ASTM A1083/A1083M-12

(Specification)Standard Specification for Steel, Sheet, Cold-Rolled, Carbon, Structural, High-Strength Low-Alloy, Produced by Twin-Roll Casting Process

Standard Specification for Steel, Sheet, Cold-Rolled, Carbon, Structural, High-Strength Low-Alloy, Produced by Twin-Roll Casting Process

ABSTRACT

This specification covers cold-rolled, carbon, structural, and high-strength low-alloy, in coils and cut lengths produced by the twin-roll casting process. Cold-rolled steel sheet is available in the following designations: commercial steel, drawing steel, structural steel, and high-strength low-alloy steel. Sheet steel grades defined by this specification are suitable for welding if appropriate welding conditions are selected. For certain welding processes, if more restrictive composition limits are desirable, they shall be specified at the time of inquiry and confirmed at the time of ordering. The material shall be capable of being bent, at room temperature, in any direction through 180° flat on itself without cracking on the outside of the bent portion. Two tension tests shall be made from each heat or from each 50 tons [45,000 kg]. Yield strength shall be determined by either the 0.2 % offset method or the 0.5 % extension under load method unless otherwise specified.

SCOPE

1.1 This specification covers cold-rolled, carbon, structural, and high-strength low-alloy, in coils and cut lengths produced by the twin-roll casting process.

1.2 Cold rolled steel sheet produced by the twin-roll casting process is available in the designations as listed in 4.1.

1.3 This specification does not apply to steel strip as described in Specification A109/A109M.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A1083/A1083M −12

Standard Specification for

Steel, Sheet, Cold-Rolled, Carbon, Structural, High-Strength

Low-Alloy, Produced by Twin-Roll Casting Process

This standard is issued under the fixed designation A1083/A1083M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E517 Test Method for Plastic Strain Ratio r for Sheet Metal

E646 Test Method for Tensile Strain-Hardening Exponents

1.1 This specification covers cold-rolled, carbon, structural,

(n -Values) of Metallic Sheet Materials

and high-strength low-alloy, in coils and cut lengths produced

by the twin-roll casting process.

3. Terminology

1.2 Cold rolled steel sheet produced by the twin-roll casting

3.1 Definitions of Terms Specific to This Standard:

process is available in the designations as listed in 4.1.

3.1.1 For definitions of other terms used in this

1.3 This specification does not apply to steel strip as

specification, refer to Terminology A941.

described in Specification A109/A109M.

3.2 aging, n—loss of ductility with an increase in hardness,

yield strength, and tensile strength that occurs when steel that

1.4 The values stated in either SI units or inch-pound units

has been slightly cold worked (such as by temper rolling) is

are to be regarded separately as standard. The values stated in

stored for some time.

each system may not be exact equivalents; therefore, each

system shall be used independently of the other. Combining

3.2.1 Discussion—Agingincreasesthetendencyofasteelto

values from the two systems may result in non-conformance

exhibit stretcher strains and fluting.

with the standard.

4. Classification

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4.1 Cold-rolled steel sheet is available in the following

responsibility of the user of this standard to establish appro-

designations:

priate safety and health practices and determine the applica-

4.1.1 Commercial Steel (CS Types A, B, and D).

bility of regulatory limitations prior to use.

4.1.2 Drawing Steel (DS Types B and D).

4.1.3 Structural Steel (SS grades 25[170], 30[205], 33[230]

2. Referenced Documents

Types 1 and 2, 40[275] Types 1 and 2, 50[340], 60[410],

2.1 ASTM Standards:

70[480], and 80[550]).

A109/A109M Specification for Steel, Strip, Carbon (0.25

4.1.4 High-Strength Low-Alloy Steel (HSLAS, in classes 1

Maximum Percent), Cold-Rolled

and 2, in grades 45[310], 50[340]. 55[380], 60[410], 65[450],

A370 Test Methods and Definitions for Mechanical Testing

70[480] and 80[550].

of Steel Products

4.2 When required for HSLAS steels, limitations on the use

A568/A568M Specification for Steel, Sheet, Carbon,

of one or more of the microalloy elements, titanium,

Structural,andHigh-Strength,Low-Alloy,Hot-Rolledand

columbium, vanadium, or molybdenum, shall be specified on

Cold-Rolled, General Requirements for

the order.

