ASTM F2788-09

(Specification)Standard Specification for Crosslinked Polyethylene (PEX) Pipe

Standard Specification for Crosslinked Polyethylene (PEX) Pipe

ABSTRACT

This specification details the physical and performance requirements, and the corresponding test methods, for the evaluation of crosslinked polyethylene (PEX) pipes that are outside diameter controlled, made in nominal pipe dimension ratios, and pressure rated for water at different temperatures. Crosslinked PEX pipes covered here shall be made from polyethylene compounds that have been crosslinked by peroxides, Azo compounds, or silane compounds in extrusion, or by electron beam after extrusion, and are primarily defined by means of three criteria, namely, nominal density, degree of crosslinking, and long-term strength tests. Sampled pipe specimens shall be tested for conformance with workmanship, dimension (out-of-roundness, outside diameter, and wall thickness), density, hydrostatic burst pressure, hydrostatic sustained pressure strength, excessive temperature-pressure capacity, environmental stress cracking, stabilizer functionality, bent-pipe hydrostatic sustained pressure strength, oxidative stability in potable chlorinated water, and degree of crosslinking requirements.

SCOPE

1.1 This specification covers crosslinked polyethylene (PEX) pipe that is outside diameter controlled, made in nominal pipe dimension ratios, and pressure rated for water at three temperatures (see Appendix X1). Included are requirements and test methods for material, workmanship, dimensions, burst pressure, hydrostatic sustained pressure, excessive temperature pressure, excessive temperature-pressure, environmental stress cracking, stabilizer functionality, bent-pipe hydrostatic pressure, oxidative stability in potable chlorinated water, and degree of crosslinking. Requirements for pipe markings are also given.

1.2 The text of this specification references notes, footnotes, and appendixes, which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.3 Except for dimensions, the values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard. For dimensions, the values stated in SI units are to be regarded as standard. The values given in parentheses for nominal sizes are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

Note 1—Metric sized (SI units) pipe should only be joined with corresponding metric sized fittings. Inch sized fittings should not be used for metric sized pipe.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F2788 – 09

Standard Specification for

Crosslinked Polyethylene (PEX) Pipe

This standard is issued under the fixed designation F2788; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 This specification covers crosslinked polyethylene

(PEX) pipe that is outside diameter controlled, made in

2. Referenced Documents

nominal pipe dimension ratios, and pressure rated for water at

2.1 ASTM Standards:

three temperatures (see Appendix X1). Included are require-

D618 Practice for Conditioning Plastics for Testing

ments and test methods for material, workmanship, dimen-

D792 Test Methods for Density and Specific Gravity (Rela-

sions, burst pressure, hydrostatic sustained pressure, excessive

tive Density) of Plastics by Displacement

temperaturepressure,excessivetemperature-pressure,environ-

D1505 Test Method for Density of Plastics by the Density-

mental stress cracking, stabilizer functionality, bent-pipe hy-

Gradient Technique

drostatic pressure, oxidative stability in potable chlorinated

D1598 Test Method for Time-to-Failure of Plastic Pipe

water, and degree of crosslinking. Requirements for pipe

Under Constant Internal Pressure

markings are also given.

D1599 TestMethodforResistancetoShort-TimeHydraulic

1.2 Thetextofthisspecificationreferencesnotes,footnotes,

Pressure of Plastic Pipe, Tubing, and Fittings

and appendixes, which provide explanatory material. These

D1600 Terminology for Abbreviated Terms Relating to

notesandfootnotes(excludingthoseintablesandfigures)shall

Plastics

not be considered as requirements of the specification.

D1898 Practice for Sampling of Plastics

1.3 Except for dimensions, the values stated in inch-pound

D2122 Test Method for Determining Dimensions of Ther-

units are to be regarded as standard. The values given in

moplastic Pipe and Fittings

parentheses are mathematical conversions to SI units that are

D2765 Test Methods for Determination of Gel Content and

provided for information only and are not considered standard.

Swell Ratio of Crosslinked Ethylene Plastics

For dimensions, the values stated in SI units are to be regarded

D2837 TestMethodforObtainingHydrostaticDesignBasis

as standard. The values given in parentheses for nominal sizes

forThermoplastic Pipe Materials or Pressure Design Basis

are mathematical conversions to inch-pound units that are

for Thermoplastic Pipe Products

provided for information only and are not considered standard.

