ASTM E2585-09(2022)

(Practice)Standard Practice for Thermal Diffusivity by the Flash Method

Standard Practice for Thermal Diffusivity by the Flash Method

SIGNIFICANCE AND USE

5.1 Thermal diffusivity is an important property, required for such purposes under transient heat flow conditions, such as design applications, determination of safe operating temperature, process control, and quality assurance.

5.2 The flash method is used to measure values of thermal diffusivity, α, of a wide range of solid materials. It is particularly advantageous because of simple specimen geometry, small specimen size requirements, rapidity of measurement and ease of handling.

5.3 Under certain strict conditions, specific heat capacity of a homogeneous isotropic opaque solid sample can be determined when the method is used in a quantitative fashion (see Test Method E1461, Appendix 1).

5.4 Thermal diffusivity results, together with related values of specific heat capacity (Cp) and density (ρ) values, can be used in many cases to derive thermal conductivity (λ), according to the relationship:

SCOPE

1.1 This practice covers practical details associated with the determination of the thermal diffusivity of primarily homogeneous isotropic solid materials. Thermal diffusivity values ranging from 10–7 to 10-3 m2/s are readily measurable by this from about 75 K to 2800 K.

1.2 This practice is adjunct to Test Method E1461.

1.3 This practice is applicable to the measurements performed on materials opaque to the spectrum of the energy pulse, but with special precautions can be used on fully or partially transparent materials.

1.4 This practice is intended to allow a wide variety of apparatus designs. It is not practical in a document of this type to establish details of construction and procedures to cover all contingencies that might offer difficulties to a person without pertinent technical knowledge, or to stop or restrict research and development for improvements in the basic technique. This practice provides guidelines for the construction principles, preferred embodiments and operating parameters for this type of instruments.

1.5 This practice is applicable to the measurements performed on essentially fully dense materials; however, in some cases it has shown to produce acceptable results when used with porous specimens. Since the magnitude of porosity, pore shapes, and parameters of pore distribution influence the behavior of the thermal diffusivity, extreme caution must be exercised when analyzing data. Special caution is advised when other properties, such as thermal conductivity, are derived from thermal diffusivity obtained by this method.

1.6 The flash can be considered an absolute (or primary) method of measurement, since no reference materials are required. It is advisable to use only reference materials to verify the performance of the instrument used.

1.7 This method is applicable only for homogeneous solid materials, in the strictest sense; however, in some cases it has been shown to produce data found to be useful in certain applications:

1.7.1 Testing of Composite Materials—When substantial non-homogeneity and anisotropy is present in a material, the thermal diffusivity data obtained with this method may be substantially in error. Nevertheless, such data, while usually lacking absolute accuracy, may be useful in comparing materials of similar structure. Extreme caution must be exercised when related properties, such as thermal conductivity, are derived, as composite materials, for example, may have heat flow patterns substantially different than uniaxial. In cases where the particle size of the composite phases is small compared to the specimen thickness (on the order of 1 to 25 % of thickness) and where the transient thermal response of the specimen appears homogenous when compared to the model, this method can produce accurate results for composite materials. Anisotropic materials can be measured by various techniques, as long as the directional thermal diffusivities (two dimensional or three dimensional) are mutually orthogonal and the measureme...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2585 − 09 (Reapproved 2022)

Standard Practice for

Thermal Diffusivity by the Flash Method

This standard is issued under the fixed designation E2585; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope required. It is advisable to use only reference materials to

verify the performance of the instrument used.

1.1 This practice covers practical details associated with the

determination of the thermal diffusivity of primarily homoge-

1.7 This method is applicable only for homogeneous solid

neous isotropic solid materials. Thermal diffusivity values

materials, in the strictest sense; however, in some cases it has

–7 -3 2

ranging from 10 to 10 m /s are readily measurable by this

been shown to produce data found to be useful in certain

from about 75 K to 2800 K.

applications:

1.2 This practice is adjunct to Test Method E1461. 1.7.1 Testing of Composite Materials—When substantial

non-homogeneity and anisotropy is present in a material, the

1.3 This practice is applicable to the measurements per-

thermal diffusivity data obtained with this method may be

formed on materials opaque to the spectrum of the energy

substantially in error. Nevertheless, such data, while usually

pulse, but with special precautions can be used on fully or

lacking absolute accuracy, may be useful in comparing mate-

partially transparent materials.

