ASTM D5848-98

(Test Method)Standard Test Method for Mass Per Unit Area of Pile Yarn Floor Coverings

Standard Test Method for Mass Per Unit Area of Pile Yarn Floor Coverings

SCOPE

1.1 This test method covers the measurement of mass per unit area of machine-made woven, knitted, and tufted pile yarn floor covering both before and after an adhesive-back coating application.

1.2 This test method encompasses three techniques for determination of mass per unit area as applicable:

1.2.1 Section 7, for determining total mass per unit area, applies to both coated and uncoated (unfinished) pile floor coverings.

1.2.2 Section 8, for determining component mass per unit area, applies only to uncoated (unfinished) pile yarn floor coverings, and

1.2.3 Section 9, for determining pile yarn mass per unit area, applies only to back-coated, or finished, pile yarn floor coverings.

1.3 Determination of mass per unit area of pile yarn floor coverings was previously contained within Test Methods D418. For user convenience, Subcommittee D13.21 subdivided Test Methods D418 into separate standards, of which this test method is one.

1.4 The values stated in SI units are to be regarded as standard for all measurements. The inch-pound units given in parentheses are provided for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in 9.5.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D 5848–98

Standard Test Method for

Mass Per Unit Area of Pile Yarn Floor Coverings

This standard is issued under the fixed designation D 5848; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 1909 Table of Commercial Moisture Regains for Textile

Fibers

1.1 This test method covers the measurement of mass per

D 5684 Terminology Relating to Pile Floor Coverings

unit area of machine-made woven, knitted, and tufted pile yarn

E 122 Practice for Choice of Sample Size to Estimate a

floor covering both before and after an adhesive-back coating

Measure of Quality for a Lot or Process

application.

1.2 This test method encompasses three techniques for

3. Terminology

determination of mass per unit area as applicable:

3.1 Definitions:

1.2.1 Section 1.3, for determining total mass per unit area,

3.1.1 pile yarn mass, n—for back-coated pile yarn floor

applies to both coated and uncoated (unfinished) pile floor

covering, the mass per unit area of pile yarn separated from the

coverings.

total mass by shearing and manually removing the pile yarn

1.2.2 Section 1.4, for determining component mass per unit

from the backing fabric with the assistance of solvent.

area, applies only to uncoated (unfinished) pile yarn floor

3.1.1.1 Discussion—Pile yarn mass includes pile yarn por-

coverings, and

tions buried in the backing and the short stubble of yarn

1.2.3 Section 1.5, for determining pile yarn mass per unit

projecting above the backing after shearing as opposed to

area, applies only to back-coated, or finished, pile yarn floor

measurement of mass per unit area that includes only the

coverings.

amount that can be shorn away from the backing. Some pile

1.3 Determination of mass per unit area of pile yarn floor

floor covering constructions, such as patterned woven Wiltons,

coverings was previously contained within Test Methods

may have pile yarns which appear infrequently on the pile

D 418. For user convenience, Subcommittee D 13.21 subdi-

surface; however, these inactive pile yarns should be included

vided Test Methods D 418 into separate standards, of which

as part of pile yarn mass per unit area not as backing. Pile yarn

this test method is one.

mass is not applicable to needlepunch materials.

1.4 The values stated in SI units are to be regarded as

3.2 For definitions of other terms relating to pile yarn floor

standard for all measurements. The inch-pound units given in

coverings, refer to Terminology D 5684. For definitions of

parentheses are provided for information only.

other textile terms used in this test method, refer to Terminol-

1.5 This standard does not purport to address all of the

ogy D 123.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Significance and Use

priate safety and health practices and determine the applica-

4.1 The determination of the mass per unit area of pile yarn

bility of regulatory limitations prior to use. Specific precau-

floor covering is useful in quality and cost control during the

tionary statements are given in 9.5.

manufacture of pile floor covering. Both appearance and

2. Referenced Documents performance may be affected by changes in mass per unit area.

4.2 In case of a dispute arising from differences in reported

2.1 ASTM Standards:

test results when using this test method for acceptance testing

D 123 Terminology Relating to Textile Materials

of commercial shipments, the purchaser and supplier should

D 418 Methods of Testing Pile Yarn Floor Covering Con-

conduct comparison testing to determine if there is a statistical

struction

3 bias between their laboratories. Competent statistical assis-

D 1193 Specification for Reagent Water

tance is recommended for the investigation of bias. As a

minimum the two parties should take a group of test specimens

ThistestmethodisunderthejurisdictionofASTMCommitteeD-13onTextiles that are as homogeneous as possible and that are from a lot of

and is the direct responsibility of Subcommittee D 13.21 on Pile Floor Coverings.

materialofthetypeinquestion.Thetestspecimensshouldthen

Current edition approved Sept. 10, 1998. Published December 1998. Originally

published as D 5848 – 95. Last previous edition D 5848 – 95.

