ASTM D2241-00

(Specification)Standard Specification for Poly(Vinyl Chloride) (PVC) Pressure-Rated Pipe (SDR Series)

Standard Specification for Poly(Vinyl Chloride) (PVC) Pressure-Rated Pipe (SDR Series)

SCOPE

1.1 This specification covers poly(vinyl chloride) (PVC) pipe made in standard thermoplastic pipe dimension ratios and pressure rated for water (see appendix). Included are criteria for classifying PVC plastic pipe materials and PVC plastic pipe, a system of nomenclature for PVC plastic pipe, and requirements and test methods for materials, workmanship, dimensions, sustained pressure, burst pressure, flattening, and extrusion quality. Methods of marking are also given.

1.2 The products covered by this specification are intended for use with the distribution of pressurized liquids only, which are chemically compatible with the piping materials. Due to inherent hazards associated with testing components and systems with compressed air or other compressed gases some manufacturers do not allow pneumatic testing of their products. Consult with specific product/component manufacturers for their specific testing procedures prior to pneumatic testing.

Note 1-Pressurized (compressed) air or other compressed gases contain large amounts of stored energy which present serious saftey hazards should a system fail for any reason.

1.3 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

The following safety hazards caveat pertains only to the test methods portion, Section , of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. A specific precautionary statement is given in Note 7.

Note 2-CPVC plastic pipe (SDR-PR), which was formerly included in this specification, is now covered by Specification F 442.

Note 3-The sustained and burst pressure test requirements, and the pressure ratings in the appendix, are calculated from stress values obtained from tests made on pipe 4 in. (100 mm) and smaller. However, tests conducted on pipe as large as 24 in. (600 mm) in diameter have shown these stress values to be valid for larger diameter PVC pipe.

Note 4-PVC pipe made to this specification is often belled for use as line pipe. For details of the solvent cement bell, see Specification D 2672 and for details of belled elastomeric joints, see Specifications D 3139 and D 3212.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: D 2241 – 00

Standard Specification for

Poly(Vinyl Chloride) (PVC) Pressure-Rated Pipe (SDR

Series)

This standard is issued under the fixed designation D 2241; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

NOTE 2—CPVC plastic pipe (SDR-PR), which was formerly included

1. Scope

in this specification, is now covered by Specification F 442.

1.1 This specification covers poly(vinyl chloride) (PVC)

NOTE 3—The sustained and burst pressure test requirements, and the

pipe made in standard thermoplastic pipe dimension ratios and

pressure ratings in the appendix, are calculated from stress values obtained

pressure rated for water (see appendix). Included are criteria

from tests made on pipe 4 in. (100 mm) and smaller. However, tests

for classifying PVC plastic pipe materials and PVC plastic conducted on pipe as large as 24 in. (600 mm) in diameter have shown

these stress values to be valid for larger diameter PVC pipe.

pipe, a system of nomenclature for PVC plastic pipe, and

NOTE 4—PVC pipe made to this specification is often belled for use as

requirements and test methods for materials, workmanship,

line pipe. For details of the solvent cement bell, see Specification D 2672

dimensions, sustained pressure, burst pressure, flattening, and

and for details of belled elastomeric joints, see Specifications D 3139 and

extrusion quality. Methods of marking are also given.

D 3212.

1.2 The products covered by this specification are intended

for use with the distribution of pressurized liquids only, which 2. Referenced Documents

are chemically compatible with the piping materials. Due to

2.1 ASTM Standards:

inherent hazards associated with testing components and sys-

D 618 Practice for Conditioning Plastics and Electrical

tems with compressed air or other compressed gases some

Insulating Materials for Testing

manufacturers do not allow pneumatic testing of their products.

D 1598 Test Method for Time-to-Failure of Plastic Pipe

Consult with specific product/component manufacturers for

Under Constant Internal Pressure

their specific testing procedures prior to pneumatic testing.