D3895 Test Method for Oxidative-Induction Time of Poly-

NOTE 1—Metric sized (SI units) pipe should only be joined with

olefins by Differential Scanning Calorimetry

corresponding metric sized fittings. Inch sized fittings should not be used

F412 Terminology Relating to Plastic Piping Systems

for metric sized pipe.

F2023 TestMethodforEvaluatingtheOxidativeResistance

1.4 This standard does not purport to address all of the

of Crosslinked Polyethylene (PEX) Tubing and Systems to

safety concerns, if any, associated with its use. It is the

Hot Chlorinated Water

responsibility of the user of this standard to establish appro-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

This test method is under the jurisdiction of ASTM Committee F17 on Plastic contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Piping Systems and is the direct responsibility of Subcommittee F17.26 on Olefin Standards volume information, refer to the standard’s Document Summary page on

Based Pipe. the ASTM website.

Current edition approved Aug. 1, 2009. Published August 2009. DOI: 10.1520/ Withdrawn. The last approved version of this historical standard is referenced

F2788-09. on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2788 – 09

2.2 ANSI Standard: hydrostatic design basis (HDB) times the design factor (DF)

B36.10 Standards Dimensions of Steel Pipe (IPS) for water. For this standard, the design factor is equal to 0.50.

2.3 Federal Standard:

HDS 5 HDB 3 DF

FED-STD-123 Marking for Shipment (Civil Agencies)

5 HDB 3 0.50 ~for this standard! (1)

2.4 Military Standard:

3.5 hydrostatic design basis (HDB)—one of a series of

MIL-STD-129 Marking for Shipment and Storage

established stress values (specified in Test Method D2837) for

2.5 NSF Standard:

a plastic compound obtained by categorizing the long-term

NSF/ANSI 14 for Plastic Piping Components and Related

hydrostatic strength determined in accordance with Test

Materials

Method D2837.

2.6 ISO Standards:

3.5.1 Discussion—A listing of HDB and HDS values are

ISO 1167 Thermoplastics pipes, fittings and assemblies for

contained in PPI publication PPI TR-4

the conveyance of fluids — Determination of the resis-

3.6 pressure rating (PR)—the estimated maximum water

tance to internal pressure — Part 1: General method

pressure the pipe is capable of withstanding continuously with

ISO 4427 Plastic piping systems - Polyethylene (PE) pipes

ahighdegreeofcertaintythatfailureofthepipewillnotoccur.

and fittings for water supply

3.7 relation between dimensions, hydrostatic design stress,

ISO 13760 Plastics pipes for the conveyance of fluids under

and pressure rating—the following expression, commonly

pressure — Miner’s rule ~ Calculation method for cumu-

known as the ISO equation is used in this specification to

lative damage

relate dimensions, hydrostatic design stress, and pressure

ISOR161-1690 PipesofPlasticMaterialsfortheTransport

rating:

of Fluids (Outside Diameters and Nominal Pressures) Part

2S/P5 ~D /t!2 1 or

o

1, Metric Series

(2)

2.7 PPI Standards:

2S/P 5 R2 I

PPI TR-3 Policies and Procedures for Developing Hydro-

static Design Basis (HDB), Pressure Design Basis (PDB),

Strength Design Basis (SDB), and Minimum Required

S = hydrostatic design stress, psi (or MPa),

Strength (MRS) Ratings for Thermoplastic Piping Mate-

P = pressure rating, psi (or MPa),

rials or Pipe

D = average outside diameter, in. (or mm),

o

PPI TR-4 PPI Listing of Hydrostatic Design Basis (HDB),

t = minimum wall thickness, in. (or mm), and

Strength Design Basis (SDB), Pressure Design Basis

R = standard dimension ratio (SDR) or dimension ratio

(PDB) and Minimum Required Strength (MRS) Ratings

(DR)

for Thermoplastic Piping Materials or Pipe

3.8 standard dimension ratio (SDR)/dimension ratio

(DR)—the ratio of outside diameter to wall thickness. For

3. Terminology

PEX-pipe, it is calculated by dividing the average outside

3.1 Definitions—Definitions are in accordance with Termi- diameter of the pipe by the minimum wall thickness. If the

nology F412, and abbreviations are in accordance with Termi-

calculated dimension ratio is a Preferred Number Series R 10

nologyD1600,unlessotherwisespecified.Theabbreviationfor modified by +1 (7, 9, 11 etc.), then it is called an SDR

crosslinked polyethylene is PEX. Plastic pipe denotes a par-

(standard dimension ratio); for all other numbers, it is called a

ticular diameter schedule of plastic pipe in which outside DR.

diameter of the pipe conforms with ISO 4427.