Annual Book of ASTM Standards, Vol 07.01.

3 4

Annual Book of ASTM Standards, Vol 11.01. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 5848

be randomly assigned to each laboratory for testing. The 6. Conditioning

average results from the two laboratories should be compared

6.1 When required, condition the specimens or the test

using Student’s t-test for unpaired data and an acceptable

sample in the standard atmosphere for testing textiles, that is

probability level chosen by the two parties prior to testing. If a

21 6 1°C (70 6 2°F) at 65 6 2 % relative humidity, for 12 h

bias is found, either its cause must be found and corrected or

or until the mass changes no more than 0.1 % in 2 h.

the purchaser and supplier must agree to interpret future test

6.2 If the fiber in any layer of the backing has a commercial

results with consideration to the known bias.

regain of over 5 %, the specimen shall be conditioned before

measuring. Commercial moisture regains for textile fibers are

5. Test Specimen

listed in Table 1 in D 1909.

5.1 Sampling Units:

7. Total Mass Per Unit Area

5.1.1 Uncoated Floor Covering—The basic sampling unit

of uncoated floor covering is a production roll.

7.1 Scope—This test method applies to both uncoated and

5.1.2 Coated Floor Covering—The basic sampling unit of

coated floor covering.

coated floor covering is a shipping roll. The number of

7.2 Summary of Test Method—Test specimens are cut from

shipping rolls obtained from each production roll ranges from

a conditioned test sample and then measured, or are cut from

one to over ten.

an unconditioned test sample and then conditioned before

5.2 Lot Sample—Take a lot sample as directed in Practice

measuring, so that the area of each test specimen is measured

E 122whenstatisticalknowledgeoftheproductvariabilityand

after conditioning. Each conditioned test specimen is weighed

test method precision is available, and a decision has been

and the mass per unit area is calculated.

made on the maximum deviation that can be tolerated between

7.3 Apparatus:

the estimate to be made from the sample and the result that

7.3.1 Balance, having a capacity and sensitivity to weigh to

wouldbeobtainedbymeasuringeverysamplingunitofthelot.

the nearest 0.1 % of the test specimen mass or to the nearest

Otherwisethenumberofsamplingunitsinalotsampleandthe

0.01 g, whichever is larger.

use of the test results obtained from the individual test samples

NOTE 1—Weighing to the nearest 0.1 % means weighing to the nearest

shall be in accordance with the manufacturer’s quality control

0.01gfortestspecimensweighing10to100g,tothenearest0.1gfor100

program or with the specification agreed upon between the

to 1000 g, and to the nearest 1 g for more than 1000 g. A 100-g, 254 by

purchaser and the supplier.

254-mm (10.0 by 10.0-in.) test specimen has a mass per unit area of 1550

2 2

5.3 TestSample—Atest sample shall consist of a full width

g/m (457 oz/yd ) while a 1000-g, 457 by 457-mm (18.0 by 18.0-in.) test

2 2

sectionoffloorcoveringcutfromoneendofeachrollinthelot specimen has a mass per unit area of 4784 g/m (141.1 oz/yd ).

sample and shall be at least 100 mm (4 in.) longer than the

7.3.2 Device for Cutting and Measuring Test Specimens, as

specimens required for the tests being conducted. Do not cut a

directed for the procedure selected in Annex A1.

test sample of coated floor covering from a seam end of a

7.4 Conditioning—Conditionthetestspecimensasdirected

production roll.

inSection1.2.3beforemeasuringandweighing.ForAnnexA1

5.4 Test Specimens:

Procedures2and3,conditionthetestsamplebeforecuttingthe

5.4.1 A test specimen is a designated area of a test sample

test specimens.

cut from the test sample. For test samples 3000 mm (120 in.)

