ASTM D2612-99(2018)

(Test Method)Standard Test Method for Fiber Cohesion in Sliver and Top (Static Tests)

Standard Test Method for Fiber Cohesion in Sliver and Top (Static Tests)

SIGNIFICANCE AND USE

5.1 Fiber cohesion is related to the resistance to drafting encountered during textile processing and is affected by such fiber properties as surface lubrication, linear density, surface configuration, fiber length, and crimp.

5.2 Fiber cohesion is affected by the alignment of fiber in sliver in addition to the factors listed in 5.1. A half turn of twist in a 140-mm specimen has been found to increase the breaking force by 30 % and a full turn by 60 %. For this reason, care must be exercised in precise mounting of specimens.

5.3 For the same reason given in 5.2, card sliver gives a different breaking tenacity than draw sliver of the same fiber. Fibers are more aligned in draw sliver, resulting in lower cohesion.

5.4 Increasing the gage length of test specimens reduces the breaking force and apparent cohesion.

5.5 The mathematical relationship between the observed value for breaking tenacity and processability has not been established, but the observed values can be used in comparing various fiber characteristics on a relative basis.

5.6 This method for measuring fiber cohesion in sliver or top (static tests) is not recommended for acceptance testing because it is an empirical method which must be followed explicitly. Results obtained under other conditions cannot be expected to be comparable.

5.6.1 In some cases, the purchaser and the supplier may have to test a commercial shipment of one or more specific materials by the best available method, even though the method has not been recommended for acceptance testing of commercial shipments. In case of dispute arising from differences in reported test results when using this test method for acceptance testing of commercial shipments, the purchaser and supplier should conduct comparative tests to determine if there is a statistical bias between their laboratories. Competent statistical assistance is recommended for the investigation of bias. As a minimum, the two parties should take a group of test sp...

SCOPE

1.1 This test method describes the measurement of fiber cohesion as the force required to cause initial drafting in a bundle of fibers in sliver and top. The observed cohesive force required to separate the fibers is converted to cohesive tenacity based on the linear density of the specimen.

Note 1: For determination of fiber cohesion in dynamic tests, refer to Test Method D4120.

1.2 The values stated in SI units are to be regarded as standard. Inch-pound units appear in parentheses for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D2612 − 99 (Reapproved 2018)

Standard Test Method for

Fiber Cohesion in Sliver and Top (Static Tests)

This standard is issued under the fixed designation D2612; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Related Properties of Textiles

1.1 This test method describes the measurement of fiber

3. Terminology

cohesion as the force required to cause initial drafting in a

3.1 Definitions:

bundle of fibers in sliver and top. The observed cohesive force

3.1.1 cohesive force, n— in sliver and top testing, the force

required to separate the fibers is converted to cohesive tenacity

required to overcome cohesion of a test specimen held in a

based on the linear density of the specimen.

fixed position between two slowly separating clamps.

NOTE 1—For determination of fiber cohesion in dynamic tests, refer to

3.1.1.1 Discussion—In static tests, cohesive force is mea-

Test Method D4120.

sured while a test specimen is held in fixed position between

1.2 The values stated in SI units are to be regarded as

two slowly separating clamps. In dynamic tests, cohesive force

standard. Inch-pound units appear in parentheses for informa-

is the force required to maintain drafting in a roving, sliver, or

tion only.

top.

1.3 This standard does not purport to address all of the

3.1.2 fiber cohesion, n—theresistancetoseparationoffibers

safety concerns, if any, associated with its use. It is the

in contact with one another.

responsibility of the user of this standard to establish appro-

3.1.2.1 Discussion—This resistance is due to the combined

priate safety, health, and environmental practices and deter-

effects of the surface characteristics, length, crimp, finish, and

mine the applicability of regulatory limitations prior to use.

linear density of the fibers. Cohesion should not be confused

1.4 This international standard was developed in accor-

with adhesion or sticking together as in a glutinous substance.

dance with internationally recognized principles on standard-

3.1.3 For definitions of other terms related to force and

ization established in the Decision on Principles for the

deformation in textiles, refer to Terminology D4848. For

Development of International Standards, Guides and Recom-

definitions of other textile terms used in this test method, refer

mendations issued by the World Trade Organization Technical

to Terminology D123.

