ASTM D5830-95(2001)

(Test Method)Standard Test Method for Solvents Analysis in Hazardous Waste Using Gas Chromatography

Standard Test Method for Solvents Analysis in Hazardous Waste Using Gas Chromatography

SCOPE

1.1 This test method is used to determine qualitatively and quantitatively the presence of the following compounds in waste samples using gas chromatography. This test method is designed for use as a screening method with a typical reporting level of 0.1 %.DichodifluoromethaneTetrahydrofuranTrichlorofluoromethaneAcetone1,1,2-Trichloro-1,2,2-Methyl Ethyl KetonetrifluoroethaneMIBKMethanolCyclohexanoneEthanol Ethyl AcetateIsopropanolPropyl Acetaten-PropanolButyl AcetateIsobutanolBenzenen-ButanolToluenetert-ButanolEthylbenzeneMethylene ChlorideXylenesChloroformStyreneCarbon TetrachlorideChlorobenzene1,1-DichloroethaneDichlorobenzenes1,2-DichloroethaneNitrobenzene1,2-DichloropropaneFluorobenzene1,1-Dichloroethylenen-Propyl Benzene>1,2-DichloroetheneIsopropyl Benzene1,1,1-TrichloroethaneIsobutyl BenzeneTetrachloroethylenen-Butyl BenzeneTrichloroethylene2-EthoxyethanolTetrachloroethane2-ButoxyethanolCyclopentane2-Ethoxyethanol AcetatePentane 2-MethoxyethanolHexane BromoformHeptane CarbitolCyclohexaneEthyl EtherIsooctane1,4-DioxaneNitropropaneDiacetone AlcoholEthanolamineAcetonitrileNitromethanePyridineEthylene ChlorideToluidineBenzyl ChlorideEthylene Glycol Propylene Glycol

1.1.1 This compound list is a compilation of hazardous solvents and other constituents that are routinely seen in hazardous waste samples.

1.2 The scope of this test method may be expanded to include other volatile and semivolatile organic constituents.

1.2.1 Hydrocarbon mixtures such as kerosene and mineral spirits.

1.2.2 High-boiling organics, defined here as compounds which boil above n-Hexadecane.

1.2.3 Other organics that the analyst is able to identify, either through retention time data or gas chromatography/mass spectrometric (GC/MS) analysis.

1.3 Gas chromatographic methods are recommended for use only by, or under close supervision of, an experienced analyst.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5830–95 (Reapproved 2001)

Standard Test Method for

Solvents Analysis in Hazardous Waste Using Gas

Chromatography

This standard is issued under the fixed designation D 5830; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 1.2 The scope of this test method may be expanded to

include other volatile and semivolatile organic constituents.

1.1 This test method is used to determine qualitatively and

1.2.1 Hydrocarbon mixtures such as kerosene and mineral

quantitatively the presence of the following compounds in

spirits.

waste samples using gas chromatography. This test method is

1.2.2 High-boiling organics, defined here as compounds

designed for use as a screening method with a typical reporting

which boil above n-Hexadecane.

level of 0.1 %.

1.2.3 Other organics that the analyst is able to identify,

Dichodifluoromethane Tetrahydrofuran

either through retention time data or gas chromatography/mass

Trichlorofluoromethane Acetone

1,1,2-Trichloro-1,2,2- Methyl Ethyl Ketone

spectrometric (GC/MS) analysis.

trifluoroethane MIBK

1.3 Gaschromatographicmethodsarerecommendedforuse

Methanol Cyclohexanone

only by, or under close supervision of, an experienced analyst.

Ethanol Ethyl Acetate

Isopropanol Propyl Acetate

1.4 This standard does not purport to address all of the

n-Propanol Butyl Acetate

safety concerns, if any, associated with its use. It is the

Isobutanol Benzene

responsibility of the user of this standard to establish appro-

n-Butanol Toluene

tert-Butanol Ethylbenzene

priate safety and health practices and determine the applica-

Methylene Chloride Xylenes

bility of regulatory limitations prior to use.