7.5 Sample and Test Specimens—Take the test sample and

wide or wider, three test specimens are required for a test

the test specimens as directed in Section 1.2.2.

method, one at each edge no nearer to the edge than 5 % of the

7.5.1 For level pile floor covering, the test specimens shall

total floor covering width and one in the middle portion of the

be at least 250 by 250 6 5 mm (10.0 by 10.0 6 0.2 in.).

testsample.Fortestsamplesatleast1500mm(60in.)widebut

7.5.2 For multilevel pile floor covering the test specimens

less than 3000 mm, take two test specimens, one at each edge

shall comprise a full pattern repeat or a whole number multiple

nonearertotheedgethan5 %ofthetotalfloorcoveringwidth.

of a full pattern repeat in each direction, but no less than as

For test samples less than 1500 mm wide, take one specimen

directed in 7.5.1. If the pattern repeat is not known and cannot

from the middle.

be determined readily, use 460 by 460 6 5 mm (18.0 by

5.4.2 Where it is known that systematic variations in a floor

18.0 6 0.2 in.) for the test specimen dimensions.

covering characteristic may occur in bands 460 mm (18 in.) or

7.6 Procedure:

more in width, as with a modular pattern device having

7.6.1 Preparation of Specimens—Follow the selected pro-

separate controls or adjustments for each module, take test

cedure of Annex A1.

specimens from the middle of each band.

7.6.2 TestSpecimenMass—Weigheachtestspecimentothe

5.4.3 When a full-width test sample is not available, take

nearest 0.1 % (or less) of the test specimen mass, M (Note 1).

specimens as directed in 5.4, and state in the report the width

7.7 Calculation:

available and the number of test specimens taken.

7.7.1 Test Specimen Total Mass Per Unit Area—Calculate

5.5 Atestresultistheaverageofthemeasurementsmadeon

thetotalmassperunitareaforeachtestspecimentothenearest

a set of test specimens as described in 5.4. In these methods,

2 2

0.3 g/m (0.01 oz/yd ) using Eq 1.

directions are given only for obtaining a test result from one

W 5M 3K/~B 3L! (1)

test sample. The value representative of the lot being sampled

will be the average of the test results for all the test samples in

where:

the lot sample.

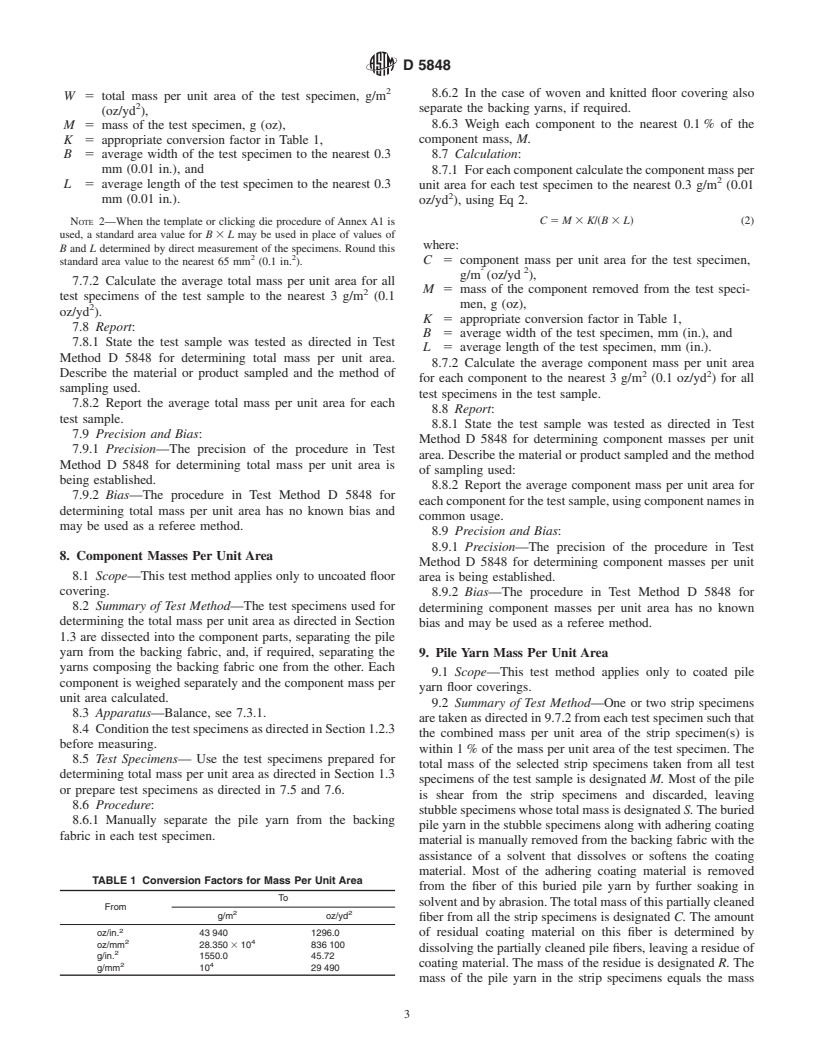

D 5848

8.6.2 In the case of woven and knitted floor covering also

W 5 total mass per unit area of the test specimen, g/m

separate the backing yarns, if required.

