ASTM D6415-99e1

(Test Method)Standard Test Method for Measuring the Curved Beam Stength of a Fiber-Reinforced Polymer-Matrix Composite

Standard Test Method for Measuring the Curved Beam Stength of a Fiber-Reinforced Polymer-Matrix Composite

SCOPE

1.1 This test method determines the curved beam strength of a continous fiber-reinforced composite material using a 90o curved beam specimen (Fig. 1). The curved beam consists of two straight legs connected by a 90o bend with a 6.4-mm inner radius. An out-of-plane (through-the-thickness) tensile stress is produced in the curved region of the specimen when load is applied. This test method is limited to use with composites consisting of layers of fabric or layers of unidirectional fibers.

1.2 This test method may also be used to measure the interlaminar tensile strength if a unidirectional specimen is used where the fibers run continuously along the legs and around the bend.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 The values stated in SI units are to be regarded standard. The values given in parentheses are provided for information purposes only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation:D6415–99

Standard Test Method for

Measuring the Curved Beam Strength of a Fiber-Reinforced

Polymer-Matrix Composite

This standard is issued under the fixed designation D 6415; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Equation 5 was editorially corrected in December 2000.

1. Scope

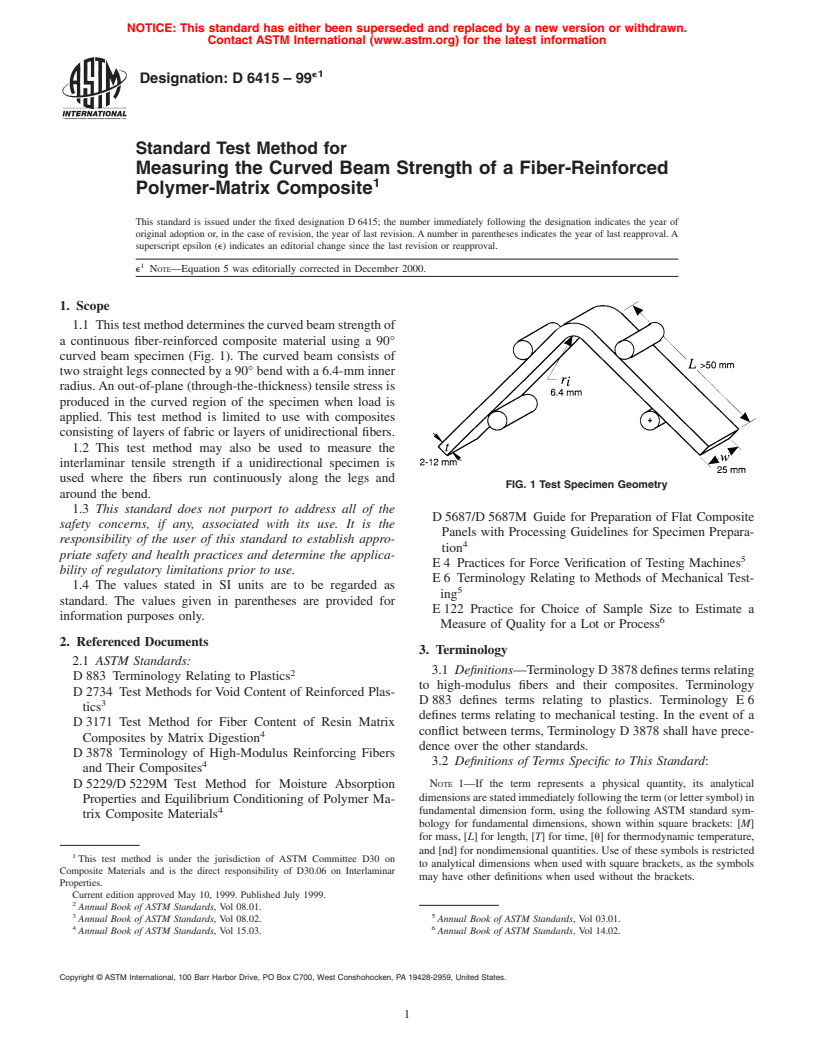

1.1 Thistestmethoddeterminesthecurvedbeamstrengthof

a continuous fiber-reinforced composite material using a 90°

curved beam specimen (Fig. 1). The curved beam consists of

two straight legs connected by a 90° bend with a 6.4-mm inner

radius.An out-of-plane (through-the-thickness) tensile stress is

produced in the curved region of the specimen when load is

applied. This test method is limited to use with composites

consisting of layers of fabric or layers of unidirectional fibers.