Chloroform Styrene

Carbon Tetrachloride Chlorobenzene

2. Referenced Documents

1,1-Dichloroethane Dichlorobenzenes

1,2-Dichloroethane Nitrobenzene

2.1 ASTM Standards:

1,2-Dichloropropane Fluorobenzene

1,1-Dichloroethylene n-Propyl Benzene D 1193 Specification for Reagent Water

1,2-Dichloroethene Isopropyl Benzene

2.2 EPA Document:

1,1,1-Trichloroethane Isobutyl Benzene

Gas Chromatography/Mass Spectrometry Method 8260,

Tetrachloroethylene n-Butyl Benzene

Test Methods for Evaluating Solid Waste Physical/

Trichloroethylene 2-Ethoxyethanol

Tetrachloroethane 2-Butoxyethanol

Chemical Methods, SW-846, Third Edition, Final Update

Cyclopentane 2-Ethoxyethanol Acetate

1, July 1992

Pentane 2-Methoxyethanol

Hexane Bromoform

3. Summary of Test Method

Heptane Carbitol

Cyclohexane Ethyl Ether

3.1 Waste samples are analyzed by direct injection, or by

Isooctane 1,4-Dioxane

carbon disulfide, M-Pyrol, or other suitable solvent extraction

Nitropropane Diacetone Alcohol

Ethanolamine Acetonitrile

and injection of the extract into a gas chromatograph. Detec-

Nitromethane Pyridine

tion is achieved using a detector which is specific for the

Ethylene Chloride Toluidine

Benzyl Chloride Ethylene Glycol needed application, for example, flame ionization detector

Propylene Glycol

(FID), electron capture detector (ECD), thermal conductivity

1.1.1 This compound list is a compilation of hazardous

solvents and other constituents that are routinely seen in

hazardous waste samples.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

This test method is under the jurisdiction of ASTM Committee D34 on Waste Standards volume information, refer to the standard’s Document Summary page on

Management and is the direct responsibility of Subcommittee D34.01.06 on the ASTM website.

Analytical Methods. Available from the Superintendent of Documents, U.S. Government Printing

Current edition approved Sept. 10, 1995. Published November 1995. Office, Washington, DC 20402.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5830–95 (2001)

detector (TCD), photoionization detector (PID), or mass selec- 5.1.2 Use of confirmation column, or confirmatory detector;

tive detector (MSD). This test method may be expanded to

5.1.3 Use of varying temperature programs or standard

utilize other detector types not previously mentioned.

comparison, or both;

5.1.4 Sample history, for example, any information avail-

4. Significance and Use

able from the waste generator; and,

4.1 This test method is useful in identifying the major

5.1.5 Physical characteristics, for example, flammability,

solvent constituents in hazardous waste samples. This test

specific gravity, or miscibility with water.

method is designed to support field or site assessments,

5.2 Interferences may also be encountered from syringe

recycling operations, plant operations, or pollution control

carryover. Immediately following each injection, the syringe

programs.

should be thoroughly rinsed with carbon disulfide, or M-Pyrol.

5. Interferences Other solvents such as methanol may be used as rinse solvents

if sample types necessitate their use, but be aware that

5.1 Interferences may be encountered from any number of

carryover and possible interferences may occur if the rinse

organic compounds that respond in the detector. Also, closely

solvent is not completely cleaned from the syringe before

eluting components may complicate identification based solely

reuse. Before each injection the syringe must be thoroughly

on retention time. When these types of interferences are

rinsed with the sample to be injected, where the first two

encountered, the analyst must rely on other sources of infor-

pumps are flushed into a separate waste receptacle.

mation for positive identification, such as:

5.1.1 Gas chromatography/mass spectrometric (GC/MS) 5.3 When carbon disulfide (CS ) is used to extract solids or

sludges that contain significant amounts of water, low recovery

confirmation, see EPA Method 8260, direct injection tech-

nique; of the water miscible solvents may result.

