ASTM F1223-14

(Test Method)Standard Test Method for Determination of Total Knee Replacement Constraint

Standard Test Method for Determination of Total Knee Replacement Constraint

SIGNIFICANCE AND USE

4.1 This test method, when applied to available products and proposed prototypes, is meant to provide a database of product functionality capabilities (in light of the suggested test regimens) that is hoped will aid the physician in making a more informed total knee replacement (TKR) selection.

4.2 A proper matching of TKR functional restorative capabilities and the recipient's (patient’s) needs is more likely to be provided by a rational testing protocol of the implant in an effort to reveal certain device characteristics pertinent to the selection process.

4.3 The TKR product designs are varied and offer a wide range of constraint (stability). The constraint of the TKR in the in vitro condition depends on several geometrical and kinematic interactions among the implant's components which can be identified and quantified. The degree of TKR's kinematic interactions should correspond to the recipient's needs as determined by the physician during clinical examination.

4.4 For mobile bearing knee systems, the constraint of the entire implant construct shall be characterized. Constraint of mobile bearings is dictated by design features at both the inferior and superior articulating interfaces.

4.5 The methodology, utility, and limitations of constraint/laxity testing are discussed.3, 4 The authors recognize that evaluating isolated implants (that is, without soft tissues) does not directly predict in vivo behavior, but will allow comparisons among designs. Constraint testing is also useful for characterizing implant performance at extreme ranges of motion which may be encountered in vivo at varying frequencies, depending on the patient’s anatomy, pre-operative capability, and post-operative activities and lifestyle.

SCOPE

1.1 This test method covers the establishment of a database of total knee replacement (TKR) motion characteristics with the intent of developing guidelines for the assignment of constraint criteria to TKR designs. (See the Rationale in Appendix X1.)

1.2 This test method covers the means by which a TKR constraint may be quantified according to motion delineated by the inherent articular design as determined under specific loading conditions in an in vitro environment.

1.3 Tests deemed applicable to the constraint determination are antero-posterior draw, medio-lateral shear, rotary laxity, valgus-varus rotation, and distraction, as applicable. Also covered is the identification of geometrical parameters of the contacting surfaces which would influence this motion and the means of reporting the test results. (See Practices E4.)

1.4 This test method is not a wear test.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1223 −14

Standard Test Method for

1

Determination of Total Knee Replacement Constraint

This standard is issued under the fixed designation F1223; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope their human counterparts:

