ASTM D2749-02

(Terminology)Standard Symbols for Dimensions of Plastic Pipe Fittings

Standard Symbols for Dimensions of Plastic Pipe Fittings

SCOPE

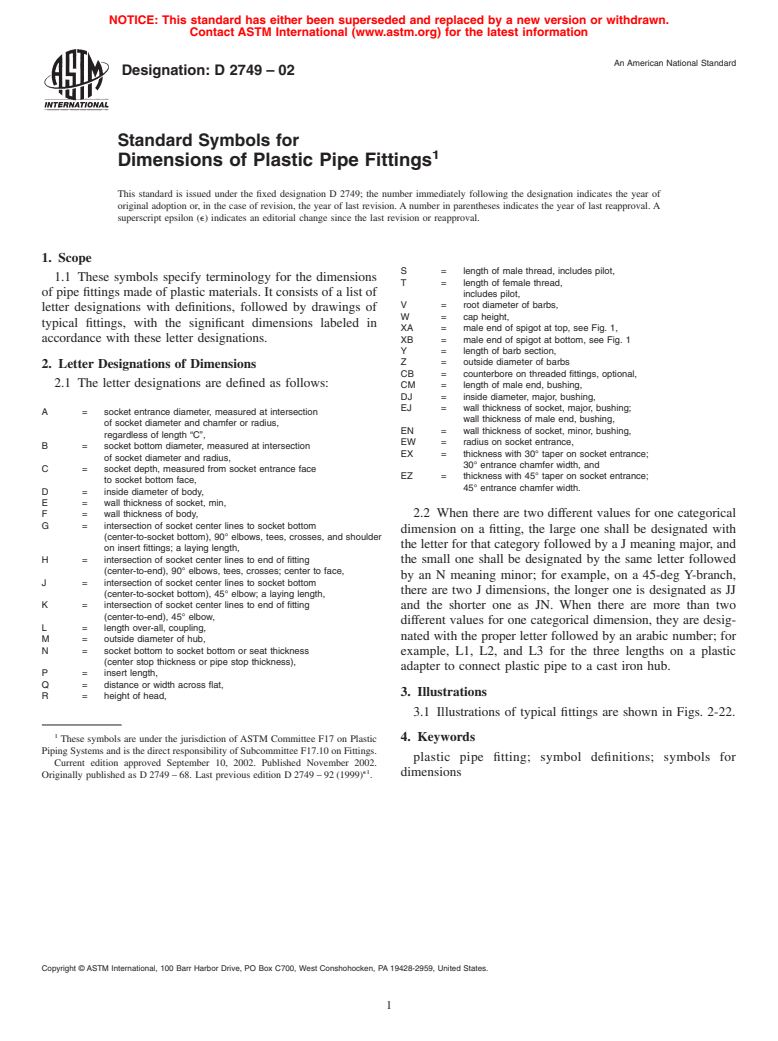

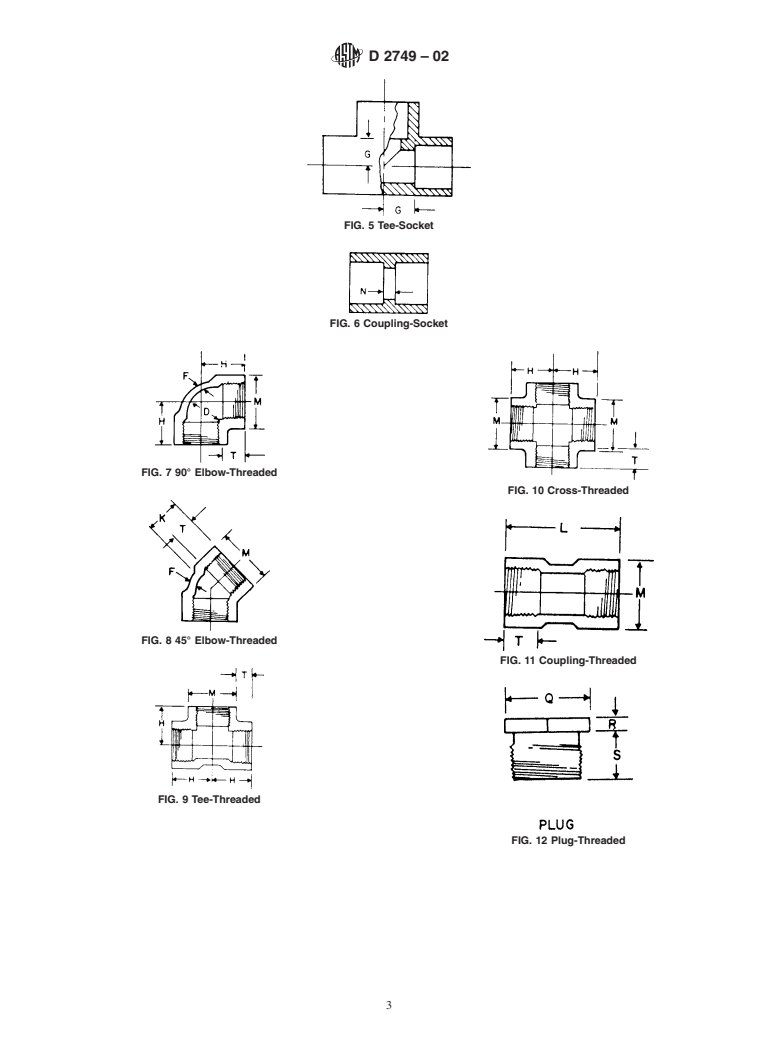

1.1 These symbols specify terminology for the dimensions of pipe fittings made of plastic materials. It consists of a list of letter designations with definitions, followed by drawings of typical fittings, with the significant dimensions labeled in accordance with these letter designations.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 2749 – 02

Standard Symbols for

1

Dimensions of Plastic Pipe Fittings

This standard is issued under the fixed designation D 2749; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

S = length of male thread, includes pilot,

1.1 These symbols specify terminology for the dimensions

T = length of female thread,

of pipe fittings made of plastic materials. It consists of a list of

includes pilot,

V = root diameter of barbs,

letter designations with definitions, followed by drawings of

W = cap height,

typical fittings, with the significant dimensions labeled in

XA = male end of spigot at top, see Fig. 1,

accordance with these letter designations.

XB = male end of spigot at bottom, see Fig. 1

Y = length of barb section,

Z = outside diameter of barbs

2. Letter Designations of Dimensions

CB = counterbore on threaded fittings, optional,

2.1 The letter designations are defined as follows:

CM = length of male end, bushing,

DJ = inside diameter, major, bushing,

EJ = wall thickness of socket, major, bushing;

A = socket entrance diameter, measured at intersection