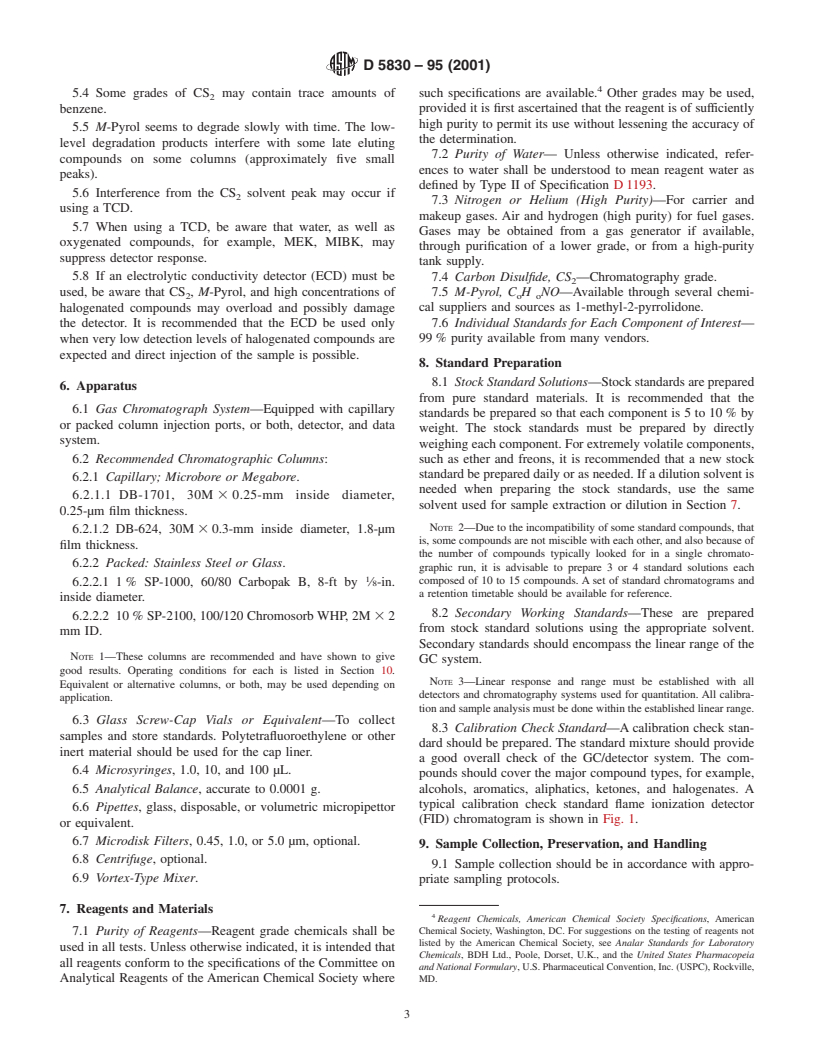

FIG. 1 Daily QC Standard FID/DB-1701

D5830–95 (2001)

5.4 Some grades of CS may contain trace amounts of such specifications are available. Other grades may be used,

benzene. provided it is first ascertained that the reagent is of sufficiently

high purity to permit its use without lessening the accuracy of

5.5 M-Pyrol seems to degrade slowly with time. The low-

the determination.

level degradation products interfere with some late eluting

7.2 Purity of Water— Unless otherwise indicated, refer-

compounds on some columns (approximately five small

ences to water shall be understood to mean reagent water as

peaks).

defined by Type II of Specification D 1193.

5.6 Interference from the CS solvent peak may occur if

7.3 Nitrogen or Helium (High Purity)—For carrier and

using a TCD.

makeup gases. Air and hydrogen (high purity) for fuel gases.

5.7 When using a TCD, be aware that water, as well as

Gases may be obtained from a gas generator if available,

oxygenated compounds, for example, MEK, MIBK, may

through purification of a lower grade, or from a high-purity

suppress detector response.

tank supply.

5.8 If an electrolytic conductivity detector (ECD) must be 7.4 Carbon Disulfide, CS —Chromatography grade.

used, be aware that CS , M-Pyrol, and high concentrations of 7.5 M-Pyrol, C H NO—Available through several chemi-

2 o o

halogenated compounds may overload and possibly damage cal suppliers and sources as 1-methyl-2-pyrrolidone.

7.6 Individual Standards for Each Component of Interest—

the detector. It is recommended that the ECD be used only

99 % purity available from many vendors.

when very low detection levels of halogenated compounds are

expected and direct injection of the sample is possible.

8. Standard Preparation

8.1 Stock Standard Solutions—Stock standards are prepared

6. Apparatus

from pure standard materials. It is recommended that the

6.1 Gas Chromatograph System—Equipped with capillary

standards be prepared so that each component is 5 to 10 % by

or packed column injection ports, or both, detector, and data

weight. The stock standards must be prepared by directly

system.

weighing each component. For extremely volatile components,

6.2 Recommended Chromatographic Columns:

such as ether and freons, it is recommended that a new stock

standard be prepared daily or as needed. If a dilution solvent is

6.2.1 Capillary; Microbore or Megabore.

needed when preparing the stock standards, use the same

6.2.1.1 DB-1701, 30M 3 0.25-mm inside diameter,

solvent used for sample extraction or dilution in Section 7.

0.25-µm film thickness.

NOTE 2—Due to the incompatibility of some standard compounds, that

6.2.1.2 DB-624, 30M 3 0.3-mm inside diameter, 1.8-µm

is, some compounds are not miscible with each other, and also because of

film thickness.

the number of compounds typically looked for in a single chromato-

6.2.2 Packed: Stainless Steel or Glass.

graphic run, it is advisable to prepare 3 or 4 standard solutions each

composed of 10 to 15 compounds. A set of standard chromatograms and

6.2.2.1 1 % SP-1000, 60/80 Carbopak B, 8-ft by ⁄8-in.

a retention timetable should be available for reference.

inside diameter.

8.2 Secondary Working Standards—These are prepared

6.2.2.2 10 % SP-2100, 100/120 Chromosorb WHP, 2M 3 2

from stock standard solutions using the appropriate solvent.

mm ID.

Secondary standards should encompass the linear range of the

NOTE 1—These columns are recommended and have shown to give

GC system.

good results. Operating conditions for each is listed in Section 10.

NOTE 3—Linear response and range must be established with all

Equivalent or alternative columns, or both, may be used depending on

detectors and chromatography systems used for quantitation. All calibra-

application.

tion and sample analysis must be done within the established linear range.