1.2 This test method may also be used to measure the

interlaminar tensile strength if a unidirectional specimen is

used where the fibers run continuously along the legs and

FIG. 1 Test Specimen Geometry

around the bend.

1.3 This standard does not purport to address all of the

D 5687/D 5687M Guide for Preparation of Flat Composite

safety concerns, if any, associated with its use. It is the

Panels with Processing Guidelines for Specimen Prepara-

responsibility of the user of this standard to establish appro-

tion

priate safety and health practices and determine the applica-

E 4 Practices for Force Verification of Testing Machines

bility of regulatory limitations prior to use.

E 6 Terminology Relating to Methods of Mechanical Test-

1.4 The values stated in SI units are to be regarded as

ing

standard. The values given in parentheses are provided for

E 122 Practice for Choice of Sample Size to Estimate a

information purposes only.

Measure of Quality for a Lot or Process

2. Referenced Documents

3. Terminology

2.1 ASTM Standards:

3.1 Definitions—TerminologyD 3878definestermsrelating

D 883 Terminology Relating to Plastics

to high-modulus fibers and their composites. Terminology

D 2734 Test Methods for Void Content of Reinforced Plas-

D 883 defines terms relating to plastics. Terminology E 6

tics

defines terms relating to mechanical testing. In the event of a

D 3171 Test Method for Fiber Content of Resin Matrix

conflict between terms, Terminology D 3878 shall have prece-

Composites by Matrix Digestion

dence over the other standards.

D 3878 Terminology of High-Modulus Reinforcing Fibers

3.2 Definitions of Terms Specific to This Standard:

and Their Composites

D 5229/D 5229M Test Method for Moisture Absorption NOTE 1—If the term represents a physical quantity, its analytical

dimensionsarestatedimmediatelyfollowingtheterm(orlettersymbol)in

Properties and Equilibrium Conditioning of Polymer Ma-

fundamental dimension form, using the following ASTM standard sym-

trix Composite Materials

bology for fundamental dimensions, shown within square brackets: [M]

for mass, [L] for length, [T] for time, [u] for thermodynamic temperature,

and [nd] for nondimensional quantities. Use of these symbols is restricted

This test method is under the jurisdiction of ASTM Committee D30 on

to analytical dimensions when used with square brackets, as the symbols

Composite Materials and is the direct responsibility of D30.06 on Interlaminar

may have other definitions when used without the brackets.

Properties.

Current edition approved May 10, 1999. Published July 1999.

Annual Book of ASTM Standards, Vol 08.01.

3 5

Annual Book of ASTM Standards, Vol 08.02. Annual Book of ASTM Standards, Vol 03.01.

4 6

Annual Book of ASTM Standards, Vol 15.03. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D6415–99

2 –2

3.2.1 applied moment, M [ML T ], n—the moment applied legs connected by a 90° bend with a 6.4-mm inner radius. The

to the curved test section of the specimen. curved beam is loaded in four-point bending to apply a

1 –2

3.2.2 curved beam strength, CBS [ML T ], n—the moment constant bending moment across the curved test section. An

per unit width, M/w, applied to the curved test section which out-of-plane tensile stress is produced in the curved region of

causes a sharp decrease in applied load or delamination(s) to the specimen to cause the failure.

form.