Barriers to Trade (TBT) Committee.

4. Summary of Test Method

2. Referenced Documents

4.1 The test procedure is based upon the measure of the

2.1 ASTM Standards:

maximum resisting force when a length of sliver or top is

D76 Specification for Tensile Testing Machines for Textiles

pulled in an axial direction. Specified lengths of sliver or top

D123 Terminology Relating to Textiles

are placed in the clamps of a tensile testing machine and the

D1776 Practice for Conditioning and Testing Textiles

maximum force developed during separation of the clamps is

D2258 Practice for Sampling Yarn for Testing

recorded. The cohesive tenacity is calculated in terms of the

D3333 Practice for Sampling Manufactured Staple Fibers,

force per unit linear density of the tested specimen. The

Sliver, or Tow for Testing

cohesive tenacity is considered a measure of the cohesion of

D4120 Test Method for Fiber Cohesion in Roving, Sliver,

the fibers in the specimen and is reported in micronewtons/tex

and Top in Dynamic Tests

(gf/denier).

D4848 Terminology Related to Force, Deformation and

5. Significance and Use

5.1 Fiber cohesion is related to the resistance to drafting

This test method is under the jurisdiction ofASTM Committee D13 on Textiles

and is the direct responsibility of Subcommittee D13.58 on Yarns and Fibers.

encountered during textile processing and is affected by such

Current edition approved Sept. 1, 2018. Published September 2018. Originally

fiber properties as surface lubrication, linear density, surface

approved in 1967. Last previous edition approved in 2011 as D2612–99 (2011).

configuration, fiber length, and crimp.

DOI: 10.1520/D2612-99R18.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.2 Fiber cohesion is affected by the alignment of fiber in

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

sliver in addition to the factors listed in 5.1.Ahalf turn of twist

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. in a 140-mm specimen has been found to increase the breaking

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

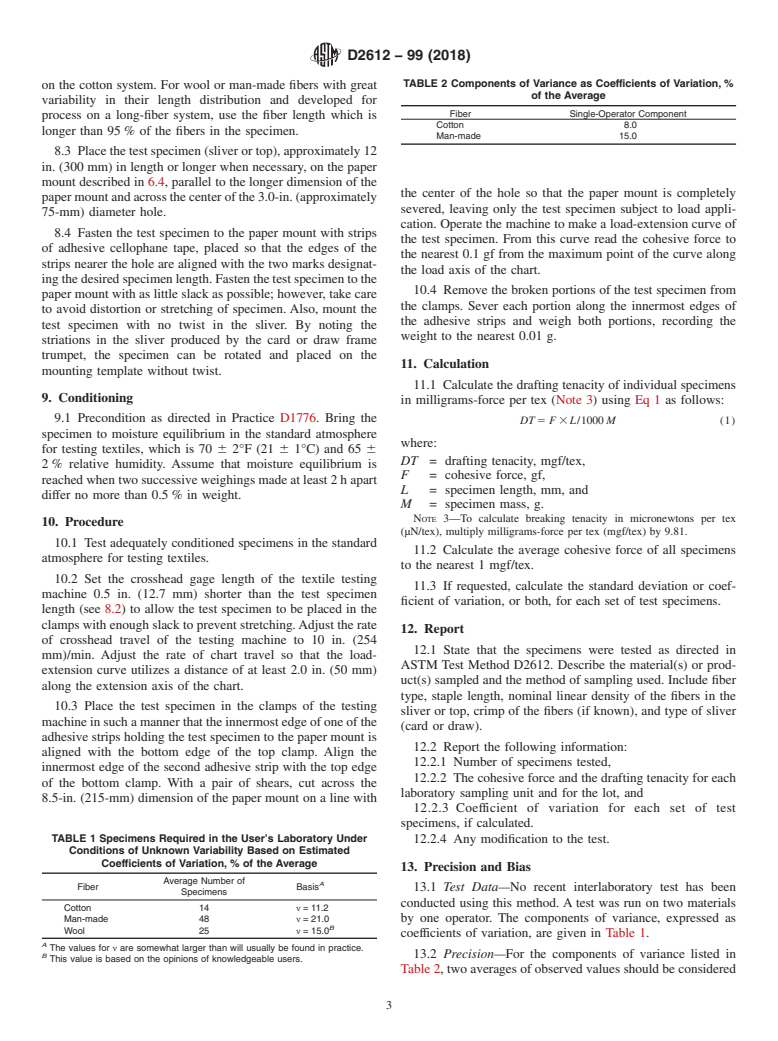

D2612 − 99 (2018)

force by 30 % and a full turn by 60 %. For this reason, care diameter hole cut in the center is used as a mounting board.

