ASTM D5977-03(2007)

(Specification)Standard Specification for High Load Rotational Spherical Bearings for Bridges and Structures

Standard Specification for High Load Rotational Spherical Bearings for Bridges and Structures

ABSTRACT

This specification covers bridge bearings that consist of a spherical rotational element, where a stainless steel convex surface slides against a concave carbon steel plate covered with woven or sheet polytetrafluoroethylene (PTFE). The function of the bearing is to transfer loads and to accommodate any relative movement, including rotation between a bridge superstructure and its supporting structure, or both. The requirements of spherical bearings with a standard horizontal load (a maximum of 10 % of vertical) are discussed. The bearings are furnished in three types: fixed spherical bearing which is for rotation only, unidirectional sliding spherical bearing which is for rotation plus movement in one direction, and multi-directional sliding spherical bearing which is for rotation plus movement in all directions. The materials to be used in producing the bearings include: steel, stainless steel (flat sliding surface and convex surface), woven fabric polytetrafluoroethylene, and sheet polytetrafluoroethylene. The following different test methods shall be performed: proof load and rotation tests for fixed and expansion bearings, coefficient of friction test for expansion bearings only, PTFE (woven or sheet) bond test for expansion bearings only, and physical property test of both PTFEs for fixed and expansion bearings.

SCOPE

1.1 This specification covers bridge bearings that consist of a spherical rotational element, where a stainless steel convex surface slides against a concave carbon steel plate covered with woven or sheet polytetrafluoroethylene (PTFE). The function of the bearing is to transfer loads and to accommodate any relative movement, including rotation between a bridge superstructure and its supporting structure, or both.

1.2 This specification covers the requirements of spherical bearings with a standard horizontal load (a maximum of 10 % of vertical).

1.3 The requirements stated in this specification are the minima necessary for the manufacture of quality bearing devices. It may be necessary to increase these minimum values due to other design conditions.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 The following safety hazards caveat pertains only to the test method portion, Section 7, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5977 −03(Reapproved 2007)

Standard Specification for

High Load Rotational Spherical Bearings for Bridges and

Structures

This standard is issued under the fixed designation D5977; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope A240/A240MSpecification for Chromium and Chromium-

Nickel Stainless Steel Plate, Sheet, and Strip for Pressure

1.1 This specification covers bridge bearings that consist of

Vessels and for General Applications

a spherical rotational element, where a stainless steel convex

A572/A572MSpecification for High-Strength Low-Alloy

surfaceslidesagainstaconcavecarbonsteelplatecoveredwith

Columbium-Vanadium Structural Steel

woven or sheet polytetrafluoroethylene (PTFE). The function

A588/A588MSpecification for High-Strength Low-Alloy

of the bearing is to transfer loads and to accommodate any

Structural Steel, up to 50 ksi [345 MPa] Minimum Yield

relative movement, including rotation between a bridge super-

Point, with Atmospheric Corrosion Resistance

structure and its supporting structure, or both.

A709/A709MSpecification for Structural Steel for Bridges

1.2 This specification covers the requirements of spherical

D638Test Method for Tensile Properties of Plastics

bearings with a standard horizontal load (a maximum of 10%

D792Test Methods for Density and Specific Gravity (Rela-

of vertical).

tive Density) of Plastics by Displacement

1.3 The requirements stated in this specification are the D1457 Specification for Polytetrafluoroethylene (Ptfe)

Molding and Extrusion Materials (Withdrawn 1996)

minima necessary for the manufacture of quality bearing

devices.Itmaybenecessarytoincreasetheseminimumvalues D1777Test Method for Thickness of Textile Materials

D2256Test Method for Tensile Properties of Yarns by the

due to other design conditions.

Single-Strand Method

1.4 The values stated in inch-pound units are to be regarded

2.2 AASHTO Standard:

as the standard. The values given in parentheses are for

AASHTO Standard Specifications for Highway Bridges

information only.