D 1599 Test Method for Short-Time Hydraulic Failure Pres-

sure of Plastic Pipe, Tubing, and Fittings

NOTE 1—Pressurized (compressed) air or other compressed gases

contain large amounts of stored energy which present serious saftey D 1600 Terminology for Abbreviated Terms Relating to

hazards should a system fail for any reason.

Plastics

D 1784 Specification for Rigid Poly(Vinyl Chloride) (PVC)

1.3 The text of this specification references notes, footnotes,

Compounds and Chlorinated Poly(Vinyl Chloride)

and appendixes which provide explanatory material. These

(CPVC) Compounds

notes and footnotes (excluding those in tables and figures) shall

D 2122 Test Method for Determining Dimensions of Ther-

not be considered as requirements of the specification.

moplastic Pipe and Fittings

1.4 The values stated in inch-pound units are to be regarded

D 2152 Test Method for Adequacy of Fusion of Extruded

as the standard. The values given in parentheses are for

Poly(Vinyl Chloride) (PVC) Pipe and Molded Fittings by

information only.

Acetone Immersion

1.5 The following safety hazards caveat pertains only to the

D 2444 Test Method for Impact Resistance of Thermoplas-

test methods portion, Section 8, of this specification: This

tic Pipe and Fittings by Means of a Tup (Falling Weight)

standard does not purport to address all of the safety concerns,

D 2672 Specification for Joints for IPS PVC Pipe Using

if any, associated with its use. It is the responsibility of the user

Solvent Cement

of this standard to establish appropriate safety and health

D 2837 Test Method for Obtaining Hydrostatic Design

practices and determine the applicability of regulatory limita-

Basis for Thermoplastic Pipe Materials

tions prior to use. A specific precautionary statement is given

D 3139 Specification for Joints for Plastic Pressure Pipes

in Note 7.

Using Flexible Elastomeric Seals

D 3212 Specification for Joints for Drain and Sewer Plastic

Pipes Using Flexible Elastomeric Seals

This specification is under the jurisdiction of ASTM Committee F-17 on Plastic

Piping System s and is the direct responsibility of Subcommittee F17.25 on Vinyl

Based Pipe.

Current edition approved June 10, 2000. Published September 2000. Originally Annual Book of ASTM Standards, Vol 08.01.

published as D 2241 – 64. Last previous edition D 2241 – 99a. Annual Book of ASTM Standards, Vol 08.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 2241 – 00

F 412 Terminology Relating to Plastic Piping Systems 4. Classification

F 442/F 442M Specification for Chlorinated Poly(Vinyl

4.1 General—This specification covers PVC pipe made to

Chloride) (CPVC) Plastic Pipe (SDR-PR)

and marked with one of six Type/Grade/Design Stress desig-

2.2 NSF Standards:

nations (see X1.2) in seven standard dimension ratios.

Standard No. 14 for Plastic Piping Components and Related

4.2 Standard Thermoplastic Pipe Dimension Ratios

Materials

(SDR)—This specification covers PVC pipe in seven standard

Standard No. 61 for Drinking Water Systems

dimension ratios, namely, 13.5, 17, 21, 26, 32.5, 41, and 64

Components—Health Effects

which are uniform for all nominal pipe sizes for each material

and pressure rating. These are referred to as SDR13.5, SDR21,

3. Terminology

SDR17, SDR26, SDR32.5, SDR41, and SDR64, respectively.

3.1 Definitions—Definitions are in accordance with Termi-

The pressure rating is uniform for all nominal pipe sizes for a

nology F 412, and abbreviations are in accordance with Ter-

given PVC pipe material and SDR (see Table X1.1).

minology D 1600, unless otherwise specified. The abbreviation

4.3 Hydrostatic Design Stresses—This specification covers

for poly(vinyl chloride) plastic is PVC.

pipe made from PVC plastics defined by four hydrostatic

3.2 Definitions of Terms Specific to This Standard:

design stresses developed on the basis of long-term tests

3.2.1 hydrostatic design stress—the estimated maximum

(appendix).

tensile stress the material is capable of withstanding continu-

5. Materials

ously with a high degree of certainty that failure of the pipe

will not occur. This stress is circumferential when internal

5.1 General—Poly(vinyl chloride) plastics used to make

hydrostatic water pressure is applied.

pipe meeting the requirements of this specification are catego-

3.2.2 pressure rating (PR)—the estimated maximum water

rized by means of two criteria, namely, (1) short-term strength

pressure the pipe is capable of withstanding continuously with

tests, and (2) long-term strength tests.

a high degree of certainty that failure of the pipe will not occur.

