ASTM C1285-97

(Test Method)Standard Test Methods for Determining Chemical Durability of Nuclear, Hazardous, and Mixed Waste Glasses: The Product Consistency Test (PCT)

Standard Test Methods for Determining Chemical Durability of Nuclear, Hazardous, and Mixed Waste Glasses: The Product Consistency Test (PCT)

SCOPE

1.1 These product consistency test methods A and B evaluate the chemical durability of homogeneous and devitrified glasses by measuring the concentrations of the chemical species released from a crushed glass to a test solution.

1.1.1 Test Method A is a seven-day crushed glass durability test performed at 90 + 2°C in a leachant of ASTM-Type I water. The test method is static and conducted in stainless steel vessels. Test Method A can specifically be used to evaluate whether the durability and elemental release characteristics of waste glasses have been consistently controlled during production. This test method is applicable to radioactive and simulated waste glasses.

1.1.2 Test Method B is a crushed glass durability test that allows testing of water glasses at varying test durations, test temperatures, ratios of glass surface area ( ) to leachant volume ( ), and leachant types. This test method is static and can be conducted in stainless steel or PFA TFE-fluorocarbon vessels, or both. Test Method B can specifically be used to evaluate the relative durability characteristics of homogeneous or devitrified glasses, or both. This test method is applicable to radioactive and simulated waste glasses. Test Method B cannot be used as a consistency test for production of high level radioactive waste glass.

1.2 These test methods must be performed in accordance with all quality assurance requirements for acceptance of the data.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 1285 – 97

Standard Test Methods for

Determining Chemical Durability of Nuclear, Hazardous, and

Mixed Waste Glasses: The Product Consistency Test (PCT)

This standard is issued under the fixed designation C 1285; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope C 162 Terminology of Glass and Glass Products

C 169 Test Methods for Chemical Analysis of Soda-Lime

1.1 These product consistency test methods A and B evalu-

and Borosilicate Glass

ate the chemical durability of homogeneous and devitrified

C 225 Test Methods for Resistance of Glass Containers to

glasses by measuring the concentrations of the chemical

Chemical Attack

species released from a crushed glass to a test solution.

C 371 Test Method for Wire-Cloth Sieve Analysis of Non-

1.1.1 Test Method A is a seven-day crushed glass chemical

plastic Ceramic Powders

durability test performed at 90 6 2°C in a leachant of

C 429 Test Method for Sieve Analysis of Raw Materials for

ASTM-Type I water. The test method is static and conducted in

Glass Manufacture

stainless steel vessels. Test Method A can specifically be used

C 693 Test Method for Density of Glass by Buoyancy

to evaluate whether the chemical durability and elemental

C 1109 Test Method for Analysis of Aqueous Leachates

release characteristics of nuclear, hazardous, and mixed waste

from Nuclear Waste Materials Using Inductively Coupled

glasses have been consistently controlled during production.

Plasma-Atomic Emission Spectrometry

This test method is applicable to radioactive and simulated

C 1174 Practice for Prediction of the Long-Term Behavior

waste glasses.

of Materials, Including Waste Forms, Used in Engineered

1.1.2 Test Method B is a crushed glass durability test that

Barrier Systems (EBS) for Geologic Disposal of

allows testing of waste glasses at varying test durations, test

High–Level Radioactive Waste

temperatures, mesh size, mass of glass, leachant volume, and

C 1317 Practice for Dissolution of Silicate or Acid Resistant

leachant types. This test method is static and can be conducted

Matrix Samples

in stainless steel or PFA TFE-fluorocarbon vessels, or both.

C 1342 Practice for Flux Fusion Sample Dissolution

Test Method B can specifically be used to evaluate the relative

D 1125 Test Methods for Electrical Conductivity and Re-

chemical durability characteristics of homogeneous or devitri-

sistivity of Water

fied glasses, or both. This test method is applicable to radio-

D 1129 Terminology Relating to Water

active (nuclear) and mixed, hazardous, and simulated waste

D 1193 Specification for Reagent Water

glasses. Test Method B cannot be used as a consistency test for

D 1293 Test Methods for pH of Water

production of high level radioactive waste glass.

D 4327 Test Method for Anions in Water by Chemically

1.2 These test methods must be performed in accordance

Suppressed Ion Chromatography

with all quality assurance requirements for acceptance of the

E 7 Terminology Relating to Metallography

data.