3.9 standard pipe material designation code—The pipe

3.2 Definitions of Terms Specific to This Standard: material designation code shall consist of the abbreviation for

3.3 crosslinked polyethylene plastics—plastics prepared by

the type of plastic (PEX) followed by four Arabic digits that

crosslinking (curing) polyethylene compounds.

describe short-term properties in accordance with applicable

3.4 hydrostatic design stress (HDS)—the estimated maxi- ASTM standards and as shown in Table 1.

mum tensile stress the material is capable of withstanding

3.9.1 Discussion—The first digit is for chlorine resistance

continuously with a high degree of certainty that failure of the tested in accordance with Test Method F2023.

pipe will not occur.This stress is circumferential when internal

(1)Adigit “0” indicates that the PEX pipe either has not been

hydrostatic water pressure is applied. The HDS is equal to the tested for chlorine resistance or that the PEX pipe does not

meet the minimum requirement for chlorine resistance.

(2) A digit “1” indicates the PEX pipe has been tested and

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St., meets the F XXXX requirement for minimum chlorine resis-

4th Floor, New York, NY 10036, http://www.ansi.org.

tanceattheenduseconditionof25%at140°F(60°C)and75%

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

at 73°F (23°C).

Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

(3) A digit “2” is reserved for future application.

www.dodssp.daps.mil.

Available from NSF International, P.O. Box 130140, 789 N. Dixboro Rd.,Ann

(4)Adigit “3” indicates that the PEX pipe has been tested and

Arbor, MI 48113-0140, http://www.nsf.org.

meets the F XXXX requirement for minimum chlorine resis-

Available from International Organization for Standardization (ISO), 1, ch. de

tance at end use condition of 50% at 140°F and 50% at 73°F.

la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://

www.iso.ch.

Available from Plastics Pipe Institute (PPI), 105 Decker Court, Suite 825,

Irving, TX 75062, http://www.plasticpipe.org. ISO R161–1690.