2.3 AWS Standards:

1.5 The following safety hazards caveat pertains only to the

C.2.2-67Metalizing withAluminum and Zinc for Protection

test method portion, Section 7, of this specification: This

of Iron and Steel

standard does not purport to address all of the safety concerns,

D.1.5ANSI/AASHTO/AWS Bridge Welding Code

if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health

3. Classification

practices and determine the applicability of regulatory limita-

3.1 The bearings are furnished in three types, as follows:

tions prior to use.

3.1.1 Fixed Spherical Bearing—Rotation only.

3.1.2 Uni-Directional Sliding Spherical Bearing—Rotation

2. Referenced Documents

plus movement in one direction.

2.1 ASTM Standards:

3.1.3 Multi-Directional Sliding Spherical Bearing—

A36/A36MSpecification for Carbon Structural Steel

Rotation plus movement in all directions.

A167 Specification for Stainless and Heat-Resisting

Chromium-Nickel Steel Plate, Sheet, and Strip

4. Material Specifications

4.1 Steel—The steel used for all major plates shall be

structural steel conforming to Specifications A36/A36M,

This specification is under the jurisdiction ofASTM Committee D04 on Road

and Paving Materials and is the direct responsibility of Subcommittee D04.32 on

Bridges and Structures.

Current edition approved Dec. 1, 2007. Published January 2008. Originally The last approved version of this historical standard is referenced on

approved in 1996. Last previous edition approved in 2003 as D5977–03. DOI: www.astm.org.

10.1520/D5977-03R07. Available from American Association of State Highway and Transportation

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM http://www.transportation.org.

Standards volume information, refer to the standard’s Document Summary page on Available from American Welding Society (AWS), 550 NW LeJeune Rd.,

the ASTM website. Miami, FL 33126, http://www.aws.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5977−03 (2007)

A588/A588M, A572/A572M,or A709/A709M, as required. 4.4.1 The thickness of the sheet PTFE shall be a minimum

AllexposedsurfacesshallbezincmetalizedaccordingtoAWS of ⁄8in.(3.17mm)andshallberecessedatleastone-halfofits

C.2.2-67 (with no chipping), having a minimum thickness of 6 thickness.

mil (0.152 mm) or treated with other project-approved coating 4.4.2 ThePTFEfortheprincipalslidesurfaceandforguide

systems such as coal tar or inorganic zinc paint. The dry film bars shall conform to the physical requirements listed in Table

thickness (DFT) of the approved paint system must be speci- 2.

fied by the owner.

5. Design Requirements

4.2 Stainless Steel:

NOTE 1—To Designer: The bearing details shall be designed in

4.2.1 Flat Sliding Surface—The sheet stainless steel used as

accordance with the requirements of the current edition with interims of

the mating sliding surface to the woven fabric PTFE or sheet

the AASHTO Standard Specifications for Highway Bridges or other

governing design procedures.

PTFE in the sliding spherical bearings shall conform to

Specification A167 or A240/A240M, type 304, 20-µin. (0.5-

5.1 Rotational Elements:

µm) rms finish.

5.1.1 The spherical radius shall be determined such that the

4.2.2 Convex Surface—The solid stainless steel plate or

resulting geometry of the bearing is capable of withstanding

sheet stainless steel used as the mating rotational convex

thegreatestratioofthehorizontalloadtoverticalloadunderall

surfacetothewovenfabricPTFEorsheetPTFEshallconform

loading conditions to prevent the unseating (separation at the

to Specification A167 or A240/A240M, type 304. The surface

edges) of the convex/concave elements.

shallbemachinedtoasurfacefinishof20-µin.(0.5-µm)rmsor

5.1.2 Unseating of the curved spherical surfaces relative to

less.

each other shall be prevented by transferring horizontal forces

through specifically designed restraints or by control of the

4.3 Woven Fabric Polytetrafluoroethylene (PTFE)—The

spherical radius.

woven fabric PTFE shall be made from virgin PTFE oriented

5.1.3 Acceptable spherical radius control shall be given

multifilament fibers with or without a high-strength backing.

when the configuration of the woven fabric PTFE concave

4.3.1 The thickness of the woven fabric PTFE in the free

radius follows the following design:

state shall be a minimum of ⁄32 in. (2.38 mm) when measured

in accordance with Method D1777.

ratio# tan α (1)

4.3.2 ThethicknessofthebondedwovenfabricPTFEunder

the application of vertical load shall be a minimum of the

where:

following:

ratio = worst case ratio of horizontal to vertical loads.

