ASTM D4698-92(2007)

(Practice)Standard Practice for Total Digestion of Sediment Samples for Chemical Analysis of Various Metals

Standard Practice for Total Digestion of Sediment Samples for Chemical Analysis of Various Metals

SIGNIFICANCE AND USE

The chemical analysis of sediments, collected from such locations as streams, rivers, lakes, and oceans can provide information of environmental significance.

These practices can be used with either suspended sediment (material actively transported by water) or bed sediment (material temporarily at rest on the bed of a water body).

Standardized practices for digesting sediments, for subsequent chemical analysis, will facilitate inter- and intra-areal comparisons as well as comparison of data generated by different groups. The use of total digestions also eliminates the ambiguities and interpretational difficulties associated with partial digestions and the operational definitions that accompany them. PROCEDURE A—FUSION Top

SCOPE

1.1 This practice covers two procedures for the total digestion of sediments for subsequent determination of metals by such techniques as flame atomic absorption spectrophotometry, graphite-furnace atomic absorption spectrophotometry, atomic emission spectroscopy, etc.

1.2 This practice is applicable in the subsequent determination of volatile, semivolatile, and nonvolatile metals of sediments.

1.3 Actual metal quantitation can be accomplished by following the various test methods outlined under other appropriate ASTM standards for the metal(s) of interest. Before selecting either of the digestion techniques outlined in this practice, the user should consult the appropriate quantitation standard(s) for any special analytical considerations, and Practice D 3976 for any special preparatory considerations.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For a specific hazard statement, see Note 7.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4698 − 92 (Reapproved2007)

Standard Practice for

Total Digestion of Sediment Samples for Chemical Analysis

of Various Metals

This standard is issued under the fixed designation D4698; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope in Closed Conduits (Withdrawn 2003)

D1193 Specification for Reagent Water

1.1 This practice covers two procedures for the total diges-

D3976 Practice for Preparation of Sediment Samples for

tion of sediments for subsequent determination of metals by

Chemical Analysis

suchtechniquesasflameatomicabsorptionspectrophotometry,

graphite-furnace atomic absorption spectrophotometry, atomic

3. Terminology

emission spectroscopy, etc.

3.1 Definitions—For definitions of terms used in this

1.2 This practice is applicable in the subsequent determina- practice, refer to Terminology D1129.

tion of volatile, semivolatile, and nonvolatile metals of sedi-

3.2 Definitions of Terms Specific to This Standard:

ments.

3.2.1 total digestion—the dissolution of a sediment matrix

such that quantitation will produce a measurement which is

1.3 Actual metal quantitation can be accomplished by fol-

more than 95 % of the constituent present in the sample.

lowing the various test methods outlined under other appropri-

ate ASTM standards for the metal(s) of interest. Before

3.2.2 partialdigestion—thedissolutionofasedimentmatrix

selecting either of the digestion techniques outlined in this

such that quantitation will produce a measurement of less than

practice, the user should consult the appropriate quantitation

95 % of the constituent present in the sample. In such cases,

standard(s) for any special analytical considerations, and Prac-

recovery is operationally defined by the digestion procedure.

tice D3976 for any special preparatory considerations.

4. Summary of Practice

1.4 This standard does not purport to address all of the

4.1 Many procedures are available for the total digestion of

safety concerns, if any, associated with its use. It is the

sediments prior to metal analysis, but almost all the methods

responsibility of the user of this standard to establish appro-

fall into one of two main classes: fusion and subsequent

priate safety and health practices and determine the applica-

dissolution of the bead, and wet digestion which directly

bility of regulatory limitations prior to use. For a specific

dissolves the sample with mineral acids. Each of the classes

hazard statement, see Note 7.

has advantages and disadvantages, as do the individual proce-

1.5 The values stated in inch-pound units are to be regarded

dures which fall under them. The two procedures outlined in

as the standard. The values given in parentheses are for

this practice were selected because they are the least restricted,

information only.

in terms of utility, for dealing with a wide variety of matrices.

Before choosing a particular method, the user should consult

2. Referenced Documents

the pertinent literature to determine the utility and applicability

2.1 ASTM Standards:

of either method, prior to final selection; or if a less rigorous

4,5 ,6,7

D1129 Terminology Relating to Water

digestion could be employed. Even then, experience with

D1192 Guide for Equipment for Sampling Water and Steam

a particular sample type or digestion test method, or both, may

have to be the final arbiter in test method selection.