F2788 – 09

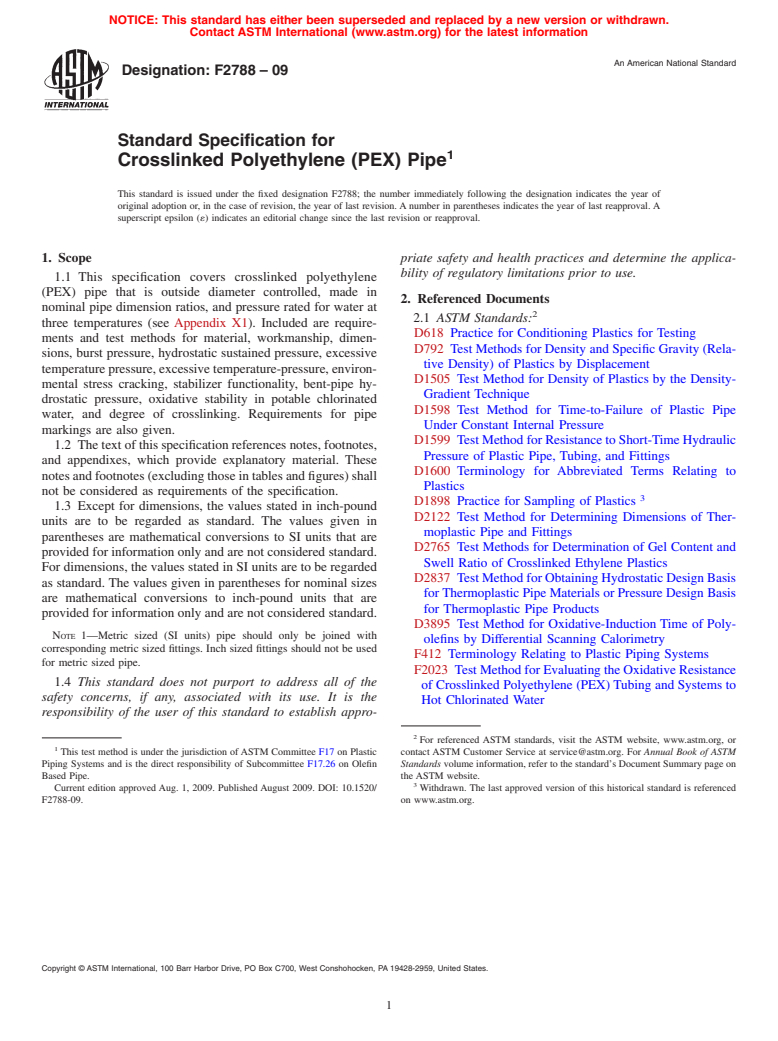

TABLE 1 Material Designation Code Cells

Property Standard 0 1 2 3 4 5 6789

Chlorine F2023 Not tested 75 % Reserved 50 % Reserved 100 % . . . .

Resistance or rated at 73°F at 73°F at 140°F

and 25 % and 50 %

at 140°F at 140°F

Reserved . . . . . . . . . . .

HDS . . . . . . . 630 . 800 .

for water at

73°F

means of three criteria, namely, (1) nominal density, (2) degree

(5) A digit “4” is reserved for future application. of crosslinking, and (3) long-term strength tests. There is a

(6) Adigit “5” indicates that the PEX pipe has been tested and strong correlation between nominal density and results of

meets the requirement for minimum chlorine resistance at end short-term strength tests.

use conditions of 100% of the time at 140°F

NOTE 2—PEX pipe intended for use in the transport of potable water

3.9.2 Discussion—The second digit is a 909. This digit is

should be evaluated and certified as safe for this purpose by a testing

reserved for a currently unspecified PEX pipe property.

agency acceptable to the local health authority. The evaluation should be

3.9.3 Discussion—The last two digits are the hydrostatic in accordance with requirements for chemical extraction, taste, and odor

that are no less restrictive than those included in NSF/ANSI 14. The seal

design stress for water at 73°F (23°C) in units of 100 psi with

or mark of the laboratory making the evaluation should be included on the

any decimal figures dropped. Where the hydrostatic design

pipe.

stress code contains less than two figures, a zero is used before

5.2 Basic Materials—PEX pipe shall be made from poly-

the number. Thus, a complete material designation code for

ethylene compounds which have been crosslinked by perox-

PEX pipe shall consist of the three letters 9PEX9 and four

ides,Azo compounds, or silane compounds in extrusion, or by

digits.