A941 TerminologyRelatingtoSteel,StainlessSteel,Related

Alloys, and Ferroalloys

4.3 Cold-rolled steel sheet is supplied for either exposed or

E18 Test Methods for Rockwell Hardness of Metallic Ma-

unexposed applications. Within the latter category, cold-rolled

terials

sheet is specified either “temper rolled” or “annealed last.” For

details on processing, attributes and limitations, and inspection

This specification is under the jurisdiction ofASTM Committee A01 on Steel, standards, refer to Specification A568/A568M.

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.19 on Steel Sheet and Strip.

5. Ordering Information

Current edition approved Nov. 1, 2012. Published November 2012. DOI:

10.1520/A1083_A1083M-12.

5.1 It is the purchaser’s responsibility to specify in the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

purchase order all ordering information necessary to describe

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

the required material. Examples of such information include,

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. but are not limited to, the following:

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A1083/A1083M−12

NOTE 2—A typical ordering description is as follows: ASTM A

5.1.1 ASTM specification number and year of issue;

XXXX-XX, cold rolled steel sheet, CS Type A, exposed, matte finish,

5.1.2 Name of material and designation (cold-rolled steel

oiled,0.035by30in.bycoil,ID24in.,OD48in.,maxweight15000lbs,

sheet) (include grade, type, and class, as appropriate, for CS,

100 000 lb, for part No. 4560, Door Panel. Or ASTM A XXXXM-XX,

DS, SS, HSLAS, (see 4.1);

cold-rolled steel sheet, SS grade 275, unexposed, matte finish, oiled, 0.88

5.1.2.1 When a type is not specified for CS or DS, Type D

mm by 760 mm by 2440 mm, 10 000 kg, for shelf bracket.

will be furnished (see 4.1);

6. General Requirements for Delivery

5.1.2.2 When a class is not specified for HSLAS, Class 1

will be furnished (see 4.1);

6.1 Material furnished under this specification shall con-

5.1.2.3 When a type is not specified for SS 33 [230] and SS

form to the applicable requirements of the current edition of

40 [275], Type 1 will be furnished (see 4.1);

Specification A568/A568M unless otherwise provided herein.

5.1.3 Classification (either exposed, unexposed, temper

7. Chemical Composition

rolled, or annealed last) (see 4.3);