rials of similar structure. Extreme caution must be exercised

1.4 This practice is intended to allow a wide variety of

when related properties, such as thermal conductivity, are

apparatus designs. It is not practical in a document of this type

derived, as composite materials, for example, may have heat

to establish details of construction and procedures to cover all

flow patterns substantially different than uniaxial. In cases

contingencies that might offer difficulties to a person without

where the particle size of the composite phases is small

pertinent technical knowledge, or to stop or restrict research

compared to the specimen thickness (on the order of 1 to 25 %

and development for improvements in the basic technique.

of thickness) and where the transient thermal response of the

This practice provides guidelines for the construction

specimen appears homogenous when compared to the model,

principles, preferred embodiments and operating parameters

this method can produce accurate results for composite mate-

for this type of instruments.

rials. Anisotropic materials can be measured by various

1.5 This practice is applicable to the measurements per-

techniques, as long as the directional thermal diffusivities (two

formed on essentially fully dense materials; however, in some

dimensional or three dimensional) are mutually orthogonal and

cases it has shown to produce acceptable results when used

the measurement and specimen preparation produce heat flow

with porous specimens. Since the magnitude of porosity, pore

only along one principle direction. Also, 2D and 3D models

shapes, and parameters of pore distribution influence the

and either independent measurements in one or two directions,

behavior of the thermal diffusivity, extreme caution must be

or simultaneous measurements of temperature response at

exercised when analyzing data. Special caution is advised

different locations on the surface of the specimen, can be

when other properties, such as thermal conductivity, are

utilized.

derived from thermal diffusivity obtained by this method.

1.7.2 Testing Liquids—This method has found an especially

1.6 The flash can be considered an absolute (or primary) useful application in determining thermal diffusivity of molten

method of measurement, since no reference materials are

materials. For this technique, specially constructed specimen

enclosures must be used.

1.7.3 Testing Layered Materials—This method has also

This practice is under the jurisdiction of ASTM Committee E37 on Thermal

Measurements and is the direct responsibility of Subcommittee E37.05 on Thermo-

been extended to test certain layered structures made of

physical Properties.

dissimilar materials, where the thermal properties of one of the

Current edition approved July 1, 2022. Published July 2022. Originally approved

layers are considered unknown. In some cases, contact con-

in 2009. Last previous edition approved in 2015 as E2585 – 09 (2015). DOI:

10.1520/E2585-09R22. ductance of the interface may also be determined.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2585 − 09 (2022)

1.8 The values stated in SI units are to be regarded as 3.2.14 ρ—density, kg/m .

standard. No other units of measurement are included in this

1 1

3.2.15 ∆t —T(5t ⁄2)/T(t ⁄2 ).

standard.

1 1

3.2.16 ∆t —T(10t ⁄2)/T(t ⁄2 ).

1.9 This standard does not purport to address all of the

3.2.17 ∆T —temperature difference between baseline and

max

safety concerns, if any, associated with its use. It is the

maximum rise, K.

responsibility of the user of this standard to establish appro-

3.3 Description of Subscripts Specific to This Standard:

priate safety, health, and environmental practices and deter-

3.3.1 C—Cowan.

mine the applicability of regulatory limitations prior to use.

1.10 This international standard was developed in accor-

3.3.2 m—maximum.

dance with internationally recognized principles on standard-

3.3.3 o—ambient.

ization established in the Decision on Principles for the

3.3.4 R—ratio.

Development of International Standards, Guides and Recom-

3.3.5 s—specimen.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

3.3.6 t—time.

3.3.7 T—thermocouple.

2. Referenced Documents

2 3.3.8 x—percent rise.

