ASTM B691-02(2007)

(Specification)Standard Specification for Iron-Nickel-Chromium-Molybdenum Alloys (UNS N08366 and UNS N08367) Rod, Bar, and Wire

Standard Specification for Iron-Nickel-Chromium-Molybdenum Alloys (UNS N08366 and UNS N08367) Rod, Bar, and Wire

ABSTRACT

This specification covers the standard for hot-finished and cold-finished rounds, squares, hexagons, octagons, and rectangles made from iron-nickel-chromium-molybdenum alloys (UNS N08366 and UNS N08367). Mechanical properties such as tensile strength, yield strength, and elongation shall be tested accordingly. Each specimen shall be subjected to chemical analysis and tension test.

SCOPE

1.1 This specification covers iron-nickel-chromium-molybdenum alloys (UNS N08366 and UNS N08367)* in the form of hot-finished and cold-finished rounds, squares, hexagons, octagons, and rectangles.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following safety hazards caveat pertains only to the test methods portion, Section 12, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B691 −02(Reapproved2007)

StandardSpecification for

Iron-Nickel-Chromium-Molybdenum Alloys (UNS N08366 and

1

UNS N08367) Rod, Bar, and Wire

This standard is issued under the fixed designation B691; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

3.1 Definitions of Terms Specific to This Standard:

1.1 This specification covers iron-nickel-chromium-

3.1.1 The terms rod, bar, and wire, as used in this

molybdenum alloys (UNS N08366 and UNS N08367)* in the

specification, are described as follows:

form of hot-finished and cold-finished rounds, squares,

3.1.2 bar, n—hot-finished or cold-finished material of

hexagons, octagons, and rectangles.

round,square,hexagon,octagon,orrectangularsolidsectionin

1.2 The values stated in inch-pound units are to be regarded

straight lengths.

as the standard. The values given in parentheses are for

3.1.3 rod, n—hot-finished material of round, square,

information only.

hexagon, octagon, or rectangular solid section furnished in

1.3 The following safety hazards caveat pertains only to the

coils for subsequent cold drawing into finished products.

test methods portion, Section 12, of this specification: This

3.1.4 wire, n—cold-finished material of round, square,

standard does not purport to address all of the safety concerns,

hexagon, octagon, or rectangle solid section furnished in coils.

if any, associated with its use. It is the responsibility of the user

of this standard to become familiar with all hazards including

4. Ordering Information

those identified in the appropriate Material Safety Data Sheet

4.1 It is the responsibility of the purchaser to specify all

(MSDS) for this product/material as provided by the

requirements that are necessary for material ordered to this

manufacturer, to establish appropriate safety and health

specification. Examples of such requirements include, but are

practices, and determine the applicability of regulatory limi-

not limited to, the following:

tations prior to use.

4.1.1 Quantity (feet, metres, or number of pieces),

4.1.2 Form (rod, bar, wire),

2. Referenced Documents

4.1.3 Name of material or UNS number,

2

2.1 ASTM Standards:

4.1.4 Finish (see 8.2),

B880 Specification for General Requirements for Chemical

4.1.5 Dimensions, including length,

Check Analysis Limits for Nickel, Nickel Alloys and

4.1.6 Certification, if required (Section 15),

Cobalt Alloys

4.1.7 Purchaser’s inspection, if required (Section 13),

E8 Test Methods for Tension Testing of Metallic Materials

4.1.8 ASTM designation and year of issue, and

E29 Practice for Using Significant Digits in Test Data to

4.1.9 Samples for product analysis, if required.

Determine Conformance with Specifications

5. Chemical Composition

E1473 Test Methods for Chemical Analysis of Nickel,

Cobalt, and High-Temperature Alloys

5.1 The material shall conform to the composition limits

specified in Table 1.

5.2 If a product (check) analysis is made by the purchaser,

1

This specification is under the jurisdiction of ASTM Committee B02 on

the material shall conform to the permissible variations for

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

product (check) analysis in Specification B880.

B02.07 on Refined Nickel and Cobalt and Their Alloys.

Current edition approved Nov. 1, 2007. Published November 2007. Originally

approved in 1981. Last previous edition approved in 2002 as B691 – 02. DOI: 6. Mechanical Properties and Other Requirements

10.1520/B0691-02R07.

