ASTM A1083/A1083M-23

(Specification)Standard Specification for Steel, Sheet, Cold-Rolled, Carbon, Structural, High-Strength Low-Alloy, Produced by Twin-Roll Casting Process

Standard Specification for Steel, Sheet, Cold-Rolled, Carbon, Structural, High-Strength Low-Alloy, Produced by Twin-Roll Casting Process

ABSTRACT

This specification covers cold-rolled, carbon, structural, and high-strength low-alloy, in coils and cut lengths produced by the twin-roll casting process. Cold-rolled steel sheet is available in the following designations: commercial steel, drawing steel, structural steel, and high-strength low-alloy steel. Sheet steel grades defined by this specification are suitable for welding if appropriate welding conditions are selected. For certain welding processes, if more restrictive composition limits are desirable, they shall be specified at the time of inquiry and confirmed at the time of ordering. The material shall be capable of being bent, at room temperature, in any direction through 180° flat on itself without cracking on the outside of the bent portion. Two tension tests shall be made from each heat or from each 50 tons [45,000 kg]. Yield strength shall be determined by either the 0.2 % offset method or the 0.5 % extension under load method unless otherwise specified.

SCOPE

1.1 This specification covers cold-rolled, carbon, structural, and high-strength low-alloy, in coils and cut lengths produced by the twin-roll casting process.

1.2 Cold rolled steel sheet produced by the twin-roll casting process is available in the designations as listed in 4.1.

1.3 This specification does not apply to steel strip as described in Specification A109/A109M.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: A1083/A1083M − 23

Standard Specification for

Steel, Sheet, Cold-Rolled, Carbon, Structural, High-Strength

1

Low-Alloy, Produced by Twin-Roll Casting Process

This standard is issued under the fixed designation A1083/A1083M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* A568/A568M Specification for Steel, Sheet, Carbon,

Structural, and High-Strength, Low-Alloy, Hot-Rolled and

1.1 This specification covers cold-rolled, carbon, structural,

Cold-Rolled, General Requirements for

and high-strength low-alloy, in coils and cut lengths produced

A941 Terminology Relating to Steel, Stainless Steel, Related

by the twin-roll casting process.

Alloys, and Ferroalloys

1.2 Cold rolled steel sheet produced by the twin-roll casting

E18 Test Methods for Rockwell Hardness of Metallic Ma-

process is available in the designations as listed in 4.1.

terials

E517 Test Method for Plastic Strain Ratio r for Sheet Metal

1.3 This specification does not apply to steel strip as

described in Specification A109/A109M. E646 Test Method for Tensile Strain-Hardening Exponents

(n -Values) of Metallic Sheet Materials

1.4 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. The values stated in

3. Terminology

each system may not be exact equivalents; therefore, each

system shall be used independently of the other. Combining 3.1 Definitions of Terms Specific to This Standard:

values from the two systems may result in non-conformance

3.1.1 For definitions of other terms used in this

with the standard.

specification, refer to Terminology A941.

3.2 aging, n—loss of ductility with an increase in hardness,

1.5 This standard does not purport to address all of the

yield strength, and tensile strength that occurs when steel that

safety concerns, if any, associated with its use. It is the

has been slightly cold worked (such as by temper rolling) is

responsibility of the user of this standard to establish appro-

stored for some time.

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

3.2.1 Discussion—Aging increases the tendency of a steel to

1.6 This international standard was developed in accor-

exhibit stretcher strains and fluting.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

4. Classification

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical 4.1 Cold-rolled steel sheet is available in the following

Barriers to Trade (TBT) Committee. designations:

4.1.1 Commercial Steel (CS Types A, B, and D).

2. Referenced Documents

4.1.2 Drawing Steel (DS Types B and D).

2

2.1 ASTM Standards:

4.1.3 Structural Steel (SS grades 25[170], 30[205], 33[230]

A109/A109M Specification for Steel, Strip, Carbon (0.25

Types 1 and 2, 40[275] Types 1 and 2, 50[340], 60[410],

Maximum Percent), Cold-Rolled

70[480], and 80[550]).

A370 Test Methods and Definitions for Mechanical Testing

4.1.4 High-Strength Low-Alloy Steel (HSLAS, in classes 1

of Steel Products

and 2, in grades 45[310], 50[340]. 55[380], 60[410], 65[450],

70[480] and 80[550].