1 3

This practice is under the jurisdiction of ASTM Committee D19 on Water and The last approved version of this historical standard is referenced on

is the direct responsibility of Subcommittee D19.07 on Sediments, Geomorphology, www.astm.org.

and Open-Channel Flow. Johnson, W., and Maxwell, J., Rock and Mineral Analysis , 2nd Edition, John

Current edition approved June 15, 2007. Published July 2007. Originally Wiley & Sons, New York, 1981, p. 489.

approved in 1987. Last previous edition approved in 2001 as D4698 – 92 (2001). Pinta, M., Modern Methods for Trace Element Analysis , Ann Arbor Science

DOI: 10.1520/D4698-92R07. Publishers, Ann Arbor, 1982, pp. 133–264.

2 6

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Dolezal, J., Povondra, C., and Sulcek, Z., Decomposition Techniques in

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Inorganic Analysis, Elsevier Publishing Co., New York, 1968, pp. 11–157.

Standards volume information, refer to the standard’s Document Summary page on Shapiro, L., “Rapid Analysis of Silicate, Carbonate, and Phosphate Rocks,”

the ASTM website. Revised Edition, U.S. Geological Survey Bulletin , 1401, 1975, p. 76.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4698 − 92 (2007)

4.2 Field collected samples should be treated according to 9.1 Purity of Reagents—Reagent grade chemicals shall be

the procedures outlined in Practice D3976. usedinalldigestions.Unlessotherwiseindicated,itisintended

thatallreagentsconformtothespecificationsoftheCommittee

4.3 Dried samples are ground to finer than 100 mesh (150

on Analytical Reagents of the American Chemical Society

µm) using an appropriate grinding device or system.

where such specifications are available. Other grades may be

4.4 Procedure A— Fusion with lithium metaborate/

used, provided it is first ascertained that the reagent is of

tetraborate.

sufficiently high purity to permit its use without lessening the

4.5 Procedure B— Wet digestion using a combination of accuracy of the subsequent quantitation.

hydrofluoric, perchloric, and nitric acids.

9.2 PurityofWater—Unlessotherwiseindicated,references

to water shall be understood to mean reagent water as defined

5. Significance and Use

by Type II of Specification D1193.

5.1 Thechemicalanalysisofsediments,collectedfromsuch

9.3 Mixed Salt Standards—The mixed salt standards are

locations as streams, rivers, lakes, and oceans can provide

provided as a guide to the user for use with atomic absorption

information of environmental significance.

analyses to reduce matrix and interelement interferences. They

5.2 These practices can be used with either suspended have been found effective for the constit-uents listed in 6.1.

sediment (material actively transported by water) or bed They may have to be modified to accommodate others.

sediment (material temporarily at rest on the bed of a water

9.4 Cesium Chloride, Solution (4 g/L)—Dissolve4gof

body).

CsCl in water and dilute to 1 L.

5.3 Standardized practices for digesting sediments, for sub-

9.5 Diluent Solution— Dissolve6gofflux mixture in 500

sequent chemical analysis, will facilitate inter- and intra-areal

mLofwater.Add12.5mLconcentratednitricacid(spgr1.41),

comparisons as well as comparison of data generated by

and dilute to 1 L with water.

different groups. The use of total digestions also eliminates the

9.6 Flux Mixture— Thoroughly mix 1 part powdered anhy-

ambiguities and interpretational difficulties associated with

drous lithium metaborate, LiBO , and 2 parts anhydrous

partial digestions and the operational definitions that accom-

lithium tetraborate, Li B O . Store in a tightly closed bottle.

2 4 7

pany them.

NOTE1—Itispossibletopurchasepre-mixedfusionfluxesfromseveral

PROCEDURE A—FUSION

suppliers, and provided they are of sufficient purity, have been found quite

satisfactory.

6. Scope

9.7 Mixed Metals Solution, Stock —Dissolve by appropriate

6.1 This procedure is effective for the total digestion of

means, the following compounds, elements, or both:aluminum

suspended and bottom sediments for the subsequent determi-

metal (1.500 g), calcium carbonate (1.249 g), iron metal (1.000

nation of aluminum, calcium, iron, magnesium, potassium,

g), magnesium metal (0.200 g), manganese metal (0.040 g),

manganese, silicon, sodium, and titanium.

KCl (0.668 g), ammonium hexafluorosilicate (18.987 g), NaCl

(0.636 g), and ammonium titanyl oxalate (1.227 g), and dilute

6.2 This practice may be appropriate for the subsequent

to 1000 mL with diluent solution (9.5). This solution will

determination of other metals provided the concentrations are

contain the following concentrations: aluminum (1500 mg/L),

high enough or if the instrumental sensitivity is sufficient.

calcium (500 mg/L), iron (1000 mg/L), magnesium (200

mg/L), manganese (40 mg/L), potassium (350 mg/L), silica

7. Interferences

(3000 mg/L), sodium (250 mg/L), and titanium (200 mg/L).