electron beam after extrusion, or by other means such that the

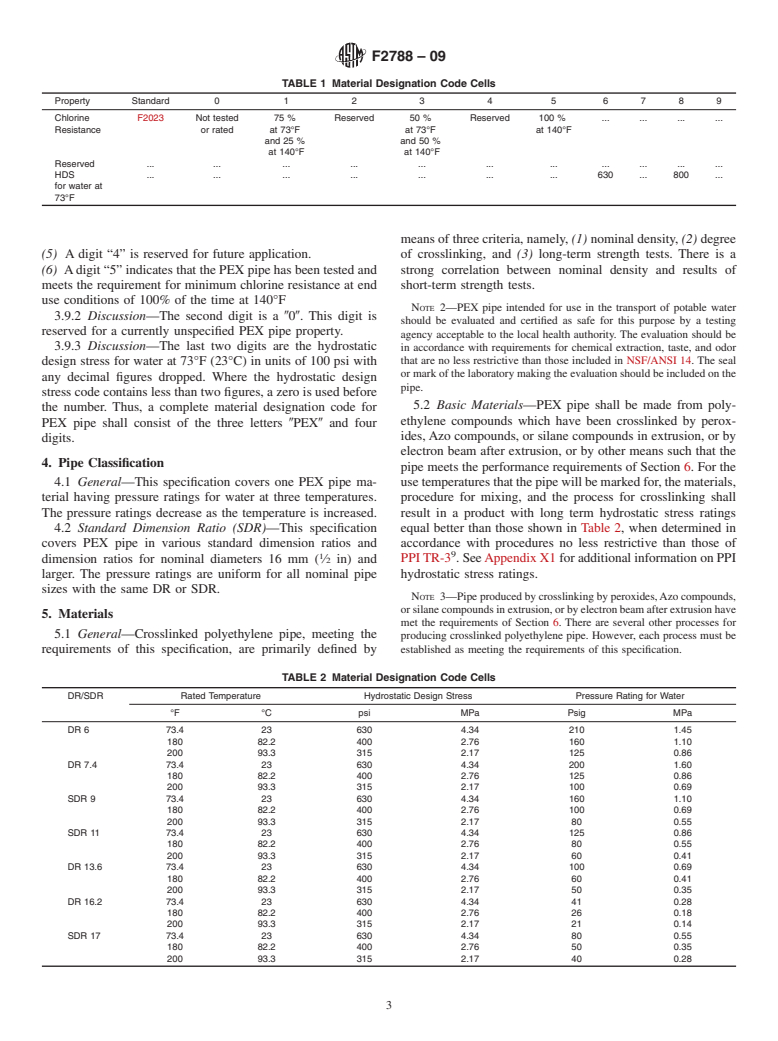

4. Pipe Classification

pipe meets the performance requirements of Section 6. For the

usetemperaturesthatthepipewillbemarkedfor,thematerials,

4.1 General—This specification covers one PEX pipe ma-

terial having pressure ratings for water at three temperatures. procedure for mixing, and the process for crosslinking shall

result in a product with long term hydrostatic stress ratings

The pressure ratings decrease as the temperature is increased.

4.2 Standard Dimension Ratio (SDR)—This specification equal better than those shown in Table 2, when determined in

accordance with procedures no less restrictive than those of

covers PEX pipe in various standard dimension ratios and

dimension ratios for nominal diameters 16 mm ( ⁄2 in) and PPITR-3 .SeeAppendixX1foradditionalinformationonPPI

larger. The pressure ratings are uniform for all nominal pipe hydrostatic stress ratings.

sizes with the same DR or SDR.

NOTE 3—Pipeproducedbycrosslinkingbyperoxides,Azocompounds,

orsilanecompoundsinextrusion,orbyelectronbeamafterextrusionhave

5. Materials

met the requirements of Section 6. There are several other processes for

5.1 General—Crosslinked polyethylene pipe, meeting the

producing crosslinked polyethylene pipe. However, each process must be

requirements of this specification, are primarily defined by established as meeting the requirements of this specification.

TABLE 2 Material Designation Code Cells

DR/SDR Rated Temperature Hydrostatic Design Stress Pressure Rating for Water

°F °C psi MPa Psig MPa

DR 6 73.4 23 630 4.34 210 1.45

180 82.2 400 2.76 160 1.10

200 93.3 315 2.17 125 0.86

DR 7.4 73.4 23 630 4.34 200 1.60

180 82.2 400 2.76 125 0.86

200 93.3 315 2.17 100 0.69

SDR 9 73.4 23 630 4.34 160 1.10

180 82.2 400 2.76 100 0.69

200 93.3 315 2.17 80 0.55

SDR 11 73.4 23 630 4.34 125 0.86

180 82.2 400 2.76 80 0.55

200 93.3 315 2.17 60 0.41

DR 13.6 73.4 23 630 4.34 100 0.69

180 82.2 400 2.76 60 0.41

200 93.3 315 2.17 50 0.35

DR 16.2 73.4 23 630 4.34 41 0.28

180 82.2 400 2.76 26 0.18

200 93.3 315 2.17 21 0.14

SDR 17 73.4 23 630 4.34 80 0.55

180 82.2 400 2.76 50 0.35

200 93.3 315 2.17 40 0.28

F2788 – 09

5.3 Pipe Material Designation—The pipe meeting the re- . For most of the pipe sizes, average OD/minimum wall is the

quirements of this specification shall be designated PEX. DR or SDR. For the smaller pipe sizes, the calculated value is

slightly lower than the DR or SDR value, and this will result in

6. Requirements

a slightly higher test pressure, as seen in Table 5. The fiber

6.1 Workmanship—The pipe shall be homogeneous stressvaluesareprovidedinTable5forthethreetemperatures.

throughout and free of visible cracks, holes, foreign inclusions,

6.6 Hydrostatic Burst Pressure—The minimum burst pres-

or other defects. The pipe shall be as uniform as commercially

sure for PEX plastic pipe shall be as shown in Table 6, when

practicable in color, opacity, density, and other physical prop-

determined in accordance with 7.7. The minimum burst pres-

erties.

sure is based on the formula:

6.2 Out-of Roundness—The maximum out-of roundness

P (burst pressure) = 2 (fiber stress) / [(average OD/minimum

requirements, shown in Table 3 for pipe,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.