(1) ⁄16 in. (1.59 mm) from 0 psi (0 N/mm ) to 3500 psi

(24.1 N/mm ).

d/2

2 α 5 arcsin 2 designrotation (2)

S S DD ~ !

(2) ⁄64 in. (1.19 mm) from 3501 psi (24.1 N/mm ) to 4500 Rmax

psi (31.0 N/mm ).

4.3.3 The woven fabric PTFE shall be mechanically inter-

where:

locked and epoxy-bonded to the substrate using a system that

d = projected diameter of the woven fabric

prevents migration of the epoxy through the fabric. The use of

PTFE,

a mechanical interlock system along with the epoxy increases

design rotation = design rotation of the bearing (in

thebondstrength,providingaredundancyforthepreventionof

degrees), and

migration of the PTFE material. Any edges, other than the

Rmax = maximum allowable radius to prevent

selvedge (woven edge), shall be oversewn so that no cut fabric

uplift within the bearing during the worst

edges are exposed.

horizontal to vertical load case.

4.3.4 The individual PTFE filaments used in making the

5.1.4 Calculationsshowingdeterminationoftheradiusshall

wovenPTFEfabricshallconformtothephysicalrequirements

be submitted for approval.

of Table 1.

5.1.5 The radius of the convex plate shall be less than the

4.4 Sheet Polytetrafluoroethylene (PTFE)—The sheet PTFE

radiuscalculatedforthewovenfabricPTFE(concaveplate)by

shall be virgin material (not reprocessed) meeting the require-

a value equal to the thickness of the PTFE.

