ASTM A677-16

(Specification)Standard Specification for Nonoriented Electrical Steel Fully Processed Types

Standard Specification for Nonoriented Electrical Steel Fully Processed Types

ABSTRACT

This specification covers the standard requirements for flat-rolled nonoriented fully processed electrical steel intended primarily for commercial power frequency applications in magnetic devices. These electrical steels are low-carbon, silicon iron, or silicon-aluminum-iron alloys that may be made by basic-oxygen, electric-furnace, or other steelmaking practice. Desirable core-loss and permeability characteristics are developed during mill processing, so additional heat treatment is usually not required. The grades contained in this specification have thicknesses of 0.014 in. (0. 36 mm), 0.0185 in. (0.47 mm) and 0.0250 in. (0.64 mm). For a given thickness there are from 7 to 9 types based on the maximum value of core loss measured at 60 Hz and 15 kG (1.5 T) using the Epstein test method. Test methods to determine the required magnetic and mechanical properties are specified. Other typical magnetic and physical properties are listed for reference.

SCOPE

1.1 This specification covers the detailed requirements to which flat-rolled nonoriented fully processed electrical steel shall conform.

1.2 This steel is produced to specified maximum core-loss values and is intended primarily for commercial power frequency (50 and 60 Hz) applications in magnetic devices. Desirable core-loss and permeability characteristics are developed during mill processing, so additional heat treatment by the user is usually not necessary.

1.3 These nonoriented fully processed electrical steels are low-carbon, silicon-iron, or silicon-aluminum-iron alloys containing up to about 3.5 % silicon and a small amount of aluminum.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to customary (cgs-emu and inch-pound) units which are provided for information only and are not considered standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:A677 −16

Standard Specification for

1

Nonoriented Electrical Steel Fully Processed Types

This standard is issued under the fixed designation A677; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope for Steel Products for Shipment

A717/A717MTestMethodforSurfaceInsulationResistivity

1.1 This specification covers the detailed requirements to

of Single-Strip Specimens

which flat-rolled nonoriented fully processed electrical steel

A719/A719MTest Method for Lamination Factor of Mag-

shall conform.

netic Materials

1.2 This steel is produced to specified maximum core-loss

A720/A720MTest Method for Ductility of Nonoriented

values and is intended primarily for commercial power fre-

Electrical Steel

quency (50 and 60 Hz) applications in magnetic devices.

A937/A937MTest Method for Determining Interlaminar

Desirable core-loss and permeability characteristics are devel-

Resistance of Insulating Coatings Using Two Adjacent

oped during mill processing, so additional heat treatment by

Test Surfaces

the user is usually not necessary.

A971/A971MTest Method for Measuring Edge Taper and

Crown of Flat-Rolled Electrical Steel Coils

1.3 These nonoriented fully processed electrical steels are

low-carbon, silicon-iron, or silicon-aluminum-iron alloys con- A976Classification of Insulating Coatings for Electrical

Steels by Composition, Relative Insulating Ability and

taining up to about 3.5% silicon and a small amount of

aluminum. Application

E18Test Methods for Rockwell Hardness of Metallic Ma-

1.4 The values stated in SI units are to be regarded as

terials

standard. The values given in parentheses are mathematical

E140Hardness Conversion Tables for Metals Relationship

conversions to customary (cgs-emu and inch-pound) units

Among Brinell Hardness, Vickers Hardness, Rockwell

whichareprovidedforinformationonlyandarenotconsidered

Hardness, Superficial Hardness, Knoop Hardness, Sclero-

standard.

scope Hardness, and Leeb Hardness

E384Test Method for Microindentation Hardness of Mate-

2. Referenced Documents

rials

2

2.1 ASTM Standards:

A34/A34MPractice for Sampling and Procurement Testing

3. Terminology

of Magnetic Materials

3.1 Definitions—The terms and symbols used in this speci-

A340Terminology of Symbols and Definitions Relating to

fication are defined in Terminology A340.

