ASTM D6415/D6415M-06

(Test Method)Standard Test Method for Measuring the Curved Beam Strength of a Fiber-Reinforced Polymer-Matrix Composite

Standard Test Method for Measuring the Curved Beam Strength of a Fiber-Reinforced Polymer-Matrix Composite

SCOPE

1.1 This test method determines the curved beam strength of a continuous fiber-reinforced composite material using a 90 curved beam specimen (Fig 1 and Fig 2). The curved beam consists of two straight legs connected by a 90 bend with a 6.4-mm [0.25 mm] inner radius. An out-of-plane (through-the-thickness) tensile stress is produced in the curved region of the specimen when force is applied. This test method is limited to use with composites consisting of layers of fabric or layers of unidirectional fibers.

1.2 This test method may also be used to measure the interlaminar tensile strength if a unidirectional specimen is used where the fibers run continuously along the legs and around the bend.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text the inch-pound units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6415/D6415M–06

Standard Test Method for

Measuring the Curved Beam Strength of a Fiber-Reinforced

1

Polymer-Matrix Composite

This standard is issued under the fixed designation D 6415/D 6415M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

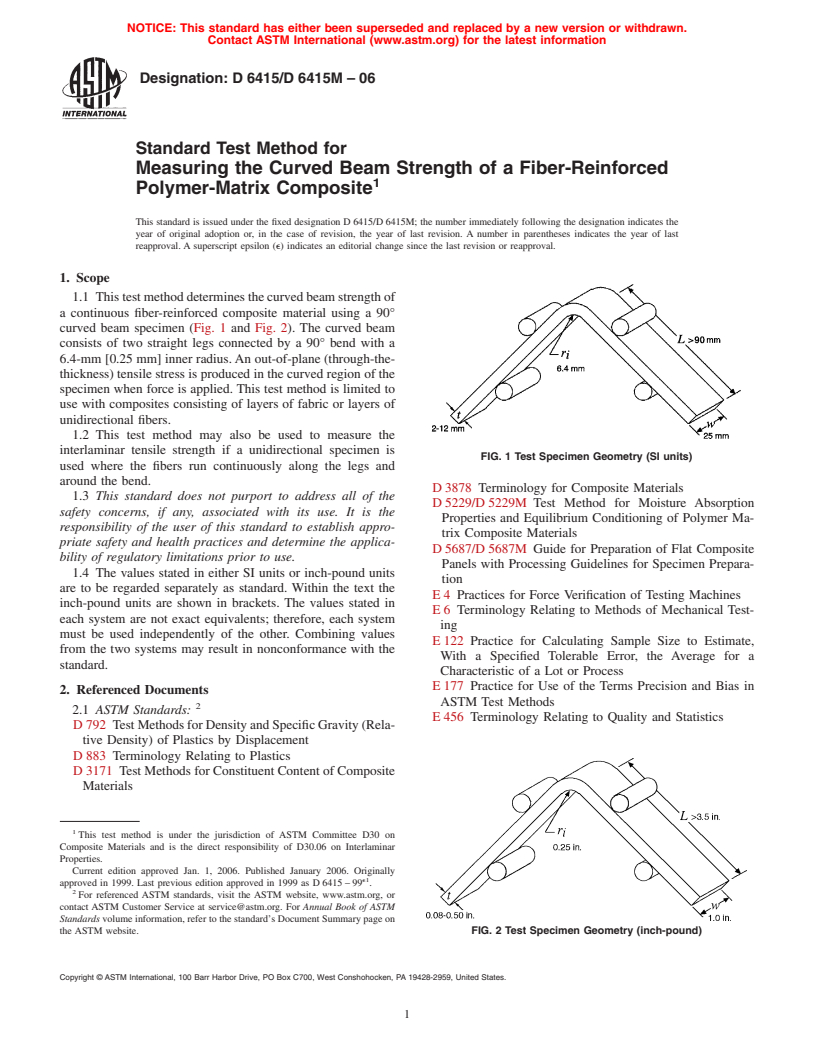

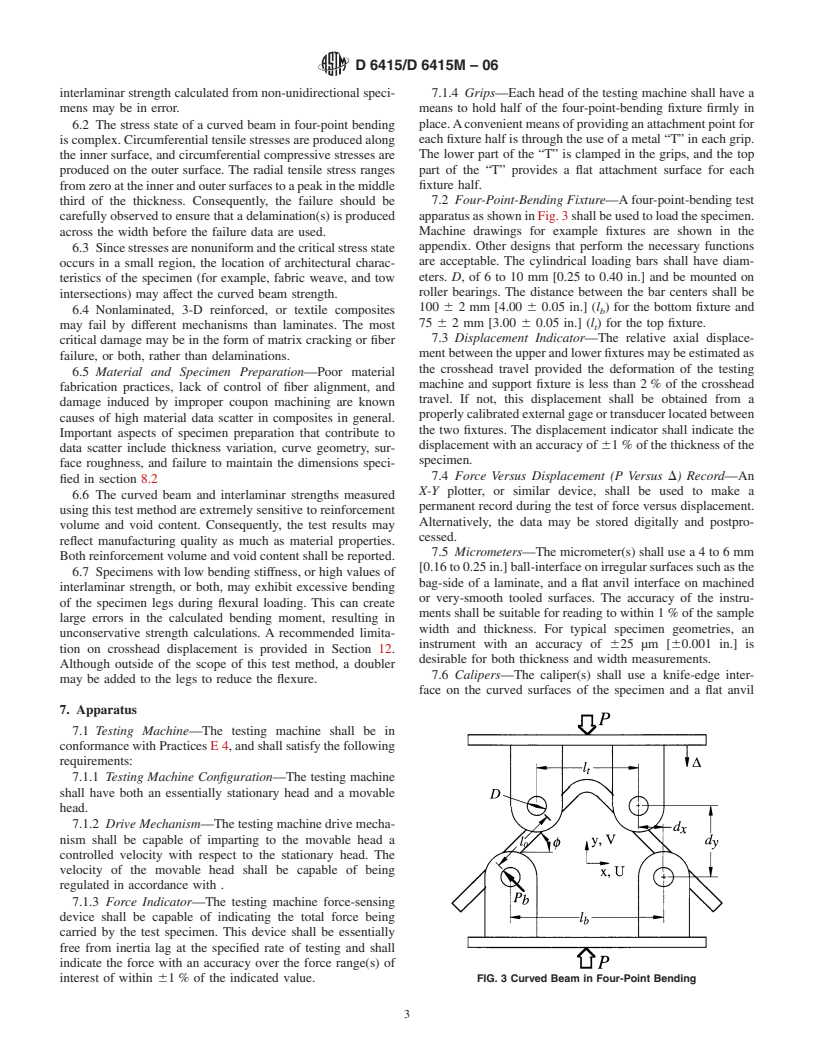

1.1 Thistestmethoddeterminesthecurvedbeamstrengthof

a continuous fiber-reinforced composite material using a 90°

curved beam specimen (Fig. 1 and Fig. 2). The curved beam

consists of two straight legs connected by a 90° bend with a

6.4-mm [0.25 mm] inner radius.An out-of-plane (through-the-

thickness) tensile stress is produced in the curved region of the

specimen when force is applied. This test method is limited to

use with composites consisting of layers of fabric or layers of

unidirectional fibers.

1.2 This test method may also be used to measure the

interlaminar tensile strength if a unidirectional specimen is

FIG. 1 Test Specimen Geometry (SI units)

used where the fibers run continuously along the legs and

around the bend.

D 3878 Terminology for Composite Materials

1.3 This standard does not purport to address all of the

D 5229/D 5229M Test Method for Moisture Absorption

safety concerns, if any, associated with its use. It is the

Properties and Equilibrium Conditioning of Polymer Ma-

responsibility of the user of this standard to establish appro-

trix Composite Materials

priate safety and health practices and determine the applica-

D 5687/D 5687M Guide for Preparation of Flat Composite

bility of regulatory limitations prior to use.

Panels with Processing Guidelines for Specimen Prepara-

