ASTM D5575-07(2013)

(Classification)Standard Classification System for Copolymers of Vinylidene Fluoride (VDF) with Other Fluorinated Monomers

Standard Classification System for Copolymers of Vinylidene Fluoride (VDF) with Other Fluorinated Monomers

ABSTRACT

This classification system covers both developing property designations and specifications for thermoplastic compositions consisting of vinylidene fluoride (VDF) polymers modified with other fluoromonomers and property-enhancing additives. Four property codes are presented: code 1 - melt temperature, code 2 - melt-flow rate or melt viscosity, or both, code 3 - tensile strength and modulus, and code 5 - density. The melt temperatures, melt-flow rate, melt viscosity, tensile properties, specific gravity, volume resistivity, dielectric constant, dissipation factor, and limiting oxygen index shall be tested to meet the requirements prescribed.

SCOPE

1.1 This classification system covers both developing property designations and specifications for thermoplastic compositions consisting of vinylidene fluoride (VDF) polymers modified with other fluoromonomers and property-enhancing additives. The other fluoromonomers include one or more of the following: hexafluoropropylene (HFP), tetrafluoroethylene (TFE), and chlorotrifluoroethylene (CTFE). The additives are those that improve its flame resistance, processing, or physical properties. However, these additives are not normally considered to be reinforcing. This classification system covers thermoplastic compositions supplied in pellet or powder forms.

1.2 A designation or specification applies only to the virgin polymers prepared from vinylidene fluoride (>50 weight %) with one or more of the following comonomers: hexafluoropropylene, tetrafluoroethylene, and chlorotrifluoroethylene. Some polymers contain additives to enhance certain properties.

1.3 This system constitutes a line callout as a means of designating and specifying properties of VDF-based copolymers. At least four of the designated properties are used to define a polymer's specification. Specification criteria from international documents can be used if their criteria match designation properties currently used by this classification system.2 This classification system is not intended for the selection of materials.

1.4 The manufacturer of the virgin resin shall establish the designation of a resin based on the property value criteria in this classification system.

1.5 The minimum specification properties are established by this classification system. Additional specification properties, based on the designation properties cited, can be established by the resin supplier and customer.

1.6 The values stated in SI units are to be regarded as standard.

1.7 The property tests are intended to provide information for specifications of modified VDF-copolymer compositions. It is not the purpose of this classification system to provide engineering data for design purposes. Note 1—Although the values listed in Table 1, Table 2, Table 3, Table 4, and Table are necessary to include the range of properties available in existing materials, they are not to be interpreted as implying that every possible combination of the properties exists or can be obtained. It is possible for a user or designer, using Tables 1-, to call out property relationships that are physically impossible to occur in a copolymer made using current technology.Note 2—Many of these polymers exhibit polymorphism.3 The type and extent of crystalline structure will vary with the thermomechanical history of the sample. Properties vary based on the technique used to prepare the specimens.

1.8 Test methods used in this classification system can result in the incidental production of hazardous materials. Modified VDF polymer fluoroplastics melt between 90 and 182°C (194 and 359°F) and are thermally stable up to about 350°C (662°F), or somewhat higher, depending on the composition. (Warning— Evolution of corrosive, colorless, and toxic hydrogen fluoride can occur under certain conditions.)

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the ...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5575 −07 (Reapproved 2013)

Standard Classification System for

Copolymers of Vinylidene Fluoride (VDF) with Other

Fluorinated Monomers

This standard is issued under the fixed designation D5575; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 1.5 Theminimumspecificationpropertiesareestablishedby

this classification system. Additional specification properties,

1.1 This classification system covers both developing prop-

basedonthedesignationpropertiescited,canbeestablishedby

erty designations and specifications for thermoplastic compo-

the resin supplier and customer.

sitions consisting of vinylidene fluoride (VDF) polymers

modified with other fluoromonomers and property-enhancing 1.6 The values stated in SI units are to be regarded as

additives. The other fluoromonomers include one or more of standard.

the following: hexafluoropropylene (HFP), tetrafluoroethylene

1.7 The property tests are intended to provide information

(TFE), and chlorotrifluoroethylene (CTFE). The additives are

forspecificationsofmodifiedVDF-copolymercompositions.It

those that improve its flame resistance, processing, or physical

is not the purpose of this classification system to provide

properties. However, these additives are not normally consid-

engineering data for design purposes.

ered to be reinforcing. This classification system covers ther-

NOTE 1—Although the values listed in Table 1, Table 2, Table 3, Table

moplastic compositions supplied in pellet or powder forms.

4,andTable5arenecessarytoincludetherangeofpropertiesavailablein

1.2 Adesignation or specification applies only to the virgin

existing materials, they are not to be interpreted as implying that every

possible combination of the properties exists or can be obtained. It is

polymers prepared from vinylidene fluoride (>50 weight %)

possible for a user or designer, using Tables 1-5, to call out property

with one or more of the following comonomers:

relationships that are physically impossible to occur in a copolymer made

hexafluoropropylene, tetrafluoroethylene, and chlorotrifluoro-

using current technology.

ethylene. Some polymers contain additives to enhance certain 3

NOTE2—Manyofthesepolymersexhibitpolymorphism. Thetypeand

properties.

extentofcrystallinestructurewillvarywiththethermomechanicalhistory

of the sample. Properties vary based on the technique used to prepare the

1.3 This system constitutes a line callout as a means of

specimens.

designating and specifying properties of VDF-based copoly-

1.8 Testmethodsusedinthisclassificationsystemcanresult

mers. At least four of the designated properties are used to

in the incidental production of hazardous materials. Modified

define a polymer’s specification. Specification criteria from

VDF polymer fluoroplastics melt between 90 and 182°C (194

international documents can be used if their criteria match

and359°F)andarethermallystableuptoabout350°C(662°F),

designation properties currently used by this classification

or somewhat higher, depending on the composition.

system. This classification system is not intended for the

(Warning—Evolutionofcorrosive,colorless,andtoxichydro-

selection of materials.

gen fluoride can occur under certain conditions.)

