ASTM D6072/D6072M-09(2015)

(Practice)Standard Practice for Obtaining Samples of Geosynthetic Clay Liners

Standard Practice for Obtaining Samples of Geosynthetic Clay Liners

SIGNIFICANCE AND USE

4.1 This practice provides a procedure by which samples of GCL should be obtained for laboratory testing. The practice applies to materials obtained prior to installation (either at a job site or at a production facility) or exhumed material after installation.

4.2 Only GCL samples obtained in accordance with 5.1 of this practice will be considered representative of the actual manufactured GCL for quality assurance/quality control (QA/QC) purposes..

4.3 The quantity of GCL received by the laboratory should be sufficient for the preparation of several representative test specimens for the standardized physical, hydraulic, and mechanical tests to be performed on the GCLs.

4.4 The procedures in this practice should be used by plant and field personnel for obtaining GCL samples for laboratory testing.

SCOPE

1.1 This practice covers procedures for sampling geosynthetic clay liners (GCLs) for the purpose of laboratory testing. These procedures are designed to ensure that representative samples are obtained and properly packaged for submittal to a testing laboratory.

1.2 The procedures in this practice may be applied to either samples of unhydrated GCLs obtained at the project site prior to installation (or at the production facility, prior to shipment to the project site) or samples exhumed from a project site after installation.

1.3 It is assumed that the number of samples to be obtained has already been determined in the project specification, standard test method, or by prior agreement between the purchaser and seller. This practice covers only the methods for obtaining a pre-arranged number of samples and does not describe methods for obtaining individual specimens from the sample.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6072/D6072M − 09 (Reapproved 2015)

Standard Practice for

Obtaining Samples of Geosynthetic Clay Liners

This standard is issued under the fixed designation D6072/D6072M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D4220 Practices for Preserving and Transporting Soil

Samples

1.1 This practice covers procedures for sampling geosyn-

D4354 Practice for Sampling of Geosynthetics and Rolled

thetic clay liners (GCLs) for the purpose of laboratory testing.

Erosion Control Products(RECPs) for Testing

These procedures are designed to ensure that representative

D4439 Terminology for Geosynthetics

samples are obtained and properly packaged for submittal to a

D5888 Guide for Storage and Handling of Geosynthetic

testing laboratory.

Clay Liners

1.2 The procedures in this practice may be applied to either

samples of unhydrated GCLs obtained at the project site prior

3. Terminology

to installation (or at the production facility, prior to shipment to

3.1 Definitions:

the project site) or samples exhumed from a project site after

3.1.1 geosynthetic clay liner (GCL), n—a manufactured

installation.

hydraulic barrier consisting of clay bonded to a layer or layers

1.3 It is assumed that the number of samples to be obtained

of geosynthetics.

has already been determined in the project specification,

3.1.2 sample, n—a portion of a material which is taken for

standard test method, or by prior agreement between the

testing or for record purposes (See Practice D4354).

purchaser and seller. This practice covers only the methods for

obtaining a pre-arranged number of samples and does not 3.1.3 specimen, n—a specific portion of a material or

laboratory sample upon which a test is performed or which is

describe methods for obtaining individual specimens from the

taken for that purpose (See Practice D4354).

sample.

3.1.4 For definitions of other geosynthetic terms used in this

1.4 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. The values stated in practice, refer to Terminology D4439.

each system may not be exact equivalents; therefore, each

system shall be used independently of the other. Combining 4. Significance and Use

values from the two systems may result in non-conformance

4.1 This practice provides a procedure by which samples of

with the standard.

GCL should be obtained for laboratory testing. The practice

1.5 This standard does not purport to address all of the

appliestomaterialsobtainedpriortoinstallation(eitheratajob

safety concerns, if any, associated with its use. It is the

site or at a production facility) or exhumed material after

responsibility of the user of this standard to establish appro-

installation.

priate safety and health practices and determine the applica-

4.2 Only GCL samples obtained in accordance with 5.1 of

bility of regulatory limitations prior to use.

this practice will be considered representative of the actual

manufactured GCL for quality assurance/quality control (QA/

2. Referenced Documents

QC) purposes.

