ASTM A971/A971M-10

(Test Method)Standard Test Method for Measuring Edge Taper and Crown of Flat-Rolled Electrical Steel Coils

Standard Test Method for Measuring Edge Taper and Crown of Flat-Rolled Electrical Steel Coils

SIGNIFICANCE AND USE

Flat-rolled electrical steel master coils are usually slit into narrower coils. Usually these slit coils are punched or sheared into laminations of various shapes. The laminations are then uniformly stacked to become the cores of magnetic devices such as motors and transformers. Stacking of many laminations exhibiting excessive taper causes assembly problems and poor appearance. Nonuniform stack lengths in motors cause imbalance and noise. When the laminations are interleaved in transformers, taper causes air spaces within the core resulting in increased noise, increased exciting current, and higher core loss.

SCOPE

1.1 This test method provides a procedure for measuring edge taper and crown of flat-rolled electrical steel coils as produced at the steel mill.

1.2 The values and equations stated in customary (cgs-emu and inch-pound) units or SI units are to be regarded separately as standard. Within this standard, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with this standard.

1.3 The following material specifications include requirements for edge taper or crown: A677, A683, A726, A840, and A876.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A971/A971M −10

Standard Test Method for

Measuring Edge Taper and Crown of Flat-Rolled Electrical

1

Steel Coils

This standard is issued under the fixed designationA971/A971M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

3

1. Scope tion Steel (Withdrawn 2011)

A876 Specification for Flat-Rolled, Grain-Oriented, Silicon-

1.1 This test method provides a procedure for measuring

Iron, Electrical Steel, Fully Processed Types

edge taper and crown of flat-rolled electrical steel coils as

produced at the steel mill.

3. Terminology

1.2 The values and equations stated in customary (cgs-emu

3.1 Definitions:Except as defined as follows, the symbols

and inch-pound) units or SI units are to be regarded separately

and terminology used in this test method are defined in

as standard. Within this standard, the SI units are shown in

Terminology A340.