2.1 ASTM Standards:

E228 Test Method for Linear Thermal Expansion of Solid

4. Summary of Practice

Materials With a Push-Rod Dilatometer

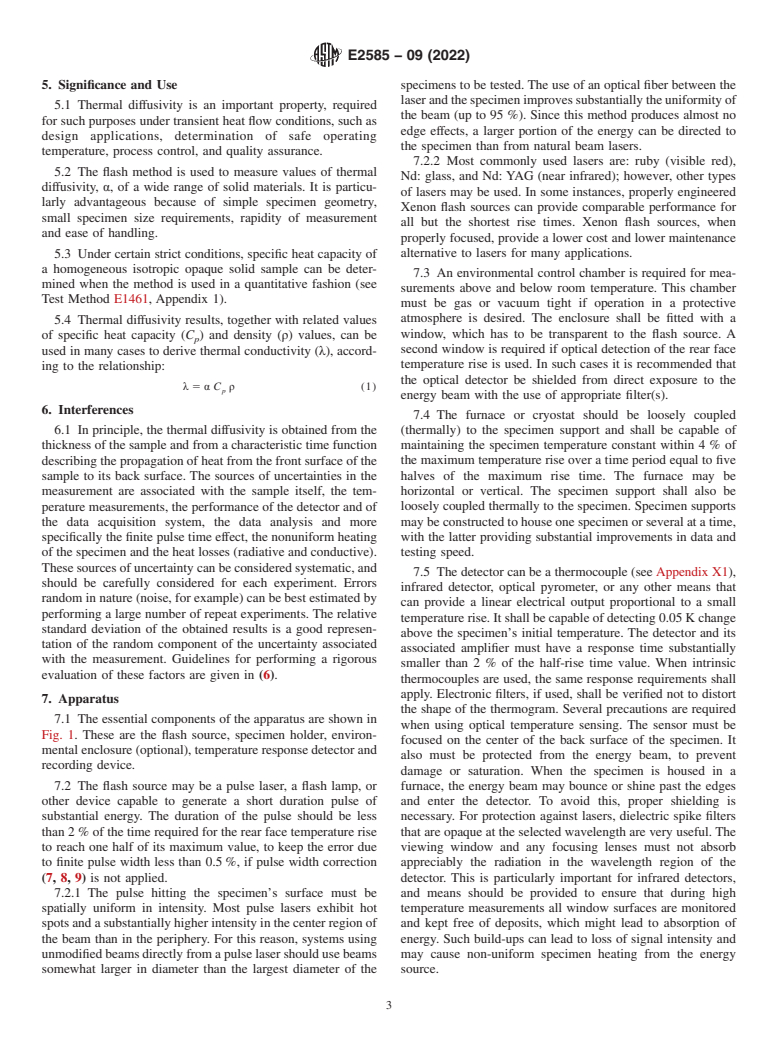

4.1 A small, thin disc specimen is subjected to a high-

E1461 Test Method for Thermal Diffusivity by the Flash

Method intensity short duration radiant energy pulse (Fig. 1). The

energy of the pulse is absorbed on the front surface of the

3. Terminology

specimen and the resulting rear face temperature rise (thermo-

gram) is recorded. The thermal diffusivity value is calculated

3.1 Definitions of Terms Specific to This Standard:

from the specimen thickness and the time required for the rear

3.1.1 thermal conductivity, λ, of a solid material—the time

face temperature rise to reach certain percentages of its

rate of steady heat flow through unit thickness of an infinite

maximum value. When the thermal diffusivity of the sample is

slab of a homogeneous material in a direction perpendicular to

to be determined over a temperature range, the measurement

the surface, induced by unit temperature difference. The

must be repeated at each temperature of interest. This is

property must be identified with a specific mean temperature,

described in detail in a number of publications (1, 2) and

since it varies with temperature.

review articles (3, 4, 5).Asummary of the theory can be found

3.1.2 thermal diffusivity,α, of a solid material—theproperty

in Test Method E1461, Appendix 1.

givenbythethermalconductivitydividedbytheproductofthe

density and heat capacity per unit mass.

3.2 Description of Symbols and Units Specific to This

Standard:

3.2.1 C —specific heat capacity, J/(kg·K).

The boldface numbers given in parentheses refer to a list of references at the

p

end of the text.

3.2.2 D—diameter, metres.

3.2.3 k—constant depending on percent rise.

3.2.4 K—correction factors.

3.2.5 K ,K —constants depending on β.

1 2

3.2.6 L—specimen thickness, m.

3.2.7 t—response time, s.

3.2.8 t ⁄2 —half-rise time or time required for the rear face

temperature rise to reach one half of its maximum value, s.

3.2.9 t*—dimensionless time (t*=4α t/D ).

s T

3.2.10 T—temperature, K.

3.2.11 α—thermal diffusivity, m /s.

3.2.12 λ—thermal conductivity, (W/m·K).

3.2.13 β—fraction of pulse duration required to reach maxi-

mum intensity.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. FIG. 1 Block Diagram of a Flash System

E2585 − 09 (2022)

5. Significance and Use specimens to be tested. The use of an optical fiber between the

laserandthespecimenimprovessubstantiallytheuniformityof

5.1 Thermal diffusivity is an important property, required

the beam (up to 95 %). Since this method produces almost no

for such purposes under transient heat flow conditions, such as

edge effects, a larger portion of the energy can be directed to

design applications, determination of safe operating

the specimen than from natural beam lasers.

temperature, process control, and quality assurance.