2.1 ASTM Standards:

4.3 The quantity of GCL received by the laboratory should

be sufficient for the preparation of several representative test

specimens for the standardized physical, hydraulic, and me-

This practice is under the jurisdiction of ASTM Committee D35 on Geosyn-

chanical tests to be performed on the GCLs.

thetics and is the direct responsibility of Subcommittee D35.04 on Geosynthetic

Clay Liners.

4.4 The procedures in this practice should be used by plant

Current edition approved Jan. 1, 2015. Published February 2015. Originally

and field personnel for obtaining GCL samples for laboratory

approved in 1996. Last previous edition approved in 2009 as D6072/D6072M–09.

testing.

DOI: 10.1520/D6072_D6072M-09R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5. Procedure

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 5.1 Obtaining Samples Prior to Installation:

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6072/D6072M − 09 (2015)

5.1.1 In accordance with the project specifications or with 5.1.13 Samples should be transmitted to the laboratory in a

Practice D4354, divide the shipment or other given quantity of manner that minimizes the amount elapsed time, sample

GCL into lots, and select lot and laboratory samples. This will handling, disturbances (such as moisture, vibration, impact,

usually involve the selection of a certain number of finished etc.) that could occur in transit. Expedited delivery will help to

GCL rolls from which samples will be cut. ensure that moisture content changes are minimized.

5.1.2 Affix on the packaging of the GCLrolls to be sampled

NOTE 3—These packaging procedures were developed under the

adhesive labels or other markings which clearly identify that

assumption that the area from which specimens are obtained is at least

the roll is to be sampled. 75 mm from the edges of the sample.

5.1.3 Record the label information from each roll to be

5.2 Exhuming Samples After Installation:

sampled for future incorporation into within the quality

5.2.1 There are two methods for exhuming GCL samples.

assurance/quality control (QA/QC) documentation for the

MethodAis the suggested method for multi-component GCLs

GCL.

or GCLs covered with a geomembrane. Method B is the

5.1.4 Segregate the rolls identified for sampling. Refer to

suggested method when there is no multi-component GCL nor

Guide D5888 for the proper equipment and techniques for

is the GCL covered with a geomembrane, although Method A

handling the GCL rolls.

can be used in cases where larger samples are required.

5.1.5 Inspect the packaging of the selected GCL rolls for

5.2.2 Method A—Hand Cutting method:

damage. Describe and record the damage, if any.