brackets. The values stated in each system may not be exact

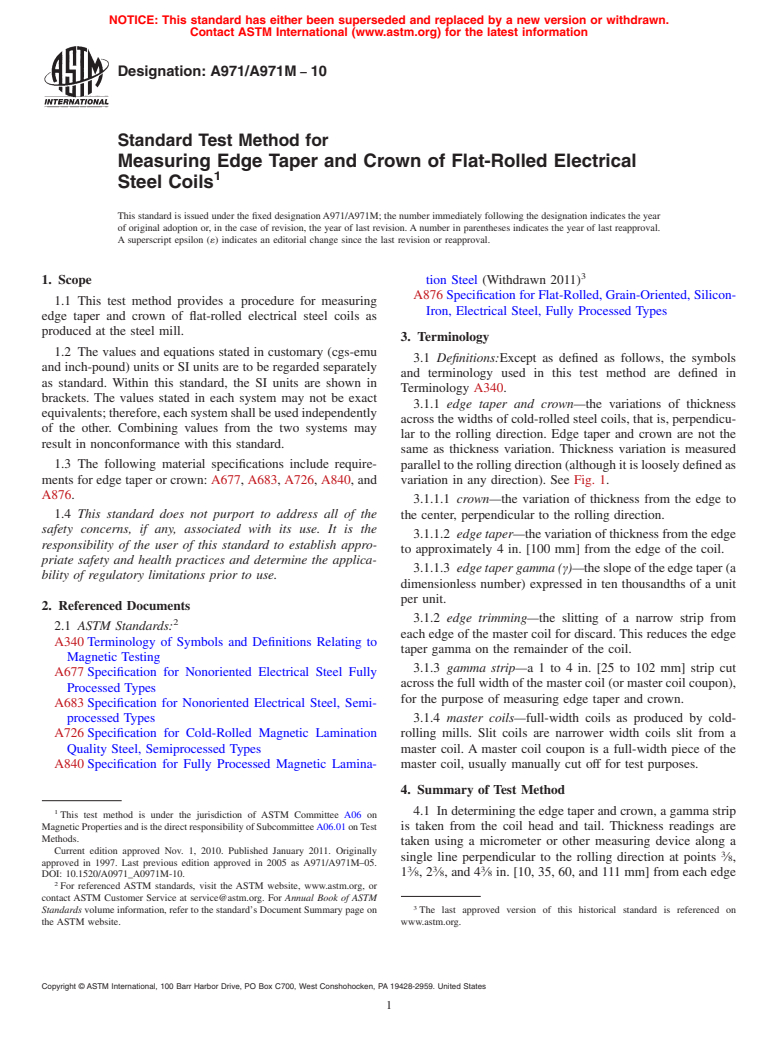

3.1.1 edge taper and crown—the variations of thickness

equivalents;therefore,eachsystemshallbeusedindependently

across the widths of cold-rolled steel coils, that is, perpendicu-

of the other. Combining values from the two systems may

lar to the rolling direction. Edge taper and crown are not the

result in nonconformance with this standard.

same as thickness variation. Thickness variation is measured

1.3 The following material specifications include require-

paralleltotherollingdirection(althoughitislooselydefinedas

ments for edge taper or crown: A677, A683, A726, A840, and variation in any direction). See Fig. 1.

A876.

3.1.1.1 crown—the variation of thickness from the edge to

1.4 This standard does not purport to address all of the the center, perpendicular to the rolling direction.

safety concerns, if any, associated with its use. It is the

3.1.1.2 edge taper—the variation of thickness from the edge

responsibility of the user of this standard to establish appro-

to approximately 4 in. [100 mm] from the edge of the coil.

priate safety and health practices and determine the applica-

3.1.1.3 edge taper gamma (γ)—theslopeoftheedgetaper(a

bility of regulatory limitations prior to use.

dimensionless number) expressed in ten thousandths of a unit

per unit.

2. Referenced Documents

3.1.2 edge trimming—the slitting of a narrow strip from

2

2.1 ASTM Standards:

each edge of the master coil for discard. This reduces the edge

A340 Terminology of Symbols and Definitions Relating to

taper gamma on the remainder of the coil.

Magnetic Testing

3.1.3 gamma strip—a 1 to 4 in. [25 to 102 mm] strip cut

A677 Specification for Nonoriented Electrical Steel Fully

across the full width of the master coil (or master coil coupon),

Processed Types

for the purpose of measuring edge taper and crown.

A683 Specification for Nonoriented Electrical Steel, Semi-

processed Types 3.1.4 master coils—full-width coils as produced by cold-

A726 Specification for Cold-Rolled Magnetic Lamination rolling mills. Slit coils are narrower width coils slit from a

Quality Steel, Semiprocessed Types master coil. A master coil coupon is a full-width piece of the

A840 Specification for Fully Processed Magnetic Lamina- master coil, usually manually cut off for test purposes.