5.1.4 Finish (see 9.1);

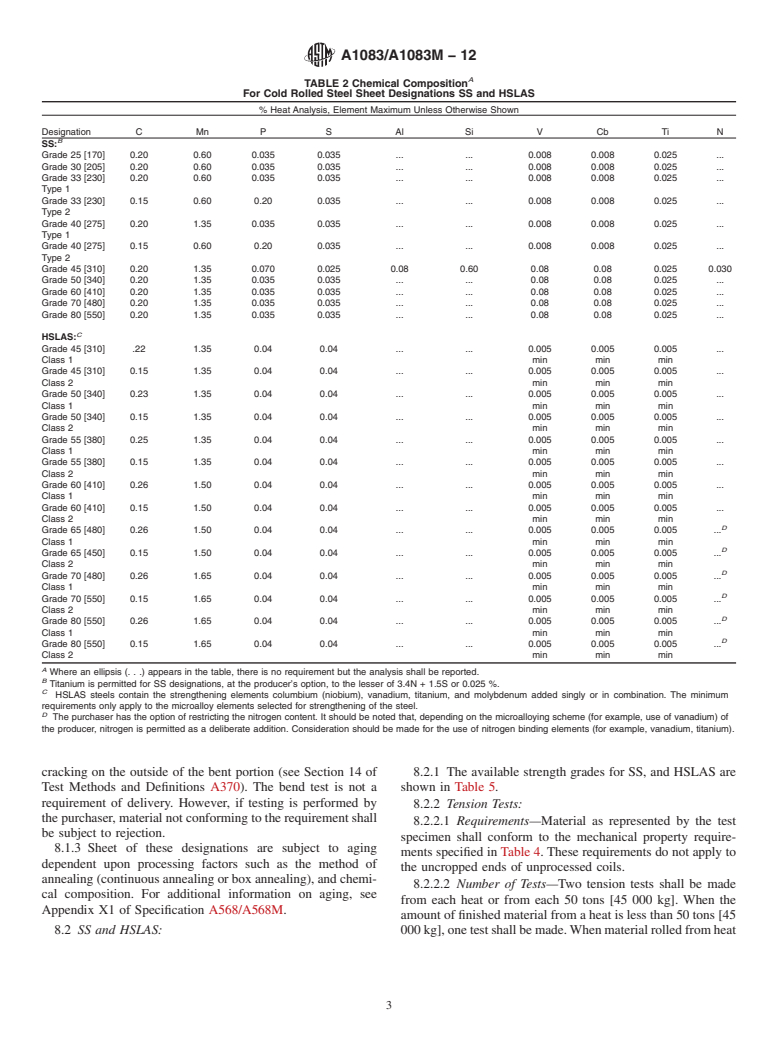

7.1 The heat analysis of the steel shall conform to the

5.1.5 Oiled or not oiled, as required (see 9.1);

chemical composition requirements of the appropriate desig-

5.1.5.1 Unless otherwise specified, the sheet shall be oiled.

nation shown in Table 1 for CS, and DS, and in Table 2 and

5.1.5.2 When required, specify the sheet to be furnished not

Table 3 for SS and HSLAS.

oiled (dry).

7.2 Each of the elements listed in Table 1, Table 2, and

5.1.6 Dimensions(thickness,width,andwhethercutlengths

Table 3 shall be included in the report of the heat analysis.

or coils);

When the amount of copper, nickel, chromium, or molybde-

NOTE 1—Not all producers are capable of meeting all the limitations

num is less than 0.02 %, report the analysis as <0.02 % or the

of the thickness tolerance tables in Specification A568/A568M. The

actual determined value. When the amount of vanadium,

purchaser should contact the producer regarding possible limitations prior

columbium, or titanium is less than 0.008 %, report the

to placing an order.

analysis as <0.008 % or the actual determined value.When the

5.1.7 Coil size (must include inside diameter, outside

amount of boron is less than 0.0005 %, report the analysis as

diameter, and maximum weight);

<0.0005 % or the actual determined value.

5.1.8 Copper bearing steel (if required);

7.3 Sheet steel grades defined by this specification are

5.1.9 Quantity;

suitable for welding if appropriate welding conditions are

5.1.10 Application (part identification and description);

selected. For certain welding processes, if more restrictive

5.1.11 A report of heat analysis will be supplied, if

composition limits are desirable, they shall be specified at the

requested, for CS, and DS. For materials with required me-

time of inquiry and confirmed at the time of ordering.

chanical properties, SS, and HSLAS, a report is required of

heat analysis and mechanical properties as determined by the

8. Mechanical Properties

tension test, and

5.1.12 Special requirements (if any). 8.1 CS and DS:

5.1.12.1 When the purchaser requires thickness tolerances 8.1.1 Typical nonmandatory mechanical properties for CS,

for 3/8 in. [10 mm] minimum edge distance (see Supplemen- and DS, are shown in Table 4.

tary Requirement in Specification A568/A568M), this require- 8.1.2 The material shall be capable of being bent, at room

ment shall be specified in the purchase order or contract. temperature,inanydirectionthrough180°flatonitselfwithout

A

TABLE 1 Chemical Composition

For Cold Rolled Steel Sheet Designations CS and DS

% Heat Analysis, Element Maximum Unless Otherwise Shown

F B C

Designation C Mn P S Al Si Cu Ni Cr Mo V Cb Ti NB

CS 0.10 0.70 0.030 0.035 . . 0.50 0.20 0.15 0.06 0.008 0.008 0.025 . .