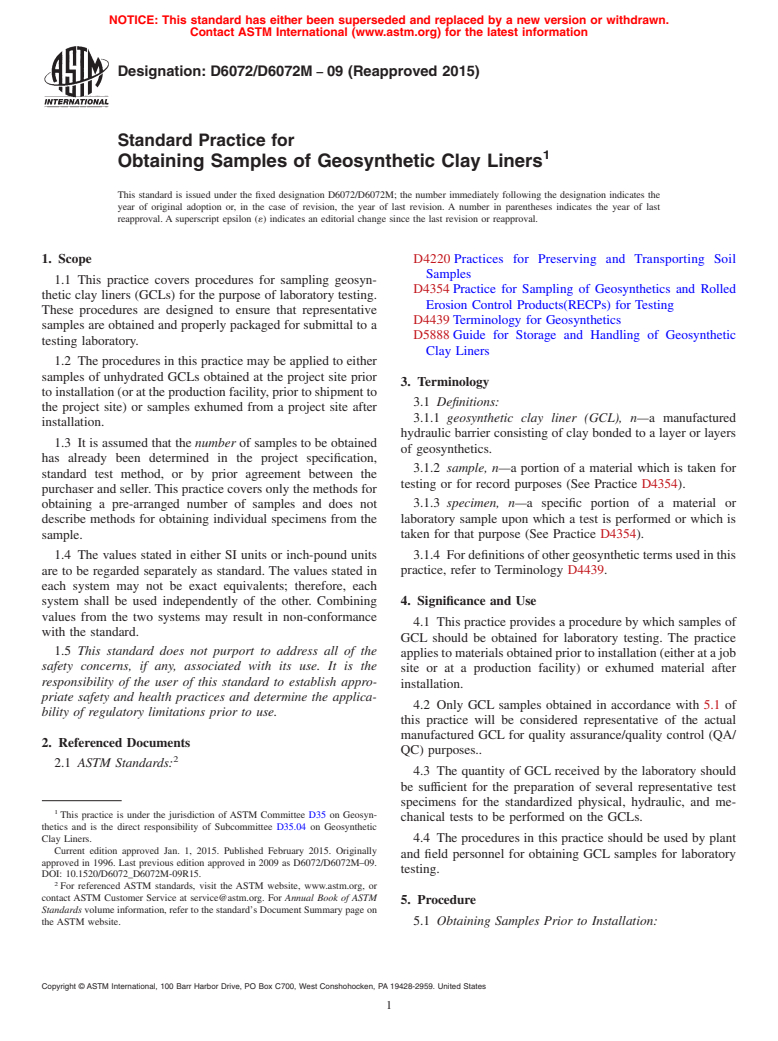

5.2.2.1 Using a small backhoe or other piece of construction

5.1.6 Remove the outer packaging from the GCL as care-

equipment carefully excavate a hole at the desired location

fully as possible, taking precautions not to damage the GCL

down to within hand shoveling distance of approximately

and to preserve the packaging as much as possible for re-use

150 mm [6 in.] of the GCL. Once cover removal begins,

after sampling is completed.

machinery should not be placed in the area to be exhumed. To

5.1.7 Obtain samples from the selected GCL rolls prior to

minimize stress on GCL, within 150 mm [6 in.] the GCL, the

deployment. If cut on a surface, the surface on which the GCL

overlying soil should be removed by hand and any overlying

is cut shall be dry, clean, smooth, hard and free of irregularities

geosynthetics shall be cut by hand. Measure the depth of the

and potential contaminants.

cover soil, as well, the inclination and direction of inclination;

for example, south, east, west, north.

NOTE 1—At the discretion of the engineer, shorter or narrower samples,

or both, may be obtained provided that the packaging procedures in this

NOTE 4—Once the overlying soil is removed, evaporation of water in

guide are followed.

the GCL may occur. Consequently, the GCL should be removed no more

than 30 min from the time the overlying soil is removed. When a GCL is

5.1.8 A unique sample number shall be written on the

overlain by a geomembrane, the geomembrane should remain in place

sample.Additional markings should be made on the sample to

until the GCL is to be sampled. If heating of the geomembrane by solar

identify the machine direction and the top/bottom sides of the

radiation is a concern during this period, a white fabric or white plastic

GCL. sheet should be draped over the geomembrane to reflect solar radiation.

5.1.9 The GCLsample shall then be manually rolled around

5.2.2.2 The sample area shall be large enough such that

a core at least 75 mm in diameter, in the same direction as the

specimens subsequently cut from the removed sample in the

cut. Care should be taken to wind the GCLwithout slack.Wide

laboratory for testing are no closer than 75 mm from any edge.

strapping tape (50 mm) shall then be wound around the sample

The sample also must not be cut too close to the side of the

in at least two places to secure the loose end. Bentonite loss

excavation so that the geomembrane and GCLmay be repaired

from the sample may be minimized by applying the tape

or patched as recommended by the manufacturers.

around the roll ends.

5.2.2.3 If the GCLis overlain with a geomembrane, first the

5.1.10 Atleasttwolayersofplasticsheetingshallbeusedto

geomembrane shall be cut over an area larger than the

wrap the GCLsampl

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6072/D6072M − 09 D6072/D6072M − 09 (Reapproved 2015)

Standard Practice for

Obtaining Samples of Geosynthetic Clay Liners

This standard is issued under the fixed designation D6072/D6072M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers procedures for sampling geosynthetic clay liners (GCLs) for the purpose of laboratory testing. These

procedures are designed to ensure that representative samples are obtained and properly packaged for submittal to a testing

laboratory.