ments of Specification D1457. The PTFE shall be resistant to

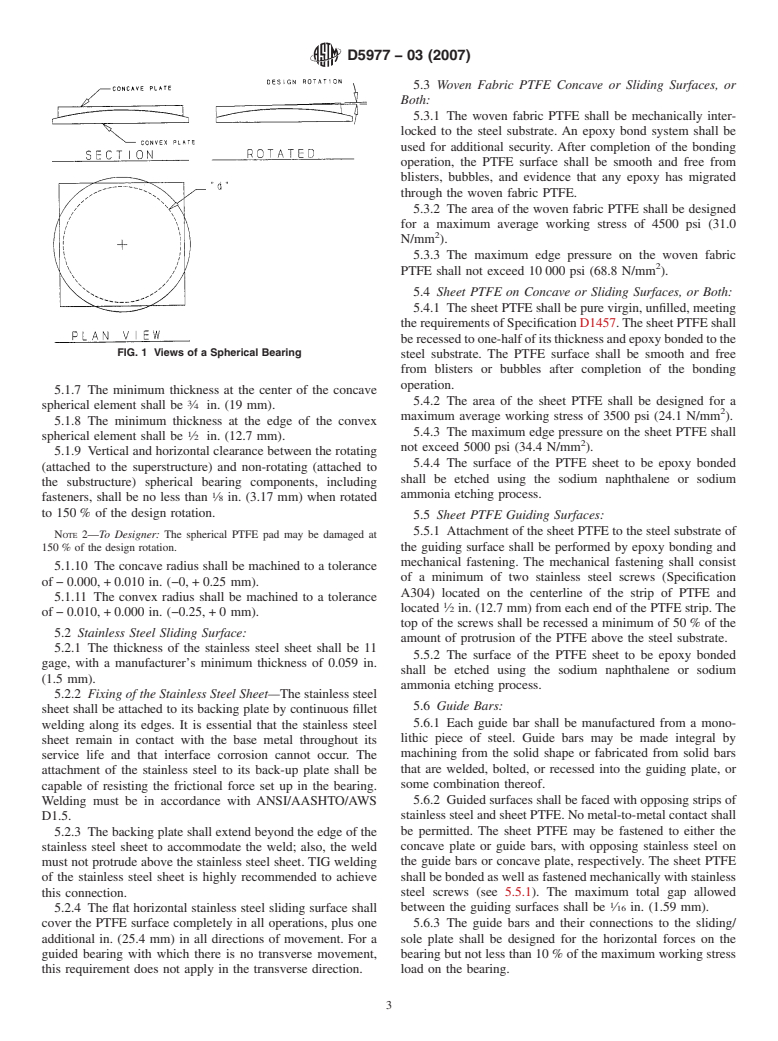

5.1.6 The concave surface shall face down whenever the

acids, alkalis, petroleum products, and nonabsorbtion of water.

resulting center of rotation is not detrimental to the system

It shall be stable for temperatures up to 500°F (260°C) and

geometry. See Fig. 1

shall be nonflammable. When used in PTFE surfaces used for

guide bars only, filler material shall be composed of milled

glass fibers or carbon.

A

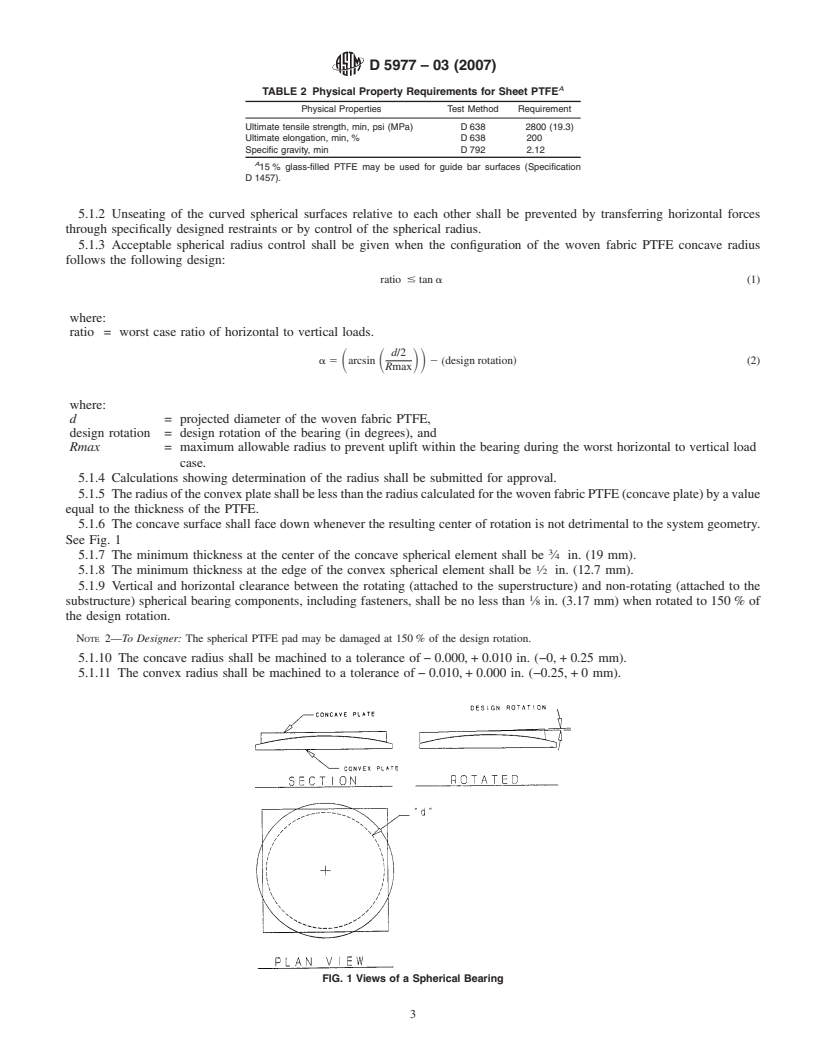

TABLE 2 Physical Property Requirements for Sheet PTFE

Physical Properties Test Method Requirement

Ultimate tensile strength, min, psi (MPa) D638 2800 (19.3)

TABLE 1 Physical Property Requirements for Woven PTFE

Ultimate elongation, min, % D638 200

Specific gravity, min D792 2.12

Physical Properties Test Method Requirement

A

Ultimate tensile strength, min, psi (MPa) D2256 24 000 (165.4) 15 % glass-filled PTFE may be used for guide bar surfaces (Specification

Ultimate elongation, min, % D2256 35

D1457).