7.1 Numerous inter-element interferences, both positive and

Store in a plastic or TFE-fluorocarbon bottle.

negative, exist for this procedure and have been amply docu-

4,5

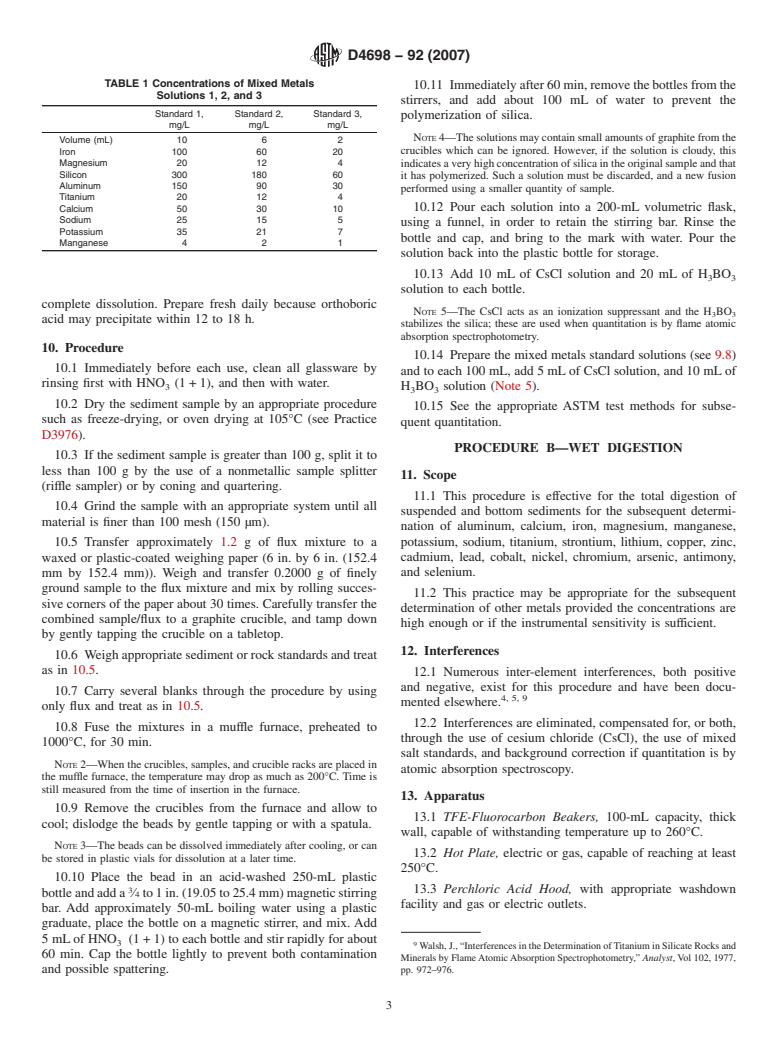

9.8 Mixed Metals Solutions, Standards 1, 2, and 3—Take

mented elsewhere.

respectively, a 10-, 6-, and 2-mL aliquot of the mixed metals

7.2 Interferencesareeliminatedorcompensatedfor,orboth,

stock solution (9.7), and dilute to 100 mL in volumetric

through the use of cesium chloride (CsCl), orthoboric acid

glassware with standard diluent solution (9.5). Concentrations

(H BO ), lithium metaborate (LiBO ), lithium tetraborate

3 3 2

are given in Table 1.

(Li B O ), and the use of mixed salt standards during quanti-

2 4 7

9.9 Nitric Acid, concentrated (sp gr 1.41).

tation by flame atomic absorption spectrophotometry.

9.10 NitricAcid(1+1)—Add250mLofconcentratednitric

8. Apparatus

acid (sp gr 1.41) to 250 mL water. Store in a plastic bottle.

8.1 Graphite Crucibles, drill point, with a 7.5-mL capacity

9.11 Orthoboric Acid Solution (50 g/L)—Dissolve 50 g of

and a 1-in. (25.4 mm) outside diameter, ⁄4-in. (19.05 mm)

H BO in water and dilute to 1 L. Heat may be required to

3 3

inside diameter, and total depth of 1 ⁄8 in. (34.925 mm).

8.2 Magnetic Stirrer.

Reagent Chemicals, American Chemical Society Specifications , American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

8.3 Muffle Furnace, capable of reaching a temperature of at

listed by the American Chemical Society, see Analar Standards for Laboratory

least 1000°C.