Magnetic Testing

A343/A343MTest Method for Alternating-Current Mag-

4. Classification

netic Properties of Materials at Power Frequencies Using

Wattmeter-Ammeter-Voltmeter Method and 25-cm Ep-

4.1 The nonoriented electrical steel types described by this

stein Test Frame

specification are as shown in Table 1.

A664Practice for Identification of Standard Electrical Steel

Grades in ASTM Specifications

5. Ordering Information

A700Guide for Packaging, Marking, and Loading Methods

5.1 Ordersformaterialunderthisspecificationshallinclude

as much of the following information as necessary to describe

1

This specification is under the jurisdiction of ASTM Committee A06 on the desired material adequately:

Magnetic Properties and is the direct responsibility of Subcommittee A06.02 on

5.1.1 ASTM specification number.

Material Specifications.

5.1.2 Core-loss type number.

Current edition approved April 1, 2016. Published April 2016. Originally

5.1.3 Surface coating type.

approved in 1973. Last previous edition approved in 2012 as A677–12. DOI:

10.1520/A0677-16.

5.1.4 Thickness, width, and length (if in cut lengths instead

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

of coils).

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.1.5 Total weight of ordered item.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 5.1.6 Limitations in coil size or lift weights.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A677−16

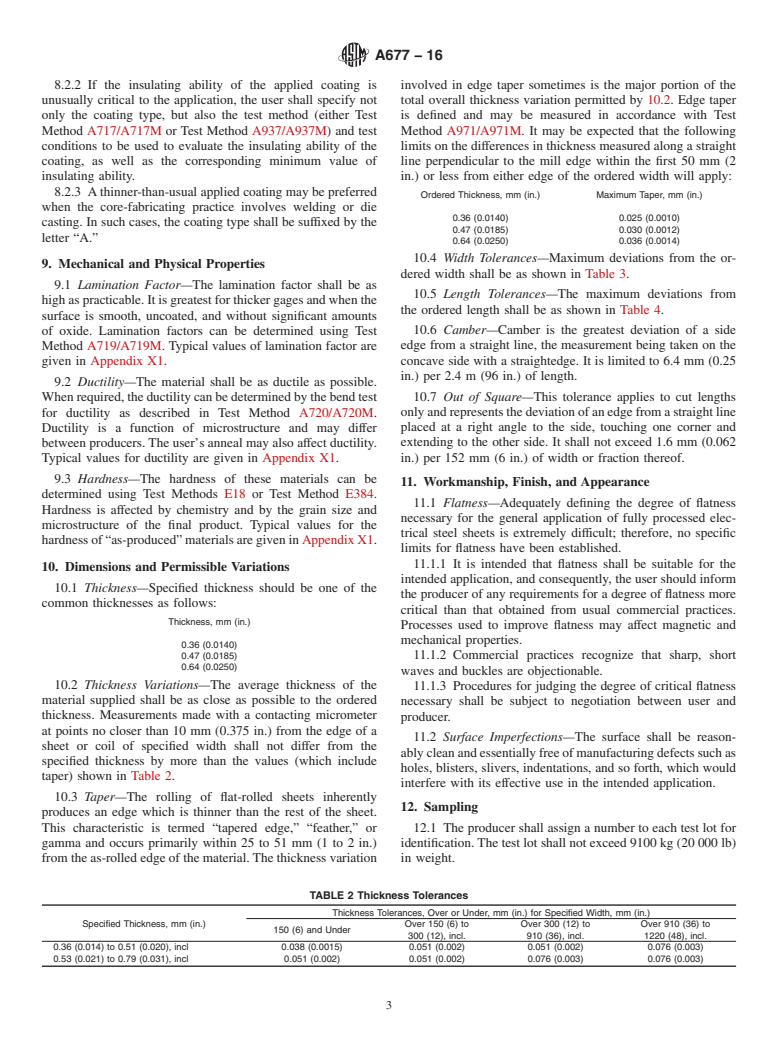

A B C

TABLE 1 Core-Loss Types and Maximum Core Losses at a Magnetic Flux Density of 1.5 T (15 kG) and 60 Hz

