ASTM D5236-99ae1

(Test Method)Standard Test Method for Distillation of Heavy Hydrocarbon Mixtures (Vacuum Potstill Method)

Standard Test Method for Distillation of Heavy Hydrocarbon Mixtures (Vacuum Potstill Method)

SCOPE

1.1 This test method covers the procedure for distillation of heavy hydrocarbon mixtures having initial boiling points greater than 150°C (300°F), such as heavy crude oils, petroleum distillates, residues, and synthetic mixtures. It employs a potstill with a low pressure drop entrainment separator operated under total takeoff conditions. Distillation conditions and equipment performance criteria are specified and typical apparatus is illustrated.

1.2 This test method details the procedures for the production of distillate fractions of standardized quality in the gas oil and lubricating oil range as well as the production of standard residua. In addition, it provides for the determination of standard distillation curves to the highest atmospheric equivalent temperature possible by conventional distillation.

1.3 The maximum achievable atmospheric equivalent temperature (AET) is dependent upon the heat tolerance of the charge. For most samples, a temperature up to 565°C (10570°F) can be attained. This maximum will be significantly lower for heat sensitive samples (for example, heavy residues) and might be somewhat higher for nonheat sensitive samples.

1.4 The recommended distillation method for crude oils up to cutpoint 400°C (752°F) AET is Test Method D 2892. This test method can be used for heavy crude oils with initial boiling points greater than 150—C (302°F). However, distillation curves and fraction qualities obtained by these methods are not comparable.

1.5 This test method contains the following annexes:

1.5.1 Annex A1—Test Method for Determination of the Temperature Response Time,

1.5.2 Annex A2—Practice for Calibration of Sensors,

1.5.3 Annex A3—Test Method for Dehydration of a Wet Sample of Oil,

1.5.4 Annex A4—Practice for Conversion of Observed Vapor Temperature to Atmospheric Equivalent Temperature (AET), and

1.5.5 Annex A5—Test Method for Determination of Wettage.

1.6 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are provided for information purposes only.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warnings see 6.5.4.2, 6.5.6.3, 6.9.3, 9.5, 9.6 and A2.3.1.3.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: D 5236 – 99a An American National Standard

Standard Test Method for

Distillation of Heavy Hydrocarbon Mixtures (Vacuum Potstill

Method)

This standard is issued under the fixed designation D 5236; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Equation A4.1 was corrected editorially in October 2000.

1. Scope 1.5.5 Annex A5—Test Method for Determination of Wet-

tage.

1.1 This test method covers the procedure for distillation of

1.6 The values stated in SI units are to be regarded as the

heavy hydrocarbon mixtures having initial boiling points

standard. The inch-pound units given in parentheses are

greater than 150°C (300°F), such as heavy crude oils, petro-

provided for information purposes only.

leum distillates, residues, and synthetic mixtures. It employs a

1.7 This standard does not purport to address all of the

potstill with a low pressure drop entrainment separator oper-

safety concerns, if any, associated with its use. It is the

ated under total takeoff conditions. Distillation conditions and

responsibility of the user of this standard to establish appro-

equipment performance criteria are specified and typical appa-

priate safety and health practices and determine the applica-

ratus is illustrated.

bility of regulatory limitations prior to use. For specific

1.2 This test method details the procedures for the produc-

warnings see 6.5.4.2, 6.5.6.3, and 6.9.3.

tion of distillate fractions of standardized quality in the gas oil

and lubricating oil range as well as the production of standard

2. Referenced Documents

residua. In addition, it provides for the determination of

2.1 ASTM Standards:

standard distillation curves to the highest atmospheric equiva-

D 941 Test Method for Density and Relative Density (Spe-

lent temperature possible by conventional distillation.

cific Gravity) of Liquids by Lipkin Bicapillary Pycnom-

1.3 The maximum achievable atmospheric equivalent tem-

eter

perature (AET) is dependent upon the heat tolerance of the

D 1217 Test Method for Density and Relative Density

charge. For most samples, a temperature up to 565°C (1050°F)

(Specific Gravity) of Liquids by Bingham Pycnometer

can be attained. This maximum will be significantly lower for

D 1250 Guide for Petroleum Measurement Tables (Descrip-

heat sensitive samples (for example, heavy residues) and might

tion only; tables published separately in 12 volumes)

be somewhat higher for nonheat sensitive samples.

D 1298 Test Method for Density, Relative Density (Specific

1.4 The recommended distillation method for crude oils up

Gravity), or API Gravity of Crude Petroleum and Liquid

to cutpoint 400°C (752°F) AET is Test Method D 2892. This

Petroleum Products by Hydrometer Method

test method can be used for heavy crude oils with initial boiling

D 1480 Test Method for Density and Relative Density

points greater than 150°C (302°F). However, distillation curves

(Specific Gravity) of Viscous Materials by Bingham Pyc-

and fraction qualities obtained by these methods are not

nometer

comparable.

