ASTM F482-84(1999)e1

(Test Method)Standard Test Method for Corrosion of Aircraft Metals by Total Immersion in Maintenance Chemicals

Standard Test Method for Corrosion of Aircraft Metals by Total Immersion in Maintenance Chemicals

SCOPE

1.1 This test method covers the determination of the corrosiveness of tank-type aircraft maintenance chemicals on aircraft metals and the corrodibility of metals in these maintenance chemicals with time. The determination is made under conditions of total immersion by a combination of weight change measurements and visual qualitative determinations of change.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautions, see Section 5.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: F 482 – 84 (Reapproved 1999)

Standard Test Method for

Corrosion of Aircraft Metals by Total Immersion in

Maintenance Chemicals

This standard is issued under the fixed designation F 482; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Paragraphs 2.1, 4.1.1, and 7.1 were changed editorially and Section 12, Keywords, was added editorially in

September 1999.

1. Scope corrodibility of media and metal (such as passive film forma-

tion or destruction, depletion of corrosive contaminate, and so

1.1 This test method covers the determination of the corro-

forth) as a function of time are not given.

siveness of tank-type aircraft maintenance chemicals on air-

craft metals and the corrodibility of metals in these mainte-

4. Apparatus

nance chemicals with time. The determination is made under

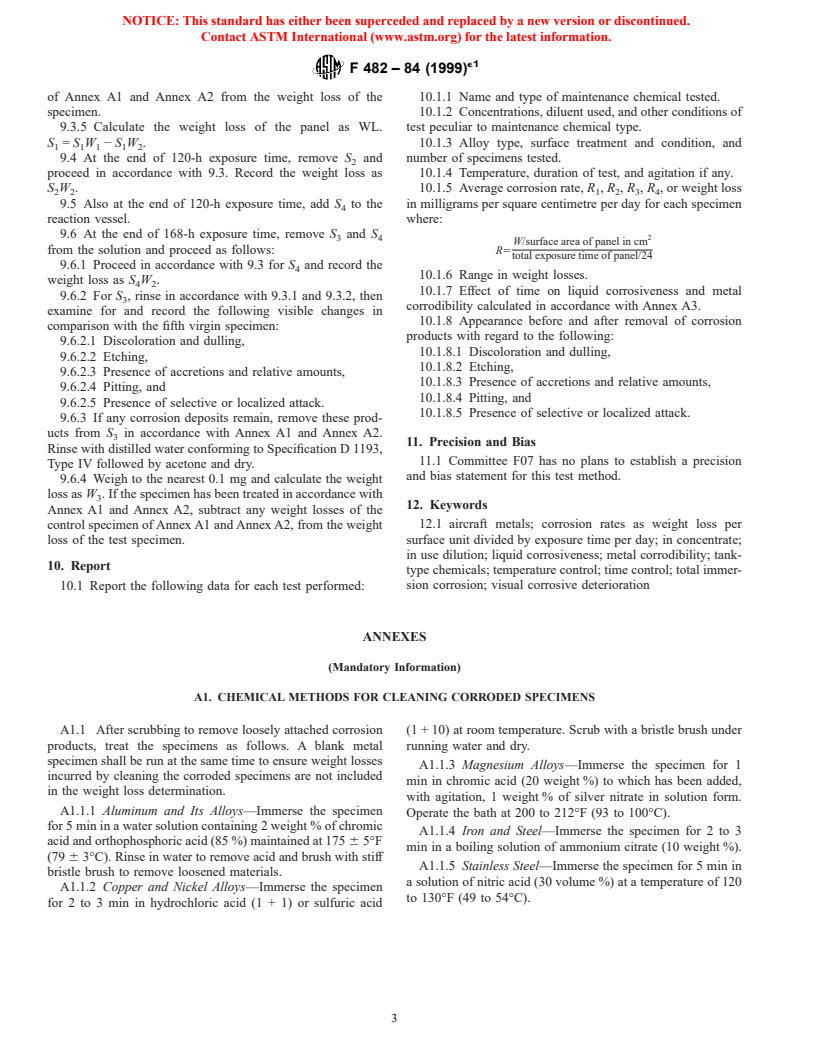

4.1 Wide-Mouth Glass Jar or Flask of suitable sizes (3000

conditions of total immersion by a combination of weight

to 4000 mL), capable of accommodating a reflux condenser, a

change measurements and visual qualitative determinations of

thermometer, and a specimen support system. Fig. 1 shows a

change.