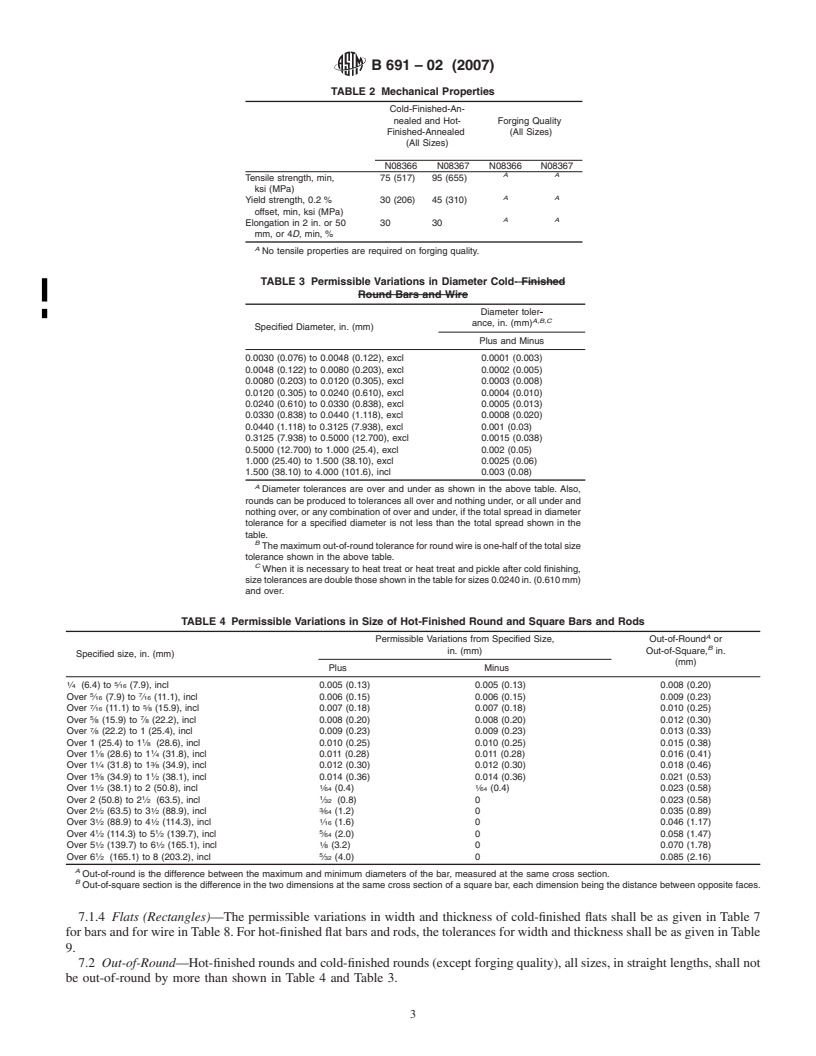

6.1 The material shall conform to the mechanical property

* New designation established in accordance withASTM E527 and SAE J1086,

Practice for Numbering Metals and Alloys. requirements specified in Table 2.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

7. Dimensions and Permissible Variations

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 7.1 Size:

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B691−02(Reapproved2007)