D 2892 Test Method for Distillation of Crude Petroleum

1.5 This test method contains the following annexes:

(15-Theoretical Plate Column)

1.5.1 Annex A1—Test Method for Determination of the

D 4057 Practice for Manual Sampling of Petroleum and

Temperature Response Time,

Petroleum Products

1.5.2 Annex A2—Practice for Calibration of Sensors,

D 4177 Practice for Automatic Sampling of Petroleum and

1.5.3 Annex A3—Test Method for Dehydration of a Wet

Petroleum Products

Sample of Oil,

D 5002 Test Method for Density and Relative Density of

1.5.4 Annex A4—Practice for Conversion of Observed Va-

Crude Oils by Digital Density Analyzer

por Temperature to Atmospheric Equivalent Temperature

(AET), and

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

This test method is under the jurisdiction of ASTM Committee D-2 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee Discontinued; see 1993 Annual Book of ASTM Standards, Vol 05.01.

D02.08.0C on Crude Distillation. Annual Book of ASTM Standards, Vol 05.01.

Current edition approved Nov. 10, 1999. Published December 1999. Originally Annual Book of ASTM Standards, Vol 05.02.

published as D 5236 – 92. Last previous edition D 5236 – 99. Annual Book of ASTM Standards, Vol 05.03.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 5236

3.1.1 boil-up rate, n—the quantity of vapor entering the ume percent, or both, are drawn using the data from 4.2 and

distillation head per unit time. 4.3.

3.1.1.1 Discussion—It is approximately equal to the takeoff

5. Significance and Use

rate, differing only by the parasitic heat losses. It is expressed

in millilitres per hour for a head of any given internal diameter

5.1 This test method is one of a number of tests conducted

or millilitres per hour per square centimetre of cross-sectional

on heavy hydrocarbon mixtures to characterize these materials

area of the throat for comparative purposes.

for a refiner or a purchaser. It provides an estimate of the yields

3.1.2 condenser, n—the apparatus connected to the outlet of

of fractions of various boiling ranges.

the distillation head in which condensation of the product 5.2 The fractions made by this test method can be used

occurs.

alone or in combination with other fractions to produce

3.1.3 distillation flask, n—the flask, of glass or metal, in samples for analytical studies and quality evaluations.

which the charge is boiled. 5.3 Residues to be used in the manufacture of asphalt can

3.1.3.1 Discussion—The flask is sometimes called a kettle also be made but may not always be suitable. The long heat

or pot. soaking that occurs in this test method may alter some of the

properties.

3.1.4 distillation head, n—the section immediately above

the distillation flask containing the entrainment separator.

NOTE 1—While the practice of reblending distillates with residue can

3.1.5 distillation pressure (or operating pressure), n—the

be done to produce a lighter residue, it is not recommended because it

pressure measured in the distillation head just before the outlet

produces blends with irregular properties.

to the recovery system.

5.4 Details of cut points must be mutually agreed upon

3.1.6 distillation temperature (or vapor temperature),

before the test begins.

n—the temperature of the vapors in the distillation head at the

5.5 This is a complex procedure involving many interacting

point of measurement.

variables. It is most important that at the time of first use of a

3.1.7 loading, n—the volume of charge relative to the

new apparatus, its components be checked as detailed in Annex

cross-sectional area of the neck.

A1 and Annex A2 and that the location of the vapor tempera-

3.1.8 pressure drop, n—the difference between the operat-

ture sensor be verified as detailed in 6.5.3 and Fig. 1.

ing pressure and the pressure measured in the distillation flask.

3.1.8.1 Discussion—It is a result of the friction developed

6. Apparatus

by driving the vapors through the system expressed in kilopas-

6.1 Four sizes of apparatus, based upon the internal diam-

cals (mm Hg).

eter of the distillation head (25, 36, 50, and 70 mm), are

3.1.9 spillover point, n—the lowest point in the head above 6

allowed. The apparatus (see Fig. 2) consists of a flask with

the entrainment separator over which the vapors can flow to the

heating mantles and upper compensator and a head containing

condensing region.

an entrainment separator. Attached to the head are the vapor

3.1.10 static hold-up (or wettage), n—the amount of liquid

temperature sensor, a connection for the vacuum gage, a

material remaining on the inside of the walls of the apparatus

condenser, a rundown line, a product receiver(s), and a vacuum

after the distillation has been completed.

pumping line with pump. The parts are connected by vacuum-

3.1.10.1 Discussion—In this test method it includes wettage

tight joints to facilitate servicing.