E 177 Practice for Use of the Terms Precision and Bias in

1.3 This standard does not purport to address all of the

ASTM Test Methods

safety concerns, if any, associated with its use. It is the

E 456 Terminology Relating to Quality and Statistics

responsibility of the user of this standard to establish appro-

E 691 Practice for Conducting an Interlaboratory Study to

priate safety and health practices and determine the applica-

Determine the Precision of a Test Method

bility of regulatory limitations prior to use.

E 1402 Terminology Relating to Sampling

2. Referenced Documents

3. Terminology

2.1 ASTM Standards:

3.1 Definitions:

C 92 Test Methods for Sieve Analysis and Water Content of

2 3.1.1 anneal—to prevent or remove materials processing

Refractory Materials

These test methods are under the jurisdiction of ASTM Committee C-26 on

Nuclear Fuel Cycle and are the direct responsibility of Subcommittee C26.13 on Annual Book of ASTM Standards, Vol 15.02.

Repository Waste. Annual Book of ASTM Standards, Vol 12.01.

Current edition approved Oct. 10, 1997. Published March 1998. Originally Annual Book of ASTM Standards, Vol 11.01.

published as C 1285 – 94. Last previous edition C 1285 – 94. Annual Book of ASTM Standards, Vol 03.01.

2 7

Annual Book of ASTM Standards, Vol 15.01. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 1285

stresses in glass by controlled cooling from a suitable tempera- 3.1.18 sample blank—a cleaned test vessel that has been

ture (modified from Terminology C 162). filled with the same amount of leachant as the sample vessels

3.1.2 annealing—a controlled cooling process for glass but contains no glass sample.

designed to reduce thermal residual stress to an acceptable 3.1.19 sensitization—in austenitic steels such as Types 304

level, and, in some cases, modify structure (modified from and 316, the precipitation of chromium carbide at the grain

Terminology C 162). boundaries in a temperature range of 400–900°C (modified

3.1.3 ASTM Type I water—purified water with a maximum from Terminology E 7).

total matter content including soluble silica of 0.1 g/m ,a 3.1.19.1 Discussion—This constitutes the greatest single

maximum electrical conductivity of 0.056 μmho/cm at 25°C, a threat to their corrosion resistance (4).

minimum electrical resistivity of 18 MV·cm at 25°C (see 3.1.20 set of samples—samples tested simultaneously in the

Specification D 1193 and Terminology D 1129). same oven.

3.1.4 chemical durability— in these test methods, the resis- 3.1.21 simulated waste glass—a glass comprised of glass

tance of a glass test specimen to the release of its constituents forming additives with simulants of, or actual chemical spe-

to an aqueous solution under the specific conditions of this test. cies, or both, in radioactive wastes or in mixed nuclear wastes,

3.1.4.1 Discussion—The response of glass under other con- or both.

ditions is outside the scope of these test methods. 3.1.22 standard—to have the quality of a model, gage,

3.1.5 closed system tests—a system that precludes the pattern, or type. (Webster’s New Twentieth Century Dictionary,

transport of matter either into or out of the system. 1973)

3.1.6 consistently controlled—to verify with a high degree 3.1.23 standardize—to make, cause, adjust, or adapt to fit a

of accuracy, as an experiment, by comparison with a standard standard (3); to cause to conform to a given standard, for

or a target, or by other experiments. (Webster’s New Twentieth example, to make standard or uniform (Webster’s New Twen-

Century Dictionary, 1973) tieth Century Dictionary, 1973).

3.1.7 devitrified glass—glass that has crystallized during 3.1.24 unsensitized austenitic steel—stainless steel which is

cooling or due to thermal heat treatment, or both. not sensitized (see sensitization).

3.1.8 hazardous waste glass—a glass comprised of glass 3.1.25 verify—to determine or test the accuracy of, as by

forming additives and hazardous waste. comparison, investigation, or reference, for example, to con-

3.1.9 glass—an inorganic product of fusion that has cooled duct experiments to verify a hypothesis. (The American Heri-

to a rigid condition without crystallizing (see Terminology tage Dictionary, 1973)

C 162). 3.1.26 vitrification—the process of fusing waste with glass

3.1.10 leachant—the solution that is being used, or is making chemicals at elevated temperatures to form a waste

intended for use, in a durability test. glass (see Terminology C 162).

3.1.11 leachate—the solution resulting from a durability

4. Summary of Test Methods

test.

4.1 Test Method A is the Product Consistency Test (PCT-A),

3.1.12 mixed waste—waste containing both radioactive and

which was developed specifically to test the chemical durabil-

hazardous components regulated by the Atomic Energy Act

ity of radioactive waste glasses during production (Table 1) (5).

