ASTM D3462/D3462M-10a

(Specification)Standard Specification for Asphalt Shingles Made from Glass Felt and Surfaced with Mineral Granules

Standard Specification for Asphalt Shingles Made from Glass Felt and Surfaced with Mineral Granules

ABSTRACT

This specification deals with the standards for asphalt roofing in shingle form, composed of glass felt or felts impregnated and coated on both sides with asphalt, and surface on the weather side with minerals. Physical requirements of the shingles such as behavior on melting, tear strength, wind resistance, fire resistance, softening point, and pliability shall be measured immediately after packaging or at a reasonable time. Physical and performance requirements after application and during in-service use are however beyond the scope of this specification.

SCOPE

1.1 This specification covers asphalt roofing in shingle form, composed of glass felt or felts impregnated and coated on both sides with asphalt, and surfaced on the weather side with mineral granules. This specification is designed for the evaluation of products as manufactured. The test methods, physical requirements, and minimum masses are to be measured immediately after packaging or at a reasonable time, as agreed upon between buyer and seller, after manufacture and before installation. Physical and performance requirements after application and during in-service use of the products described herein are beyond the scope of this material specification.

1.2 Shingles meeting this specification are intended to be applied with a headlap of not less than 51 mm (2 in.).

1.3 The shingles shall be supplied with a factory-applied self-sealing adhesive or be designed to be locked together during installation of the shingles.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.5 The following safety hazards caveat pertains only to the test method described in this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3462/D3462M −10a

StandardSpecification for

Asphalt Shingles Made from Glass Felt and Surfaced with

1

Mineral Granules

This standard is issued under the fixed designation D3462/D3462M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 This specification covers asphalt roofing in shingle 2.1 ASTM Standards:

form, composed of glass felt or felts impregnated and coated D5 Test Method for Penetration of Bituminous Materials

on both sides with asphalt, and surfaced on the weather side D36 Test Method for Softening Point of Bitumen (Ring-and-

with mineral granules. This specification is designed for the Ball Apparatus)

evaluation of products as manufactured. The test methods, D228 Test Methods for Sampling, Testing, and Analysis of

physical requirements, and minimum masses are to be mea- Asphalt Roll Roofing, Cap Sheets, and Shingles Used in

sured immediately after packaging or at a reasonable time, as Roofing and Waterproofing

agreed upon between buyer and seller, after manufacture and D1079 Terminology Relating to Roofing and Waterproofing

before installation. Physical and performance requirements D1922 Test Method for Propagation Tear Resistance of

after application and during in-service use of the products Plastic Film and Thin Sheeting by Pendulum Method

described herein are beyond the scope of this material speci- D3161 Test Method for Wind-Resistance of Asphalt

fication. Shingles (Fan-Induced Method)

D4977 Test Method for Granule Adhesion to Mineral Sur-

1.2 Shingles meeting this specification are intended to be

faced Roofing by Abrasion

applied with a headlap of not less than 51 mm (2 in.).

E108 Test Methods for Fire Tests of Roof Coverings

1.3 The shingles shall be supplied with a factory-applied

3. Terminology

self-sealing adhesive or be designed to be locked together

during installation of the shingles.

3.1 Definitions:

1.4 The values stated in either SI units or inch-pound units 3.1.1 For definitions of terms, see Terminology D1079.

3.1.2 For testing purposes, under Test Methods D228, glass

are to be regarded separately as standard. The values stated in

each system may not be exact equivalents; therefore, each felt shall be considered as felt.

system shall be used independently of the other. Combining

4. Materials and Manufacture

values from the two systems may result in non-conformance

4.1 The glass felt shall be a thin porous sheet composed

with the standard.

predominately of fine glass fibers uniformly deposited in a

1.5 The following safety hazards caveat pertains only to the

nonwoven pattern. It is permitted to reinforce the glass felt

test method described in this specification: This standard does

withrandomorparallel-orientedglassyarns,orboth,whichare

not purport to address all of the safety concerns, if any,

permitted to be gathered or twisted, bonded or unbonded. The

associated with its use. It is the responsibility of the user of this

felt shall contain a substantially water-insoluble binding agent.

standard to establish appropriate safety and health practices

and determine the applicability of regulatory limitations prior 4.2 In the process of manufacture, one or more thicknesses

to use. of glass felt shall be impregnated with an asphaltic material.

When more than one thickness of felt is used, the mats shall be

adhered to each other with a continuous layer of asphaltic

1

This specification is under the jurisdiction of ASTM Committee D08 on

Roofing and Waterproofing and is the direct responsibility of Subcommittee D08.02

2

on Steep Roofing Products and Assemblies. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved July 1, 2010. Published July 2010. Originally approved contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in 1983. Last previous edition approved in 2010 as D3462 – 10. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

D3462_D3462M-10A. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3462/D3462M−10a