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

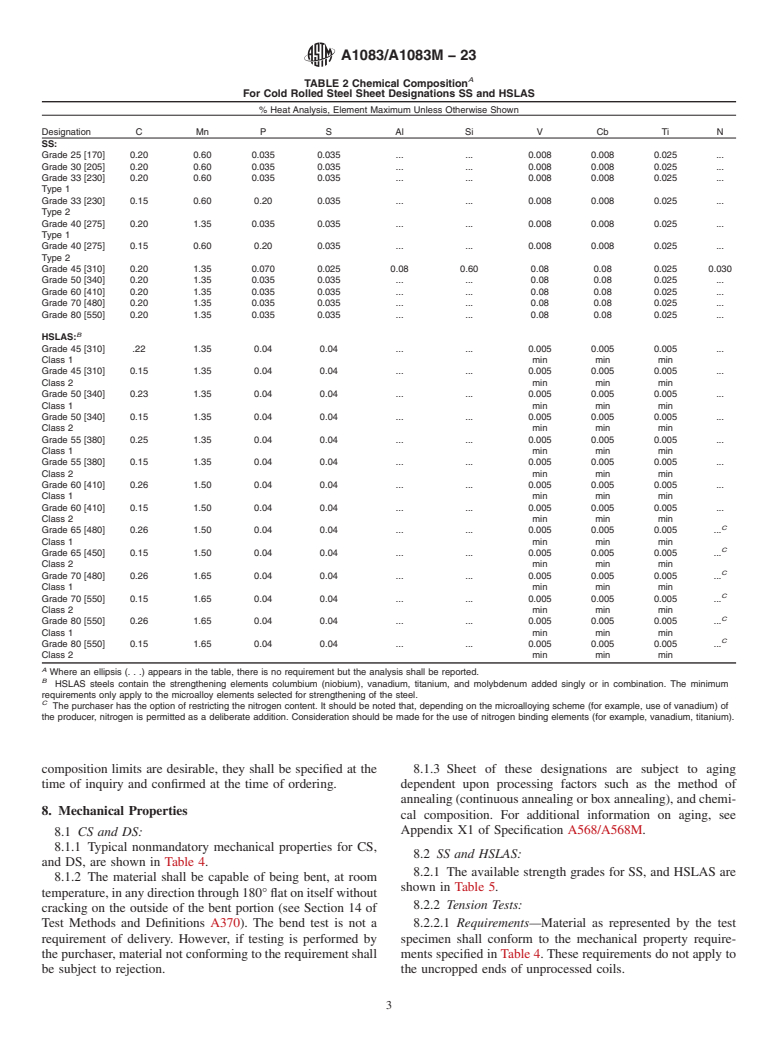

4.2 When required for HSLAS steels, limitations on the use

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.19 on Steel Sheet and Strip.

of one or more of the microalloy elements, titanium,

Current edition approved Nov. 1, 2023. Published November 2023. Originally

columbium, vanadium, or molybdenum, shall be specified on

approved in 2012. Last previous edition approved in 2017 as A1083/A1083M – 12

the order.

(2017). DOI: 10.1520/A1083_A1083M-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.3 Cold-rolled steel sheet is supplied for either exposed or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

unexposed applications. Within the latter category, cold-rolled

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. sheet is specified either “temper rolled” or “annealed last.” For

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 --------------

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A1083/A1083M − 12 (Reapproved 2017) A1083/A1083M − 23

Standard Specification for

Steel, Sheet, Cold-Rolled, Carbon, Structural, High-Strength

1

Low-Alloy, Produced by Twin-Roll Casting Process

This standard is issued under the fixed designation A1083/A1083M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This specification covers cold-rolled, carbon, structural, and high-strength low-alloy, in coils and cut lengths produced by the

twin-roll casting process.

1.2 Cold rolled steel sheet produced by the twin-roll casting process is available in the designations as listed in 4.1.

1.3 This specification does not apply to steel strip as described in Specification A109/A109M.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and healthsafety, health, and environmental practices and determine

the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A109/A109M Specification for Steel, Strip, Carbon (0.25 Maximum Percent), Cold-Rolled

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A568/A568M Specification for Steel, Sheet, Carbon, Structural, and High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled,

General Requirements for

A941 Terminology Relating to Steel, Stainless Steel, Related Alloys, and Ferroalloys

E18 Test Methods for Rockwell Hardness of Metallic Materials

E517 Test Method for Plastic Strain Ratio r for Sheet Metal

E646 Test Method for Tensile Strain-Hardening Exponents (n -Values) of Metallic Sheet Materials

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.19

on Steel Sheet and Strip.

Current edition approved Sept. 1, 2017Nov. 1, 2023. Published September 2017November 2023. Originally approved in 2012. Last previous edition approved in 20122017

as A1083/A1083M – 12.A1083/A1083M – 12 (2017). DOI: 10.1520/A1083_A1083M-12R17.10.1520/A1083_A1083M-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A1083/A1083M − 23

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 For definitions of other terms used in this specification, refer to Terminology A941.

3.2 aging, n—loss of ductility with an increase in hardness, yield strength, and tensile strength that occurs when steel that has been

slightly cold worked (such as by temper rolling) is stored for some time.

3.2.1 Discussion—

Aging increases the tendency of a steel to exhibit stretcher strains and fluting.

4. Classification

4.1 Cold-rolled steel sheet is available in the following designations:

4.1.1 Commercial Steel (CS Types A, B, and D).

4.1.2 Drawing Steel (DS Types B and D).

4.1.3 Structural Steel (SS grades 25[170], 30[205], 33[230] Types 1 and 2, 40[275] Types 1 and 2, 50[340], 60[410], 70[480], and

80[550]).

4.1.4 High-Strength Low-Alloy Steel (HSLAS, in classes 1 and 2, in grades 45[310], 50[340]. 55[380], 60[410], 65[450], 70[480]

and 80[550].

4.2 When required for HSLAS steels, limitations on the use of one or more of the microalloy eleme

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.