typical arrangement, but any array meeting the provisions of

1.2 This standard does not purport to address all of the

4.2-4.5 will be acceptable.

safety concerns, if any, associated with its use. It is the

4.1.1 If agitation is required, the apparatus should be ca-

responsibility of the user of this standard to establish appro-

pable of accepting a stirring mechanism, such as a magnetic

priate safety and health practices and determine the applica-

stirrer or impeller. The glass jar or flask should be chosen so

bility of regulatory limitations prior to use. For specific

that the specimens will remain fully immersed in a vertical

precautions, see Section 5.

position during the test, and the ratio of area of immersed metal

2. Referenced Documents to volume of solution will be in accordance with 8.1.

4.2 Specimen-Supporting Device—a glass or fluorocarbon

2.1 ASTM Standards:

plastic supporting system designed to keep the specimen fully

D 235 Specification for Mineral Spirits (Petroleum Spirits)

immersed while assuring free contact with the corroding

(Hydrocarbon Dry Cleaning Solvent)

solution, and designed to physically isolate the specimens from

D 1193 Specification for Reagent Water

each other.

E 1 Specification for ASTM Thermometers

4.3 Condenser—a glass reflux condenser of the water-

3. Significance and Use cooled type, having a condenser jacket 200 to 300 mm in

length.

3.1 This test method not only provides information on the

4.4 Constant-Temperature Device—any suitable regulated

accumulated effects of corrosion at specific time periods under

heating device (mantle, hot plate, or bath) may be used for

a given set of conditions, but also provides information on the

maintaining the solution at the required temperature.

initial rate of corrosion of virgin metal, the corrosion rate of

4.5 Thermometer—an ASTM 3-in. (75-mm) immersion

metal per unit time after long exposure, and the initial

thermometer having a range from 0 to 302°F (150°C) and

corrosion rate of virgin metal after long exposure of the

conforming to requirements for Thermometer 1F in accordance

corroding fluid to metal. The test also provides a means of

with Specification E 1.

determining the direction corrosion will take with time, al-

though causes for increase or decrease in the corrosiveness and

5. Safety Precautions

5.1 The solvents used in the cleaning of test specimens are

This test method is under the jurisdiction of ASTM Committee F07 on

flammable and harmful if inhaled. Keep away from sparks and

Aerospace and Aircraft and is the direct responsibility of Subcommittee F07.07 on

open flames. Avoid breathing vapors and prolonged or repeated

Qualification Testing of Aircraft Cleaning Materials.

contact with the skin. Use with adequate ventilation.

Current edition approved Nov. 30, 1984. Published March 1985. Originally

published as F 482 – 77. Last previous edition F 482 – 77. 5.2 The material used for aircraft maintenance may contain

Annual Book of ASTM Standards, Vol 11.01.

Annual Book of ASTM Standards, Vol 14.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

F 482 – 84 (1999)

conforming to Specification D 235. Swab the surface of the

individual specimen thoroughly using clean forceps to hold the

specimen and the cotton swab.

7.2 Shake off the excess solvent. Transfer and immerse the

test specimens separately several times in a beaker of methyl

ethyl ketone.

7.3 Shake off excess methyl ethyl ketone and dry in a

vacuum desiccator or in a low temperature oven at 100 6 5°F

(37.7 6 3°C) for 15 min.

8. Conditioning

8.1 Volume of Solution—The volume of solution shall be

500 mL per specimen. Use fresh solution for each set of

replicates.