must be exercised in precise mounting of specimens. Two gage reference lines, separated by a distance equal to the

desired specimen length, are drawn across the short dimension

5.3 For the same reason given in 5.2, card sliver gives a

of the paper. The hole is centered between the two reference

different breaking tenacity than draw sliver of the same fiber.

gage lines.

Fibers are more aligned in draw sliver, resulting in lower

cohesion. 6.5 Tape, cellophane adhesive or masking type, 13-mm

(0.5-in.) wide.

5.4 Increasing the gage length of test specimens reduces the

breaking force and apparent cohesion.

7. Sampling

5.5 The mathematical relationship between the observed

7.1 Lot Sampling—As a lot sample for acceptance testing,

value for breaking tenacity and processability has not been

take at random the number of shipping containers directed in

established, but the observed values can be used in comparing

the applicable material specification or other agreement be-

various fiber characteristics on a relative basis.

tween the purchaser and supplier, such as an agreement to use

5.6 This method for measuring fiber cohesion in sliver or Practice D3333 or Practice D2258. Consider shipping contain-

top (static tests) is not recommended for acceptance testing

ers to be the primary sampling units.

because it is an empirical method which must be followed

NOTE 2—An adequate specification or other agreement between the

explicitly. Results obtained under other conditions cannot be

purchaser or supplier requires taking into account the variability between

expected to be comparable.

shipping units, between packages, ends or other laboratory sampling unit

5.6.1 In some cases, the purchaser and the supplier may within a shipping unit if applicable, and within specimens from a single

package, end or other laboratory sampling unit to provide a sampling plan

have to test a commercial shipment of one or more specific

with a meaningful producer’s risk, consumer’s risk, acceptable quality

materials by the best available method, even though the

level, and limiting quantity level.

method has not been recommended for acceptance testing of

7.2 Laboratory Sample—As a laboratory sample for accep-

commercial shipments. In case of dispute arising from differ-

tance testing, take at random from each shipping container in

ences in reported test results when using this test method for

the lot sample the number of laboratory sampling units as

acceptance testing of commercial shipments, the purchaser and

directed in an applicable material specification or other agree-

supplier should conduct comparative tests to determine if there

ment between purchaser and supplier such as an agreement to

is a statistical bias between their laboratories. Competent

use Practice D3333 or Practice D2258. Preferably, the same

statistical assistance is recommended for the investigation of

number of laboratory sampling units are taken from each

bias.As a minimum, the two parties should take a group of test

shipping container in the lot sample. If differing numbers of

specimens, which are as homogeneous as possible and which

laboratory sampling units are to be taken from shipping

are from a lot of material of the type in question. Test

containers in the lot sample, determine at random which

specimens then should be randomly assigned in equal numbers

shippingcontainersaretohaveeachnumberoflaboratoryunits

to each laboratory for testing.The average results from the two

drawn.

laboratories should be compared using appropriate statistical

7.2.1 Eachlaboratorysamplingunitshouldbeatleast100m

analysis and a probability level chosen by the two parties prior

(100 yd) long.

to testing. If a bias is found, either its cause must be found and

corrected or the purchaser and the supplier must agree to 7.3 Test Specimens—From each laboratory sampling unit,

interpret future test results with consideration to the known

take one specimen. If the standard deviation determined for the

bias. laboratory sample is more than a value agreed upon between

the purchaser and supplier, continue testing one specimen from

6. Apparatus and Material each unit in the laboratory sample until the standard deviation

for all specimens tested is not more than the agreed to value or,

6.1 Tensile Testing Machine, a constant-rate-of-specimen-

by agreement

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.