ASTM E2058-00

(Test Method)Standard Test Methods for Measurement of Synthetic Polymer Material Flammability Using a Fire Propagation Apparatus (FPA)

Standard Test Methods for Measurement of Synthetic Polymer Material Flammability Using a Fire Propagation Apparatus (FPA)

SCOPE

1.1 This fire-test-response standard determines and quantifies synthetic polymer material flammability characteristics, related to the propensity of materials to support fire propagation, by means of a fire propagation apparatus (FPA). Material flammability characteristics that are quantified include time to ignition (tign), chemical ( Qchem), and convective ( Qc) heat release rates, mass loss rate ( m) and effective heat of combustion (EHC).

1.2 The following test methods, capable of being performed separately and independently, are included herein:

1.2.1 Ignition Test, to determine tign for a horizontal specimen;

1.2.2 Combustion Test, to determine Qchem, Qc'm, and EHC from burning of a horizontal specimen; and,

1.2.3 Fire Propagation Test to determine Qchem from burning of a vertical specimen.

1.3 Distinguishing features of the FPA include tungsten-quartz external, isolated heaters to provide a radiant flux of up to 65 kW/m 2 to the test specimen, which remains constant whether the surface regresses or expands; provision for combustion or upward fire propagation in prescribed flows of normal air, air enriched with up to 40 % oxygen, air oxygen vitiated, pure nitrogen or mixtures of gaseous suppression agents with the preceding air mixtures; and, the capability of measuring heat release rates and exhaust product flows generated during upward fire propagation on a vertical test specimen 0.305 m high.

1.4 The FPA is used to evaluate the flammability of synthetic polymer materials and products. It is also designed to obtain the transient response of such materials and products to prescribed heat fluxes in specified inert or oxidizing environments and to obtain laboratory measurements of generation rates of fire products (CO2, CO, and, if desired, gaseous hydrocarbons) for use in fire safety engineering.

1.5 Ignition of the specimen is by means of a pilot flame at a prescribed location with respect to the specimen surface.

1.6 The Fire Propagation test of vertical specimens is not suitable for materials that, on heating, melt sufficiently to form a liquid pool.

1.7 Values stated are in SI units. Values in parentheses are for information only.

1.8 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products or assemblies under actual fire conditions.

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 2058 – 00

Standard Test Methods for

Measurement of Synthetic Polymer Material Flammability

Using a Fire Propagation Apparatus (FPA)

This standard is issued under the fixed designation E 2058; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope suitable for materials that, on heating, melt sufficiently to form

a liquid pool.

1.1 This fire-test-response standard determines and quanti-

1.7 Values stated are in SI units. Values in parentheses are

fies synthetic polymer material flammability characteristics,

for information only.

related to the propensity of materials to support fire propaga-

1.8 This standard is used to measure and describe the

tion, by means of a fire propagation apparatus (FPA). Material

response of materials, products, or assemblies to heat and flame

flammability characteristics that are quantified include time to

under controlled conditions, but does not by itself incorporate

˙ ˙

ignition (t ), chemical ( Q ), and convective ( Q ) heat

ign chem c

all factors required for fire hazard or fire risk assessment of the

release rates, mass loss rate ( m˙ ) and effective heat of

materials, products or assemblies under actual fire conditions.

combustion (EHC).

1.9 This standard does not purport to address all of the

1.2 The following test methods, capable of being performed

safety concerns, if any, associated with its use. It is the

separately and independently, are included herein:

responsibility of the user of this standard to establish appro-

1.2.1 Ignition Test, to determine t for a horizontal speci-

ign

priate safety and health practices and determine the applica-

men;

bility of regulatory limitations prior to use. For specific hazard

˙ ˙

1.2.2 Combustion Test, to determine Q , Q , m˙ , and EHC

chem c

statements, see Section 7.

from burning of a horizontal specimen; and,

˙

1.2.3 Fire Propagation Test, to determine Q from burn-

chem

2. Referenced Documents

ing of a vertical specimen.

2.1 ASTM Standards:

1.3 Distinguishing features of the FPA include tungsten-

E 176 Terminology of Fire Standards

quartz external, isolated heaters to provide a radiant flux of up

E 906 Test Method for Heat and Visible Smoke Release

to 65 kW/m to the test specimen, which remains constant

Rates for Materials and Products

whether the surface regresses or expands; provision for com-

E 1321 Test Method for Determining Material Ignition and

bustion or upward fire propagation in prescribed flows of

Flame Spread Properties

normal air, air enriched with up to 40 % oxygen, air oxygen

E 1354 Test Method for Heat and Visible Smoke Release

vitiated, pure nitrogen or mixtures of gaseous suppression

Rates for Materials and Products Using an Oxygen Con-

agents with the preceding air mixtures; and, the capability of

sumption Calorimeter

measuring heat release rates and exhaust product flows gener-

E 1623 Test Method for Determination of Fire and Thermal

ated during upward fire propagation on a vertical test specimen

Parameters of Materials, Products, and Systems Using an

0.305 m high.