7.2.2 Most commonly used lasers are: ruby (visible red),

5.2 The flash method is used to measure values of thermal

Nd: glass, and Nd: YAG (near infrared); however, other types

diffusivity, α, of a wide range of solid materials. It is particu-

of lasers may be used. In some instances, properly engineered

larly advantageous because of simple specimen geometry,

Xenon flash sources can provide comparable performance for

small specimen size requirements, rapidity of measurement

all but the shortest rise times. Xenon flash sources, when

and ease of handling.

properly focused, provide a lower cost and lower maintenance

5.3 Under certain strict conditions, specific heat capacity of alternative to lasers for many applications.

a homogeneous isotropic opaque solid sample can be deter-

7.3 An environmental control chamber is required for mea-

mined when the method is used in a quantitative fashion (see

surements above and below room temperature. This chamber

Test Method E1461, Appendix 1).

must be gas or vacuum tight if operation in a protective

atmosphere is desired. The enclosure shall be fitted with a

5.4 Thermal diffusivity results, together with related values

window, which has to be transparent to the flash source. A

of specific heat capacity (C ) and density (ρ) values, can be

p

second window is required if optical detection of the rear face

used in many cases to derive thermal conductivity (λ), accord-

temperature rise is used. In such cases it is recommended that

ing to the relationship:

the optical detector be shielded from direct exposure to the

λ 5α C ρ (1)

p

energy beam with the use of appropriate filter(s).

6. Interferences

7.4 The furnace or cryostat should be loosely coupled

(thermally) to the specimen support and shall be capable of

6.1 In principle, the thermal diffusivity is obtained from the

thickness of the sample and from a characteristic time function maintaining the specimen temperature constant within4%of

the maximum temperature rise over a time period equal to five

describing the propagation of heat from the front surface of the

sample to its back surface. The sources of uncertainties in the halves of the maximum rise time. The furnace may be

measurement are associated with the sample itself, the tem- horizontal or vertical. The specimen support shall also be

perature measurements, the performance of the detector and of loosely coupled thermally to the specimen. Specimen supports

the data acquisition system, the data analysis and more may be constructed to house one specimen or several at a time,

specifically the finite pulse time effect, the nonuniform heating with the latter providing substantial improvements in data and

of the specimen and the heat losses (radiative and conductive). testing speed.

Thesesourcesofuncertaintycanbeconsideredsystematic,and

7.5 The detector can be a thermocouple (see Appendix X1),

should be carefully considered for each experiment. Errors

infrared detector, optical pyrometer, or any other means that

random in nature (noise, for example) can be best estimated by

can provide a linear electrical output proportional to a small

performing a large number of repeat experiments. The relative

temperature rise. It shall be capable of detecting 0.05 K change

standard deviation of the obtained results is a good represen-

above the specimen’s initial temperature. The detector and its

tation of the random component of the uncertainty associated

associated amplifier must have a response time substantially

with the measurement. Guidelines for performing a rigorous

smaller than2%ofthe half-rise time value. When intrinsic

evaluation of these factors are given in (6).

thermocouples are used, the same response requirements shall

apply. Electronic filters, if used, shall be verified not to distort

7. Apparatus

the shape of the thermogram. Several precautions are required

7.1 The essential components of the apparatus are shown in

when using optical temperature sensing. The sensor must be

Fig. 1. These are the flash source, specimen holder, environ-

focused on the center of the back surface of the specimen. It

mental enclosure (optional), temperature response detector and

also must be protected from the energy beam, to prevent

recording device.

damage or saturation. When the specimen is housed in a

7.2 The flash source may be a pulse laser, a flash lamp, or furnace, the energy beam may bounce or shine past the edges

other device capable to generate a short duration pulse of and enter the detector. To avoid this, proper shielding is

substantial energy. The duration of the pulse should be less necessary. For protection against lasers, dielectric spike filters

than 2 % of the time required for the rear face temperature rise that are opaque at the selected wavelength are very useful.The

to reach one half of its maximum value, to keep the error due viewing window and any focusing lenses must not absorb

to finite pulse width less than 0.5 %, if pulse width correction appreciably the radiation in the wavelength region of the

(7, 8, 9) is not applied. detector. This is particularly important for infrared detectors,

7.2.1 The pulse hitting the specimen’s surface must be and means should be provided to ensure that during high

spatially uniform in intensity. Most pulse lasers exhibit hot temperature measurements all window surfaces are monitored

spotsandasubstantiallyhigherintensityinthecenterregionof and kept free of deposits, which might lead to absorption of

the beam than in the periphery. For this reason, systems using

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.