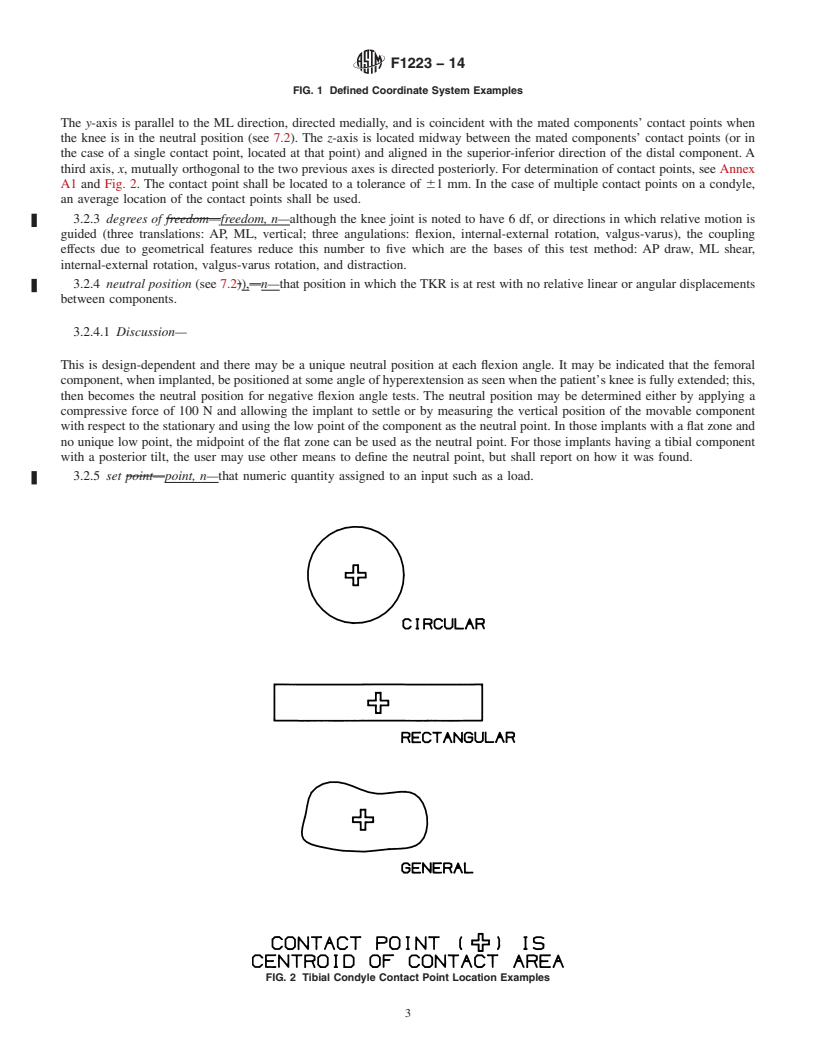

3.1.1 anterior curvature, n—a condylar design which is

1.1 This test method covers the establishment of a database

generally planar except for a concave—upward region anteri-

of total knee replacement (TKR) motion characteristics with

orly on the tibial component.

the intent of developing guidelines for the assignment of

constraint criteria to TKR designs. (See the Rationale in

3.1.2 anterior posterior (AP),n—any geometrical length

Appendix X1.)

aligned with the AP orientation.

1.2 This test method covers the means by which a TKR

3.1.3 AP displacement, n—the relative linear translation

constraint may be quantified according to motion delineated by

between components in the AP direction.

the inherent articular design as determined under specific

3.1.4 AP draw load, n—the force applied to the movable

loading conditions in an in vitro environment.

component with its vector aligned in the AP direction causing

1.3 Tests deemed applicable to the constraint determination

or intending to cause an AP displacement.

are antero-posterior draw, medio-lateral shear, rotary laxity,

3.1.5 biconcave, n—a condylar design with pronounced AP

valgus-varus rotation, and distraction, as applicable. Also

and MLcondylar radii seen as a “dish” in the tibial component

covered is the identification of geometrical parameters of the

or a “toroid” in the femoral component.

contacting surfaces which would influence this motion and the

3.1.6 bearing surface, n—those regions of the component

means of reporting the test results. (See Practices E4.)

which are intended to contact its counterpart for load transmis-

1.4 This test method is not a wear test.

sion.

1.5 The values stated in SI units are to be regarded as

3.1.7 condyles, n—entity designed to emulate the joint

standard. No other units of measurement are included in this

anatomy and used as a bearing surface primarily for transmis-

standard.

sion of the joint reaction force with geometrical properties

1.6 This standard does not purport to address all of the

which tend to govern the general kinematics of the TKR.

safety concerns, if any, associated with its use. It is the

3.1.8 distraction, n—the separation of the femoral compo-

responsibility of the user of this standard to establish appro-

nent(s) from the tibial component(s) in the z-direction.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. 3.1.9 femoral side constraint, n—thatconstraintprovidedby

the superior articulating interfaces, determined by fixing the

2. Referenced Documents

inferior surface of the mobile bearing component during

2

2.1 ASTM Standards:

testing.

E4 Practices for Force Verification of Testing Machines

3.1.10 flexion angle, n—the angulation of the femoral com-

F2083 Specification for Knee Replacement Prosthesis

ponent (about an axis parallel to the y-axis) from the fully

3. Terminology

extended knee position to a position in which a “local” vertical

axis on the component now points posteriorly.

