ASTM B919-01(2006)

(Specification)Standard Specification for Welded Copper Heat Exchanger Tubes With Internal Enhancement

Standard Specification for Welded Copper Heat Exchanger Tubes With Internal Enhancement

ABSTRACT

This specification establishes the requirements for welded, internally enhanced copper tube, in straight lengths or coils, suitable for use in refrigeration and air conditioning products or other heat exchangers. The following types of welded tubes are: as-welded and welded tube, subsequently annealed. The material of manufacture shall be sheet or strip, of the required alloy, and may be either cold worked or annealed. The welded tube shall be manufactured from either cold rolled or annealed sheet or strip. The sheet or strip shall be formed into a tubular shape on a suitable forming mill. The material shall conform to the chemical requirements specified. The microstructure shall show complete recrystallization and shall have an average grain size within the limits specified. Nondestructive examination, electromagnetic test, cleanness requirements, and cuprous oxide requirement shall be made to conform to the specified requirements.

SCOPE

1.1 This specification establishes the requirements for welded, internally enhanced copper tube, in straight lengths or coils, suitable for use in refrigeration and air conditioning products or other heat exchangers.

1.2 Units The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units, which are provided for information only and are not considered standard.

1.3 The product shall be produced of the following coppers. Unless otherwise specified, tubes made from any one of these coppers may be supplied:Copper UNS No.Type of MetalC10200Oxygen-free without residual deoxidantsC12200Phosphorized, high residual phosphorus (DHP)

The following pertains to the test method described in of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B919 – 01 (Reapproved 2006)

Standard Specification for

Welded Copper Heat Exchanger Tubes With Internal

1

Enhancement

This standard is issued under the fixed designation B919; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E8 Test Methods for Tension Testing of Metallic Materials

E29 Practice for Using Significant Digits in Test Data to

1.1 This specification establishes the requirements for

Determine Conformance with Specifications

welded, internally enhanced copper tube, in straight lengths or

E53 Test Method for Determination of Copper in Unalloyed

coils, suitable for use in refrigeration and air conditioning

Copper by Gravimetry

products or other heat exchangers.

E62 Test Methods for Chemical Analysis of Copper and

1.2 Units—The values stated in inch-pound units are to be

Copper Alloys (Photometric Methods)

regarded as standard. The values given in parentheses are

E112 Test Methods for Determining Average Grain Size

mathematical conversions to SI units, which are provided for

E243 Practice for Electromagnetic (Eddy-Current) Exami-

information only and are not considered standard.

nation of Copper and Copper-Alloy Tubes

1.3 The product shall be produced of the following coppers.

E255 Practice for Sampling Copper and Copper Alloys for

Unless otherwise specified, tubes made from any one of these

the Determination of Chemical Composition

coppers may be supplied:

Copper UNS No. Type of Metal

3. Terminology

C10200 Oxygen-free without residual deoxidants

3.1 For the definition of terms related to copper and copper

C12200 Phosphorized, high residual phosphorus (DHP)

alloys refer to Terminology B846.