8.2 Solution Concentration:

8.2.1 Unless otherwise specified, test the specimens in

solutions of the maintenance chemical in the concentrated

as-received condition and at the recommended dilution using

distilled or deionized water conforming to Specification

D 1193, Type IV. (For solid materials, concentrated condition

shall mean in a saturated solution of the solid material.) In case

the material is not soluble to the extent noted, record this fact

and continue with the test.

8.2.2 Test diphase materials with an appropriate amount of

each phase loaded into the test vessel to simulate use condi-

tions. Totally immerse the corrosion specimens in the working

phase of the maintenance chemical.

8.2.3 If water is not used as the diluent, record the type and

specification of diluent used in the test.

8.3 Temperature—Unless otherwise specified, the tempera-

ture shall be 100 6 2°F (37.7 6 3°C).

8.4 Test Duration—Total test duration shall be 168 h, with

specimens being added or removed at intermediate intervals.

A = Condenser

B = Stirring mechanism

8.5 If the maintenance chemical is to be used with agitation,

C = Containing vessel

also test the specimens with appropriate agitation to simulate

D = Specimen holder

E = Thermometer use conditions.

F = Metal specimen

G = Maintenance chemical solution

9. Procedure

9.1 Weigh four of five specimens (S , S , S , and S )ofthe

NOTE—THIS IS ONE FORM THAT THE EQUIPMENT CAN TAKE, AND IS NOT

1 2 3 4

MANDATORY.ANY ARRAY MEETING THE REQUIREMENTS OF 4.2-4.5 WILL BE

same alloy to the nearest 0.1 mg. Record the weights S W ,

1 1

ACCEPTABLE.

S W , S W , S W . Retain the fifth specimen of each alloy for

2 1 3 1 4 1

FIG. 1 Test Apparatus

comparison purposes.

9.2 Immerse three of the specimens (S , S , and S )inthe

1 2 3

flammable solvents, acids, or alkalis, or other toxic com- test solution using only specimens of the same alloy in the

pounds. Take suitable precautions to prevent personnel injury. containing vessel. Retain S for use in accordance with 9.5.

9.3 At the end of 48-h exposure time, remove S and

6. Test Specimens

proceed as follows:

6.1 The test specimens of a given alloy shall be taken from

9.3.1 Rinse thoroughly under hot tap water, 120 to 140°F

the same sheet stock and shall measure 2 by 1 by 0.06 in. (50.8 (49 to 60°C), while scrubbing with a stiff bristle brush. Follow

by 25.4 by 1.6 mm) with a 0.125-in. (3.2-mm) diameter

with distilled or deionized water conforming to Specification

mounting hole and suitably located at one end of the specimen. D 1193, Type IV at room temperature.

At least two and preferably three replicates should be tested in 9.3.2 Rinse with a stream of acetone from a wash bottle and

each concentration of maintenance chemical solution in accor- dry.

dance with 8.2. The total area of the specimen shall be taken as 9.3.3 If corrosion deposits are still adhered, remove corro-

2 2

4.4 in. (28.2 cm ). sion products in accordance with Annex A1 and Annex A2 and

rinse dry in accordance with 9.3.1 and 9.3.2.

7. Test Specimen

9.3.4 Weigh to the nearest 0.1 mg and record as S W .Ifthe

1 2

7.1 Preheat the test specimens to 150 6 5°F (60 6 2°C) and specimen has been treated in accordance with Annex A1 and

immerse in a beaker containing Mineral Spirits, Type II, Annex A2, subtract any weight losses of the control specimen

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

F 482 – 84 (1999)

of Annex A1 and Annex A2 from the weight loss of the 10.1.1 Name and type of maintenance chemical tested.

specimen. 10.1.2 Concentrations, diluent used, and other conditions of

9.3.5 Calculate the weight loss of the panel as WL. test peculiar to maintenance chemical type.

S = S W − S W . 10.1.3 Alloy type, surface treatment and condition, and

1 1 1 1 2

9.4 At

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.