TABLE 1 Chemical Requirements

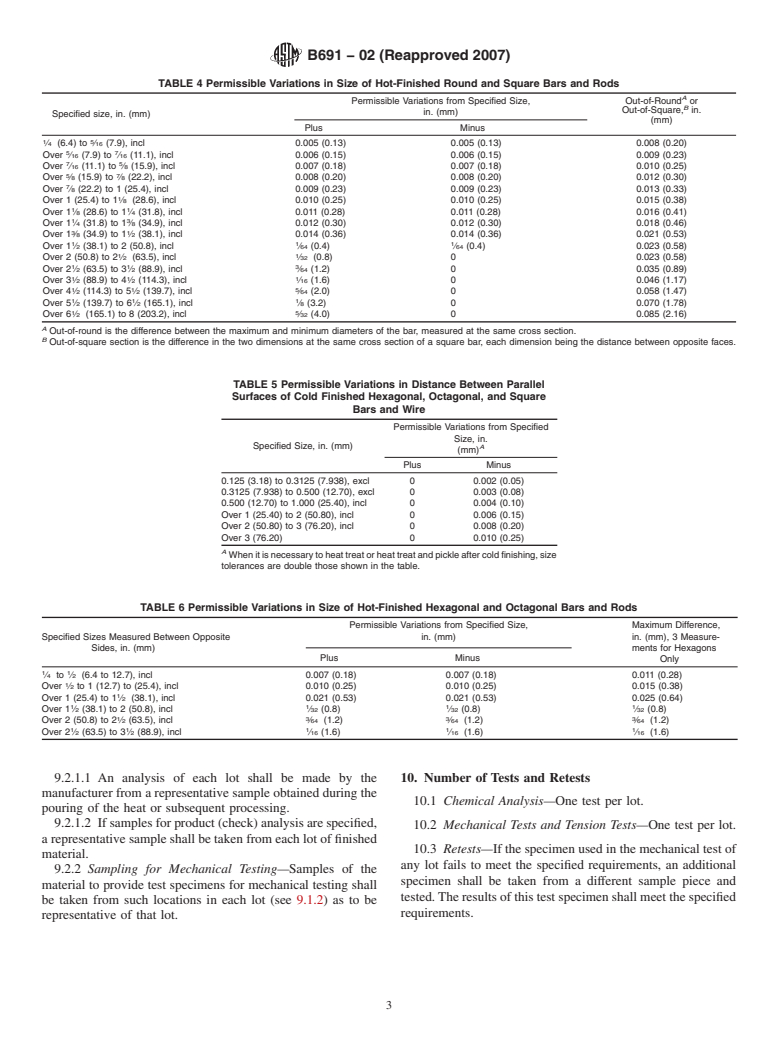

7.1.3 Hexagons and Octagons—The permissible variations

Composition Limits, % in size of cold-finished hexagons and octagons shall be as

Element

N08366 N08367 given in Table 5. For hot-finished bar and rod hexagons and

Carbon 0.035 max 0.030 max octagons they shall be as given in Table 6.

Manganese 2.00 max 2.00 max

7.1.4 Flats (Rectangles) —The permissible variations in

Silicon 1.00 ma

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B691–95 Designation: B 691 – 02 (Reapproved 2007)

Standard Specification for

Iron-Nickel-Chromium-Molybdenum Alloys (UNS N08366 and

1

UNS N08367) Rod, Bar, and Wire

This standard is issued under the fixed designation B 691; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers iron-nickel-chromium-molybdenum alloys (UNS N08366 and UNS N08367)* in the form of

hot-finished and cold-finished rounds, squares, hexagons, octagons, and rectangles.

1.2 The values stated in inch-pound units are to be regarded as the standard.The values given in parentheses are for information

only.

1.3 Thefollowingsafetyhazardscaveatpertainsonlytothetestmethodsportion,Section12,ofthisspecification: This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the

user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet

(MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and

determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

B 880 SpecificationforGeneralRequirementsforChemicalCheckAnalysisLimitsforNickel,NickelAlloysandCobaltAlloys

E 8 Test Methods for Tension Testing of Metallic Materials

E 29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E140Hardness Conversion Tables for Metals (Relationship Between Brinell Hardness, Vickers Hardness, Rockwell Hardness,

2

Rockwell Superficial Hardness, and Knoop Hardness)

E 1473 Test Methods for Chemical Analysis of Nickel, Cobalt, and High-Temperature Alloys

3. Terminology

3.1 Definitions of Terms Specific to This Standard: 3.1.1TheThe terms rod, bar, and wire, as used in this specification, are

described as follows:

3.1.1.13.1.1 bar, n—hot-finished or cold-finished material of round, square, hexagon, octagon, or rectangular solid section in

straight lengths.

3.1.1.2rod

3.1.2 rod, n—hot-finished material of round, square, hexagon, octagon, or rectangular solid section furnished in coils for

subsequent cold drawing into finished products.

3.1.1.3wire

3.1.3 wire, n—cold-finished material of round, square, hexagon, octagon, or rectangle solid section furnished in coils.

4. Ordering Information

4.1Orders for material under this specification shall include the following information, as required: Ordering Information

4.1 It is the responsibility of the purchaser to specify all requirements that are necessary for material ordered to this

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB-2onNonferrousMetalsandAlloysandisthedirectresponsibilityofSubcommitteeB02.07onRefined

Nickel and Cobalt, and Alloys Containing Nickel or Cobalt, or Both, as Principal Constituents.

Current edition approved Aug. 15, 1995. Published October 1995. Originally published as B691–81. Last previous edition B691–94.

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB02onNonferrousMetalsandAlloysandisthedirectresponsibilityofSubcommitteeB02.07onRefined

Nickel and Cobalt and Their Alloys.

Current edition approved Nov. 1, 2007. Published November 2007. Originally approved in 1981. Last previous edition approved in 2002 as B 691 – 02.

* New designation established in accordance with ASTM E 527 and SAE J1086, Practice for Numbering Metals and Alloys.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 03.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B 691 – 02 (2007)

specification. Examples of such requirements include, but are not limited to, the following:

4.1.1 Quantity (feet, metres, or number o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.