D, E

Type A

CS 0.02 to 0.60 0.030 0.035 . . 0.50 0.20 0.15 0.06 0.008 0.008 0.025 . .

D

Type B 0.15

CS 0.15 0.80 0.10 0.035 . . 0.50 0.30 0.30 0.15 0.008 0.008 0.025 . .

D,E

Type D

DS 0.02 to 0.50 0.020 0.030 . . 0.50 0.20 0.15 0.06 0.008 0.008 0.025 . .

Type B 0.15

DS 0.15 0.60 0.030 0.035 . . 0.50 0.30 0.30 0.15 0.008 0.008 0.025 . .

Type D

A

Where an ellipsis (. . .) appears in the table, there is no requirement, but the analysis result shall be reported.

B

Chromium is permitted, at the producer’s option, to 0.25 % maximum when the carbon content is less than or equal to 0.05 %.

C

For steels containing 0.02 % or more carbon, titanium is permitted at the producer’s option, to the lesser of 3.4N + 1.5S or 0.025 %.

D

When an aluminum deoxidized steel is required for the application, it is permissible to order Commercial Steel (CS) to a minimum of 0.01 % total aluminum.

E

Specify Type B to avoid carbon levels below 0.02 %.

F

F When copper steel is specified, a minimum of 0.20% is required. When copper steel is not specified, the copper limit is a maximum requirement.

A1083/A1083M−12

A

TABLE 2 Chemical Composition

For Cold Rolled Steel Sheet Designations SS and HSLAS

% Heat Analysis, Element Maximum Unless Otherwise Shown

Designation C Mn P S Al Si V Cb Ti N

B

SS:

Grade 25 [170] 0.20 0.60 0.035 0.035 . . 0.008 0.008 0.025 .

Grade 30 [205] 0.20 0.60 0.035 0.035 . . 0.008 0.008 0.025 .

Grade 33 [230] 0.20 0.60 0.035 0.035 . . 0.008 0.008 0.025 .

Type 1

Grade 33 [230] 0.15 0.60 0.20 0.035 . . 0.008 0.008 0.025 .

Type 2

Grade 40 [275] 0.20 1.35 0.035 0.035 . . 0.008 0.008 0.025 .

Type 1

Grade 40 [275] 0.15 0.60 0.20 0.035 . . 0.008 0.008 0.025 .

Type 2

Grade 45 [310] 0.20 1.35 0.070 0.025 0.08 0.60 0.08 0.08 0.025 0.030

Grade 50 [340] 0.20 1.35 0.035 0.035 . . 0.08 0.08 0.025 .

Grade 60 [410] 0.20 1.35 0.035 0.035 . . 0.08 0.08 0.025 .

Grade 70 [480] 0.20 1.35 0.035 0.035 . . 0.08 0.08 0.025 .

Grade 80 [550] 0.20 1.35 0.035 0.035 . . 0.08 0.08 0.025 .

C

HSLAS:

Grade 45 [310] .22 1.35 0.04 0.04 . . 0.005 0.005 0.005 .

Class 1 min min min

Grade 45 [310] 0.15 1.35 0.04 0.04 . . 0.005 0.005 0.005 .

Class 2 min min min

Grade 50 [340] 0.23 1.35 0.04 0.04 . . 0.005 0.005 0.005 .

Class 1 min min min

Grade 50 [340] 0.15 1.35 0.04 0.04 . . 0.005 0.005 0.005 .

Class 2 min min min

Grade 55 [380] 0.25 1.35 0.04 0.04 . . 0.005 0.005 0.005 .

Class 1 min min min

Grade 55 [380] 0.15 1.35 0.04 0.04 . . 0.005 0.005 0.005 .

Class 2 min min min

Grade 60 [410] 0.26 1.50 0.04 0.04 . . 0.005 0.005 0.005 .