3u –1 –2

5. Significance and Use

3.2.3 interlaminar tensile strength, F [ML T ], n—the

5.1 Out-of-plane stress analyses are not easily performed.

strengthofthecompositematerialintheout-of-plane(through-

the-thickness) direction. Failure criteria are varied and poorly validated. Interlaminar

allowables are not readily available. However, stress analysts

3.3 Symbols:

3.3.1 CBS = curved beam strength (see 3.2.2). routinely encounter structural details in which they cannot

ignore the out-of-plane loads. This test method is designed to

3.3.2 d,d = horizontal and vertical distances between two

x y

adjacent top and bottom loading bars, respectively. produce out-of-plane structural failure data for structural de-

sign and analysis, quality assurance, and research and devel-

3.3.3 D = diameter of the cylindrical loading bars on the

opment. For unidirectional specimens, this test method is

four-point-bending fixture.

3.3.4 E,E =moduliintheradialandtangentialdirections, designed to produce interlaminar tensile strength data. Factors

r u

thatinfluencethecurvedbeamstrengthandshouldthereforebe

respectively.

3u

3.3.5 F = interlaminar tensile strength (see 3.2.3). reported include the following: material, methods of material

preparation, methods of processing and specimen fabrication,

3.3.6 g = parameter used in strength calculation.

3.3.7 l = distance between the centerlines of the bottom specimen preparation, specimen conditioning, environment of

b

testing, speed of testing, time at temperature, void content, and

loading bars on the four-point-bending fixture.

3.3.8 l = distance along the specimen’s leg between the volume percent reinforcement.

centerlines of a top and bottom loading bar.

6. Interferences

3.3.9 l = distance between the centerlines of the top load-

t

6.1 Failureinnon-unidirectionalspecimensmaybeinitiated

ing bars on the four-point-bending fixture.

from matrix cracks or free edge stresses. Consequently, the

3.3.10 M = applied moment (see 3.2.1).

interlaminar strength calculated from non-unidirectional speci-

3.3.11 P = total force applied to the four-point-bending

mens may be in error.

fixture.

max

6.2 The stress state of a curved beam in four-point bending

3.3.12 P = maximum force applied to the four-point-

is complex. Circumferential tensile stresses are produced along

bending fixture before failure.

the inner surface, and circumferential compressive stresses are

3.3.13 P = force applied to the specimen by a single

b

produced on the outer surface. The radial tensile stress ranges

loading bar.

fromzeroattheinnerandoutersurfacestoapeakinthemiddle

3.3.14 r, u = cylindrical coordinates of any point in the

third of the thickness. Consequently, the failure should be

curved segment.

carefully observed to ensure that a delamination(s) is produced

3.3.15 r,r = inner and outer radii of curved segment.

i o

across the width before the failure data are used.

3.3.16 r = radial position of the maximum interlaminar

m

6.3 Sincestressesarenonuniformandthecriticalstressstate

(radial) tensile stress.

occurs in a small region, the location of architectural charac-

3.3.17 t = average thickness of specimen.

teristics of the specimen (for example, fabric weave, and tow

3.3.18 w = width of the specimen.

intersections) may affect the curved beam strength.

3.3.19 D = relative displacement between the top and

6.4 Nonlaminated, 3-D reinforced, or textile composites

bottom halves of the four-point-bending fixture.

may fail by different mechanisms than laminates. The most

3.3.20 k = parameter used in strength calculation.

critical damage may be in the form of matrix cracking or fiber

3.3.21 r = parameter used in strength calculation.

failure, or both, rather than delaminations.

3.3.22 f = angle from horizontal of the specimen legs in

6.5 Material, Fabrication, and Specimen Preparation—

degrees.

Poor material fabrication practices, lack of control of fiber

3.3.23 f = angle from horizontal of the specimen legs at

i

alignment, and damage induced by improper coupon machin-

the start of the test in degrees (0.5 3 angle between the legs).

ing are known causes of high material data scatter in compos-

3.3.24 s = radial stress component in curved segment.

r

ites. The curved beam and interlaminar strengths measured

4. Summary of Test Method

using this test method are extremely sensitive to fiber volume

4.1 A90° curved-beam test specimen is used to measure the

and void content. Consequently, the test results may reflect

curvedbeamstrengthofacontinuous-fiber-reinforcedcompos- manufacturing quality as much as material properties.

ite material (Fig. 1). The curved beam strength represents the

7. Apparatus

momentperunitwidthwhichcausesadelamination(s)toform.

