ASTM A400-23

(Practice)Standard Practice for Steel Bars, Selection Guide, Composition, and Mechanical Properties

Standard Practice for Steel Bars, Selection Guide, Composition, and Mechanical Properties

SIGNIFICANCE AND USE

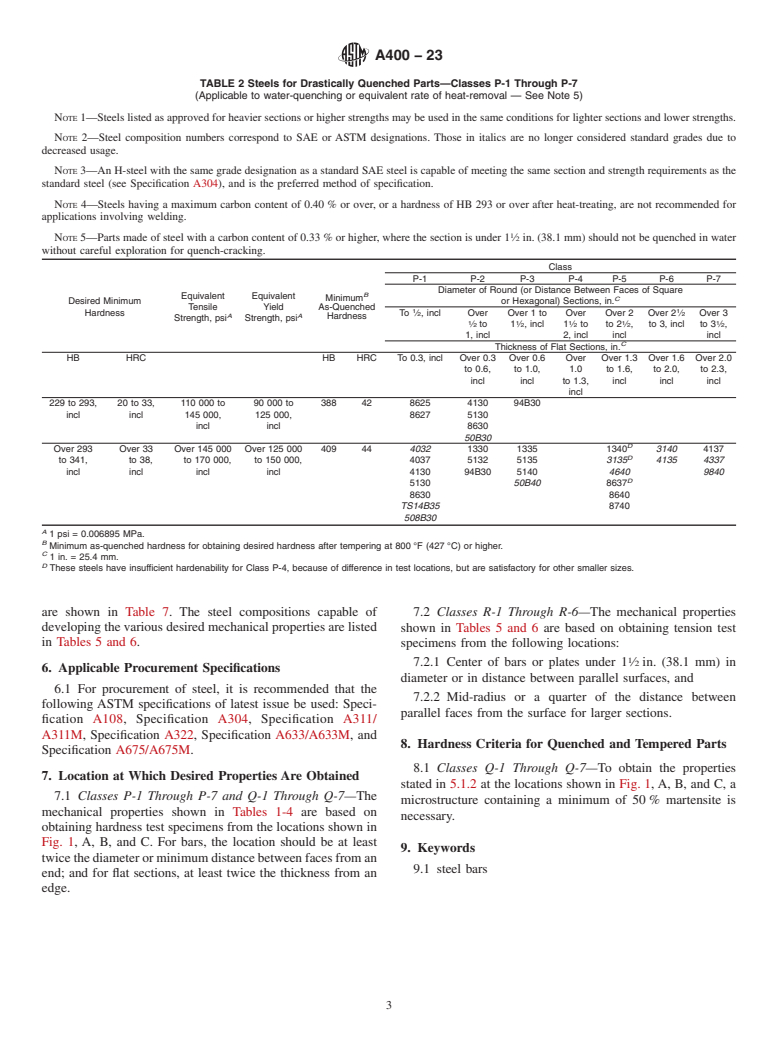

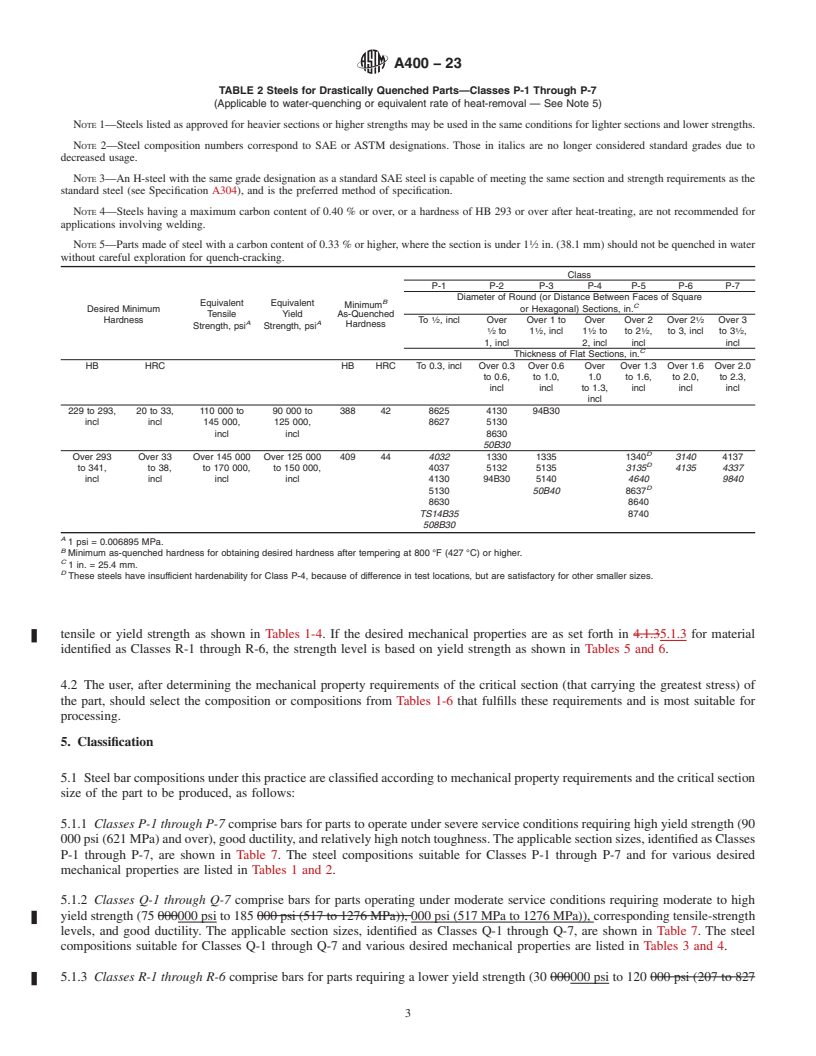

4.1 If the desired mechanical properties are as described in 5.1.1 for material identified as Classes P-1 through P-7, or in 5.1.2 for material identified as Classes Q-1 through Q-7, the strength level desired can be based on hardness or the equivalent tensile or yield strength as shown in Tables 1-4. If the desired mechanical properties are as set forth in 5.1.3 for material identified as Classes R-1 through R-6, the strength level is based on yield strength as shown in Tables 5 and 6.

4.2 The user, after determining the mechanical property requirements of the critical section (that carrying the greatest stress) of the part, should select the composition or compositions from Tables 1-6 that fulfills these requirements and is most suitable for processing.

SCOPE

1.1 This practice covers the selection of steel bars according to section and to the mechanical properties desired in the part to be produced. This is not a specification for the procurement of steel. Applicable procurement specifications are listed in Section 6.

1.2 Several steel compositions intended for various sections and mechanical property requirements are presented in Tables 1-6. The criteria for placing a steel composition in one of the three general class designations, Classes P, Q, and R (described in Section 5) are as follows:

1.2.1 Classes P and Q should be capable of developing the mechanical properties shown in Tables 1-4 by liquid quenching from a suitable austenitizing temperature, and tempering at 800 °F (427 °C) or higher. A hardness indicated by tests made at a location shown in Fig. 1, A, B, or C, is taken as evidence that a composition is capable of meeting other equivalent mechanical properties shown in the tables. Normal good shop practices are assumed, with control of austenitizing and tempering temperatures, and mild agitation of the part in the quenching bath.

FIG. 1 Locations in Typical Cross Sections of Steel Bars at Which Desired Properties Are Obtained

1.2.2 Class R should be capable of developing the mechanical properties shown in Tables 5 and 6 as hot rolled, by cold drawing, or by cold drawing with additional thermal treatment. The locations for obtaining tension tests are described in 7.2.