3.1 Definitions—Items in this category refer to the geo-

3.1.10.1 Discussion—For many implants, 0° of flexion can

metricalandkinematicaspectsofTKRdesignsastheyrelateto

be defined as when the undersurface of the tibial component is

parallel to the femoral component surface that in vivo contacts

1

This test method is under the jurisdiction ofASTM Committee F04 on Medical

and Surgical Materials and Devices and is the direct responsibility of Subcommittee the most distal surface of the femur.This technique may not be

F04.22 on Arthroplasty.

possibleforsomeimplantsthataredesignedtohaveaposterior

Current edition approved May 15, 2014. Published June 2014. Originally

tilt of the tibial component. In these cases, the user shall

approved in 1989. Last previous edition approved in 2012 as F1223 – 08 (2012).

specify how the 0° of flexion position was defined.

DOI: 10.1520/F1223-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.1.11 hinge, n—a mechanical physical coupling between

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

femoral and tibial components which provides a single axis

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. about which flexion occurs.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Consho

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F1223 − 08 (Reapproved 2012) F1223 − 14

Standard Test Method for

1

Determination of Total Knee Replacement Constraint

This standard is issued under the fixed designation F1223; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the establishment of a database of total knee replacement (TKR) motion characteristics with the

intent of developing guidelines for the assignment of constraint criteria to TKR designs. (See the Rationale in Appendix X1.)

1.2 This test method covers the means by which a TKR constraint may be quantified according to motion delineated by the

inherent articular design as determined under specific loading conditions in an in vitro environment.

1.3 Tests deemed applicable to the constraint determination are antero-posterior draw, medio-lateral shear, rotary laxity,

valgus-varus rotation, and distraction, as applicable. Also covered is the identification of geometrical parameters of the contacting

surfaces which would influence this motion and the means of reporting the test results. (See Practices E4.)

1.4 This test method is not a wear test.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E4 Practices for Force Verification of Testing Machines

F2083 Specification for Knee Replacement Prosthesis

3. Terminology

3.1 Definitions—Items in this category refer to the geometrical and kinematic aspects of TKR designs as they relate to their

human counterparts:

3.1.1 anterior curvature—curvature, n—a condylar design which is generally planar except for a concave—upward region

anteriorly on the tibial component.

3.1.2 anterior posterior (AP)(AP),—n—any geometrical length aligned with the AP orientation.

3.1.3 AP displacement—displacement, n—the relative linear translation between components in the AP direction.

3.1.4 AP draw load—load, n—the force applied to the movable component with its vector aligned in the AP direction causing

or intending to cause an AP displacement.

3.1.5 biconcave—biconcave, n—a condylar design with pronounced AP and ML condylar radii seen as a “dish” in the tibial

component or a “toroid” in the femoral component.

3.1.6 bearing surface—surface, n—those regions of the component which are intended to contact its counterpart for load

transmission.

3.1.7 condyles—condyles, n—entity designed to emulate the joint anatomy and used as a bearing surface primarily for

transmission of the joint reaction force with geometrical properties which tend to govern the general kinematics of the TKR.

3.1.8 distraction—distraction, n—the separation of the femoral component(s) from the tibial component(s) in the z-direction.

1

This test method is under the jurisdiction of ASTM Committee F04 on Medical and Surgical Materials and Devices and is the direct responsibility of Subcommittee

F04.22 on Arthroplasty.

Current edition approved Dec. 1, 2012May 15, 2014. Published December 2012June 2014. Originally approved in 1989. Last previous edition approved in 20082012 as

F1223 – 08.F1223 – 08 (2012). DOI: 10.1520/F1223-08R12.10.1520/F1223-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1223 − 14

3.1.9 femoral side constraint—constraint, n—that constraint provided by the superior articulating interfaces, determined by

fixing the inferior surface of the mobile bearing component during testing.

3.1.10 flexion angle—angle, n—the angulation of the femoral component (about an axis parallel to the y-axis) from the fully

extended knee position to a position in which a “local” vertical axis on the component now points

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.