NOTE 5—The PVC pipe intended for use in the transport of potable

3.2.3 relation between standard dimension ratio, hydro-

water should be evaluated and certified as safe for this purpose by a testing

static design stress, and pressure rating—The following ex-

agency acceptable to the local health authority. The evaluation should be

pression, commonly known as the ISO equation, is used in

in accordance with requirements for chemical extraction, taste, and odor

this specification to relate standard dimension ratio, hydrostatic that are no less restrictive than those included in NSF Standard No. 14.

The seal or mark of the laboratory making the evaluation should be

design stress, and pressure rating:

included on the pipe.

2S/P 5 R 2 1 or 2 S/P 5 ~D /t! 2 1

5.2 Basic Materials—This specification covers pipe made

where:

from PVC plastics having certain physical and chemical

S = hydrostatic design stress, psi (or MPa),

properties as described in Specification D 1784.

P = pressure rating, psi (or MPa),

5.3 Compound—The PVC compounds used for this pipe

D = average outside diameter, in. (or mm),

shall equal or exceed one of the following classes described in

t = minimum wall thickness, in. (or mm), and

Specification D 1784: PVC 12454 or 14333.

R = standard thermoplastic pipe dimension ratio (D /t for

5.4 Rework Material—The manufacturer shall use only his

PVC pipe), also known as SDR.

own clean rework pipe material and the pipe produced shall

3.2.4 standard thermoplastic pipe dimension ratio (SDR)—

meet all the requirements of this specification.

the ratio of pipe diameter to wall thickness. For PVC pipe it is

6. Requirements

calculated by dividing the average outside diameter of the pipe

in inches or in millimetres by the minimum wall thickness in

6.1 Dimensions and Tolerances:

inches or in millimetres. If the wall thickness calculated by this

6.1.1 Outside Diameters—The outside diameters and toler-

formula is less than 0.060 in. (1.52 mm), it shall be arbitrarily

ances shall be as shown in Table 1 when measured in

increased to 0.060 in. The SDR values shall be rounded to the

accordance with Test Method D 2122. The tolerances for

nearest 0.5.

out-of-roundness shall apply only on pipe prior to shipment.

3.2.5 standard thermoplastic pipe materials designation

6.1.2 Wall Thickness—The wall thicknesses and tolerances

code—The pipe materials designation code shall consist of the

shall be as shown in Table 2 when measured in accordance

abbreviation PVC for the type of plastic, followed by the

with Test Method D 2122.

ASTM type and grade in Arabic numerals and the design stress

6.2 Sustained Pressure—The pipe shall not fail, balloon,

in units of 100 psi (0.7 MPa) with any decimal figures dropped.

burst, or weep as defined in Test Method D 1598 at the test

When the design stress code contains less than two figures, a

pressures given in Table 3 when tested in accordance with 8.4.

cipher shall be used before the number. Thus a complete

6.2.1 Accelerated Regression Test—The accelerated regres-

material code shall consist of three letters and four figures for

sion test shall be used in place of both the sustained and burst

PVC plastic pipe materials.

pressure tests, at the option of the manufacturer. The test shall

be conducted in accordance with 8.4.1. The pipe shall demon-

strate a hydrostatic design basis projection at the 100 000-h

Available from the National Sanitation Foundation, P.O. Box 1468, Ann Arbor,

intercept that meets the hydrostatic design basis category

MI 48106.

