ASTM F2634-15(2021)

(Test Method)Standard Test Method for Laboratory Testing of Polyethylene (PE) Butt Fusion Joints using Tensile-Impact Method

Standard Test Method for Laboratory Testing of Polyethylene (PE) Butt Fusion Joints using Tensile-Impact Method

SIGNIFICANCE AND USE

4.1 This test method is designed to impart tensile impact energy to a butt fused plastic pipe specimen, record the energy to fail the specimen and plot the load over time curve of the tensile test. Energy recorded at yield and rupture and the rupture mode (brittle or ductile) are used as criteria in the evaluation of the butt fusion joint. The evaluation of the force/time curve not only makes it possible to compare different butt fusion parameters but also to evaluate the rupture mode of the specimen to determine joint integrity. Each coupon's test results will usually be compared to test results for coupons machined from the base pipe material, un-fused.

4.1.1 These data are also useful for qualitative characterization and for research and development. For many materials, there may be a specification that requires the use of this test method, but with some procedural modifications that take precedence when adhering to the specification. Therefore, it is advisable to refer to that material specification before using this test method.

4.2 Tensile properties may vary with specimen preparation and with speed and environment of testing. Consequently, where precise comparative results are desired, these factors must be carefully controlled.

4.2.1 It is realized that a material cannot be tested without also testing the method of preparation of that material. Hence, when comparative tests of materials per se are desired, the greatest care must be exercised to ensure that all specimens are prepared in exactly the same way, unless the test is to include the effects of specimen preparation. While care must be taken to secure the maximum degree of uniformity in details of preparation, treatment, and handling, the exact dimensions of the test specimens are entered into the Data Acquisition System (DAS) before initiating the test.

SCOPE

1.1 This is a tensile impact test method that develops enough tensile impact energy at specific rates of strain to rupture standard tensile impact specimens of butt fused plastic pipe. It is used to determine the quality of PE butt fusion joints made in the field or in qualification testing. It can also be used to determine the optimum butt fusion joining parameters of PE materials.

1.2 This test method is applicable for testing pipe specimens with a diameter 2.37 in. (60.3 mm) and larger with a wall thickness from 0.25 in. (6.3 mm) and larger.

Note 1: This test method is similar to ISO 13953.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This test method may be used alone or together with other test methods, to evaluate the quality of the butt fused joints. When this test, conducted at laboratory temperatures per 9.2, is combined with the elevated temperature, sustained pressure test in Specification D3035, both the short term and long term strength of the PE butt fusion joint will be verified.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2634 − 15 (Reapproved 2021)

Standard Test Method for

Laboratory Testing of Polyethylene (PE) Butt Fusion Joints

using Tensile-Impact Method

This standard is issued under the fixed designation F2634; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2.1 ASTM Standards:

1.1 This is a tensile impact test method that develops

D883 Terminology Relating to Plastics

enough tensile impact energy at specific rates of strain to

D2513 Specification for Polyethylene (PE) Gas Pressure

rupture standard tensile impact specimens of butt fused plastic

Pipe, Tubing, and Fittings

pipe. It is used to determine the quality of PE butt fusion joints

D3035 SpecificationforPolyethylene(PE)PlasticPipe(DR-

made in the field or in qualification testing. It can also be used

PR) Based on Controlled Outside Diameter

to determine the optimum butt fusion joining parameters of PE

E177 Practice for Use of the Terms Precision and Bias in

materials.

ASTM Test Methods

1.2 Thistestmethodisapplicablefortestingpipespecimens

E691 Practice for Conducting an Interlaboratory Study to

with a diameter 2.37 in. (60.3 mm) and larger with a wall

Determine the Precision of a Test Method

thickness from 0.25 in. (6.3 mm) and larger.

2.2 ISO Standard

NOTE 1—This test method is similar to ISO 13953. ISO 13953 Polyethylene (PE) pipes and fittings - Determi-

nation of the tensile strength and failure mode of test

1.3 The values stated in inch-pound units are to be regarded

pieces from a butt-fused joint

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only

3. Terminology

and are not considered standard.

3.1 Definitions of Terms Specific to This Standard:

1.4 This test method may be used alone or together with

3.1.1 brittle rupture —Abrittle rupture in a butt fusion joint

other test methods, to evaluate the quality of the butt fused

specimen consists of a clean or nearly clean part between the

joints.Whenthistest,conductedatlaboratorytemperaturesper

joining surfaces resulting in a smooth surface on both sides.