of the distillation flask in the case of the steel flasks, but not in

6.2 Distillation Flask:

the case of glass flasks that are removed for weighing after the

6.2.1 The sizes specified for flasks are at least 50 % larger

distillation is completed.

than the size of the charge to provide space for suppression of

3.1.11 takeoff rate, n—the quantity of product removed per

foam and for bubble breaking. The size of the charge for each

unit time.

size of still is determined from the loading factor. The

3.1.11.1 Discussion—It is approximately equal to the

recommended loading factor is between 200 and 400 mL of

boil-up rate differing only by parasitic heat losses.

charge per square centimetre of cross sectional area in the neck

of the head. Table 1 shows the range of charge volume that is

4. Summary of Test Method

recommended with each size of apparatus.

4.1 A weighed volume of sample is distilled at absolute 6.2.2 Flasks are made of borosilicate glass except those

larger than 10 L, which are made of stainless steel for reasons

pressures between 6.6 and 0.013 kPa (50 and 0.1 mm Hg) at

specified distillation rates. Cuts are taken at preselected tem- of safety.

6.2.3 The flask is fitted with a thermowell reaching to within

peratures. Records of vapor temperature, operating pressure,

and other variables are made at intervals, including at each cut 6 mm of the bottom and offset from the center to avoid a

stirring bar. In the case of glass flasks, the bottom shall be

point.

slightly flattened or slightly concave, but not perfectly flat to

4.2 The mass of each fraction is obtained. Distillation yields

facilitate the rotation of the magnetic stirrer. Steel flasks can

by mass are calculated from the mass of each fraction relative

have a cooling coil for rapid quenching of the distillation in an

to the total mass recovery.

emergency. Fig. 3 shows a typical example.

4.3 The density of each fraction is obtained. Distillation

yields by volume are calculated from the volume computed for

each fraction at 15°C (59°F) relative to the total recovery.

4.4 Distillation curves of temperature versus mass or vol- Cooke, Industrial and Engineering Chemistry, Vol 55, 1963, p. 36.