Intermediate Scale Calorimeter (ICAL)

1.4 The FPA is used to evaluate the flammability of syn-

thetic polymer materials and products. It is also designed to

3. Terminology

obtain the transient response of such materials and products to

3.1 Definitions—For definitions of terms used in these test

prescribed heat fluxes in specified inert or oxidizing environ-

methods, refer to Terminology E 176.

ments and to obtain laboratory measurements of generation

3.2 Definitions of Terms Specific to This Standard:

rates of fire products (CO , CO, and, if desired, gaseous

3.2.1 effective heat of combustion, EHC, (kJ/kg), n—the

hydrocarbons) for use in fire safety engineering.

energy generated by chemical reactions per unit mass of fuel

1.5 Ignition of the specimen is by means of a pilot flame at

vaporized.

a prescribed location with respect to the specimen surface.

3.3 Symbols:

1.6 The Fire Propagation test of vertical specimens is not

A = cross sectional area of test section duct (m )

d

These test methods are under the jurisdiction of ASTM Committee E-05 on Fire

Standards and are the direct responsibility of Subcommittee E05.22 on Surface

Burning.

Current edition approved Jan. 10, 2000. Published April 2000.

Annual Book of ASTM Standards, Vol 04.07.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

E 2058

4.3 The Combustion test method is used to determine the

c = specific heat of air at constant pressure (kJ/kg K)

p

˙

chemical and convective heat release rates when the horizontal

G = mass flow rate of CO in test section duct (kg/s)

co

˙

test specimen is exposed to an external radiant heat flux.

G = mass flow rate of CO in test section duct (kg/s)

co 2

DH = effective heat of combustion (kJ/kg) 4.4 The Fire Propagation test method is used to determine

eff

K = flow coefficient of averaging Pitot tube [duct gas

the chemical heat release rate of a burning, vertical specimen

1/2

velocity/(2Dp /r) ] (-)

during upward fire propagation and burning initiated by a heat

m

M = ultimate change in specimen mass resulting from

flux near the base of the specimen. Chemical heat release rate

loss

combustion (kg)

is derived from the release rates of carbon dioxide and carbon

m˙ = mass loss rate of test specimen (kg/s)

monoxide. Observations also are made of the flame height on

m˙ = mass flow rate of gaseous mixture in test section

d

the vertical specimen during fire propagation.

duct (kg/s)

P = atmospheric pressure (Pa)

5. Significance and Use

atm

Dp = pressure differential across averaging Pitot tube in

m

5.1 These test methods are an integral part of existing test

test section duct (Pa)

standards for cable fire propagation and clean room material

Q = cumulative heat released during Combustion Test

flammability, as well as, in an approval standard for conveyor

(kJ)

belting (1-3). Refs (1-3) use these test methods because

˙

Q = chemical heat release rate (kW)

chem

fire-test-response results obtained from the test methods cor-

˙

Q = convective heat release rate (kW)

c

relate with fire behavior during real-scale fire propagation tests,

T = gas temperature in test section duct before igni-

a

as discussed in X1.4

tion (K)

5.2 The Ignition, Combustion, or Fire Propagation test

T = gas temperature in test section duct (K)

d

method, or a combination thereof, have been performed with

t = time (s)

materials and products containing a wide range of polymer

t = ignition time (s)

ign

compositions and structures, as described in X1.7.

Dt = time between data scans (s)

X = measured carbon dioxide analyzer reading or

5.3 The Fire Propagation test method is different from the

CO

mole fraction of carbon dioxide (-) test methods in the ASTM standards listed in 2.1 by virtue of

X = measured carbon monoxide analyzer reading or

producing laboratory measurements of the chemical heat

CO

mole fraction of CO (-)

release rate during upward fire propagation and burning on a

3.4 Superscripts:

vertical test specimen in normal air, oxygen-enriched air, or in

oxygen-vitiated air. Test methods from other standards, for

example, Test Method E 1321, which yields measurements

• –1

= per unit time (s )

during lateral/horizontal or downward flame spread on mate-

= before ignition of the specimen

rials and Test Methods E 906, E 1354, and E 1623, which yield

3.5 Subscripts:

measurements of the rate of heat release from materials fully

involved in flaming combustion, generally use an external

radiant flux, rather than the flames from the burning material

= test section duct

d

= fire product itself, to characterize fire behavior.