4. Summary of Test Method

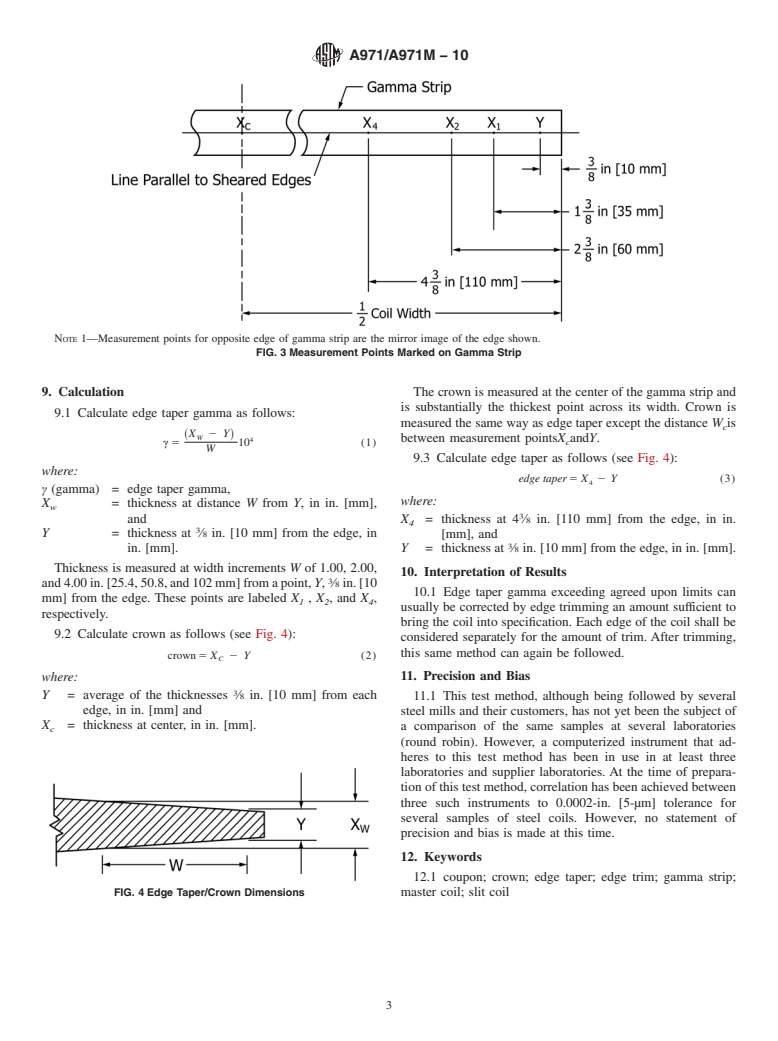

1 4.1 In determining the edge taper and crown, a gamma strip

This test method is under the jurisdiction of ASTM Committee A06 on

MagneticPropertiesandisthedirectresponsibilityofSubcommitteeA06.01onTest

is taken from the coil head and tail. Thickness readings are

Methods.

taken using a micrometer or other measuring device along a

Current edition approved Nov. 1, 2010. Published January 2011. Originally

3

single line perpendicular to the rolling direction at points ⁄8,

approved in 1997. Last previous edition approved in 2005 as A971/A971M–05.

3 3 3

1 ⁄8,2 ⁄8, and 4 ⁄8 in. [10, 35, 60, and 111 mm] from each edge

DOI: 10.1520/A0971_A0971M-10.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A971/A971M−10

FIG. 1Typical Steel Mill Coil Thickness Profile across Width of Coil

to determine edge taper and in the center to determine crown. fitted with an edge guide or other means to establish a strip

The readings are recorded, and

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A971/A971M–05 Designation: A971/A971M – 10

Standard Test Method for

Measuring Edge Taper and Crown of Flat-Rolled Electrical

1

Steel Coils

This standard is issued under the fixed designationA971/A971M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method provides a procedure for measuring edge taper and crown of flat-rolled electrical steel coils as produced

at the steel mill.

1.2 The values and equations stated in customary (cgs-emu and inch-pound) units or SI units are to be regarded separately as

standard. Within this standard, the SI units are shown in brackets. The values stated in each system may not be exact equivalents;

therefore, each system shall be used independently of the other. Combining values from the two systems may result in

nonconformance with this standard.

1.3 Thefollowingmaterialspecificationsincluderequirementsforedgetaperorcrown:A677,A683,A726,A840/A840MA840,

and A876.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

A340 Terminology of Symbols and Definitions Relating to Magnetic Testing

A677 Specification for Nonoriented Electrical Steel Fully Processed Types

A683 Specification for Nonoriented Electrical Steel, Semiprocessed Types

A726 Specification for Cold-Rolled Magnetic Lamination Quality Steel, Semiprocessed Types

A840/A840M840 Specification for Fully Processed Magnetic Lamination Steel

A876 Specification for Flat-Rolled, Grain-Oriented, Silicon-Iron, Electrical Steel, Fully Processed Types

3. Terminology

3.1 Definitions: Except as defined as follows, the symbols and terminology used in this test method are defined in Terminology

A340.