D5977−03 (2007)

5.3 Woven Fabric PTFE Concave or Sliding Surfaces, or

Both:

5.3.1 The woven fabric PTFE shall be mechanically inter-

locked to the steel substrate. An epoxy bond system shall be

used for additional security. After completion of the bonding

operation, the PTFE surface shall be smooth and free from

blisters, bubbles, and evidence that any epoxy has migrated

through the woven fabric PTFE.

5.3.2 The area of the woven fabric PTFE shall be designed

for a maximum average working stress of 4500 psi (31.0

N/mm ).

5.3.3 The maximum edge pressure on the woven fabric

PTFE shall not exceed 10000 psi (68.8 N/mm ).

5.4 Sheet PTFE on Concave or Sliding Surfaces, or Both:

5.4.1 ThesheetPTFEshallbepurevirgin,unfilled,meeting

therequirementsofSpecificationD1457.ThesheetPTFEshall

berecessedtoone-halfofitsthicknessandepoxybondedtothe

FIG. 1 Views of a Spherical Bearing

steel substrate. The PTFE surface shall be smooth and free

from blisters or bubbles after completion of the bonding

operation.

5.1.7 The minimum thickness at the center of the concave

5.4.2 The area of the sheet PTFE shall be designed for a

spherical element shall be ⁄4 in. (19 mm).

maximum average working stress of 3500 psi (24.1 N/mm ).

5.1.8 The minimum thickness at the edge of the convex

1 5.4.3 The maximum edge pressure on the sheet PTFE shall

spherical element shall be ⁄2 in. (12.7 mm).

not exceed 5000 psi (34.4 N/mm ).

5.1.9 Vertical and horizontal cl

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D5977–96 Designation: D 5977 – 03 (Reapproved 2007)

Standard Specification for

High Load Rotational Spherical Bearings for Bridges and

Structures

This standard is issued under the fixed designation D5977; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 Thisspecificationcoversbridgebearingsthatconsistofasphericalrotationalelement,whereastainlesssteelconvexsurface

slides against a concave carbon steel plate covered with woven or sheet polytetrafluoroethylene (PTFE). The function of the

bearing is to transfer loads and to accommodate any relative movement, including rotation between a bridge superstructure and

its supporting structure, or both.

1.2 This specification covers the requirements of spherical bearings with a standard horizontal load (a maximum of 10% of

vertical).

1.3 Therequirementsstatedinthisspecificationaretheminimanecessaryforthemanufactureofqualitybearingdevices.Itmay

be necessary to increase these minimum values due to other design conditions.

1.4 Thevaluesstatedininch-poundunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformation

only.

1.5 The following safety hazards caveat pertains only to the test method portion, Section 7, of this specification: This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

A36/A36M Specification for Carbon Structural Steel

A167 Specification for Stainless and Heat-Resisting Chromium-Nickel Steel Plate, Sheet, and Strip

A240/A240M Specification for Heat-Resisting Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for

Pressure Vessels and for General Applications

A572/A572M Specification for High-Strength Low-Alloy Columbium-Vanadium Structural Steel

A588/A588MSpecification for High-Strength Low-Alloy Structural Steel with 50 ksi [345 MPa] MinimumYield Point to 4 in.