D

for As-Sheared Epstein Specimens

0.36 mm (0.0140 in.) Thickness 0.47 mm (0.0185 in.) Thickness 0.64 mm (0.0250 in.) Thickness

Maximum Core Loss, Maximum Core Loss, Maximum Core Loss,

Core-Loss Type Core-Loss Type Core-Loss Type

W/kg (W/lb) W/kg (W/lb) W/kg (W/lb)

36F145 3.20 (1.45) . . . . . . . . . . . . . . . . . .

36F155 3.42 (1.55) 47F165 3.64 (1.65) 64F200 4.41 (2.00)

36F165 3.64

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A677 − 12 A677 − 16

Standard Specification for

1

Nonoriented Electrical Steel Fully Processed Types

This standard is issued under the fixed designation A677; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers the detailed requirements to which flat-rolled nonoriented fully processed electrical steel shall

conform.

1.2 This steel is produced to specified maximum core-loss values and is intended primarily for commercial power frequency

(50 and 60 Hz) applications in magnetic devices. Desirable core-loss and permeability characteristics are developed during mill

processing, so additional heat treatment by the user is usually not necessary.

1.3 These nonoriented fully processed electrical steels are low-carbon, silicon-iron, or silicon-aluminum-iron alloys containing

up to about 3.5 % silicon and a small amount of aluminum.

1.4 The values stated in customary (cgs-emu and inch-pound) SI units are to be regarded as standard. The values given in

parentheses are mathematical conversions to SI customary (cgs-emu and inch-pound) units which are provided for information

only and are not considered standard.

2. Referenced Documents

2

2.1 ASTM Standards:

A34/A34M Practice for Sampling and Procurement Testing of Magnetic Materials

A340 Terminology of Symbols and Definitions Relating to Magnetic Testing

A343/A343M Test Method for Alternating-Current Magnetic Properties of Materials at Power Frequencies Using Wattmeter-

Ammeter-Voltmeter Method and 25-cm Epstein Test Frame

A664 Practice for Identification of Standard Electrical Steel Grades in ASTM Specifications

A700 Guide for Packaging, Marking, and Loading Methods for Steel Products for Shipment

A717/A717M Test Method for Surface Insulation Resistivity of Single-Strip Specimens

A719/A719M Test Method for Lamination Factor of Magnetic Materials

A720/A720M Test Method for Ductility of Nonoriented Electrical Steel

A937/A937M Test Method for Determining Interlaminar Resistance of Insulating Coatings Using Two Adjacent Test Surfaces

A971/A971M Test Method for Measuring Edge Taper and Crown of Flat-Rolled Electrical Steel Coils

A976 Classification of Insulating Coatings for Electrical Steels by Composition, Relative Insulating Ability and Application

E18 Test Methods for Rockwell Hardness of Metallic Materials

E92 Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials

E140 Hardness Conversion Tables for Metals Relationship Among Brinell Hardness, Vickers Hardness, Rockwell Hardness,

Superficial Hardness, Knoop Hardness, Scleroscope Hardness, and Leeb Hardness

E384 Test Method for Microindentation Hardness of Materials

3. Terminology

3.1 Definitions—The terms and symbols used in this specification are defined in Terminology A340.

4. Classification

4.1 The nonoriented electrical steel types described by this specification are as shown in Table 1.

1

This specification is under the jurisdiction of ASTM Committee A06 on Magnetic Properties and is the direct responsibility of Subcommittee A06.02 on Material

Specifications.