requirement (see the table for“ Hydrostatic Design Basis

ISO R161–1960, Pipes of Plastics Materials for the Transport of Fluids

(Outside Diameters and Nominal Pressures) Part 1, Metric Series. Categories’’ of Test Method D 2837) for the PVC material

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 2241 – 00

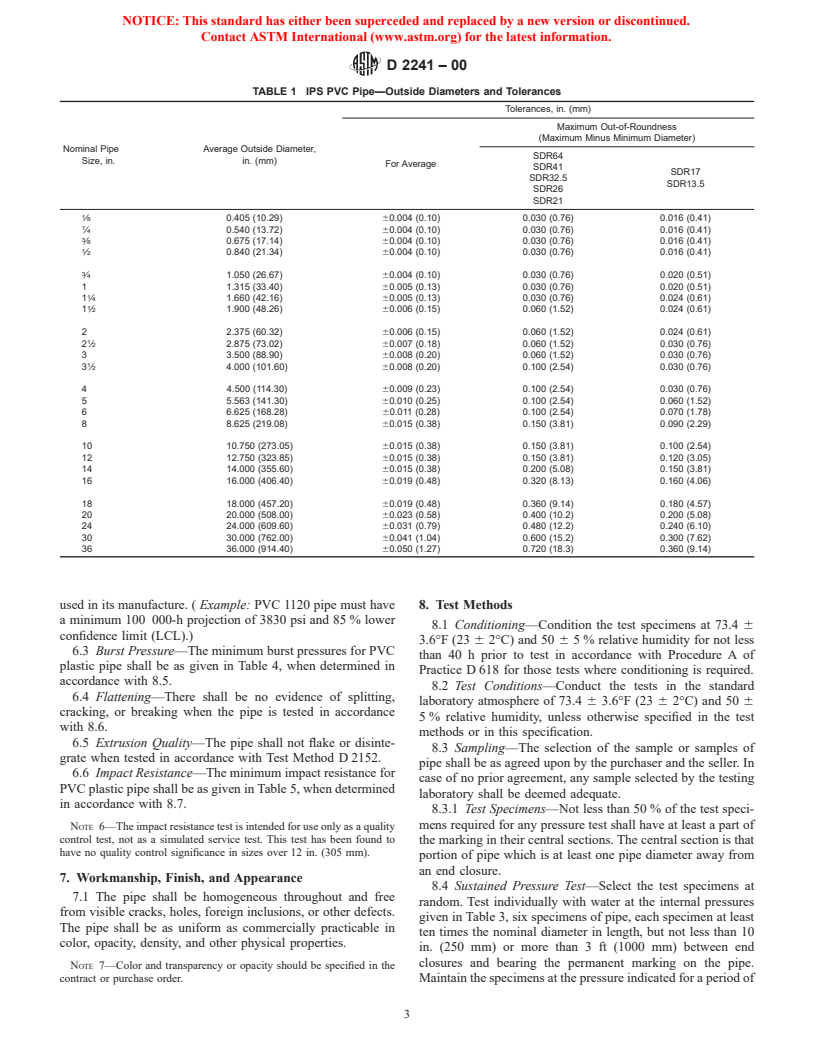

TABLE 1 IPS PVC Pipe—Outside Diameters and Tolerances

Tolerances, in. (mm)

Maximum Out-of-Roundness

(Maximum Minus Minimum Diameter)

Nominal Pipe Average Outside Diameter,

SDR64

Size, in. in. (mm)

For Average

SDR41

SDR17

SDR32.5

SDR13.5

SDR26

SDR21

⁄8 0.405 (10.29) 60.004 (0.10) 0.030 (0.76) 0.016 (0.41)

⁄4 0.540 (13.72) 60.004 (0.10) 0.030 (0.76) 0.016 (0.41)

⁄8 0.675 (17.14) 60.004 (0.10) 0.030 (0.76) 0.016 (0.41)

⁄2 0.840 (21.34) 60.004 (0.10) 0.030 (0.76) 0.016 (0.41)

⁄4 1.050 (26.67) 60.004 (0.10) 0.030 (0.76) 0.020 (0.51)