[100mm]Thick 588/A588M SpecificationforHigh-StrengthLow-AlloyStructuralSteel,upto50ksi[345MPa]Minimum

Yield Point, with Atmospheric Corrosion Resistance

A709/A 709MSpecification for Carbon and High-Strength Low-Alloy Structural Steel Shapes, Plates, and Bars and

Quenched-and-Tempered Alloy Structural Steel Plates for Bridges 709/A709M Specification for Structural Steel for

Bridges

D638 Test Method for Tensile Properties of Plastics

D792 Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement

D1457 Specification for Polytetrafluoroethylene (PTFE) Molding and Extrusion Materials

D1777 Test Method for Measuring Thickness of Textile Materials

D2256 Test Method for Tensile Properties of Yarns by the Single-Strand Method

2.2 AASHTO Standard:

This specification is under the jurisdiction ofASTM Committee D-4 on Road and Paving Materials and is the direct responsibility of Subcommittee D04.32 on Bridges

and Structures.

Current edition approved July 10, 1996. Published September 1996.

This specification is under the jurisdiction ofASTM Committee D04 on Road and Paving Materials and is the direct responsibility of Subcommittee D04.32 on Bridges

and Structures.

Current edition approved Dec. 1, 2007. Published January 2008. Originally approved in 1996. Last previous edition approved in 2003 as D5977–03.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

, Vol 01.04.volume information, refer to the standard’s Document Summary page on the ASTM website.

Annual Book of ASTM Standards, Vol 01.03.

Available from American Association of State Highway and Transportation Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001,

http://www.transportation.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 5977 – 03 (2007)

AASHTO Standard Specifications for Highway Bridges

2.3 AWS Standards:

C.2.2-67 Metalizing with Aluminum and Zinc for Protection of Iron and Steel

D.1.5 ANSI/AASHTO/AWS Bridge Welding Code

3. Classification

3.1 The bearings are furnished in three types, as follows:

3.1.1 Fixed Spherical Bearing—Rotation only.

3.1.2 Uni-Directional Sliding Spherical Bearing—Rotation plus movement in one direction.

3.1.3 Multi-Directional Sliding Spherical Bearing—Rotation plus movement in all directions.

4. Material Specifications

4.1 Steel—ThesteelusedforallmajorplatesshallbestructuralsteelconformingtoSpecificationsA36/A36M,A588/A588M,

A572/A572M, orA709/A709M, as required.All exposed surfaces shall be zinc metalized according toAWS C.2.2-67 (with no

chipping), having a minimum thickness of 6 mil (0.152 mm) or treated with other project-approved coating systems such as coal

tar or inorganic zinc paint. The dry film thickness (DFT) of the approved paint system must be specified by the owner.

4.2 Stainless Steel:

4.2.1 Flat Sliding Surface—ThesheetstainlesssteelusedasthematingslidingsurfacetothewovenfabricPTFEorsheetPTFE

in the sliding spherical bearings shall conform to Specification A167 or A240/A240M, type 304, 20-µin. (0.5-µm) rms finish.

4.2.2 Convex Surface— The solid stainless steel plate or sheet stainless steel used as the mating rotational convex surface to

the woven fabric PTFE or sheet PTFE shall conform to Specification A167 or A240/A240M, type 304. The surface shall be

machined to a surface finish of 20-µin. (0.5-µm) rms or less.

4.3 Woven Fabric Polytetrafluoroethylene (PTFE)—The woven fabric PTFE shall be made from virgin PTFE oriented

multifilament fibers with or without a high-strength backing.

4.3.1 The thickness of the woven fabric PTFE in the free state shall be a minimum of ⁄32 in. (2.38 mm) when measured in

accordance with Method D1777.

4.3.2 The thickness of the bonded woven fabric PTFE under the application of vertical load shall be a minimum of the

following:

2 2

(1) ⁄16 in. (1.59 mm) from 0 psi (0 N/mm ) to 3500 psi (24.1 N/mm ).

2 2

(2) ⁄64 in. (1.19 mm) from 3501 psi (24.1 N/mm ) to 4500 psi (31.0 N/mm ).

4.3.3 ThewovenfabricPTFEshallbemechanicallyinterlockedandepoxy-bondedtothesubstrateusingasystemthatprevents

migration of the epoxy through the fabric. The use of a mechanical interlock system along with the epoxy increases the bond

strength,providingaredundancyforthepreventionofmigrationofthePTFEmaterial.Anyedges,otherthantheselvedge(woven

edge), shall be oversewn so that no cut fabric edges are exposed.

