ASTM B961-08

(Specification)Standard Specification for Silver Coated Copper and Copper Alloy Stranded Conductors for Electronic Space Application

Standard Specification for Silver Coated Copper and Copper Alloy Stranded Conductors for Electronic Space Application

SCOPE

1.1 This specification covers uninsulated silver-coated soft or annealed copper and copper alloy stranded conductors for use in electronic space application.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. This precautionary caveat pertains only to Section 9.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B961 −08

StandardSpecification for

Silver Coated Copper and Copper Alloy Stranded

Conductors for Electronic Space Application

This standard is issued under the fixed designation B961; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E3Guide for Preparation of Metallographic Specimens

1.1 This specification covers uninsulated silver-coated soft

2.2 European Space Agency (ESA):

or annealed copper and copper alloy stranded conductors for

ESA/SCC3901Generic Specification No. 3901

use in electronic space application.

2.3 European Cooperation for Space Standardization

1.2 The values stated in either SI units or inch-pound units

(ECSS):

are to be regarded separately as standard. The values stated in

ECSS-Q-70-20A Determination of the Susceptibility of

each system may not be exact equivalents; therefore, each

Silver Plated Copper wire and Cable to “Red Plague”

system shall be used independently of the other. Combining

Corrosion

values from the two systems may result in non-conformance

with the standard.

3. Ordering Information

1.3 This standard does not purport to address all of the 3.1 Ordersformaterialunderthisspecificationshallinclude

safety concerns, if any, associated with its use. It is the

the following information:

responsibility of the user of this standard to establish appro- 3.1.1 Quantity of each size.

priate safety and health practices and determine the applica-

3.1.2 Customer specification requirements including con-

bility of regulatory limitations prior to use.This precautionary ductor size, designation, and construction.

caveat pertains only to Section 9.

3.1.3 Whether silver-coated copper or silver-coated copper-

alloy.

2. Referenced Documents

3.1.4 Package size (Section 12).

3.1.5 Special package marking if required (Section 11), and

2.1 ASTM Standards:

3.1.6 Place of inspection (Section 10).

NOTE 1—The following documents of the issue in effect on date of

materialpurchaseformapartofthisspecificationtotheextentreferenced

4. Coating of Wires

herein.

B193Test Method for Resistivity of Electrical Conductor

4.1 Coating Thickness—The silver coating of wires com-

Materials

posing stranded conductors shall be uniform such that no area

B258Specification for Nominal Diameters and Cross-

around the strand circumference is covered by less than 80

SectionalAreasofAWGSizesofSolidRoundWiresUsed

micro-inches of silver. Uniform silver coating shall be verified

as Electrical Conductors

by micro-sectioning as outlined in section 9.1.

B298Specification for Silver-Coated Soft orAnnealed Cop-

4.1.1 Single points caused by eccentric strands or minute

per Wire

scratches shall not be less than 60 micro-inches minimum or

B286Specification for Copper Conductors for Use in

exceed 3 points in number around the micro-sectioned strand

Hookup Wire for Electronic Equipment

circumference.

B624Specification for High-Strength, High-Conductivity

4.2 Thesilvercoatingofwirescomposingstrandedconduc-

Copper-Alloy Wire for Electronic Application

tors (before and after stranding) shall conform to the polysul-

fide test in accordance with Specification B298.

This test method is under the jurisdiction of ASTM Committee B01 on

4.3 Theaveragesilvercoatingthicknessofwirescomposing

Electrical Conductors and is the direct responsibility of Subcommittee B01.04 on

stranded conductors shall be verified by electronic determina-

Conductors of Copper and Copper Alloys.

Current edition approved Sept. 1, 2008. Published October 2008. DOI: 10.1520/

tion (Method A) in accordance with Specification B298.

B0961-08.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on ESA Publications Division, ESTEC, P.O. Box 299, 2200 AG Noordwijk, The

the ASTM website. Netherlands (ESA/SCC3901 download available from www.escies.org).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B961−08

4.4 Red Plague Corrosion Test—Representative samples of Necessary joints made in the wire and rods prior to final

thesilvercoatedconductorsshallconformtocodes0–3ofthe drawing shall be in accordance with the best workmanship

accelerated corrosion test for un-insulated silver-plated con- practice.

ductors as outlined in section 9.2 (Explanatory Note 1).

8. Physical and Electrical Test

5. General Requirements 8.1 Tests to determine conformance of the coating to the

requirementsprescribedinSection4shallbeperformedbefore

5.1 Temper—Unless otherwise specified, all coated conduc-

insulating.

tors shall be furnished in the annealed temper.