1 1.315 (33.40) 60.005 (0.13) 0.030 (0.76) 0.020 (0.51)

1 ⁄4 1.660 (42.16) 60.005 (0.13) 0.030 (0.76) 0.024 (0.61)

1 ⁄2 1.900 (48.26) 60.006 (0.15) 0.060 (1.52) 0.024 (0.61)

2 2.375 (60.32) 60.006 (0.15) 0.060 (1.52) 0.024 (0.61)

2 ⁄2 2.875 (73.02) 60.007 (0.18) 0.060 (1.52) 0.030 (0.76)

3 3.500 (88.90) 60.008 (0.20) 0.060 (1.52) 0.030 (0.76)

3 ⁄2 4.000 (101.60) 60.008 (0.20) 0.100 (2.54) 0.030 (0.76)

4 4.500 (114.30) 60.009 (0.23) 0.100 (2.54) 0.030 (0.76)

5 5.563 (141.30) 60.010 (0.25) 0.100 (2.54) 0.060 (1.52)

6 6.625 (168.28) 60.011 (0.28) 0.100 (2.54) 0.070 (1.78)

8 8.625 (219.08) 60.015 (0.38) 0.150 (3.81) 0.090 (2.29)

10 10.750 (273.05) 60.015 (0.38) 0.150 (3.81) 0.100 (2.54)

12 12.750 (323.85) 60.015 (0.38) 0.150 (3.81) 0.120 (3.05)

14 14.000 (355.60) 60.015 (0.38) 0.200 (5.08) 0.150 (3.81)

16 16.000 (406.40) 60.019 (0.48) 0.320 (8.13) 0.160 (4.06)

18 18.000 (457.20) 60.019 (0.48) 0.360 (9.14) 0.180 (4.57)

20 20.000 (508.00) 60.023 (0.58) 0.400 (10.2) 0.200 (5.08)

24 24.000 (609.60) 60.031 (0.79) 0.480 (12.2) 0.240 (6.10)

30 30.000 (762.00) 60.041 (1.04) 0.600 (15.2) 0.300 (7.62)

36 36.000 (914.40) 60.050 (1.27) 0.720 (18.3) 0.360 (9.14)

used in its manufacture. ( Example: PVC 1120 pipe must have 8. Test Methods

a minimum 100 000-h projection of 3830 psi and 85 % lower

8.1 Conditioning—Condition the test specimens at 73.4 6

confidence limit (LCL).)

3.6°F (23 6 2°C) and 50 6 5 % relative humidity for not less

6.3 Burst Pressure—The minimum burst pressures for PVC

than 40 h prior to test in accordance with Procedure A of

plastic pipe shall be as given in Table 4, when determined in

Practice D 618 for those tests where conditioning is required.

accordance with 8.5.

8.2 Test Conditions—Conduct the tests in the standard

6.4 Flattening—There shall be no evidence of splitting,

laboratory atmosphere of 73.4 6 3.6°F (23 6 2°C) and 50 6

cracking, or breaking when the pipe is tested in accordance

5 % relative humidity, unless otherwise specified in the test

with 8.6.

methods or in this specification.

6.5 Extrusion Quality—The pipe shall not flake or disinte-

8.3 Sampling—The selection of the sample or samples of

grate when tested in accordance with Test Method D 2152.

pipe shall be as agreed upon by the purchaser and the seller. In

6.6 Impact Resistance—The minimum impact resistance for

case of no prior agreement, any sample selected by the testing

PVC plastic pipe shall be as given in Table 5, when determined

laboratory shall be deemed adequate.

in accordance with 8.7.

8.3.1 Test Specimens—Not less than 50 % of the test speci-

mens required for any pressure test shall have at least a part of

NOTE 6—The impact resistance test is intended for use only as a quality

control test, not as a simulated service test. This test has been found to the marking in their central sections. The central section is that

have no quality control significance in sizes over 12 in. (305 mm).

portion of pipe whic

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.