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

9. Reagents MD.

D4698 − 92 (2007)

TABLE 1 Concentrations of Mixed Metals

10.11 Immediatelyafter60min,removethebottlesfromthe

Solutions 1, 2, and 3

stirrers, and add about 100 mL of water to prevent the

Standard 1, Standard 2, Standard 3,

polymerization of silica.

mg/L mg/L mg/L

NOTE4—Thesolutionsmaycontainsmallamountsofgraphitefromthe

Volume (mL) 10 6 2

crucibles which can be ignored. However, if the solution is cloudy, this

Iron 100 60 20

Magnesium 20 12 4

indicatesaveryhighconcentrationofsilicaintheoriginalsampleandthat

Silicon 300 180 60

it has polymerized. Such a solution must be discarded, and a new fusion

Aluminum 150 90 30

performed using a smaller quantity of sample.

Titanium 20 12 4

10.12 Pour each solution into a 200-mL volumetric flask,

Calcium 50 30 10

Sodium 25 15 5

using a funnel, in order to retain the stirring bar. Rinse the

Potassium 35 21 7

bottle and cap, and bring to the mark with water. Pour the

Manganese 4 2 1

solution back into the plastic bottle for storage.

10.13 Add 10 mL of CsCl solution and 20 mL of H BO

3 3

solution to each bottle.

complete dissolution. Prepare fresh daily because orthoboric

NOTE 5—The CsCl acts as an ionization suppressant and the H BO

3 3

acid may precipitate within 12 to 18 h.

stabilizes the silica; these are used when quantitation is by flame atomic

absorption spectrophotometry.

10. Procedure

10.14 Prepare the mixed metals standard solutions (see 9.8)

10.1 Immediately before each use, clean all glassware by

and to each 100 mL, add 5 mLof CsCl solution, and 10 mLof

rinsing first with HNO (1 + 1), and then with water.

H BO solution (Note 5).

3 3

10.2 Dry the sediment sample by an appropriate procedure

10.15 See the appropriate ASTM test methods for subse-

such as freeze-drying, or oven drying at 105°C (see Practice

quent quantitation.

D3976).

PROCEDURE B—WET DIGESTION

10.3 If the sediment sample is greater than 100 g, split it to

less than 100 g by the use of a nonmetallic sample splitter

11. Scope

(riffle sampler) or by coning and quartering.

11.1 This procedure is effective for the total digestion of

10.4 Grind the sample with an appropriate system until all

suspended and bottom sediments for the subsequent determi-

material is finer than 100 mesh (150 µm).

nation of aluminum, calcium, iron, magnesium, manganese,

potassium, sodium, titanium, strontium, lithium, copper, zinc,

10.5 Transfer approximately 1.2 g of flux mixture to a

waxed or plastic-coated weighing paper (6 in. by 6 in. (152.4 cadmium, lead, cobalt, nickel, chromium, arsenic, antimony,

and selenium.

mm by 152.4 mm)). Weigh and transfer 0.2000 g of finely

ground sample to the flux mixture and mix by rolling succes-

11.2 This practice may be appropriate for the subsequent

sive corners of the paper about 30 times. Carefully transfer the

determination of other metals provided the concentrations are

combined sample/flux to a graphite crucible, and tamp down

high enough or if the instrumental sensitivity is sufficient.

by gently tapping the crucible on a tabletop.

12. Interferences

10.6 Weighappropriatesedimentorrockstandardsandtreat

as in 10.5.

12.1 Numerous inter-element interferences, both positive

and negative, exist for this procedure and have been docu-

10.7 Carry several blanks through the procedure by using

4, 5, 9

mented elsewhere.

only flux and treat as in 10.5.

12.2 Interferences are eliminated, compensated for, or both,

10.8 Fuse the mixtures in a muffle furnace, preheated to

through the use of cesium chloride (CsCl), the use of mixed

1000°C, for 30 min.

salt standards, and background correction if quantitation is by

NOTE 2—When the crucibles, samples, and crucible racks are placed in

atomic absorption spectroscopy.

the muffle furnace, the temperature may drop as much as 200°C. Time is

still measured from the time of insertion in the furnace.

13. Apparatus

10.9 Remove the crucibles from the furnace and allow to

13.1 TFE-Fluorocarbon Beakers, 100-mL capacity, thick

cool; dislodge the beads by gentle tapping or with a spatula.

wall, capable of withstanding temperature up to 260°C.

NOTE 3—The beads can be dissolved immediately after cooling, or can

13.2 Hot Plate, electric or gas, capable of reaching at least

be stored in plastic vials for dissolution at a later time.

250°C.

10.10 Place the bead in an acid-washed 250-mL plastic

3 13.3 Perchloric Acid Hood, with appropriate washdown

bottleandadda ⁄4to1in.(19.05to25.4mm)magnetic

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.