(AEA) (1) and the Resource Conservation and Recovery Act

It can also be used to test hazardous, mixed, and various

(RCRA), (2) respectively; the term “radioactive component”

simulated waste glasses. The test method is easily reproduc-

refers only to the actual radionuclides dispersed or suspended

ible, can be performed remotely on highly radioactive samples

in the waste substance (3).

and can yield results rapidly. The glass does not need to be

3.1.13 mixed waste glass—a glass comprised of glass form-

annealed prior to testing. In this test method the glass is

ing additives and both hazardous and radioactive constituents.

crushed and sieved to U.S. Standard ASTM − 100 to + 200

3.1.14 nuclear waste glass—a glass comprised of glass

mesh (0.149–0.074 mm), the particles are cleaned of adhering

forming additives and radioactive waste.

fines, and an amount of sized and cleaned glass that is greater

3.1.15 open system tests—a system that permits the trans-

than or equal to1gis placed in a Type 304L stainless steel

port of matter into or out of the system, for example, O or CO

2 2

vessel. An amount of ASTM Type I water equal to 10 cc/g of

diffusion, or both, into or out of the system.

sample mass (m ) is added and the vessel is sealed. The

3.1.16 radioactive—of or exhibiting radioactivity (Ameri-

solid

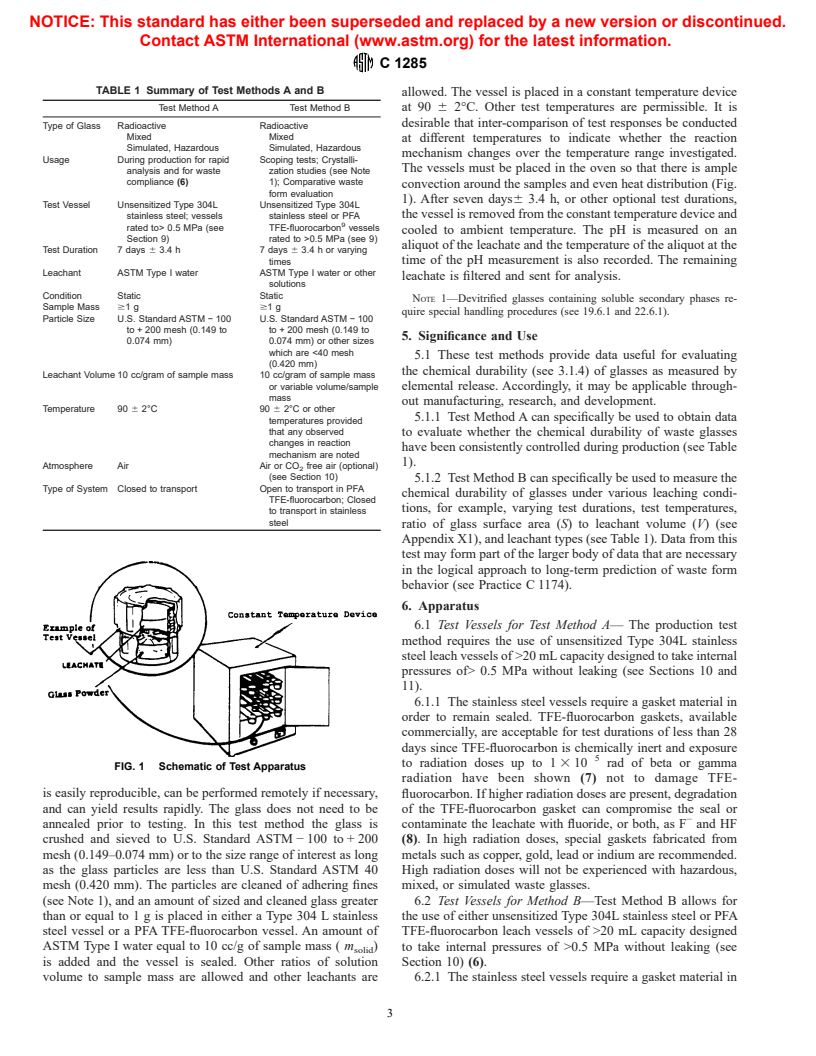

vessel is placed in a constant temperature device at 90 6 2°C.