9.2, is combined with the elevated temperature, sustained

(See Fig. 1.)

pressure test in Specification D3035, both the short term and

3.1.2 ductile rupture—Aductileruptureinabuttfusionjoint

long term strength of the PE butt fusion joint will be verified.

specimen consists of either an elongation rupture of the

1.5 This standard does not purport to address all of the

machined pipe outside the joint area (see Fig. 2) or adjacent to

safety concerns, if any, associated with its use. It is the

the butt fusion joint interface but resulting in considerable

responsibility of the user of this standard to establish appro-

material tearing between the pipe end surfaces (see Fig. 3).

priate safety, health, and environmental practices and deter-

3.1.3 maximum force—the maximum force obtained during

mine the applicability of regulatory limitations prior to use.

the test.

1.6 This international standard was developed in accor-

3.1.4 rupture energy—the energy required to rupture the

dance with internationally recognized principles on standard-

coupon.

ization established in the Decision on Principles for the

3.1.5 yield point —The point on the force/time curve where

Development of International Standards, Guides and Recom-

significant plastic deformation begins to occur. For the pur-

mendations issued by the World Trade Organization Technical

poses of this standard, this is defined as occurring at zero slope

Barriers to Trade (TBT) Committee.

point on the force/time curve.

1 2

This test method is under the jurisdiction of ASTM Committee F17 on Plastic For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Piping Systems and is the direct responsibility of Subcommittee F17.40 on Test contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Methods. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Nov. 1, 2021. Published December 2021. Originally the ASTM website.

approved in 2007. Last previous edition approved in 2015 as F2634 – 15. DOI: Available from International Organization for Standardization (ISO), 1 rue de

10.1520/F2634-15R21. Varembé, Case postale 56, CH-1211, Geneva 20, Switzerland, http://www.iso.ch.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2634 − 15 (2021)

FIG. 1 Brittle Rupture

FIG. 2 Ductile Rupture Outside Fusion Interface

FIG. 3 Ductile Rupture Adjacent to Fusion Interface

3.1.6 yield energy —The energy imparted to the coupon by 4.1.1 These data are also useful for qualitative characteriza-

the yield point. tion and for research and development. For many materials,

there may be a specification that requires the use of this test

3.1.7 average velocity—Theaveragevelocityistheaverage

method, but with some procedural modifications that take

crosshead speed for the duration (until coupon rupture) of the

precedence when adhering to the specification. Therefore, it is

tensile test (inches/ sec.)

advisabletorefertothatmaterialspecificationbeforeusingthis

3.1.8 instantaneous velocity—The crosshead velocity at

test method.

any discrete point during the test. This may be plotted to show

4.2 Tensile properties may vary with specimen preparation

the consistency of the velocity profile through the duration of

and with speed and environment of testing. Consequently,

the test.

where precise comparative results are desired, these factors

3.1.9 yield stress—The stress value corresponding to the

must be carefully controlled.

yield point.

4.2.1 It is realized that a material cannot be tested without

3.1.9.1 Discussion—Additional definitions of terms apply-

also testing the method of preparation of that material. Hence,

ing to tensile test methods appear in Terminology D883.

when comparative tests of materials per se are desired, the

greatest care must be exercised to ensure that all specimens are

4. Significance and Use

prepared in exactly the same way, unless the test is to include

4.1 This test method is designed to impart tensile impact

the effects of specimen preparation. While care must be taken

energy to a butt fused plastic pipe specimen, record the energy

to secure the maximum degree of uniformity in details of

to fail the specimen and plot the load over time curve of the

preparation, treatment, and handling, the exact dimensions of

tensile test. Energy recorded at yield and rupture and the

thetestspecimensareenteredintotheDataAcquisitionSystem

rupture mode (brittle or ductile) are used as criteria in the

(DAS) before initiating the test.

evaluation of the butt fusion joint. The evaluation of the

force/time curve not only makes it possible to compare

5. Apparatus

different butt fusion parameters but also to evaluate the rupture

mode of the specimen to determine joint integrity. Each 5.1 Testing Machine, A testing machine of the controlled

coupon’stestresultswillusuallybecomparedtotestresultsfor rate-of-crosshead-movement type and comprising essentially

coupons machined from the base pipe material, un-fused. the following:

F2634 − 15 (2021)

5.1.1 Fixed Member, a fixed or essentially stationary mem- 5.2 Measuring Instrument, Apparatus for measuring the

ber with tooling to pin a standard pipe specimen configuration. width and thickness of the test specimen shall maintain an

5.1.2 Movable Member, a movable member with tooling to accuracy within .001 in. of gage.

pin a standard pipe specimen configuration.