If the curved beam is unidirectional with all fibers running 7.1 Testing Machine—The testing machine shall be in

continuously along the legs and around the bend and an conformance with Practices E 4, and shall satisfy the following

appropriate failure mode is observed, an interlaminar (through- requirements:

the-thickness) tensile strength may also be calculated. The 7.1.1 Testing Machine Heads—The testing machine shall

curved beam is uniform thickness and consists of two straight have both an essentially stationary head and a movable head.

e1

D6415–99

7.1.2 Drive Mechanism—The testing machine drive mecha- permanent record during the test of load versus displacement.

nism shall be capable of imparting to the movable head a Alternatively, the data may be stored digitally and postpro-

controlled velocity with respect to the stationary head. The cessed.

velocity of the movable head shall be capable of being 7.5 Micrometers—The micrometer(s) shall use a suitable-

regulated in accordance with 11.6.

size diameter ball-interface on irregular surfaces such as the

bag-side of a laminate, and a flat anvil interface on machined

7.1.3 Load Indicator—The testing machine load-sensing

device shall be capable of indicating the total load being or very-smooth tooled surfaces. The accuracy of the instru-

ments shall be suitable for reading to within 1 % of the sample

carried by the test specimen. This device shall be essentially

free from inertia lag at the specified rate of testing and shall width and thickness. For typical specimen geometries, an

instrument with an accuracy of 625 µm [60.001 in.] is

indicate the load with an accuracy over the load range(s) of

interest of within 61 % of the indicated value. desirable for both thickness and width measurements.

7.6 Calipers—The caliper(s) shall use a knife-edge inter-

7.1.4 Grips—Each head of the testing machine shall have a

face on the curved surfaces of the specimen and a flat anvil

means to hold half of the four-point-bending fixture firmly in

interface on machined or very-smooth tooled surfaces. The

place.Aconvenientmeansofprovidinganattachmentpointfor

accuracy of the instruments shall be suitable for reading to

each fixture half is through the use of a metal “T” in each grip.

within 1 % of the sample width and thickness. For typical

The lower part of the “T” is clamped in the grips, and the top

specimen geometries, an instrument with an accuracy of 625

part of the “T” provides a flat attachment surface for each

µm [60.001 in.] is desirable for both thickness and width

fixture half.

measurements.