j

5.4 These test methods are not intended to be routine quality

4. Summary of Test Method

control tests. They are intended for evaluation of specific

4.1 Three separate test methods are composed herein, and

flammability characteristics of materials. Materials to be ana-

are used independently in conjunction with a Fire Propagation

lyzed consist of specimens from an end-use product or the

Apparatus. The Ignition and Combustion test methods involve

various components used in the end-use product. Results from

the use of horizontal specimens subjected to a controlled,

the laboratory procedures provide input to fire propagation and

external radiant heat flux, which can be set from 0 up to 65

fire growth models, risk analysis studies, building and product

kW/m . The Fire Propagation test method involves the use of

designs, and materials research and development.

vertical specimens subjected to ignition near the base of the

specimen from an external radiant heat flux and a pilot flame. 6. Apparatus

Both the Combustion and Fire Propagation test methods can be

6.1 General:

performed using an inlet air supply that is either normal air or

6.1.1 Where dimensions are stated in the text or in figures,

other gaseous mixtures, such as air with added nitrogen or air

they shall be considered mandatory and shall be followed

enriched with up to 40 % oxygen.

within a nominal tolerance of 6 0.5 %. An exception is the

4.2 The Ignition test method is used to determine the time

case of components meant to fit together, where the joint

required for ignition, t , of horizontal specimens by a pilot

ign

tolerance shall be appropriate for a sliding fit.

flame as a function of the magnitude of a constant, externally

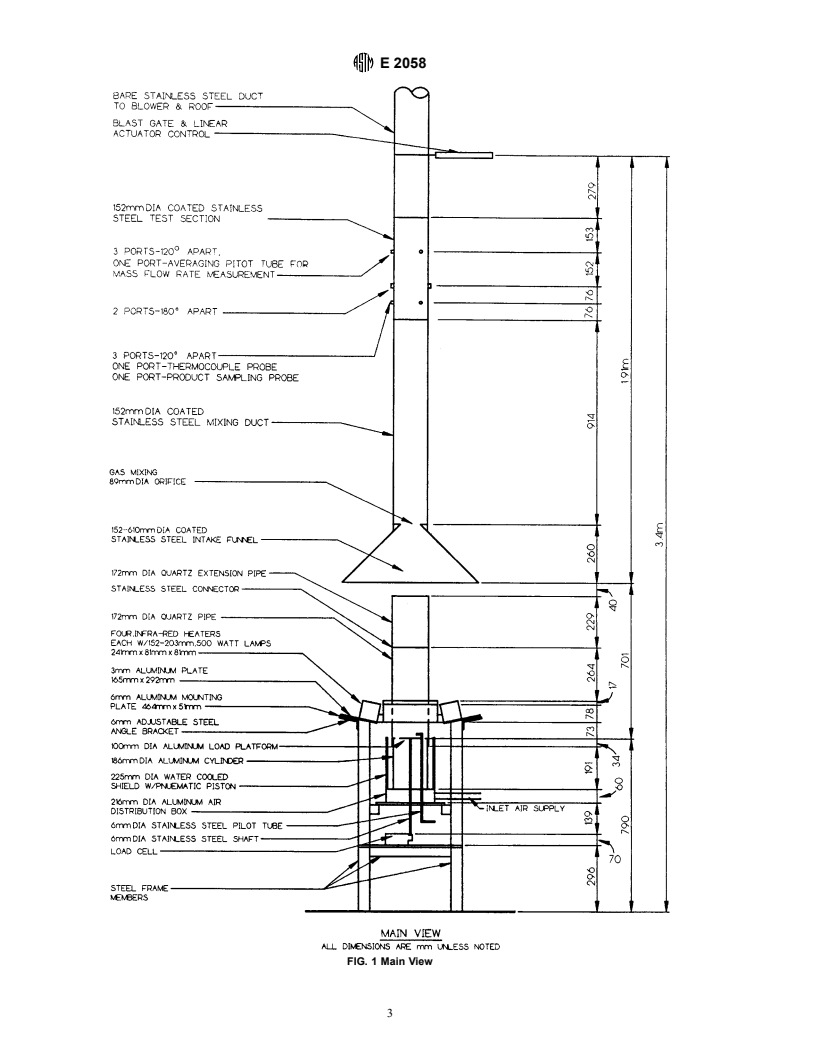

6.1.2 The apparatus (see overview in Fig. 1 and exploded

applied radiant heat flux. Measurements also are made of time

views in Figs. 2 and 3) shall consist of the following compo-

required until initial fuel vaporization. The surface of these

nents: an infrared heating system, a load cell system, an

specimens is coated with a thin layer of black paint to ensure

complete absorption of the radiant heat flux from the infrared

heating system (note that the coating does not itself undergo

The boldface numbers in parentheses refer to the list of references at the end of

sustained flaming). this standard.