wall thickness of male end, bushing,

of socket diameter and chamfer or radius,

EN = wall thickness of socket, minor, bushing,

regardless of length “C”,

EW = radius on socket entrance,

B = socket bottom diameter, measured at intersection

EX = thickness with 30° taper on socket entrance;

of socket diameter and radius,

30° entrance chamfer width, and

C = socket depth, measured from socket entrance face

EZ = thickness with 45° taper on socket entrance;

to socket bottom face,

45° entrance chamfer width.

D = inside diameter of body,

E = wall thickness of socket, min,

F = wall thickness of body, 2.2 When there are two different values for one categorical

G = intersection of socket center lines to socket bottom

dimension on a fitting, the large one shall be designated with

(center-to-socket bottom), 90° elbows, tees, crosses, and shoulder

the letter for that category followed by a J meaning major, and

on insert fittings; a laying length,

H = intersection of socket center lines to end of fitting

the small one shall be designated by the same letter followed

(center-to-end), 90° elbows, tees, crosses; center to face,

by an N meaning minor; for example, on a 45-deg Y-branch,

J = intersection of socket center lines to socket bottom

there are two J dimensions, the longer one is designated as JJ

(center-to-socket bottom), 45° elbow; a laying length,

K = intersection of socket center lines to end of fitting

and the shorter one as JN. When there are more than two

(center-to-end), 45° elbow,

different values for one categorical dimension, they are desig-

L = length over-all, coupling,

nated with the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.