1.2 The procedures in this practice may be applied to either samples of unhydrated GCLs obtained at the project site prior to

installation (or at the production facility, prior to shipment to the project site) or samples exhumed from a project site after

installation.

1.3 It is assumed that the number of samples to be obtained has already been determined in the project specification, standard

test method, or by prior agreement between the purchaser and seller. This practice covers only the methods for obtaining a

pre-arranged number of samples and does not describe methods for obtaining individual specimens from the sample.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D4220 Practices for Preserving and Transporting Soil Samples

D4354 Practice for Sampling of Geosynthetics and Rolled Erosion Control Products(RECPs) for Testing

D4439 Terminology for Geosynthetics

D5888 Guide for Storage and Handling of Geosynthetic Clay Liners

3. Terminology

3.1 Definitions:

3.1.1 geosynthetic clay liner (GCL), n—a manufactured hydraulic barrier consisting of clay bonded to a layer or layers of

geosynthetics.

3.1.2 sample, n—a portion of a material which is taken for testing or for record purposes (See Practice D4354).

3.1.3 specimen, n—a specific portion of a material or laboratory sample upon which a test is performed or which is taken for

that purpose (See Practice D4354).

3.1.4 For definitions of other geosynthetic terms used in this practice, refer to Terminology D4439.

4. Significance and Use

4.1 This practice provides a procedure by which samples of GCL should be obtained for laboratory testing. The practice applies

to materials obtained prior to installation (either at a job site or at a production facility) or exhumed material after installation.

This practice is under the jurisdiction of ASTM Committee D35 on Geosynthetics and is the direct responsibility of Subcommittee D35.04 on Geosynthetic Clay Liners.

Current edition approved Nov. 1, 2009Jan. 1, 2015. Published December 2009February 2015. Originally approved in 1996. Last previous edition approved in 20082009

as D6072D6072/D6072M–08.–09. DOI: 10.1520/D6072-09.10.1520/D6072_D6072M-09R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6072/D6072M − 09 (2015)

4.2 Only GCL samples obtained in accordance with 5.1 of this practice will be considered representative of the actual

manufactured GCL for quality assurance/quality control (QA/QC) purposes.

4.3 The quantity of GCL received by the laboratory should be sufficient for the preparation of several representative test

specimens for the standardized physical, hydraulic, and mechanical tests to be performed on the GCLs.

4.4 The procedures in this practice should be used by plant and field personnel for obtaining GCL samples for laboratory testing.

5. Procedure

5.1 Obtaining Samples prior to Installation:Obtaining Samples Prior to Installation:

5.1.1 In accordance with the project specifications or with Practice D4354, divide the shipment or other given quantity of GCL

into lots, and select lot and laboratory samples. This will usually involve the selection of a certain number of finished GCL rolls

from which samples will be cut.

5.1.2 Affix on the packaging of the GCL rolls to be sampled adhesive labels or other markings which clearly identify that the

roll is to be sampled.

5.1.3 Record the label information from each roll to be sampled for future incorporation into within the quality assurance/quality

control (QA/QC) documentation for the GCL.

5.1.4 Segregate the rolls identified for sampling. Refer to Guide D5888 for the proper equipment and techniques for handling

the GCL rolls.

5.1.5 Inspect the packaging of the selected GCL rolls for damage. Describe and record the damage, if any.

5.1.6 Remove the outer packaging from the GCL as carefully as possible, taking precautions not to damage the GCL and to

preserve the packaging as much as possible for re-use after sampling is completed.

5.1.7 Obtain samples from the selected GCL rolls prior to deployment. If cut on a surface, the surface on which the GCL is cut

shall be dry, clean, smooth, hard and free of irregularities and potential contaminants.

NOTE 1—At the discretion of the engineer, shorter or narrower samples, or both, may be obtained provided that the packaging procedures in this guide

are followed.

5.1.8 A unique sample number shall be written on the sample. Additional markings should be made on the sample to identify

the machine direction and the top/bottom sides of the GCL.