(oz/yd ),

8.6.3 Weigh each component to the nearest 0.1 % of the

M 5 mass of the test specimen, g (oz),

K 5 appropriate conversion factor in Table 1, component mass, M.

B 5 average width of the test specimen to the nearest 0.3 8.7 Calculation:

mm (0.01 in.), and

8.7.1 Foreachcomponentcalculatethecomponentmassper

L 5 average length of the test specimen to the nearest 0.3

unit area for each test specimen to the nearest 0.3 g/m (0.01

mm (0.01 in.).

oz/yd ), using Eq 2.

C 5M 3K/ B 3L! (2)

NOTE 2—When the template or clicking die procedure of Annex A1 is ~

used, a standard area value for B 3L may be used in place of values of

where:

B and L determined by direct measurement of the specimens. Round this

2 2

C 5 component mass per unit area for the test specimen,

standard area value to the nearest 65 mm (0.1 in. ).

g/m (oz/yd ),

7.7.2 Calculate the average total mass per unit area for all

M 5 mass of the component removed from the test speci-

test specimens of the test sample to the nearest 3 g/m (0.1

men, g (oz),

oz/yd ).

K 5 appropriate conversion factor in Table 1,

7.8 Report:

B 5 average width of the test specimen, mm (in.), and

7.8.1 State the test sample was tested as directed in Test

L 5 average length of the test specimen, mm (in.).

Method D 5848 for determining total mass per unit area.

8.7.2 Calculate the average component mass per unit area

Describe the material or product sampled and the method of 2 2

for each component to the nearest 3 g/m (0.1 oz/yd ) for all

sampling used.

test specimens in the test sample.

7.8.2 Report the average total mass per unit area for each

8.8 Report:

test sample.

8.8.1 State the test sample was tested as directed in Test

7.9 Precision and Bias:

Method D 5848 for determining component masses per unit

7.9.1 Precision—The precision of the procedure in Test

area. Describe the material or product sampled and the method

Method D 5848 for determining total mass per unit area is

of sampling used:

being established.

8.8.2 Report the average component mass per unit area for

7.9.2 Bias—The procedure in Test Method D 5848 for

eachcomponentforthetestsample,usingcomponentnamesin

determining total mass per unit area has no known bias and

common usage.

may be used as a referee method.

8.9 Precision and Bias:

8.9.1 Precision—The precision of the procedure in Test

8. Component Masses Per Unit Area

Method D 5848 for determining component masses per unit

8.1 Scope—This test method applies only to uncoated floor

area is being established.

covering.

8.9.2 Bias—The procedure in Test Method D 5848 for

8.2 Summary of Test Method—The test specimens used for

determining component masses per unit area has no known

determining the total mass per unit area as directed in Section

bias and may be used as a referee method.

1.3 are dissected into the component parts, separating the pile

yarn from the backing fabric, and, if required, separating the 9. Pile Yarn Mass Per Unit Area

yarns composing the backing fabric one from the other. Each

9.1 Scope—This test method applies only to coated pile

component is weighed separately and the component mass per

yarn floor coverings.

unit area calculated.

9.2 Summary of Test Method—One or two strip specimens

8.3 Apparatus—Balance, see 7.3.1.

are taken as directed in 9.7.2 from each test specimen such that

8.4 ConditionthetestspecimensasdirectedinSection1.2.3

the combined mass per unit area of the strip specimen(s) is

before measuring.

within 1 % of the mass per unit area of the test specimen. The

8.5 Test Specimens— Use the test specimens prepared for

total mass of the selected strip specimens taken from all test

determining total mass per unit area as directed in Section 1.3

specimens of the test sample is designated M. Most of the pile

or prepare test specimens as directed in 7.5 and 7.6.

is shear from the strip specimens and discarded, leaving

8.6 Procedure:

stubblespecimenswhosetotalmassisdesignatedS.Theburied

8.6.1 Manually separate the pile yarn from the backing

pile yarn in the stubble specimens along with adhering coating

fabri

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.