5.1.3 Tooling for specimens, Fixed clevis members attached

6. Test Specimens

to the testing machine for pinning the test specimen between

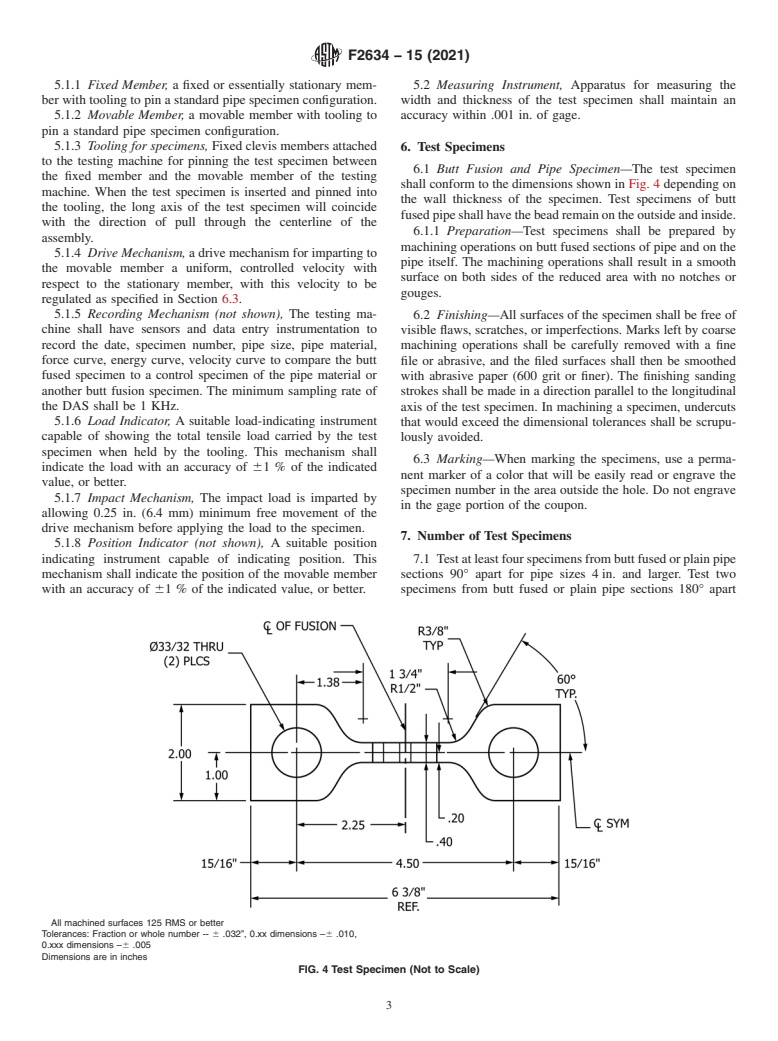

6.1 Butt Fusion and Pipe Specimen—The test specimen

the fixed member and the movable member of the testing

shall conform to the dimensions shown in Fig. 4 depending on

machine. When the test specimen is inserted and pinned into

the wall thickness of the specimen. Test specimens of butt

the tooling, the long axis of the test specimen will coincide

fusedpipeshallhavethebeadremainontheoutsideandinside.

with the direction of pull through the centerline of the

6.1.1 Preparation—Test specimens shall be prepared by

assembly.

machining operations on butt fused sections of pipe and on the

5.1.4 Drive Mechanism, a drive mechanism for imparting to

pipe itself. The machining operations shall result in a smooth

the movable member a uniform, controlled velocity with

surface on both sides of the reduced area with no notches or

respect to the stationary member, with this velocity to be

gouges.

regulated as specified in Section 6.3.

5.1.5 Recording Mechanism (not shown), The testing ma-

6.2 Finishing—All surfaces of the specimen shall be free of

chine shall have sensors and data entry instrumentation to visible flaws, scratches, or imperfections. Marks left by coarse

record the date, specimen number, pipe size, pipe material,

machining operations shall be carefully removed with a fine

force curve, energy curve, velocity curve to compare the butt file or abrasive, and the filed surfaces shall then be smoothed

fused specimen to a control specimen of the pipe material or

with abrasive paper (600 grit or finer). The finishing sanding

another butt fusion specimen. The minimum sampling rate of strokes shall be made in a direction parallel to the longitudinal

the DAS shall be 1 KHz.

axis of the test specimen. In machining a specimen, undercuts

5.1.6 Load Indicator, A suitable load-indicating instrument that would exceed the dimensional tolerances shall be scrupu-

capable of showing the total tensile load carried by the test

lously avoided.

specimen when held by the tooling. This mechanism shall

6.3 Marking—When marking the specimens, use a perma-

indicate the load with an accuracy of 61 % of the indicated

nent marker of a color that will be easily read or engrave the

value, or better.

specimen number in the area outside the hole. Do not engrave

5.1.7 Impact Mechanism, The impact load is imparted by

in the gage portion of the coupon.

allowing 0.25 in. (6.4 mm) minimum free movement of the

drive mechanism before applying the load to the specimen.