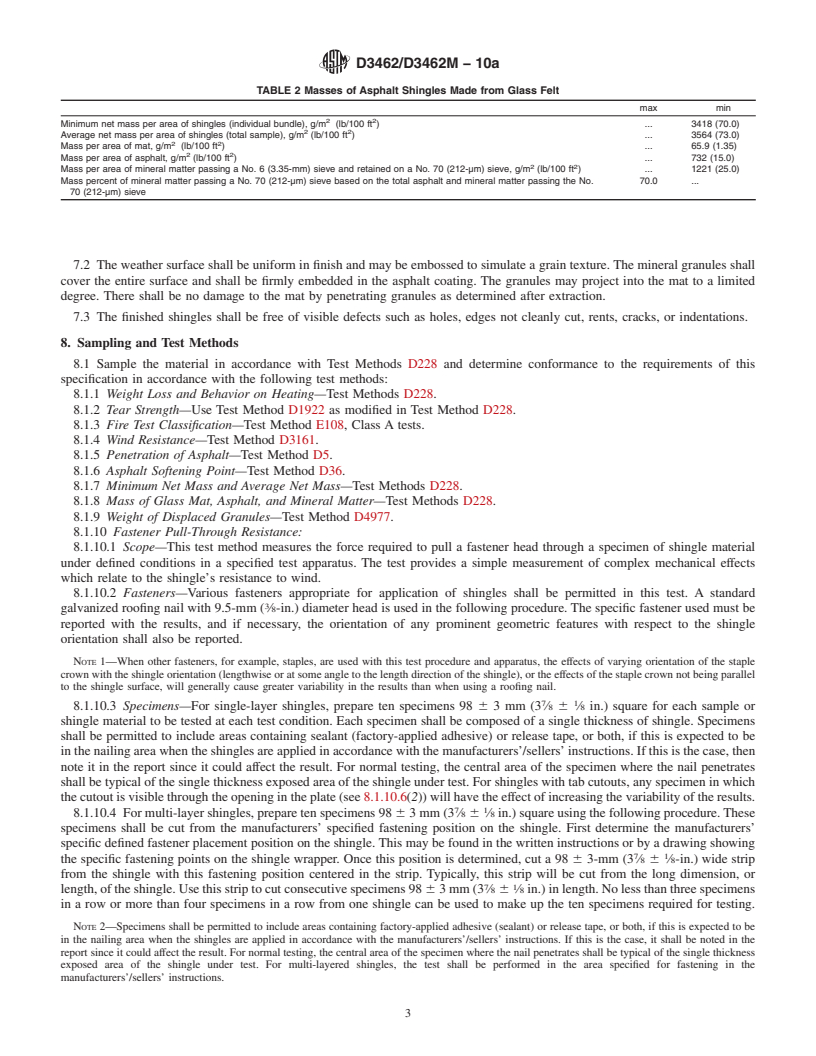

material between adjacent felts. The nature of the asphaltic 6. Dimensions, Masses, and Permissible Variations

material and the thickness of the adhering layers shall ensure a

6.1 The form and size of the shingles shall be as agreed

firm bond between adjacent glass felts. The single felt or

upon by the purchaser and seller.

laminated felts shall then be coated on both sides with a hot

6.2 The sh

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D3462/D3462M − 10a D3462/D3462M − 10a

Standard Specification for

Asphalt Shingles Made from Glass Felt and Surfaced with

1

Mineral Granules

This standard is issued under the fixed designation D3462/D3462M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers asphalt roofing in shingle form, composed of glass felt or felts impregnated and coated on both

sides with asphalt, and surfaced on the weather side with mineral granules. This specification is designed for the evaluation of

products as manufactured. The test methods, physical requirements, and minimum masses are to be measured immediately after

packaging or at a reasonable time, as agreed upon between buyer and seller, after manufacture and before installation. Physical

and performance requirements after application and during in-service use of the products described herein are beyond the scope

of this material specification.

1.2 Shingles meeting this specification are intended to be applied with a headlap of not less than 51 mm (2 in.).

1.3 The shingles shall be supplied with a factory-applied self-sealing adhesive or be designed to be locked together during

installation of the shingles.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.5 The following safety hazards caveat pertains only to the test method described in this specification:This standard does not

purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to

establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D5 Test Method for Penetration of Bituminous Materials

D36 Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus)

D228 Test Methods for Sampling, Testing, and Analysis of Asphalt Roll Roofing, Cap Sheets, and Shingles Used in Roofing and

Waterproofing

D1079 Terminology Relating to Roofing and Waterproofing

D1922 Test Method for Propagation Tear Resistance of Plastic Film and Thin Sheeting by Pendulum Method

D3161 Test Method for Wind-Resistance of Asphalt Shingles (Fan-Induced Method)

D4977 Test Method for Granule Adhesion to Mineral Surfaced Roofing by Abrasion

E108 Test Methods for Fire Tests of Roof Coverings

3. Terminology

3.1 Definitions:

3.1.1 For definitions of terms, see Terminology D1079.

3.1.2 For testing purposes, under Test Methods D228, glass felt shall be considered as felt.

1

This specification is under the jurisdiction of ASTM Committee D08 on Roofing and Waterproofing and is the direct responsibility of Subcommittee D08.02 on Steep

Roofing Products and Assemblies.

Current edition approved July 1, 2010. Published July 2010. Originally approved in 1983. Last previous edition approved in 2010 as D3462 – 10. DOI:

10.1520/D3462_D3462M-10A.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3462/D3462M − 10a

4. Materials and Manufacture

4.1 The glass felt shall be a thin porous sheet composed predominately of fine glass fibers uniformly deposited in a nonwoven

pattern. It is permitted to reinforce the glass felt with random or parallel-oriented glass yarns, or both, which are permitted to be

gathered or twisted, bonded or unbonded. The felt shall contain a substantially water-insoluble binding agent.

4.2 In the process of manufacture, one or more thicknesses of glass felt shall be impregnated with an asphaltic material. When

more than one thickness of felt is used, the mats shall be adhered to each other with a continuous layer of asphaltic material

between adjacent felts. The nature of the asphaltic material and the thickness of the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.