Class 1 min min min

Grade 60 [410] 0.15 1.50 0.04 0.04 . . 0.005 0.005 0.005 .

Class 2 min min min

D

Grade 65 [480] 0.26 1.50 0.04 0.04 . . 0.005 0.005 0.005 .

Class 1 min min min

D

Grade 65 [450] 0.15 1.50 0.04 0.04 . . 0.005 0.005 0.005 .

Class 2 min min min

D

Grade 70 [480] 0.26 1.65 0.04 0.04 . . 0.005 0.005 0.005 .

Class 1 min min min

D

Grade 70 [550] 0.15 1.65 0.04 0.04 . . 0.005 0.005 0.005 .

Class 2 min min min

D

Grade 80 [550] 0.26 1.65 0.04 0.04 . . 0.005 0.005 0.005 .

Class 1 min min min

D

Grade 80 [550] 0.15 1.65 0.04 0.04 . . 0.005 0.005 0.005 .

Class 2 min min min

A

Where an ellipsis (. . .) appears in the table, there is no requirement but the analysis shall be reported.

B

Titanium is permitted for SS designations, at the producer’s option, to the lesser of 3.4N + 1.5S or 0.025 %.

C

HSLAS steels contain the strengthening elements columbium (niobium), vanadium, titanium, and molybdenum added singly or in combination. The minimum

requirements only apply to the microalloy elements selected for strengthening of the steel.

D

The purchaser has the option of restricting the nitrogen content. It should be noted that, depending on the microalloying scheme (for example, use of vanadium) of

the producer, nitrogen is permitted as a deliberate addition. Consideration should be made for the use of nitrogen binding elements (for example, vanadium, titanium).

cracking on the outside of the bent portion (see Section 14 of 8.2.1 The available strength grades for SS, and HSLAS are

Test Methods and Definitions A370). The bend test is not a shown in Table 5.

requirement of delivery. However, if testing is performed by

8.2.2 Tension Tests:

the purchaser, material not conforming to the requirement shall

8.2.2.1 Requirements—Material as represented by the test

be subject to rejection.

specimen shall conform to the mechanical property require-

8.1.3 Sheet of these designations are subject to aging

ments specified in Table 4. These requirements do not apply to

dependent upon processing factors such as the method of

the uncropped ends of unprocessed coils.

annealing(continuousannealingorboxannealing),andchemi-

8.2.2.2 Number of Tests—Two tension tests shall be made

cal composition. For additional information on aging, see

from each heat or from each 50 tons [45 000 kg]. When the

Appendix X1 of Specification A568/A568M.

amount of finished material from a heat is less than 50 tons [45

8.2 SS and HSLAS: 000kg],onetestshallbemade.Whenmaterialrolledfromheat

A1083/A1083M−12

TABLE 3 Chemical Requirements: Cu, Ni, Cr, and Mo for

radius is required, where curved or offset bends are involved,

Structural Steels and High-Strength Low-Alloy Steels

or where stretching or drawing are also a consideration, the

% Heat Analysis, Maximum Unless Otherwise Specified

producer shall be consulted.

A,B B B,C B,C

Designation Limits Cu Ni Cr Mo

SS:

All Grades L 0.35 0.20 0.15 0.06 9. Finish and Appearance

H 0.50 0.30 0.30 0.16

9.1 Surface Finish:

HSLAS:

All Grades L 0.35 0.20 0.15 0.06

9.1.1 Unless otherwise specified, the sheet shall have a

and Classes

matte finish. When required, specify the appropriate surface

H 0.50 0.30 0.30 0.16

texture and condition. For additional information, see the

A

When copper is specified, a minimum of 0.20 % is required. When copper steel

Finish and Condition section of Specification A568/A568M.

is not specified, the copper limit is a maximum requirement.

B

B For limit H steels, the sum of copper, nickel, chromium, and molybdenum

For additional information see “Finish and Condition” section

shall not excee

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.