ASTM E619-84(1995)

(Practice)Standard Practice for Evaluating Foreign Odors in Paper Packaging

Standard Practice for Evaluating Foreign Odors in Paper Packaging

SCOPE

1.1 This practice covers the evaluation of odors in paper packaging and establishes smelling and testing procedures for trained sensory panels.

1.2 This practice covers effective techniques for determining the type and source of the odor and establishing the severity of contamination.

1.3 The techniques used in this practice are applicable to all paper packaging products and to auxiliary components, such as coatings, inks, and adhesives, as well as plastic materials used in conjunction with paper.

1.4 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of whoever uses this standard to consult and establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 619 – 84 (Reapproved 1995)

Standard Practice for

Evaluating Foreign Odors in Paper Packaging

This standard is issued under the fixed designation E 619; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 4. Sensory Test Panel Selection and Training

1.1 This practice covers the evaluation of odors in paper 4.1 General—Sensory panel selection and training are de-

packaging and establishes smelling and testing procedures for scribed in STP 758 and in references therein.

trained sensory panels. 4.2 Size—The test panel on a specific odor problem should

1.2 This practice covers effective techniques for determin- consist of at least five members and should render a minimum

ing the type and source of the odor and establishing the severity total of ten judgments per sample. A maximum of twelve

of contamination. subjects may be used, if available. When possible, the subjects

1.3 The techniques used in this practice are applicable to all should be drawn from a larger pool of qualified panelists.

paper packaging products and to auxiliary components, such as 4.3 Selection—The important criteria in panel selection are:

coatings, inks, and adhesives, as well as plastic materials used (a) normal ability to detect and identify odors and flavors; (b)

in conjunction with paper. ability to discriminate differences, and reproduce results; and

1.4 This standard does not purport to address all of the (c) interest in the testing work for which the panelists are to be

safety concerns, if any, associated with its use. It is the trained. Usually a suitable panel can be recruited from avail-

responsibility of the user of this standard to establish appro- able employees unless their number is limited. It is helpful if

priate safety and health practices and determine the applica- panel members have a scientific background, with some

bility of regulatory limitations prior to use. knowledge of chemistry or food technology; however, this

should not be a criterion for selection. Nontechnical personnel

2. Summary of Practice

have often proved to be excellent panel members after appro-

2.1 Under the leadership of the test supervisor, qualified and

priate training. No willing and available person should be

trained subjects individually examine sample specimens by one excluded from consideration. Panel members should be

or more of the test procedures described in this practice.

requalified periodically.

Subjects judge the intensity of a perceived off-odor in terms of

5. Testing Facilities and Apparatus

a numerical rating scale and also attempt to give a qualitative

description of the taint. The assembled observations are then 5.1 General—Appropriate physical conditions for sensory

interpreted by the supervisor. panel operations are described in STP 434.

5.2 Testing Room—Detection of low levels of odor requires

3. Significance and Use

a working space in which individual members of the panel can

3.1 Use—This practice should be used by panelists, trained concentrate on the task. The room should be comfortable as to

as described in ASTM STP 758 , under the direction of a

temperature, humidity, and noise, and relatively free of labo-

knowledgeable supervisor. ratory industrial odors. If ambient odor levels are too high,

3.2 Significance—This practice can be used to evaluate

testing of the samples must be transferred to another location.

indigenous and foreign odors in paper packaging materials as Interruptions and other distracting influences should be

to type and intensity. A knowledgeable supervisor may be able

avoided.

to determine the source of a foreign odor from the information 5.3 Sample Containers—Clean, dry, closed, odor-free con-

obtained from this procedure.

tainers of appropriate sizes are needed for storing samples and

for confining specimens to develop maximum odor intensity or

to test for taste transfer. Laboratory glassware, capped glass

This practice is under the jurisdiction of ASTM Committee E-18 on Sensory

jars, and glass battery jars with plate glass lids are suitable for

Evaluation Materials and Products and is the direct responsibility of Subcommittee

this purpose. Rubber gaskets or stoppers should not be used.