7. Number of Test Specimens

5.1.8 Position Indicator (not shown), A suitable position

indicating instrument capable of indicating position. This 7.1 Testatleastfourspecimensfrombuttfusedorplainpipe

mechanism shall indicate the position of the movable member sections 90° apart for pipe sizes 4 in. and larger. Test two

with an accuracy of 61 % of the indicated value, or better. specimens from butt fused or plain pipe sections 180° apart

All machined surfaces 125 RMS or better

Tolerances: Fraction or whole number -- 6 .032”, 0.xx dimensions –6 .010,

0.xxx dimensions –6 .005

Dimensions are in inches

FIG. 4 Test Specimen (Not to Scale)

F2634 − 15 (2021)

(top center and bottom center) for pipe sizes 2 in. to 4 in. It is D 5 P 2 P (1)

~ !

n n 0

advisable to take as many samples from a fused pipe section as

10.3 Calculate instantaneous velocity (V ) as follows:

n

is practicable.

D 2 D

~ !

n n21

V 5 (2)

n 21

~SR!

8. Speed of Testing

10.4 Calculate average velocity (V ) as follows:

8.1 Speed of the tensile impact testing shall be relative to n

r

the modulus of elasticity and wall thickness of the plastic pipe

V 5 V (3)

materials.

avg ( n

r

i51

8.2 Choose the speed of testing from Table 1. Determine

10.5 Calculate test specimen engineering area (A) as fol-

thischosenspeedoftestingbythespecificationforthematerial

lows:

being tested, or by agreement between those concerned.

A 5 t*w (4)

9. Conditioning

10.6 Calculate tensile stress (σ ) as follows:

n

9.1 Conditioning—Condition the test specimens at 73.4 °F

F

n

σ 5 (5)

n

6 3.6 °F (23 6 2°C) for not less than 1 h prior to test.

A

9.2 Test Conditions—Conduct the tests at 73.4 °F 6 3.6 °F

10.7 Calculate cumulative energy (E ) (at any point) as

n

(23 °C 6 2 °C) unless otherwise specified by contract or the

follows:

relevant ASTM material specification.

n

E F * D 2 D (6)

~ !

n( i i i21

i51

10. Calculations

10.1 Definitions: 11. Procedure

11.1 Set up the machine and set the speed of testing to the

P = Indicated position of movable member at any given

n

proper rate as required in Section 8.

time

n

P = Indicated initial position of movable member 11.2 Measurethewidthandwallthicknessofeachspecimen

P = Indicated position of movable member at time n-1

in the gage section to the nearest 0.001 in. (0.025 mm). Each

n-1

(previous indicated value)

dimension shall be measured in a minimum of three places in

F = Indicated Force at any given time

n n the gage section and the smallest measured value shall be

D = Displacement from initial position P

n 0 recorded in the DAS.

V = Instantaneous velocity at any given time n

n

11.3 Pin each specimen in the clevis tooling of the testing

V = Average test velocity

avg

machine. This will align the long axis of the specimen and the

E = Cumulative Energy applied to the test specimen from

n

tooling with the direction of pull of the machine. See Fig. 5.

beginning of test to any given time n

E = Cumulative Energy at yield point

y 11.4 Enter all appropriate data.

E = Cumulative Energy at rupture point

r

11.5 Perform the test. For each specimen, the data acquisi-

σ = Tensile stress at any given time n

n

tion system shall record the force curve over time and the

t = Test specimen minimum gage section thickness

position curve over time at the minimum sampling rate given

w = Test specimen minimum wall thickness

in 5.1.5.

A = Test specimen cross sectional area

y = Time at yield point

12. Report

r = Time at rupture

SR = Sampling rate on data acquisition system 12.1 Report the following information:

12.1.1 Completeidentificationofthetestspecimensinclud-

10.2 Calculate Displacement (D ) as follows:

n

ing the pipe size and DR, material tested including manufac-

turer’s code numbers, and related applicable standards, date,

TABLE 1 Test Speed—Tolerance= + .5 in./s (+ 12.7 mm/s to –

who performed the test, testing company and any other data

25.4mm/s)

that would help evaluate the joints.

Tensile Impact

12.1.2 Individual test record for each specimen tested with

Pipe Material Standard Wall Thickness Testing Speed

Polyethylene Pip

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.