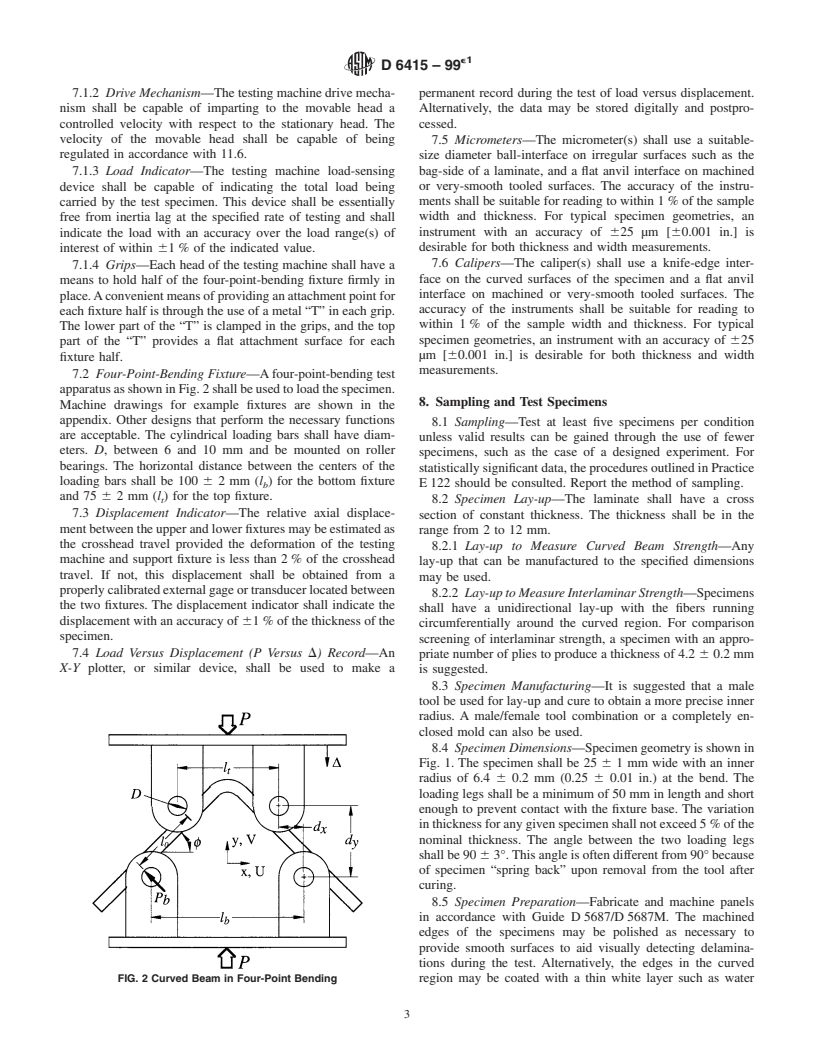

7.2 Four-Point-Bending Fixture—Afour-point-bending test

apparatusasshowninFig.2shallbeusedtoloadthespecimen.

8. Sampling and Test Specimens

Machine drawings for example fixtures are shown in the

appendix. Other designs that perform the necessary functions

8.1 Sampling—Test at least five specimens per condition

are acceptable. The cylindrical loading bars shall have diam-

unless valid results can be gained through the use of fewer

eters. D, between 6 and 10 mm and be mounted on roller

specimens, such as the case of a designed experiment. For

bearings. The horizontal distance between the centers of the

statistically significant data, the procedures outlined in Practice

loading bars shall be 100 62mm(l ) for the bottom fixture

E 122 should be consulted. Report the method of sampling.

b

and 75 62mm(l) for the top fixture.

t 8.2 Specimen Lay-up—The laminate shall have a cross

7.3 Displacement Indicator—The relative axial displace- section of constant thickness. The thickness shall be in the

mentbetweentheupperandlowerfixturesmaybeestimatedas

range from 2 to 12 mm.

the crosshead travel provided the deformation of the testing

8.2.1 Lay-up to Measure Curved Beam Strength—Any

machine and support fixture is less than 2 % of the crosshead

lay-up that can be manufactured to the specified dimensions

travel. If not, this displacement shall be obtained from a

may be used.

properlycalibratedexternalgageortransducerlocatedbetween

8.2.2 Lay-up to Measure Interlaminar Strength—Specimens

the two fixtures. The displacement indicator shall indicate the

shall have a unidirectional lay-up with the fibers running

displacement with an accuracy of 61 % of the thickness of the

circumferentially around the curved region. For comparison

specimen.

screening of interlaminar strength, a specimen with an appro-

7.4 Load Versus Displacement (P Versus D) Record—An

priate number of plies to produce a thickness of 4.2 6 0.2 mm

X-Y plotter, or similar device, shall be used to make a

is suggested.

8.3 Specimen Manufacturing—It is suggested that a male

tool be used for lay-up and cure to obtain a more precise inner

radius. A male/female tool combination or a completely en-

closed mold can also be used.

8.4 Specimen Dimensions—Specimen geometry is shown in

Fig. 1. The specimen shall be 25 6 1 mm wide with an inner

radius of 6.4 6 0.2 mm (0.25 6 0.01 in.) at the bend. The

loading legs shall be a minimum of 50 mm in length and short

enough to prevent contact with the fixture base. The variation

inthicknessforanygivenspecimenshallnotexceed5 %ofthe

nominal thickness. The angle between the two loading legs

shall be 90 6 3°.This angle is often different from 90° because

of specimen “spring back” upon removal from the tool after

curing.

8.5 Specimen Preparation—Fabricate and machine panels

in accordance with Guide D 5687/D 5687M. The machined

edges of the specimens may be polished as necessary to

provide smooth

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.