E18.05 on Sensory Applications—General.

Current edition approved Nov. 30, 1984. Published January 1985.

Guidelines for the Selection and Training of Sensory Evaluation Panels, ASTM

STP 758, ASTM, 1981. Manual on Sensory Testing Methods, ASTM STP 434, ASTM, 1968.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 619 – 84 (1995)

Closures should provide adequate protection and contribute no aluminum foil, open one end temporarily and sniff while gently

odors of their own. Samples for storage may be wrapped squeezing and releasing the package to expel puffs of air.

directly in clean, low-odor, aluminum foil.

7.2.1.4 Opening Fresh Surfaces—Valuable information

about the origin and severity of an odor contamination can

6. Materials often be obtained by exposing fresh surfaces at the instant of

smelling. For example, coated paper board and corrugated

6.1 Water—Moistening of material to intensify odors or to

sheets can be torn apart into two layers from a corner or edge;

develop potential odors is frequently necessary. Tap water may

several layers may be separated sequentially from more com-

be used provided it is free of a chlorine smell or other residual

plex laminar constructions; wax can be scraped with a knife; or

odor. Bottled spring water or distilled water are suitable

glued joints can be broken open.

alternatives, if odorless. When necessary, water may be further

7.2.2 Direct Examination After Confinement—The follow-

purified by filtering through charcoal. In any case, the water

ing confinement methods have been used successfully in

should be smelled and tasted before use to assure its suitability.

preparing paper packaging materials for odor examination:

6.2 Fatty Materials—Various materials containing oil or fat

7.2.2.1 Confining in Glass Pint or Quart Jars—Confine the

may be used to pick up certain types of odors in transfer tests

sample for a standardized period (16 to 24 h) at room

such as those described in 7.4. Mineral oil (odorless), cream,

temperature (20 to 25°C) or for appropriate periods at 38°C in

butter, and milk chocolate are recommended.

special situations like those indicated in Table 1. Alternatively,

6.3 Standard Samples—It is good practice to include refer-

heat for1hat 52°C, cool, and test immediately. Restrict

ence materials if available. Commercially produced packaging

specimen size so as to maintain a minimum of 25 % head space

material representing either satisfactory or maximum permis-

in a jar. Normally, prepare a separate jar for each panelist. (If

sible levels of odor are suitable. However, maintenance of such

the amount of sample is limited, the same jar may be smelled

standards is usually difficult, since age and storage conditions

twice, provided1hor more is allowed in-between for

may drastically alter odor properties. As part of quality control

recovery.)

practices, a schedule should be established for acquiring and

7.2.2.2 Confining in Covered Glass Battery Jars—Store in

discarding standard samples; when appropriate, this schedule

should be accepted in advance by both manufacturer and battery jars (or similar large containers) for a standardized

period (16 to 24 h) at room temperature (20 to 25°C). Use a

purchaser. (When a product normally contains traces of spe-

cific solvents, gas chromatographic analysis is often used to sample of appropriate size. Prepare one jar per sample; this will

normally suffice for the whole panel.

help in selecting standards of uniform quality.)

7.3 Methods That Involve Moistening of Samples—Water

7. Methods for Preparing Test Specimens for brings out some types of odors. The following techniques may

be used, and are particularly appropriate for products that

Examination

normally may be subjected to moisture (see 5.1 for water

7.1 General—A single method will not suffice for the

quality):

preparation of test specimens because of the wide range of

7.3.1 Examination After Dampening—Sprinkle the sample

materials that may be tested and the many types of odors that

lightly with water, and smell immediately or after confining for

may be present. The more common methods are described in

a standardized brief period (30 min to 2 h) at room temperature

this section. Each laboratory should select and standardize the

(20 to 25°C) or at 38°C.

particular preparation procedures that seem best for specific

7.3.2 Examination After Confinement over Water—Store the

products with which it is concerned.

sample in a covered glass jar containing water adjacent to but

7.2 Methods that Utilize Direct Examination—There are

not in direct contact with the sample. Smell after storage for a

two categories of direct testing methods: immediate examina-

standardized period (16 to 24 h) at room temperature (20 to

tion without prior confinement and examination after samples

25°C) or for4hat 38°C.

have been confined appropriately in a closed container to

7.4 Methods That Examine Transfer to an Oily

enhance odor intensity.