Current edition approved Nov. 1, 2012April 1, 2016. Published December 2012April 2016. Originally approved in 1973. Last previous edition approved in 20072012 as

A677A677 – 12.–07. DOI: 10.1520/A0677-12.10.1520/A0677-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A677 − 16

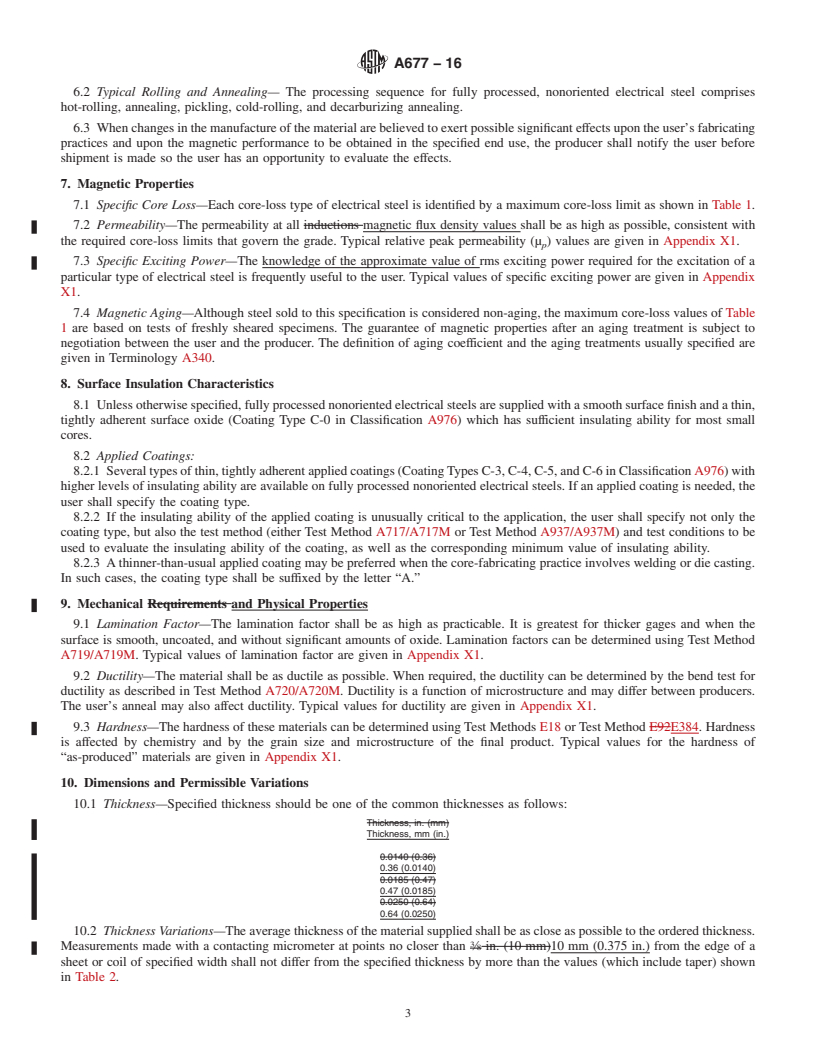

A B C

TABLE 1 Core-Loss Types and Maximum Core Losses at a Magnetic Flux Density of 15 kG (1.5 T) and 60 Hz

D

for As-Sheared Epstein Specimens

0.0140-in. (0.36-mm) Thickness 0.0185-in. (0.47-mm) Thickness 0.0250-in. (0.64-mm) Thickness

Maximum Core Loss, Maximum Core Loss, Maximum Core Loss,

Core-Loss Type Core-Loss Type Core-Loss Type

W/lb (W/kg) W/lb (W/kg) W/lb (W/kg)

36F145 1.45 (3.20) . . . . . . . . . . . . . . . . . .

36F155 1.55 (3.42) 47F165 1.65 (3.64) 64F200 2.00 (4.41)

36F165 1.65 (3.64) 47F180 1.80 (3.97) 64F210 2.10 (4.63)

36F175 1.75 (3.86) 47F190 1.90 (4.19) 64F225 2.25 (4

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.