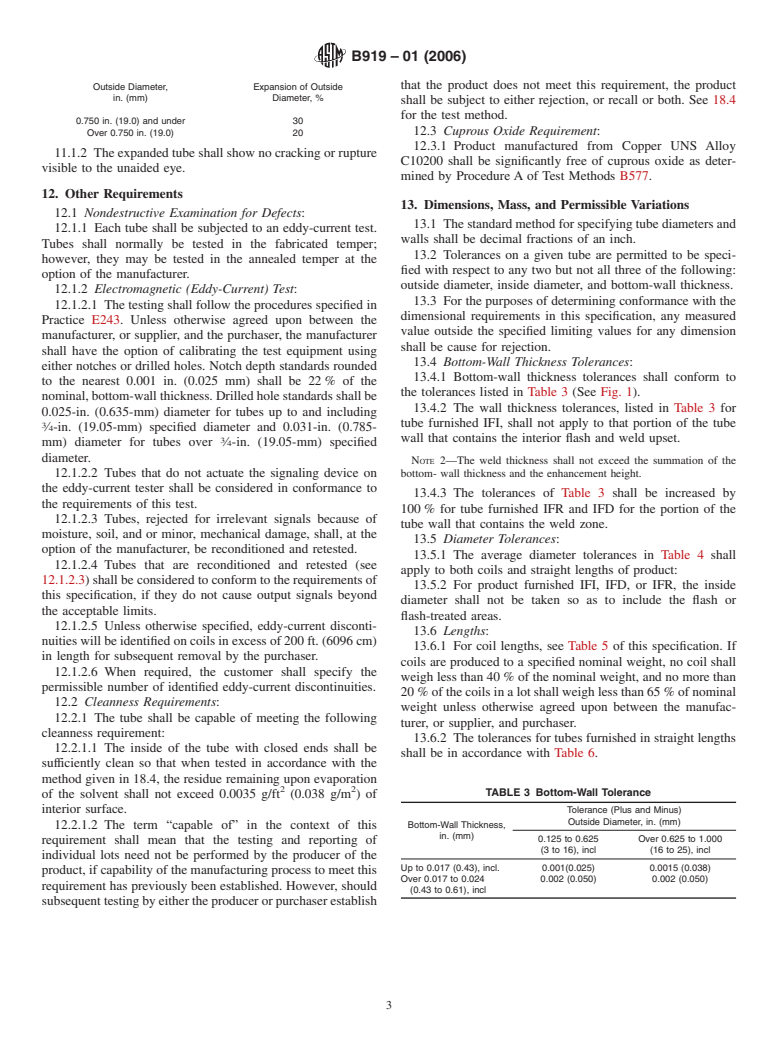

1.4 The following pertains to the test method described in 3.2 Definitions:

18.4 of this specification. This standard does not purport to 3.2.1 bottom wall, n—the wall thickness measured from the

address all of the safety concerns, if any, associated with its base of the enhancement to the outside surface.

use. It is the responsibility of the user of this standard to

3.2.2 coil, n—a length of the product wound into a series of

establish appropriate safety and health practices and deter- connected turns.

mine the applicability of regulatory requirements prior to use. 3.2.3 enhancement, n—a geometrical feature intentionally

formed on a tube I.D. surface to improve heat transfer.

2. Referenced Documents

3.2.4 level wound, adj—a type of coil in which the turns are

2

2.1 ASTM Standards:

wound into layers parallel to the axis of the coil such that

B153 Test Method for Expansion (Pin Test) of Copper and successive turns in a given layer are next to one another.

Copper-Alloy Pipe and Tubing

3.3 Definitions of Terms Specific to This Standard:

B577 Test Methods for Detection of Cuprous Oxide (Hy- 3.3.1 roundness tolerance, n—the roundness tolerance is

drogen Embrittlement Susceptibility) in Copper

defined as the maximum OD at a point minus the minimum

B601 Classification for Temper Designations for Copper OD, at the same plane of intersection of the tube, divided by

and Copper Alloys—Wrought and Cast

the specified OD 3 100 %.

B846 Terminology for Copper and Copper Alloys 3.3.2 squareness of cut, n—the maximum deviation of one

E3 Guide for Preparation of Metallographic Specimens

side of a cross section from the opposite side, when measured

against the projected perpendicularity of the plane of the

projected center of the tube at the ends.

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe

4. Classification

and Tube.

Current edition approved Oct. 1, 2006. Published November 2006. Originally

4.1 The following types of welded tube are manufactured

approved in 2001. Last previous edition approved in 2001 as B919 – 01. DOI:

under the scope of this specification:

10.1520/B0919-01R06.

2

4.1.1 As-Welded—Welded tube without subsequent heat

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM treatment or cold work.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B919 – 01 (2006)

TABLE 1 Chemical Requirements

4.1.2 Welded Tube, Subsequently Annealed—Welded tube

annealed to produce a uniform grain size appropriate to the UNS Alloy Number Copper, wt % Phosphorus, wt %

A

specified annealed temper.

C10200 99.95 min

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.