Substance—To aid in identifying off odors and in estimating

7.2.1 Direct Examination Without Confinement—This ap-

their potential for contaminating fatty foods, the following are

proach is usual in the preliminary investigation of an odor

useful procedures:

problem. Testing may be done by one or two experienced

persons rather than a full sensory panel. Typical useful tech- 7.4.1 Examination for Transfer to Mineral Oil—Place the

niques are as follows:

specimen in a covered glass dish adjacent to, but not in contact

7.2.1.1 Examining Single Sheets—Crumple one or more with, 10 mL of odorless mineral oil in a 4-in. glass Petri dish

for a standardized period (16 to 24 h) at room temperature (20

individual sheets of the sample into a loose ball, then partially

open and sniff immediately while holding up to the face. To to 25°C). Oil soluble contaminants such as printing ink

solvents, kerosine, etc., can be detected by smelling the oil and

sample a large roll, cut or tear a conveniently sized represen-

tative specimen and test in the same way. comparing with an oil reference sample.

7.2.1.2 Examining Stacks of Sheets—Riffle a stack of sheets 7.4.2 Examination for Transfer to Butter—Prepare a sand-

to expose many fresh surfaces in rapid succession, while

wich consisting of a pat of butter between two pieces of the

simultaneously sniffing at the edge of the stack. specimen, and place in a covered glass Petri dish or a suitable

7.2.1.3 Examining Samples in Bundles—When a stack or screw cap jar. (A single test sandwich is adequate for a panel of

bundle of sample sheets is received appropriately wrapped in five to six people.) For a reference sample, place a similar pat

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 619 – 84 (1995)