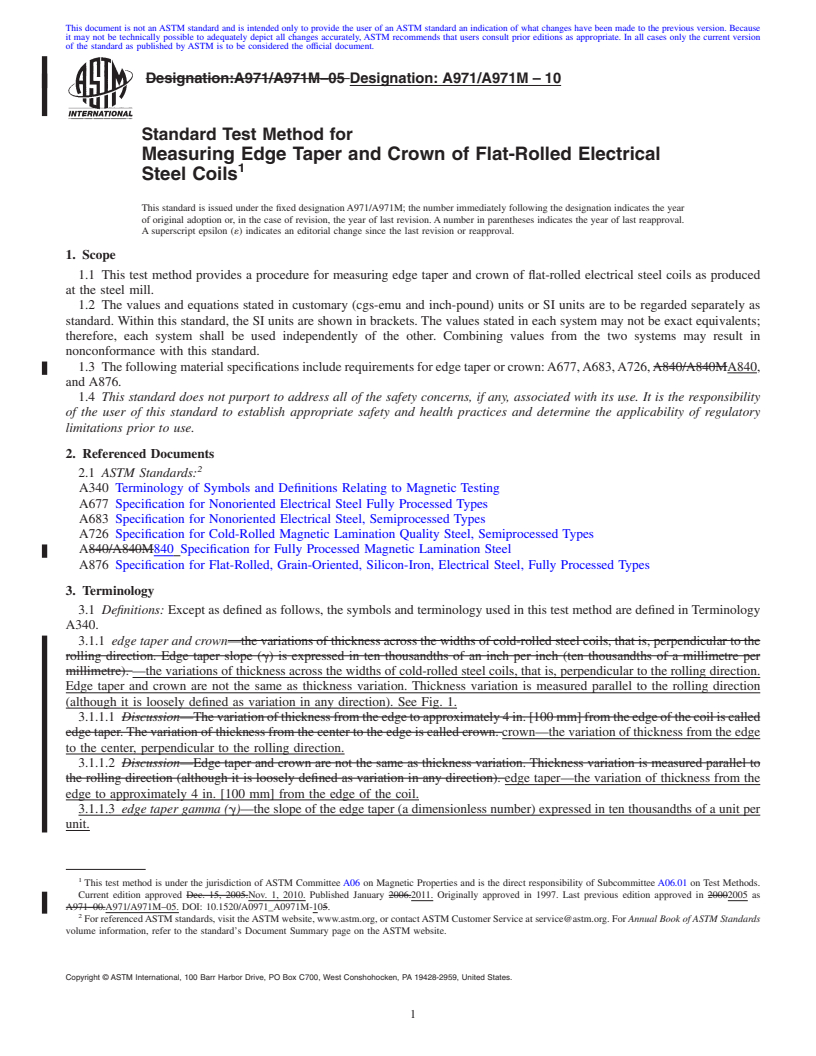

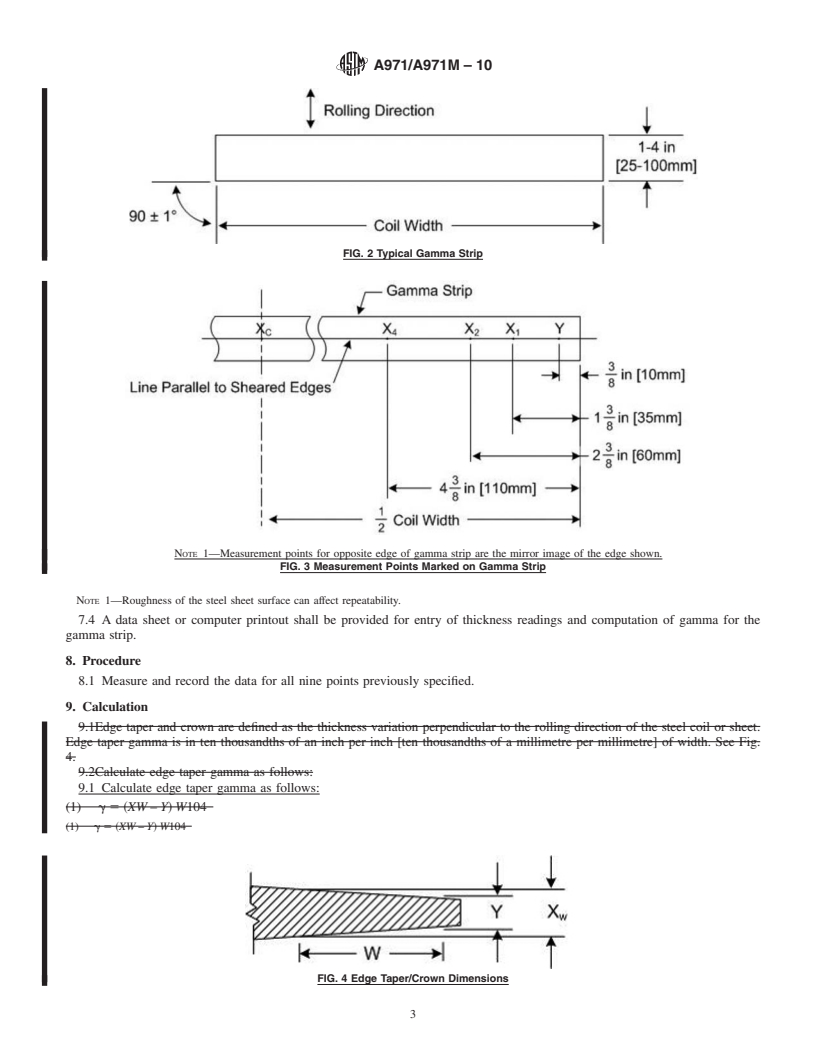

3.1.1 edge taper and crown—the variations of thickness across the widths of cold-rolled steel coils, that is, perpendicular to the

rolling direction. Edge taper slope (g) is expressed in ten thousandths of an inch per inch (ten thousandths of a millimetre per

millimetre). —the variations of thickness across the widths of cold-rolled steel coils, that is, perpendicular to the rolling direction.

Edge taper and crown are not the same as thickness variation. Thickness variation is measured parallel to the rolling direction

(although it is loosely defined as variation in any direction). See Fig. 1.

3.1.1.1 Discussion—Thevariationofthicknessfromtheedgetoapproximately4in.[100mm]fromtheedgeofthecoiliscalled

edge taper. The variation of thickness from the center to the edge is called crown. crown—the variation of thickness from the edge

to the center, perpendicular to the rolling direction.

3.1.1.2 Discussion—Edge taper and crown are not the same as thickness variation. Thickness variation is measured parallel to

the rolling direction (although it is loosely defined as variation in any direction). edge taper—the variation of thickness from the

edge to approximately 4 in. [100 mm] from the edge of the coil.

3.1.1.3 edge taper gamma (g)—the slope of the edge taper (a dimensionless number) expressed in ten thousandths of a unit per

unit.

1

This test method is under the jurisdiction of ASTM Committee A06 on Magnetic Properties and is the direct responsibility of Subcommittee A06.01 on Test Methods.

Current edition approved Dec. 15, 2005.Nov. 1, 2010. Published January 2006.2011. Originally approved in 1997. Last previous edition approved in 20002005 as

A971–00.A971/A971M–05. DOI: 10.1520/A0971_A0971M-105.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A971/A971M – 10

3.1.2 edge trimming—the slitting of a narrow strip from each edge of the master coil for discard. This reduces the edge taper

gamma on the remainder of the master coil.

3.1.3 gamma strip—a 1 to 4 in. [25 to 102 mm] strip cut across the full width

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.