ASTM D8138-23

(Specification)Standard Specification for Preformed Silicone Joint Sealing System for Bridges

Standard Specification for Preformed Silicone Joint Sealing System for Bridges

ABSTRACT

This specification covers the material, manufacturing, and physical requirements for preformed silicone joint seals used in bridges. The seal consists of a silicone rubber gland preformed to a continuous length and is designed to prevent any tension from occurring in the seal or bonding point during normal movement. The seal is installed by bonding it to the joint header with a silicone-based adhesive, sealing the joint to prevent liquid intrusion. Physical requirements for the preformed silicone joint seal gland cover resistance to accelerated weathering, tensile strength, elongation at break, hardness, tear strength, compression set, and heat-aged properties, whereas physical requirements for the silicone-based adhesive cover tensile strength, elongation at break, sag/flow, tack-free time, resistance to UV, and cure through to 1/4-in. thickness.

SCOPE

1.1 This specification covers the material requirements for preformed silicone joint seals for bridges. The seal consists of a silicone rubber gland preformed to a continuous length. Its design shall prevent any tension from occurring in the seal or bonding point during normal movement. The seal is installed by bonding it to the joint header with a silicone-based adhesive and is designed to seal the joint, preventing liquid intrusion.

1.2 The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D8138 − 23

Standard Specification for

1

Preformed Silicone Joint Sealing System for Bridges

This standard is issued under the fixed designation D8138; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope tic Elastomers—Tension

D573 Test Method for Rubber—Deterioration in an Air

1.1 This specification covers the material requirements for

Oven

preformed silicone joint seals for bridges. The seal consists of

D624 Test Method for Tear Strength of Conventional Vul-

a silicone rubber gland preformed to a continuous length. Its

canized Rubber and Thermoplastic Elastomers

design shall prevent any tension from occurring in the seal or

D2240 Test Method for Rubber Property—Durometer Hard-

bonding point during normal movement. The seal is installed

ness

by bonding it to the joint header with a silicone-based adhesive

and is designed to seal the joint, preventing liquid intrusion.

3. Materials and Manufacture

1.2 The values given in parentheses are mathematical con-

3.1 The seals shall be preformed to a continuous length, and

versions to SI units that are provided for information only and

the material shall be silicone rubber.

are not considered standard.

3.2 The adhesive shall be a silicone-based adhesive.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Physical Requirements

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter- 4.1 The materials for the seal shall conform to the physical

mine the applicability of regulatory limitations prior to use. properties prescribed in Table 1.

1.4 This international standard was developed in accor-

4.2 The materials for the adhesive shall conform to the

dance with internationally recognized principles on standard-

physical properties prescribed in Table 2.

ization established in the Decision on Principles for the

4.3 In the applicable requirements of Table 1 and the test

Development of International Standards, Guides and Recom-

method, all deflection shall be based on the nominal width.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

5. Dimensions and Working Parameters

2. Referenced Documents

5.1 The size, shape, and dimensional tolerances shall be as

2

outlined in 5.2.

2.1 ASTM Standards:

C639 Test Method for Rheological (Flow) Properties of

5.2 Measurements used for physical laboratory testing shall

Elastomeric Sealants

be taken to the nearest 0.01 in. (0.3 mm) and reported/recorded

C679 Test Method for Tack-Free Time of Elastomeric Seal-

to the nearest 0.1 in. (3 mm) as the average of the measure-

ants

ments. The measured width shall be greater than or equal to the

C793 Test Method for Effects of Laboratory Accelerated

nominal width. Measurements shall be taken at quarter points

Weathering on Elastomeric Joint Sealants

of the sample.