5.1.9 The GCL sample shall then be manually rolled around a core at least 75 mm in diameter, in the same direction as the cut.

Care should be taken to wind the GCL without slack. Wide strapping tape (50 mm) shall then be wound around the sample in at

least two places to secure the loose end. Bentonite loss from the sample may be minimized by applying the tape around the roll

ends.

5.1.10 At least two layers of plastic sheeting shall be used to wrap the GCL sample roll for shipment to the laboratory, so as

to minimize GCL sample disturbance or changes in moisture content. A thin cellophane material may be used for the inner

wrapping, provided it is wound securely and repeatedly around the rolled sample. The outer sheeting shall be at least 0.15 mm (6

mils)[6 mils] in thickness and shall be wrapped to minimize the amount of GCL shifting within the wrapping.

5.1.11 To ensure proper sample chain-of-custody tracking, all shipping documents shall indicate the sample number, project

name and contact, and laboratory name and contact.

5.1.12 If an additional sample from the same GCL roll is required for testing, 5.1.6 through 5.1.10 of this practice may be

repeated on the exposed end of the roll until a sufficient amount of GCL is obtained.

NOTE 2—Additional material cut from the same roll is still considered part of the same sample therefore should not be designated any differently than

those samples previously obtained from the same roll.

5.1.13 Samples should be transmitted to the laboratory in a manner that minimizes the amount elapsed time, sample handling,

disturbances (such as moisture, vibration, impact, etc.) that could occur in transit. Expedited delivery will help to ensure that

moisture content changes are minimized.

NOTE 3—These packaging procedures were developed under the assumption that the area from which specimens are obtained is at least 75 mm 75 mm

from the edges of the sample.

5.2 Exhuming Samples after Installation:Exhuming Samples After Installation:

5.2.1 There are two methods for exhuming GCL samples. Method A is the suggested method for multi-component GCLs or

GCLs covered with a geomembrane. Method B is the suggested method when there is no multi-component GCL nor is the GCL

covered with a geomembrane, although Method A can be used in cases where larger samples are required.