8.2 Tests to determine conformance to the elongation re-

5.2 Elongation—The elongation of stranded conductors

quirements prescribed in section 5.2 shall be made before

shall be permitted to vary from the requirements of the

insulating.

applicable Specifications B298 and B624 by the following

amounts: 8.3 Tests to determine conformance to electrical resistance

5.2.1 Forstrandedsilvercoatedcopperconductors22AWG requirements prescribed in 3.1.2 shall be made on the uninsu-

andsmaller,thetestshallbeperformedonthewholeconductor lated conductor in accordance with Test Method B193.

and the elongation measured when the first strand of the

9. Test Methods

conductor breaks. The minimum average elongation shall not

9.1 Micro-Sectioning of Strands:

be less than 10 % with no individual specimen less than 5 %.

9.1.1 The silver coating shall be evaluated for uniform

5.2.2 For stranded silver coated copper conductors larger

coating requirements using the following procedure for micro-

than 22 AWG, strands shall be carefully removed from the

sectioningofstrands.Section9.1shallbeperformedaccording

conductor and tested for elongation. The minimum average

to best commercial metallographic practice. Guide E3 would

elongationshallnotbelessthan10%withnoindividualstrand

provide a good background reference for metallographic ex-

less than 5 %.

amination and preparation of samples.

5.2.3 Forstrandedsilvercoatedcopperalloyconductors,the

9.1.2 The test specimen shall consist of untwisted strands

test shall be performed on the whole conductor only and the

from the completed conductor. The test specimen shall be

elongation measured when the first strand of the conductor

breaks. The minimum elongation shall not be less than 6 %. electroplated with a copper or nickel coating, which is not less

than 25 µm. The copper or nickel coating will provide

6. Lay of Stranded Conductors protection of the specimen edges for follow-up grinding and

polishing preparation.

6.1 The direction of lay of the outside layer of stranded

9.1.3 Mount the test specimen in a low exotherm (heat)

conductors shall be left-hand.

casting resin encapsulating the specimen for metallographic

6.2 Thedirectionoflayoftheotherlayersshallbereversed

preparation and cross-sectioning.

insuccessivelayers,unlessotherwiseagreeduponbetweenthe

9.1.4 The specimen should be ground and polished using

manufacturer and the purchaser.

appropriate grinding disk pads and diamond paste. The dia-

mond paste should go down to at least 0.25 µm.

6.3 The length of lay of the individual wires composing the

9.1.5 Etch the polished specimen in a new solution of

outside layer of the stranded conductor shall not be less than 8

nor more than 16 times the outside diameter of that layer. ammonia(commerciallypure),whichcontainstwodropsof37

% hydrogen peroxide.

7. Joints 9.1.6 Use a metallographic microscope to examine the

etched cross-section with at least 400× magnification. The

7.1 No joints shall be made at the final draw prior to

specimen shall meet the requirements of section 4.1.

stranding. No joints shall be made in the individual strands or

in the completed conductor during the stranding process. 9.2 Red Plague Corrosion Test:

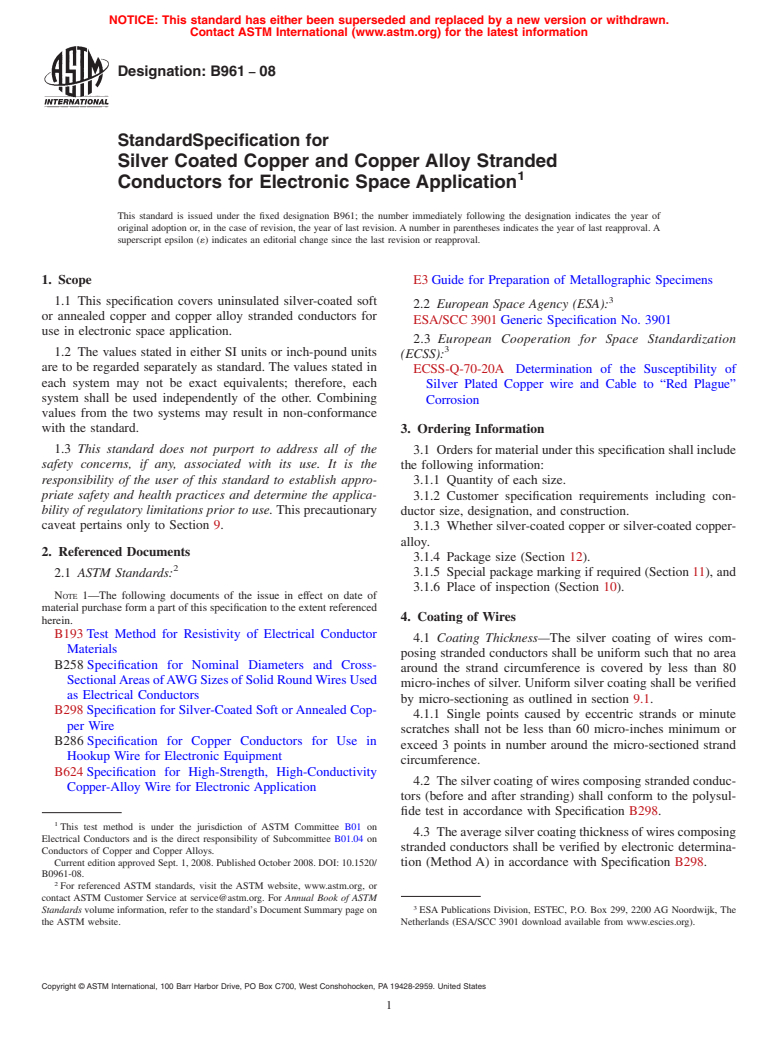

FIG. 1Prepared Test Sample

B961−08

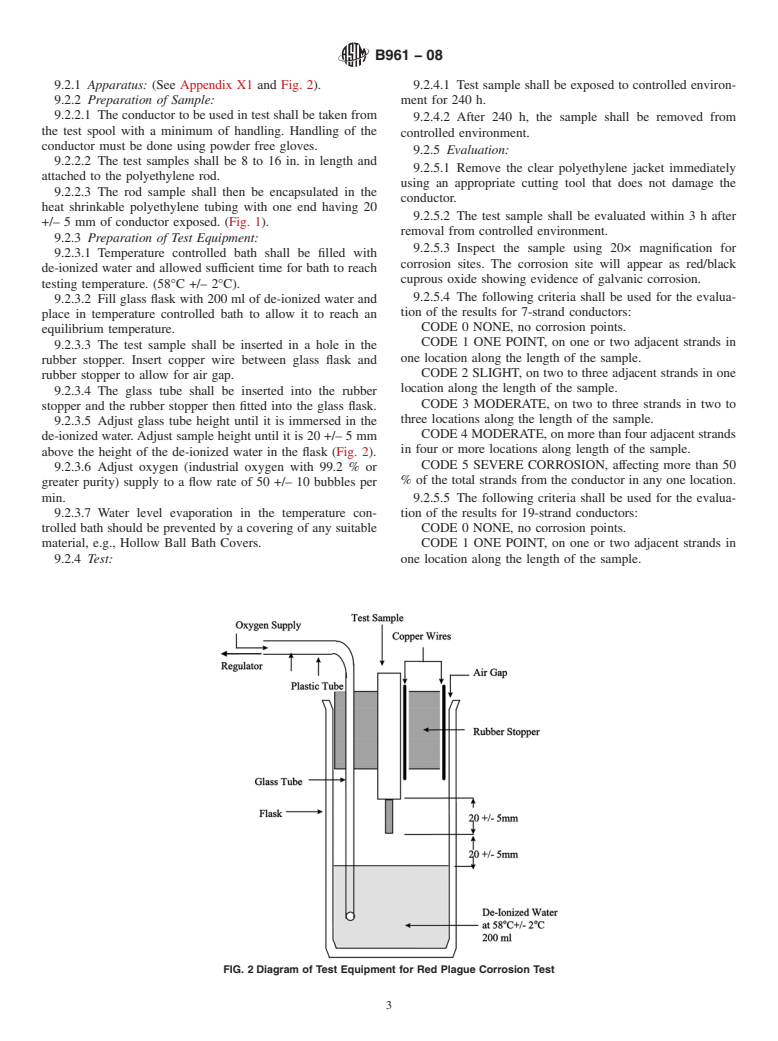

9.2.1 Apparatus: (See Appendix X1 and Fig. 2). 9.2.4.1 Test sample shall be exposed to controlled environ-

9.2.2 Preparation of Sample: ment for 240 h.

9.2.2.1 The conductor to be used in test shall be taken from

9.2.4.2 After 240 h, the sample shall be removed from

the test spool with a minimum of handling. Handling of the

controlled environment.

conductor must be done using powder free gloves.

9.2.5 Evaluation:

9.2.2.2 The test samples shall be 8 to 16 in. in length and

9.2.5.1 Remove the clear polyethylene jacket immediately

attached to the polyethylene rod.

using an appropriate cutting tool that does not damage the

9.2.2.3 The rod sample shall then be encapsulated in the

conductor.

heat shrinkable polyethylene tubing with one end having 20

9.2.5.2 The test sample shall be evaluated within 3 h after

+/– 5 mm of conductor exposed. (Fig. 1).

removal from controlled environment.

9.2.3 Preparation of Test Equipment:

9.2.5.3 Inspect the sample using 20× magnification for

9.2.3.1 Temperature controlled bath shall be filled with

corrosion sites. The corrosion site will appear

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.