6.3 Glass Screw-Cap Vials or Equivalent—To collect

8.3 Calibration Check Standard—A calibration check stan-

samples and store standards. Polytetrafluoroethylene or other

dard should be prepared. The standard mixture should provide

inert material should be used for the cap liner.

a good overall check of the GC/detector system. The com-

6.4 Microsyringes, 1.0, 10, and 100 µL.

pounds should cover the major compound types, for example,

6.5 Analytical Balance, accurate to 0.0001 g. alcohols, aromatics, aliphatics, ketones, and halogenates. A

typical calibration check standard flame ionization detector

6.6 Pipettes, glass, disposable, or volumetric micropipettor

(FID) chromatogram is shown in Fig. 1.

or equivalent.

6.7 Microdisk Filters, 0.45, 1.0, or 5.0 µm, optional.

9. Sample Collection, Preservation, and Handling

6.8 Centrifuge, optional.

9.1 Sample collection should be in accordance with appro-

6.9 Vortex-Type Mixer.

priate sampling protocols.

7. Reagents and Materials

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

7.1 Purity of Reagents—Reagent grade chemicals shall be

listed by the American Chemical Society, see Analar Standards for Laboratory

used in all tests. Unless otherwise indicated, it is intended that

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

all reagents conform to the specifications of the Committee on

and National Formulary, U.S. Pharmaceutical Convention, Inc. (USPC), Rockville,

Analytical Reagents of the American Chemical Society where MD.

D5830–95 (2001)

9.2 Samples should be collected in glass containers, that

Column flow rate 3.5 mL/min

Make-up gas flow 29 mL/min

have tightly sealing caps. If very volatile organics are of

Airflow (FID) Approximately 300 mL/min

particular interest, the headspace in the container should be

Hydrogen flow (FID) Approximately 30 mL/min

kept to a minimum.

Injector temperature 275°C

Detector temperature 275°C

9.3 Sample Transfer Implements—Implements are required

Initial oven temperature 35°C

to transfer portions of waste samples from the sample contain-

Initial time 5 min

Level 1 rate 5°C/min

ers to the laboratory containers. Liquid samples may be

Level 1 final value 150°C

transferred using disposable pipets. Solids and semisolids may

Level 1 hold time 4 min

be transferred using a conventional laboratory spatula.

Level 2 rate 20°C/min

Level 2 final value 225°C

9.4 Samples shall be handled maintaining safe laboratory

Run time 45 min

practices.Any samples with special hazards must be appropri-

ately labeled.

10.2.3 For Packed SP-1000 with FID

9.5 Unused sample material, laboratory dilutions, and waste Column flow rate 40 mL/min

Air pressure (FID) 300 kPa

from the samples may be regulated. Consult your specialist or

Hydrogen pressure (FID) 130 kPa

the regulations, or both, for guidance in the proper handling

Injector temperature 250°C

and disposal of laboratory wastes. Detector temperature 250°C

Initial oven temperature 90°C

Initial time 6 min

10. Procedure

Level 1 rate 3°C/min

Level 1 final value 120°C

10.1 Sample Preparation:

Level 2 rate 5°C/min

Level 2 final value 180°C

10.1.1 Analyze liquid matrices with relatively low viscosity

Level 3 rate 10°C/min

using direct injection into the GC, either as received or after

Level 3 final value 230°C

dilution with CS , M-Pyrol, or other suitable solvent.

2 Run time 46 min

10.1.2 Analyze solid or semisolid samples as follows:

10.2.4 For packed SP-2100 with FID

10.1.2.1 For carbon disulfide or M-Pyrol preparation, weigh

Carrier gas flow 30 mL/min

3 g of the waste sample in a 15-mL glass vial. Add3gof

Injector temperatuare 250°C

carbon disulfide or M-Pyrol to the vial and the mixture is

Detector temperature 300°C

Airflow (FID) Approximately 300 mL/min

vortexed vigorously. After allowing the solids to settle, inject

Hydrogen flow (FID) Approximately 30 mL/min

the CS or M-Pyrol extract into the GC.

2 Initial oven temperature 45°C

Initial hold time 3 min

10.1.2.2 Use alternate sample sizes and extraction solvent

Level 1 rate 15°C/min

weights if necessary. Actual sample size and solvent weight

Level 1 final value 90°C

must be recorded in the appropriate sample preparation log

Level 2 rate 10°C/min

Level 2 final value 195°C

book. It is essential for accurate waste sample analysis that

Run time 16.5 min

sample size be sufficient to ensure a representative sample. If

alternate sample size or extraction solvent volumes, or both,

10.3 Linear Range Determination—The linearity and linear

are used, this must be reflected in the calculations under the

range for each compound must be established on any GC

dilution factor in Section 11.

system used for quantitation. This must be done on an an

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.