can Heritage Dictionary, 1973); a material giving or capable of

The vessels must be placed in the constant temperature devices

giving off radiant energy in the form of particles or rays, as

so that there is ample convection around the samples and even

alpha, beta, and gamma rays, by the disintegration of atomic

heat distribution (Fig. 1). After seven days 63.4 h the vessel is

nuclei; said of certain elements, such as radium, thorium, and

removed from the oven and cooled to ambient temperature.

uranium, and their products (Webster’s New Twentieth Century

The pH is measured on an aliquot of the leachate and the

Dictionary, 1973).

temperature of the aliquot at the time of the pH measurement

3.1.17 radioactivity—spontaneous nuclear disintegration

is also recorded. The remaining leachate is filtered and sent for

with emission of corpuscular or electromagnetic radiation, or

analysis.

both (consult Terminology D 1129).

4.2 Test Method B is the Product Consistency Test (PCT-B),

which was developed to test the chemical durability of radio-

The boldface numbers in parentheses refer to the list of references at the end of

these test methods. active, mixed, or simulated waste glasses (5). The test method

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 1285

TABLE 1 Summary of Test Methods A and B

allowed. The vessel is placed in a constant temperature device

Test Method A Test Method B at 90 6 2°C. Other test temperatures are permissible. It is

desirable that inter-comparison of test responses be conducted

Type of Glass Radioactive Radioactive

Mixed Mixed

at different temperatures to indicate whether the reaction

Simulated, Hazardous Simulated, Hazardous

mechanism changes over the temperature range investigated.

Usage During production for rapid Scoping tests; Crystalli-

The vessels must be placed in the oven so that there is ample

analysis and for waste zation studies (see Note

compliance (6) 1); Comparative waste

convection around the samples and even heat distribution (Fig.

form evaluation

1). After seven days6 3.4 h, or other optional test durations,

Test Vessel Unsensitized Type 304L Unsensitized Type 304L

the vessel is removed from the constant temperature device and

stainless steel; vessels stainless steel or PFA

rated to> 0.5 MPa (see TFE-fluorocarbon vessels

cooled to ambient temperature. The pH is measured on an

Section 9) rated to >0.5 MPa (see 9)

aliquot of the leachate and the temperature of the aliquot at the

Test Duration 7 days 6 3.4 h 7 days 6 3.4 h or varying

times time of the pH measurement is also recorded. The remaining

Leachant ASTM Type I water ASTM Type I water or other

leachate is filtered and sent for analysis.

solutions

Condition Static Static

NOTE 1—Devitrified glasses containing soluble secondary phases re-

Sample Mass $1g $1g

quire special handling procedures (see 19.6.1 and 22.6.1).

Particle Size U.S. Standard ASTM − 100 U.S. Standard ASTM − 100

to + 200 mesh (0.149 to to + 200 mesh (0.149 to

5. Significance and Use

0.074 mm) 0.074 mm) or other sizes

which are <40 mesh

5.1 These test methods provide data useful for evaluating

(0.420 mm)

the chemical durability (see 3.1.4) of glasses as measured by

Leachant Volume 10 cc/gram of sample mass 10 cc/gram of sample mass

or variable volume/sample elemental release. Accordingly, it may be applicable through-

mass

out manufacturing, research, and development.

Temperature 90 6 2°C 90 6 2°C or other

5.1.1 Test Method A can specifically be used to obtain data

temperatures provided

that any observed to evaluate whether the chemical durability of waste glasses

changes in reaction

have been consistently controlled during production (see Table

mechanism are noted

1).

Atmosphere Air Air or CO free air (optional)

(see Section 10)

5.1.2 Test Method B can specifically be used to measure the

Type of System Closed to transport Open to transport in PFA

chemical durability of glasses under various leaching condi-

TFE-fluorocarbon; Closed

tions, for example, varying test durations, test temperatures,

to transport in stainless

steel

ratio of glass surface area (S) to leachant volume (V) (see

Appendix X1), and leachant types (see Table 1). Data from this

test may form part of the larger body of data that are necessary

in the logical approach to long-term prediction of waste form

behavior (see Practice C 1174).

6. Apparatus

6.1 Test Vessels for Test Method A— The production test

method requires the use of unsensitized Type 304L stainless

steel leach vessels of >20 mL capacity designed to take internal

pressures of> 0.5 MPa without leaking (see Sections 10 and

11).

6.1.1 The stainless steel vessels require a gasket material in

order to remain sealed. TFE-fluorocarbon gaskets, available

commercially, are acceptable for test durations of less than 28

days since TFE-fluorocarbon is chemically inert and exposure

to ra

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.