1.4 The values stated in either SI units or inch-pound units

tion

are to be regarded separately as standard. Within the text the

E4 Practices for Force Verification of Testing Machines

inch-pound units are shown in brackets. The values stated in

E6 Terminology Relating to Methods of Mechanical Test-

each system are not exact equivalents; therefore, each system

ing

must be used independently of the other. Combining values

E 122 Practice for Calculating Sample Size to Estimate,

from the two systems may result in nonconformance with the

With a Specified Tolerable Error, the Average for a

standard.

Characteristic of a Lot or Process

E 177 Practice for Use of the Terms Precision and Bias in

2. Referenced Documents

ASTM Test Methods

2

2.1 ASTM Standards:

E 456 Terminology Relating to Quality and Statistics

D 792 TestMethodsforDensityandSpecificGravity(Rela-

tive Density) of Plastics by Displacement

D 883 Terminology Relating to Plastics

D 3171 Test Methods for Constituent Content of Composite

Materials

1

This test method is under the jurisdiction of ASTM Committee D30 on

Composite Materials and is the direct responsibility of D30.06 on Interlaminar

Properties.

Current edition approved Jan. 1, 2006. Published January 2006. Originally

e1

approved in 1999. Last previous edition approved in 1999 as D 6415 – 99 .

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. FIG. 2 Test Specimen Geometry (inch-pound)

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D6415/D6415M–06

E 1309 Guide for Identification of Fiber-Reinforced 3.3.15 r, u = cylindrical coordinates of any point in the

Polymer-Matrix Composite Materials in Databases curved segment.

E 1434 GuideforRecordingMechanicalTestDataofFiber- 3.3.16 r,r = inner and outer radii of curved segment.

i o

Reinforced Composite Materials in Databases 3.3.17 r = radial position of the maximum interlaminar

m

(radial) tensile stress.

E 1471 Guide for Identification of Fibers, Fillers, and Core

Materials in Computerized Material Property Databases 3.3.18 S = standard deviation statistic of a sample popu-

n–1

lation for a given property.

3.3.19 t = average thickness of specimen.

3. Terminology

3.3.20 w = width of the specimen.

3.1 Definitions—TerminologyD 3878definestermsrelating

3.3.21 x = test result for an individual specimen from the

1

to high-modulus fibers and their composites. Terminology

sample population for a given property.

D 883 defines terms relating to plastics. Terminology E6

–

3.3.22 x = mean or average (estimate of mean) of a sample

defines terms relating to mechanical testing. Terminology

population for a given property.

E 456 and Practice E 177 define terms relating to statistics. In

3.3.23 D = relative disp

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.