4.3.4 TheindividualPTFEfilamentsusedinmakingthewovenPTFEfabricshallconformtothephysicalrequirementsofTable

1.

4.4 Sheet Polytetrafluoroethylene (PTFE)—ThesheetPTFEshallbevirginmaterial(notreprocessed)meetingtherequirements

of Specification D1457. The PTFE shall be resistant to acids, alkalis, petroleum products, and nonabsorbtion of water. It shall be

stable for temperatures up to 500°F (260°C) and shall be nonflammable. When used in PTFE surfaces used for guide bars only,

filler material shall be composed of milled glass fibers or carbon.

4.4.1 The thickness of the sheet PTFE shall be a minimum of ⁄8 in. (3.17 mm) and shall be recessed at least one-half of its

thickness.

4.4.2 The PTFE for the principal slide surface and for guide bars shall conform to the physical requirements listed in Table 2.

5. Design Requirements Design Requirements

NOTE 1—To Designer: The bearing details shall be designed in accordance with the requirements of the current edition with interims of theAASHTO

Standard Specifications for Highway Bridges or other governing design procedures.

5.1 Rotational Elements:

5.1.1 The spherical radius shall be determined such that the resulting geometry of the bearing is capable of withstanding the

greatest ratio of the horizontal load to vertical load under all loading conditions to prevent the unseating (separation at the edges)

of the convex/concave elements.

Annual Book of ASTM Standards, Vol 08.01.

Available from American Welding Society (AWS), 550 NW LeJeune Rd., Miami, FL 33126, http://www.aws.org.

TABLE 1 Physical Property Requirements for Woven PTFE

Physical Properties Test Method Requirement

Ultimate tensile strength, min, psi (MPa) D 2256 24 000 (165.4)

Ultimate elongation, min, % D 2256 35

D 5977 – 03 (2007)

A

TABLE 2 Physical Property Requirements for Sheet PTFE

Physical Properties Test Method Requirement

Ultimate tensile strength, min, psi (MPa) D 638 2800 (19.3)

Ultimate elongation, min, % D 638 200

Specific gravity, min D 792 2.12

A

15 % glass-filled PTFE may be used for guide bar surfaces (Specification

D 1457).

5.1.2 Unseating of the curved spherical surfaces relative to each other shall be prevented by transferring horizontal forces

through specifically designed restraints or by control of the spherical radius.

5.1.3 Acceptable spherical radius control shall be given when the configuration of the woven fabric PTFE concave radius

follows the following design:

ratio #tan a (1)

where:

ratio = worst case ratio of horizontal to vertical loads.

d/2

a5 arcsin 2 ~designrotation! (2)

S S DD

Rmax

where:

d = projected diameter of the woven fabric PTFE,

design rotation = design rotation of the bearing (in degrees), and

Rmax = maximum allowable radius to prevent uplift within the bearing during the worst horizontal to vertical load

case.

5.1.4 Calculations showing determination of the radius shall be submitted for approval.

5.1.5 TheradiusoftheconvexplateshallbelessthantheradiuscalculatedforthewovenfabricPTFE(concaveplate)byavalue

equal to the thickness of the PTFE.

5.1.6 The concave surface shall face down whenever the resulting center of rotation is not detrimental to the system geometry.

See Fig. 1

5.1.7 The minimum thickness at the center of the concave spherical element shall be ⁄4 in. (19 mm).

5.1.8 The minimum thickness at the edge of the convex spherical element shall be ⁄2 in. (12.7 mm).

5.1.9 Vertical and horizontal clearance between the rotating (attached to the superstructure) and non-rotating (attached to the

substructure) spherical bearing components, including fasteners, shall be no less than ⁄8 in. (3.17 mm) when rotated to 150% of

the design rotation.

NOTE 2—To Designer: The spherical PTFE pad may be damaged at 150% of the design rotation.