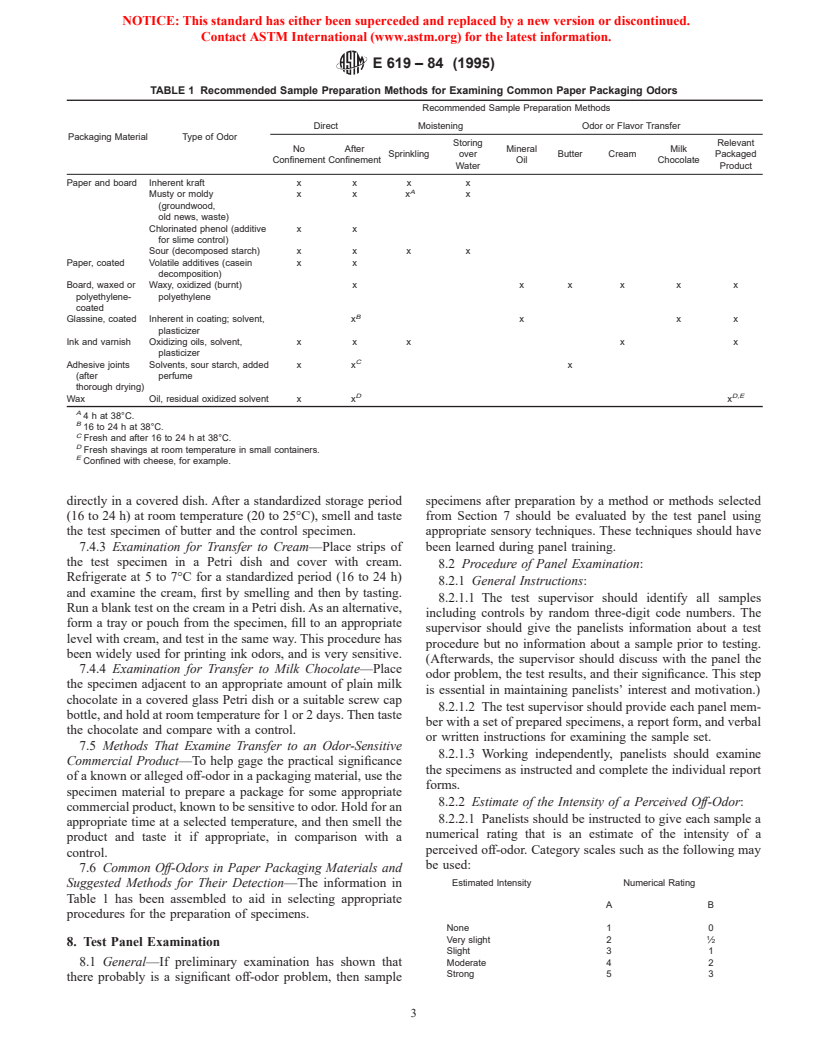

TABLE 1 Recommended Sample Preparation Methods for Examining Common Paper Packaging Odors

Recommended Sample Preparation Methods

Direct Moistening Odor or Flavor Transfer

Packaging Material Type of Odor

Storing Relevant

No After Mineral Milk

Sprinkling over Butter Cream Packaged

Confinement Confinement Oil Chocolate

Water Product

Paper and board Inherent kraft x x x x

A

Musty or moldy xx x x

(groundwood,

old news, waste)

Chlorinated phenol (additive xx

for slime control)

Sour (decomposed starch) x x x x

Paper, coated Volatile additives (casein xx

decomposition)

Board, waxed or Waxy, oxidized (burnt) xxxxxx

polyethylene- polyethylene

coated

B

Glassine, coated Inherent in coating; solvent, x xxx

plasticizer

Ink and varnish Oxidizing oils, solvent, xx x x x

plasticizer

C

Adhesive joints Solvents, sour starch, added xx x

(after perfume

thorough drying)

D D,E

Wax Oil, residual oxidized solvent x x x

A

4 h at 38°C.

B

16 to 24 h at 38°C.

C

Fresh and after 16 to 24 h at 38°C.

D

Fresh shavings at room temperature in small containers.

E

Confined with cheese, for example.

directly in a covered dish. After a standardized storage period specimens after preparation by a method or methods selected

(16 to 24 h) at room temperature (20 to 25°C), smell and taste from Section 7 should be evaluated by the test panel using

the test specimen of butter and the control specimen. appropriate sensory techniques. These techniques should have

7.4.3 Examination for Transfer to Cream—Place strips of been learned during panel training.

the test specimen in a Petri dish and cover with cream.

8.2 Procedure of Panel Examination:

Refrigerate at 5 to 7°C for a standardized period (16 to 24 h)

8.2.1 General Instructions:

and examine the cream, first by smelling and then by tasting.

8.2.1.1 The test supervisor should identify all samples

Run a blank test on the cream in a Petri dish. As an alternative,

including controls by random three-digit code numbers. The

form a tray or pouch from the specimen, fill to an appropriate

supervisor should give the panelists information about a test

level with cream, and test in the same way. This procedure has

procedure but no information about a sample prior to testing.

been widely used for printing ink odors, and is very sensitive.

(Afterwards, the supervisor should discuss with the panel the

7.4.4 Examination for Transfer to Milk Chocolate—Place

odor problem, the test results, and their significance. This step

the specimen adjacent to an appropriate amount of plain milk

is essential in maintaining panelists’ interest and motivation.)

chocolate in a covered glass Petri dish or a suitable screw cap

8.2.1.2 The test supervisor should provide each panel mem-

bottle, and hold at room temperature for 1 or 2 days. Then taste

ber with a set of prepared specimens, a report form, and verbal

the chocolate and compare with a control.

or written instructions for examining the sample set.

7.5 Methods That Examine Transfer to an Odor-Sensitive

8.2.1.3 Working independently, panelists should examine

Commercial Product—To help gage the practical significance

the specimens as instructed and complete the individual r

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.