1.3 It is not implied that the compositions listed in the tables are the only ones satisfactory for a certain class and mechanical property requirement. Steels with lower alloy contents are often satisfactory through the use of special processing techniques.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: A400 − 23

Standard Practice for

Steel Bars, Selection Guide, Composition, and Mechanical

1

Properties

This standard is issued under the fixed designation A400; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 1.5 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 This practice covers the selection of steel bars according

ization established in the Decision on Principles for the

to section and to the mechanical properties desired in the part

Development of International Standards, Guides and Recom-

to be produced. This is not a specification for the procurement

mendations issued by the World Trade Organization Technical

of steel. Applicable procurement specifications are listed in

Barriers to Trade (TBT) Committee.

Section 6.

1.2 Several steel compositions intended for various sections

2. Referenced Documents

and mechanical property requirements are presented in Tables

2

2.1 ASTM Standards:

1-6. The criteria for placing a steel composition in one of the

A108 Specification for Steel Bar, Carbon and Alloy, Cold-

three general class designations, Classes P, Q, and R (described

Finished

in Section 5) are as follows:

A304 Specification for Carbon and Alloy Steel Bars Subject

1.2.1 Classes P and Q should be capable of developing the

to End-Quench Hardenability Requirements

mechanical properties shown in Tables 1-4 by liquid quenching

A311/A311M Specification for Cold-Drawn, Stress-

from a suitable austenitizing temperature, and tempering at

Relieved Carbon Steel Bars Subject to Mechanical Prop-

800 °F (427 °C) or higher. A hardness indicated by tests made

erty Requirements

at a location shown in Fig. 1, A, B, or C, is taken as evidence

A322 Specification for Steel Bars, Alloy, Standard Grades

that a composition is capable of meeting other equivalent

A633/A633M Specification for Normalized High-Strength

mechanical properties shown in the tables. Normal good shop

Low-Alloy Structural Steel Plates

practices are assumed, with control of austenitizing and tem-

A675/A675M Specification for Steel Bars, Carbon, Hot-

pering temperatures, and mild agitation of the part in the

Wrought, Special Quality, Mechanical Properties

quenching bath.