D 5236

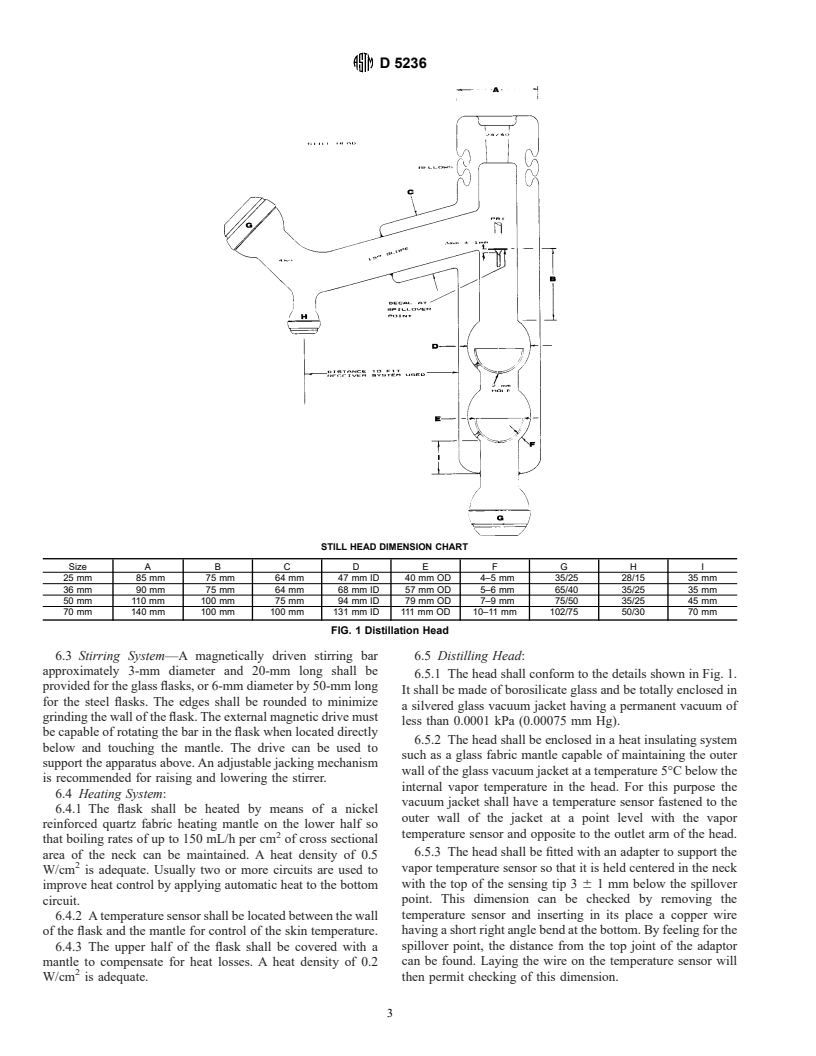

STILL HEAD DIMENSION CHART

Size A B C D E F G H I

25 mm 85 mm 75 mm 64 mm 47 mm ID 40 mm OD 4–5 mm 35/25 28/15 35 mm

36 mm 90 mm 75 mm 64 mm 68 mm ID 57 mm OD 5–6 mm 65/40 35/25 35 mm

50 mm 110 mm 100 mm 75 mm 94 mm ID 79 mm OD 7–9 mm 75/50 35/25 45 mm

70 mm 140 mm 100 mm 100 mm 131 mm ID 111 mm OD 10–11 mm 102/75 50/30 70 mm

FIG. 1 Distillation Head

6.3 Stirring System—A magnetically driven stirring bar 6.5 Distilling Head:

approximately 3-mm diameter and 20-mm long shall be

6.5.1 The head shall conform to the details shown in Fig. 1.

provided for the glass flasks, or 6-mm diameter by 50-mm long

It shall be made of borosilicate glass and be totally enclosed in

for the steel flasks. The edges shall be rounded to minimize

a silvered glass vacuum jacket having a permanent vacuum of

grinding the wall of the flask. The external magnetic drive must

less than 0.0001 kPa (0.00075 mm Hg).

be capable of rotating the bar in the flask when located directly

6.5.2 The head shall be enclosed in a heat insulating system

below and touching the mantle. The drive can be used to

such as a glass fabric mantle capable of maintaining the outer

support the apparatus above. An adjustable jacking mechanism

wall of the glass vacuum jacket at a temperature 5°C below the

is recommended for raising and lowering the stirrer.

internal vapor temperature in the head. For this purpose the

6.4 Heating System:

vacuum jacket shall have a temperature sensor fastened to the

6.4.1 The flask shall be heated by means of a nickel

outer wall of the jacket at a point level with the vapor

reinforced quartz fabric heating mantle on the lower half so

2 temperature sensor and opposite to the outlet arm of the head.

that boiling rates of up to 150 mL/h per cm of cross sectional

6.5.3 The head shall be fitted with an adapter to support the

area of the neck can be maintained. A heat density of 0.5

vapor temperature sensor so that it is held centered in the neck

W/cm is adequate. Usually two or more circuits are used to

with the top of the sensing tip 3 6 1 mm below the spillover

improve heat control by applying automatic heat to the bottom

point. This dimension can be checked by removing the

circuit.

temperature sensor and inserting in its place a copper wire

6.4.2 A temperature sensor shall be located between the wall

having a short right angle bend at the bottom. By feeling for the

of the flask and the mantle for control of the skin temperature.

6.4.3 The upper half of the flask shall be covered with a spillover point, the distance from the top joint of the adaptor

mantle to compensate for heat losses. A heat density of 0.2 can be found. Laying the wire on the temperature sensor will

W/cm is adequate. then permit checking of this dimension.

D 5236

SYSTEM SIZE A B

25 mm 35/25 3 L

36 mm 65/40 6 L

50 mm 75/50 12 L

70 mm 102/75 24 L

FIG. 3 Distillation Flask

FIG. 2 Apparatus

of the two major sources of error in distillation data.)

TABLE 1 Standard Charge and Flask Size

6.5.4.3 Verification of the calibration of the vapor tempera-

Throat

ture measuring devices is to be made on a regular basis.

Inside

Cross-Sectional Charge, L Flask, L

Diameter, mm

Verification at least once a month is recommended. Verification

Area, cm

of the calibration of the sensors can be accomplished poten-

25 5 1–2 2–3

36 10 2–4 3–6 tiometrically by the use of standard precision resistance or by

50 20 4–8 6–12

distilling a pure compound with accurately known boiling

70 40 8–16 12–24

point, as described in A2.2.3.

6.5.5 A head trap as illustrated in Fig. 4 shall be fitted to the

6.5.4 The vapor temperature sensor shall be either a plati- adapter described in 6.5.3 for connection to the vacuum sensor.

num resistance thermometer, a thermocouple with the junction It shall be kept filled with crushed dry ice at all times while in

head fused to the lower tip of the well or any other device service.

which meets the requirements in 6.5.4 and 6.5.4.1. It shall have 6.5.6 A vacuum sensor shall be connected to the sidearm of

a response time of less than 60 s as described in Annex A1. the trap. The sensor shall be capable of reading the pressure

6.5.4.1 The vapor temperature measuring device shall have with a precision equal to or better than 0.00

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.