E 2058

FIG. 1 Main View

E 2058

FIG. 2 Exploded View of Specimen Mounting

E 2058

NOTE 1—All dimensions are in mm unless noted.

FIG. 3 Exploded Main View

E 2058

ignition pilot flame and timer, a product gas analysis system, a 6.6.1 Gas Sampling—The gas sampling arrangement is

combustion air distribution system, a water-cooled shield, an shown in Fig. 4. This arrangement consists of a sampling probe

exhaust system, test section instruments, calibration instru- in the test section duct, a plastic filter (5-micron pore size) to

ments, and a digital data acquisition system. prevent entry of soot, a condenser operating at temperatures in

6.2 Infrared (IR) Heating System—The IR Heating System the range –5°C to 0°C to remove liquids, a tube containing an

shall consist of four 241-mm long heaters (see different views indicating desiccant (10–20 mesh) to remove most of the

in Figs. 1-3) and a power controller. remaining moisture, a filter to prevent soot from entering the

6.2.1 IR Heaters—Each of four IR heaters shall contain six analyzers, if not already removed, a sampling pump that

tungsten filament tubular quartz lamps in a compact reflector transports the flow through the sampling line, a system flow

body that produces up to 510 kW/m of radiant flux in front of meter, and manifolds to direct the flow to individual analyzers

the quartz window that covers the lamps. The reflector body is (CO, CO ,O , and hydrocarbon gas). The sampling probe,

2 2

water cooled and the lamp chamber, between the quartz made of 6.35-mm (0.25-in.) O.D. stainless steel tubing inserted

window and reflector, is air cooled for prolonged life. The through a test section port, shall be positioned such that the

emitter of each lamp is a 127-mm long tungsten filament in an open end of the tube is at the center of the test section. The

argon atmosphere enclosed in a 9.5-mm outer diameter clear sampling probe is connected to a tee fitting that allows either

quartz tube. The emitter operates at approximately 2205°C sample or calibration gas to flow to the analyzer, and the excess

(4000°F) at rated voltage, with a spectral energy peak at 1.15 to waste.

micron. Wavelengths greater than about 2-microns are ab-

6.6.2 Carbon Dioxide/Carbon Monoxide Analyzers—The

sorbed by the quartz bulb envelope and heater front window,

carbon dioxide analyzer shall permit measurements from 0 to

which are air cooled.

15 000 ppm and the carbon monoxide analyzer shall permit

6.2.2 Power Controller—The controller shall maintain the

measurements from 0 to 500 ppm concentration levels. Drift

output voltage required by the heater array despite variations in

shall be not more than 6 1 % of full scale over a 24-h period.

load impedance through the use of phase angle power control

Precision shall be 1 % of full-scale and the 10 to 90 % of

to match the hot/cold resistance characteristics of the tungsten/

full-scale response time shall be1sor less.

quartz lamps. The controller also shall incorporate average

6.6.3 Inlet-Air Oxygen Analyzer—This analyzer shall have a

voltage feedback to linearize the relationship between the

10 to 90 % of full-scale response time of1sor less, an

voltage set by the operator and the output voltage to the lamps.

accuracy of 1 % of full-scale, a drift of not more than 6 50

6.3 Load Cell System—The load cell system, shown in Figs.

ppm O over ⁄2 handa0to50% range.

1-3, shall consist of a load cell, which shall have an accuracy

6.6.4 Optional Product Analyzers for the Combustion

of 0.1 g, and a measuring range of 0–1000 g; a 6.35-mm

Test—An additional oxygen analyzer can be used to measure

diameter stainless steel shaft, at least 330 mm long, resting on

the depletion of oxygen in the combustion products. This

the load cell support point; a 100-mm diameter, 1.5-mm thick

analyzer should have the same specifications as the inlet-air

aluminum load platform connected to the upper end of the

analyzer but should have a concentration range of 19 to 21 %.

stainless steel shaft by a collar; and two low friction, ball-

A hydrocarbon gas analyzer employing the flame ionization

bushing bearings that guide the shaft as it passes through the

method of detection can be used to determine the total gaseous

top and bottom, respectively, of the air distribution chamber.

hydrocarbon concentration. This analyzer should have a 10 to

The stainless steel shaft shall incor

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.