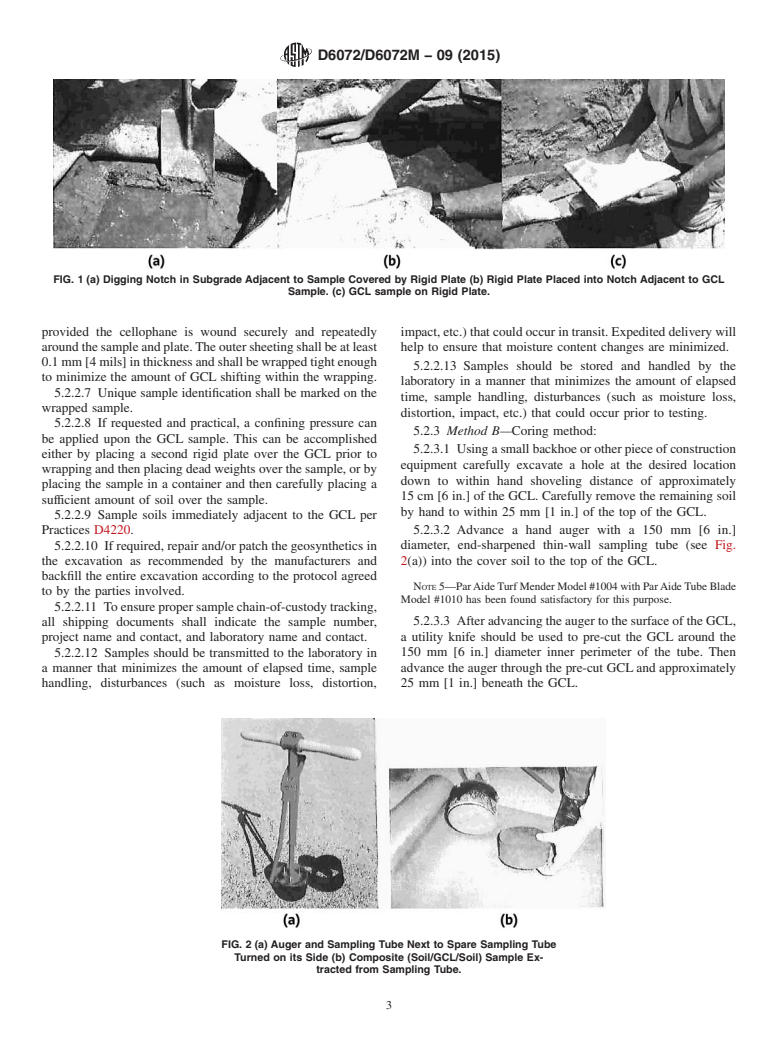

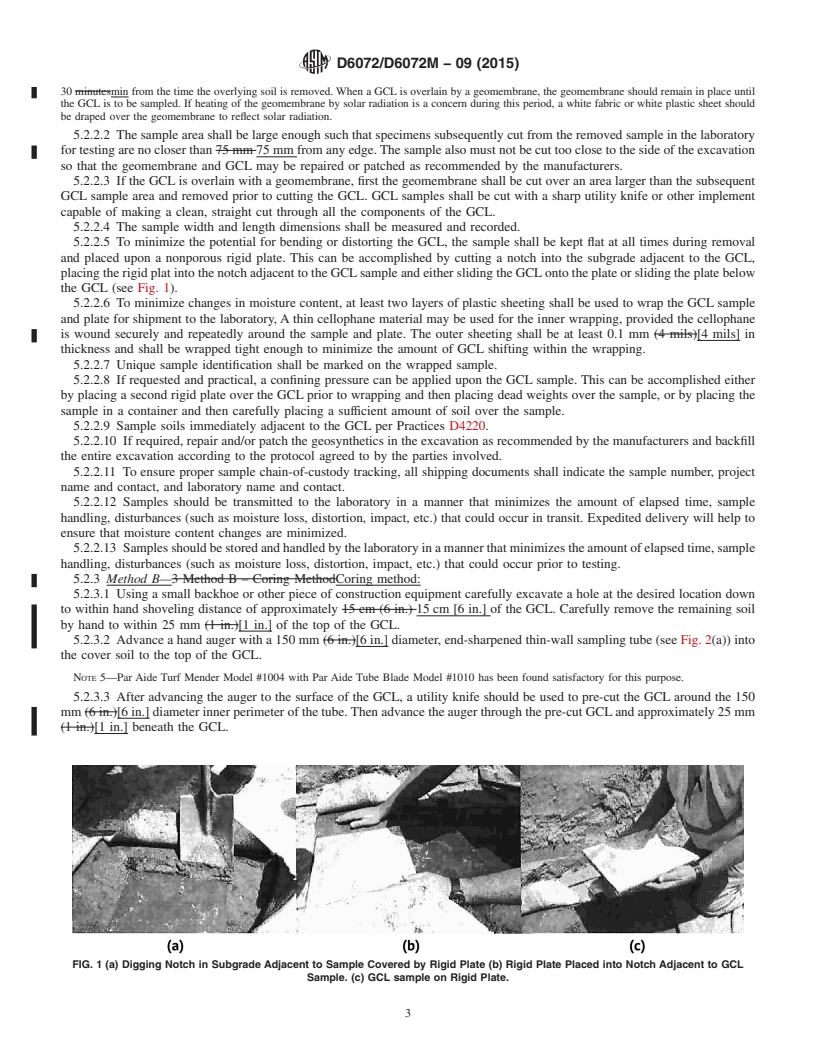

5.2.2 Method A—Method A – Hand Cutting method.method:

5.2.2.1 Using a small backhoe or other piece of construction equipment carefully excavate a hole at the desired location down

to within hand shoveling distance of approximately 150 mm (6 in.) 150 mm [6 in.] of the GCL. Once cover removal begins,

machinery should not be placed in the area to be exhumed. To minimize stress on GCL, within 150 mm (6 in.) 150 mm [6 in.]

the GCL, the overlying soil should be removed by hand an

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.