5.1.10 The concave radius shall be machined to a tolerance of−0.000,+0.010 in. (−0,+0.25 mm).

5.1.11 The convex radius shall be machined to a tolerance of−0.010,+0.000 in. (−0.25,+0 mm).

FIG. 1 Views of a Spherical Bearing

D 5977 – 03 (2007)

5.2 Stainless Steel Sliding Surface :

5.2.1 Thethicknessofthestainlesssteelsheetshallbe11gage,withamanufacturer’sminimumthicknessof0.059in.(1.5mm).

5.2.2 Fixing of the Stainless Steel Sheet—The stainless steel sheet shall be attached to its backing plate by continuous fillet

welding along its edges. It is essential that the stainless steel sheet remain in contact with the base metal throughout its service

lifeandthatinterfacecorrosioncannotoccur.Theattachmentofthestainlesssteeltoitsback-upplateshallbecapableofresisting

the frictional force set up in the bearing. Welding must be in accordance with ANSI/AASHTO/AWS D1.5.

5.2.3 The backing plate shall extend beyond the edge of the stainless steel sheet to accommodate the weld; also, the weld must

not protrude above the stainless steel sheet. TIG welding of the stainless steel sheet is highly recommended to achieve this

connection.

5.2.4 The flat horizontal stainless steel sliding surface shall cover the PTFE surface completely in all operations, plus one

additional in. (25.4 mm) in all directions of movement. For a guided bearing with which there is no transverse movement, this

requirement does not apply in the transverse direction.

5.3 Woven Fabric PTFE Concave or Sliding Surfaces, or Both:

5.3.1 The woven fabric PTFE shall be mechanically interlocked to the steel substrate.An epoxy bond system shall be used for

additional security.After completion of the bonding operation, the PTFE surface shall be smooth and free from blisters, bubbles,

and evidence that any epoxy has migrated through the woven fabric PTFE.

5.3.2 The area of the woven fabric PTFE shall be designed for a maximum average working stress of 4500 psi (31.0 N/mm ).

5.3.3 The maximum edge pressure on the woven fabric PTFE shall not exceed 10000 psi (68.8 N/mm ).

5.4 Sheet PTFE on Concave or Sliding Surfaces, or Both:

5.4.1 The sheet PTFE shall be pure virgin, unfilled, meeting the requirements of Specification D1457. The sheet PTFE shall

be recessed to one-half of its thickness and epoxy bonded to the steel substrate. The PTFE surface shall be smooth and free from

blisters or bubbles after completion of the bonding operation.

5.4.2 The area of the sheet PTFE shall be designed for a maximum average working stress of 3500 psi (24.1 N/mm ).

5.4.3 The maximum edge pressure on the sheet PTFE shall not exceed 5000 psi (34.4 N/mm ).

5.4.4 The surface of the PTFE sheet to be epoxy bonded shall be etched using the sodium naphthalene or sodium ammonia

etching process.

5.5 Sheet PTFE Guiding Surfaces :

5.5.1 Attachment of the sheet PTFE to the steel substrate of the guiding surface shall be performed by epoxy bonding and

mechanical fastening. The mechanical fastening shall consist of a minimum of two stainless steel screws (Specification A304)

locatedonthecenterlineofthestripofPTFEandlocated ⁄2in.(12.7mm)fromeachendofthePTFEstrip.Thetopofthescrews

shall be recessed a minimum of 50% of the amount of protrusion of the PTFE above the steel substrate.

5.5.2 The surface of the PTFE sheet to be epoxy bonded shall be etched using the sodium naphthalene or sodium ammonia

etching process.

5.6 Guide Bars:

5.6.1 Each guide bar shall be manufactured from a monolithic piece of steel. Guide bars may be made integral by machining

from the solid shape or fabricated from solid bars that are welded, bolted, or recessed into the guiding plate, or some combination

thereof.

5.6.2 Guided surfaces shall be faced with opposing strips of stainless steel and sheet PTFE. No metal-to-metal contact shall be

permitted. The shee

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.