A941 Terminology Relating to Steel, Stainless Steel, Related

1.2.2 Class R should be capable of developing the mechani-

Alloys, and Ferroalloys

cal properties shown in Tables 5 and 6 as hot rolled, by cold

drawing, or by cold drawing with additional thermal treatment.

3. Terminology

The locations for obtaining tension tests are described in 7.2.

3.1 Definitions—For definitions of terms used in this

1.3 It is not implied that the compositions listed in the tables

standard, refer to Terminology A941.

are the only ones satisfactory for a certain class and mechanical

property requirement. Steels with lower alloy contents are

4. Significance and Use

often satisfactory through the use of special processing tech-

4.1 If the desired mechanical properties are as described in

niques.

5.1.1 for material identified as Classes P-1 through P-7, or in

1.4 The values stated in inch-pound units are to be regarded

5.1.2 for material identified as Classes Q-1 through Q-7, the

as standard. The values given in parentheses are mathematical

strength level desired can be based on hardness or the

conversions to SI units that are provided for information only

equivalent tensile or yield strength as shown in Tables 1-4. If

and are not considered standard.

the desired mechanical properties are as set forth in 5.1.3 for

1

This practice is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

2

A01.15 on Bars. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2023. Published November 2023. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1956. Last previous edition approved in 2017 as A400 – 17. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/A0400-23. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A400 − 23

TABLE 1 Steels f

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A400 − 17 A400 − 23

Standard Practice for

Steel Bars, Selection Guide, Composition, and Mechanical

1

Properties

This standard is issued under the fixed designation A400; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*Scope

1.1 This practice covers the selection of steel bars according to section and to the mechanical properties desired in the part to be

produced. This is not a specification for the procurement of steel. Applicable procurement specifications are listed in Section 56.

1.2 Several steel compositions intended for various sections and mechanical property requirements are presented in Tables 1-6.

The criteria for placing a steel composition in one of the three general class designations, Classes P, Q, and R (described in Section

45) are as follows:

1.2.1 Classes P and Q should be capable of developing the mechanical properties shown in Tables 1-4 by liquid quenching from

a suitable austenitizing temperature, and tempering at 800 °F (427 °C) or higher. A hardness indicated by tests made at a location

shown in Fig. 1, A, B, or C, is taken as evidence that a composition is capable of meeting other equivalent mechanical properties

shown in the tables. Normal good shop practices are assumed, with control of austenitizing and tempering temperatures, and mild

agitation of the part in the quenching bath.

1.2.2 Class R should be capable of developing the mechanical properties shown in Tables 5 and 6 as hot rolled, by cold drawing,

or by cold drawing with additional thermal treatment. The locations for obtaining tension tests are described in 6.27.2.

1.3 It is not implied that the compositions listed in the tables are the only ones satisfactory for a certain class and mechanical

property requirement. Steels with lower alloy contents are often satisfactory through the use of special processing techniques.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

1

This practice is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.15

on Bars.

Current edition approved Nov. 1, 2017Nov. 1, 2023. Published December 2017November 2023. Originally approved in 1956. Last previous edition approved in 20122017

as A400 – 69 (2012).A400 – 17. DOI: 10.1520/A0400-17.10.1520/A0400-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A400 − 23

TABLE 1 Steels for Moderately Quenched Parts—Classes P-1 Through P-7

(Applicable to oil-quenching or equivalent rate of heat-removal.)

NOTE 1—Steels listed as approved for a certain section or strength may be used for lighter sections and lower strengths.

NOTE 2—Steel composition numbers correspond to SAE or ASTM designations. Those in italics are no longer considered standard grades due to

decreased usage.

NOTE 3—An H-steel with the same grade designation as a standard SAE steel is capable of meeting the same section and strength requirements as the

standard steel (see Specification A304), and is the preferred method of specification.

NOTE 4—Steels having a maximum carbon content of 0.40 % or over, or a hardness of HB 293 or over after heat-treating, are not recommended for

applications involving welding.

Class

P-1 P-2 P-3 P-4 P-5 P-6 P-7

Diameter of Round

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.