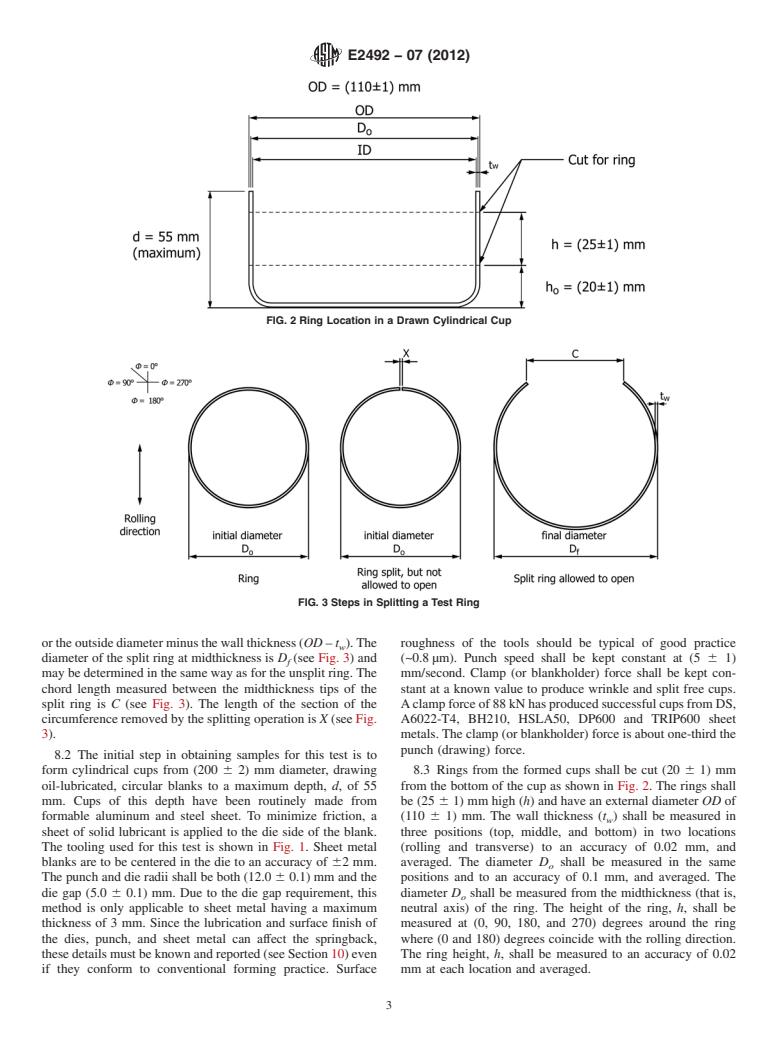

8.1 The dimensions used in this section are defined here for

5.3 Dimensional Measurement Apparatus—Methods of convenience. The depth of the drawn cup is d (see Fig. 2). The

measuring the location of the ring to be extracted from the cup height of the ring extracted from the cup is h (see Fig. 2). The

(h ) (see Fig. 2), the initial ring diameter (D ), the ring height wall thickness of the cup is t . The diameter of the unsplit ring

o o w

(h), the ring wall thickness (t ) and the final diameter of the is D , measured to the midthickness (see Fig. 3). D is equal to

w o o

split open ring (D) are required. Most methods having the the average of the outside and inside diameters (OD/2 + ID/2)

f

E2492 − 07 (2012)

FIG. 2 Ring Location in a Drawn Cylindrical Cup

FIG. 3 Steps in Splitting a Test Ring

ortheoutsidediameterminusthewallthickness(OD–t ).The roughness of the tools should be typical of good practice

w

diameter of the split ring at midthickness is D (see Fig. 3) and (~0.8 µm). Punch speed shall be kept constant at (5 6 1)

f

may be determined in the same way as for the unsplit ring.The mm/second. Clamp (or blankholder) force shall be kept con-

chord length measured between the midthickness tips of the stant at a known value to produce wrinkle and split free cups.

split ring is C (see Fig. 3). The length of the section of the Aclampforceof88kNhasproducedsuccessfulcupsfromDS,

circumference removed by the splitting operation is X (see Fig. A6022-T4, BH210, HSLA50, DP600 and TRIP600 sheet

3). metals.The clamp (or blankholder) force is about one-third the

punch (drawing) force.

8.2 The initial step in obtaining samples for this test is to

form cylindrical cups from (200 6 2) mm diameter, drawing 8.3 Rings from the formed cups shall be cut (20 6 1) mm

oil-lubricated, circular blanks to a maximum depth, d,of55 from the bottom of the cup as shown in Fig. 2. The rings shall

mm. Cups of this depth have been routinely made from be (25 6 1) mm high (h) and have an external diameter OD of

formable aluminum and steel sheet. To minimize friction, a (110 6 1) mm. The wall thickness (t ) shall be measured in

w

sheet of solid lubricant is applied to the die side of the blank. three positions (top, middle, and bottom) in two locations

The tooling used for this test is shown in Fig. 1. Sheet metal (rolling and transverse) to an accur

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.