D395 Test Methods for Rubber Property—Compression Set

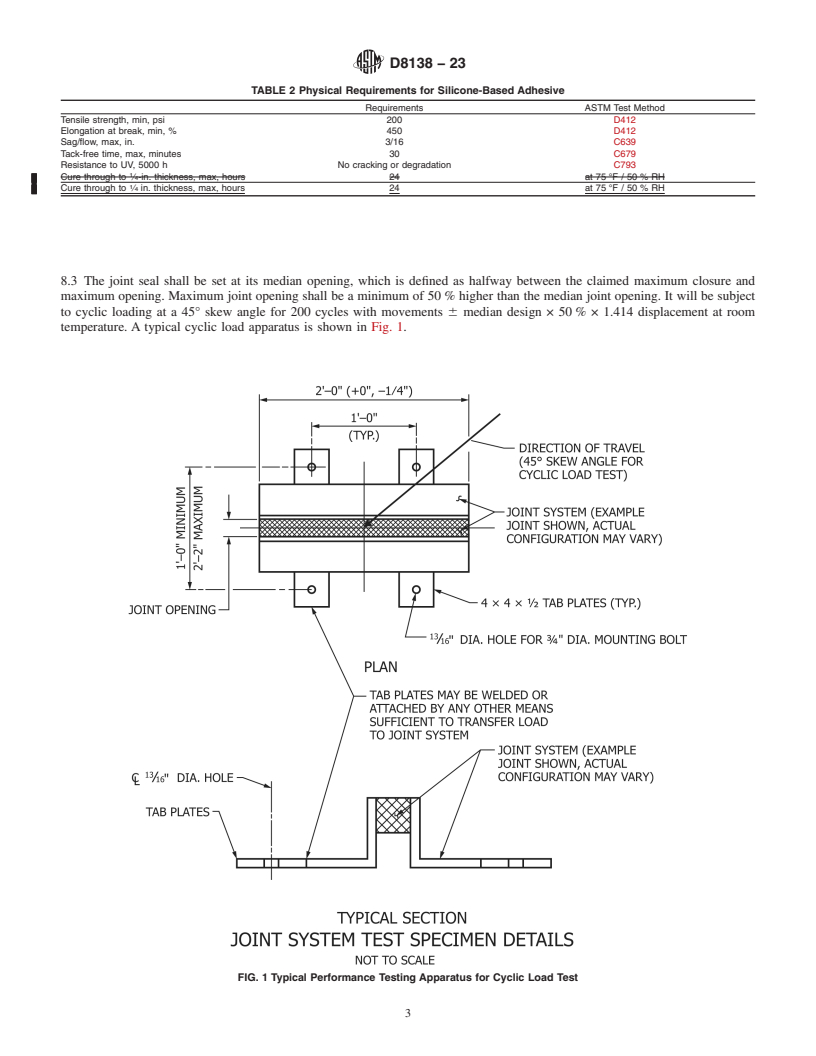

5.3 The lengths of samples for performance testing purposes

D412 Test Methods for Vulcanized Rubber and Thermoplas-

shall be 2 ft 6 0.25 in. (601 6 6 mm) length for the seal and

appropriate amount of silicone-based adhesive per manufac-

turer’s recommendation.

1

This specification is under the jurisdiction of ASTM Committee D04 on Road

and Paving Materials and is the direct responsibility of Subcommittee D04.32 on

6. Sampling

Bridges and Structures.

Current edition approved May 1, 2023. Published May 2023. Originally

6.1 Samples shall be taken at random from each shipment of

approved in 2018. Last previous edition approved in 2018 as D8138 – 18. DOI:

material. If the shipment consists of more than one lot, each lot

10.1520/D8138-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or shall be sampled.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.2 A lot shall consist of the quantity for each copious

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. section agreed upon between the purchaser and the supplier.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D8138 − 23

TABLE 1 Physical Requirements for Preformed Silicone Joint Seal Gland

Requirements ASTM Test Method

Resistance to accelerated weathering, 5000

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D8138 − 18 D8138 − 23

Standard Specification for

1

Preformed Silicone Joint Sealing System for Bridges

This standard is issued under the fixed designation D8138; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers the material requirements for preformed silicone joint seals for bridges. The seal consists of a silicone

rubber gland preformed to a continuous length. Its design shall prevent any tension from occurring in the seal or bonding point

during normal movement. The seal is installed by bonding it to the joint header with a silicone-based adhesive and is designed to

seal the joint, preventing liquid intrusion.

1.2 The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not

considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C639 Test Method for Rheological (Flow) Properties of Elastomeric Sealants

C679 Test Method for Tack-Free Time of Elastomeric Sealants

C793 Test Method for Effects of Laboratory Accelerated Weathering on Elastomeric Joint Sealants

D395 Test Methods for Rubber Property—Compression Set

D412 Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension

D573 Test Method for Rubber—Deterioration in an Air Oven

D624 Test Method for Tear Strength of Conventional Vulcanized Rubber and Thermoplastic Elastomers

D2240 Test Method for Rubber Property—Durometer Hardness

3. Materials and Manufacture

3.1 The seals shall be preformed to a continuous length, and the material shall be silicone rubber.

3.2 The adhesive shall be a silicone-based adhesive.

1

This specification is under the jurisdiction of ASTM Committee D04 on Road and Paving Materials and is the direct responsibility of Subcommittee D04.32 on Bridges

and Structures.

Current edition approved April 1, 2018May 1, 2023. Published April 2018May 2023. Originally approved in 2018. Last previous edition approved in 2018 as D8138 – 18.

DOI: 10.1520/D8138-18.10.1520/D8138-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D8138 − 23

4. Physical Requirements

4.1 The materials for the seal shall conform to the physical properties prescribed in Table 1.

4.2 The materials for the adhesive shall conform to the physical properties prescribed in Table 2.

4.3 In the applicable requirements of Table 1 and the test method, all deflection shall be based on the nominal width.

5. Dimensions and Working Parameters

5.1 The size, shape, and dimensional tolerances shall be as outlined in 5.2.

5.2 Measurements used for physical laboratory testing shall be taken to the nearest 0.01 in. (0.3 mm) and reported/recorded to the

nearest 0.1 in. (3 mm) as the average of the measurements. The measured width shall be greater than or equal to the nominal width.

Measurements shall be taken at quarter points of the sample.

5.3 The lengths of samples for performance testing purposes shall be 2 ft 6 0.25 in. (601 6 6 mm) length for the seal and

appropriate amount of silicone-based adhesive per manufacturer’s recommendation.

6. Sampling

6.1 Samples shall be taken at random from each shipment of material. If the shipment consists of more than one lot, each lot shall

be sampled.

6.2 A lot shall consist of the quantity for each copious section agreed upon between the purchaser and the sup

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.