1.4 The manufacturer of the virgin resin shall establish the

1.9 This standard does not purport to address all of the

designation of a resin based on the property value criteria in

safety concerns, if any, associated with its use. It is the

this classification system.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

ThisclassificationsystemisunderthejurisdictionofASTMCommitteeD20on

bility of regulatory limitations prior to use.SeeWarning in1.8

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic

Materials.

and Section 10 for specific hazards statements.

Current edition approved Sept. 1, 2013. Published October 2013. Originally

NOTE 3—Many, but not all of the codes and specifications found in this

approved in 1994. Last previous edition approved in 2007 as D5575-07.

This standard is needed to cover commercial products outside the scope of classification system are also in ISO12086-1 and ISO12086-2.

Specification D3222. DOI: 10.1520/D5575-07R13.

Fluoropolymer property specification data from international standards can

include properties intentionally excluded from this classification system (for

example,composition).Theonlypropertycriteriafromotherdocumentsthatcanbe Lovinger, A. J., “Poly(vinylidene fluoride),” Developments in Crystalline

used are those having similar properties allowed under the designation system. Polymers, Vol 1, Chapter 5, D.C. Bassett, Ed., Applied Science, London, 1982.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5575−07 (2013)

TABLE 1 Codes for the Information on Fluoropolymers Used in

D257Test Methods for DC Resistance or Conductance of

Data Block 1

Insulating Materials

Code Meaning

D618Practice for Conditioning Plastics for Testing

A modified

D638Test Method for Tensile Properties of Plastics

B block copolymer

D792Test Methods for Density and Specific Gravity (Rela-

H homopolymer

K copolymer

tive Density) of Plastics by Displacement

L graft polymer

D883Terminology Relating to Plastics

R random copolymer

Z other D1238Test Method for Melt Flow Rates of Thermoplastics

by Extrusion Plastometer

D1600TerminologyforAbbreviatedTermsRelatingtoPlas-

TABLE 2 Code-Letters Used in Data Block 2 (Intended

tics

Application or Method of Processing, Essential Properties,

D2863Test Method for Measuring the Minimum Oxygen

Additives, or Other Information

Concentration to Support Candle-Like Combustion of

Code Position 1 Code Positions 2 to 8

Plastics (Oxygen Index)

A adhesives C colored

D3222Specification for Unmodified Poly(Vinylidene Fluo-

B blow molding D powder

B1 extrusion blow molding D2 free-flowing

ride) (PVDF) Molding Extrusion and Coating Materials

B2 injection blow molding D3 not free-flowing

D3418Test Method for Transition Temperatures and En-

C calendaring E expandable

thalpies of Fusion and Crystallization of Polymers by

E extrusion F special burning characteristics

G general use F1 nonflammable

Differential Scanning Calorimetry

H coating F2 flame retarded

D3835Test Method for Determination of Properties of

H1 powder coating F4 reduced smoke emission

Polymeric Materials by Means of a Capillary Rheometer

H2 dip coating G granules

K cable and wire coating G1 pellets

D3892Practice for Packaging/Packing of Plastics

L monofilament extrusion L light and weather stabilized

D4591Test Method for Determining Temperatures and

M molding (injection/transfer) M nucleated

Heats of Transitions of Fluoropolymers by Differential

Q compression molding N natural (no color added)

R rotational molding N1 suitable for food contact

Scanning Calorimetry

V thermoforming N2 high purity

D4703Practice for Compression Molding Thermoplastic

X no indication P impact modified

Y textile yarns, spinning R mold release agent Materials into Test Specimens, Plaques, or Sheets

Z other S lubricated

D5740Guide for Writing Material Standards in the Classi-

T transparent

fication Format

T1 translucent

T2 opaque IEEE/ASTMS1–10Standard for Use of the International

W1 improved chemical resistance

System of Units (SI)

Y increased electrical conductivity

Z antistatic

2.2 IEC and ISO Standards:

IEC 60093Recommended Methods of Test for Volume and

Surface Resistivities of Electrical Insulating Materials

TABLE 3 Designatory and Specification Properties for Data Block

IEC60250RecommendedMethodsfortheDeterminationof

the Permittivity and Dielectric Dissipation Factor of

A

Position Number Property

B

Electrical Insulating Materials at Power,Audio and Radio

1 melt temperature

B

2 melt flow rate/melt viscosity

Frequencies Including Metre Wavelengths

B

3 tensile strength and modulus

ISO 291 Plastics—Standard Atmospheres for Conditioning

4 tensile elongation

B

5 density and Testing (Practice D618)

6 electrical

ISO 293 Plastics—Compression Molding Test Specimens

7 flammability by oxygen index (OI)

of Thermoplastic Materials (Practice4703)

8 specimen preparation method and type

ISO 472 Plastics—Vocabulary (Terminology D883)

A

Property test information for Positions 1 to 7 are given in Section 8.

B

ISO527/1,2,3Plastics—DeterminationofTensileProperties

Positions 1, 2, 3, and 5 are mandated as the minimum specification properties.

(Test Method D638)

ISO 1043/1 Plastics—Symbols—Part 1: Symbols for Basic

Polymers and Their Special Characteristics (Terminology

2. Referenced Documents

D883)

2.1 ASTM Standards: ISO 1043/2Plastics—Symbols—Part 2: Fillers and Rein-

forcing Materials (Terminology D883)

NOTE 4—For ASTM and ISO documents, the equivalent or a compa-

ISO 1133Plastics—Determination of the Melt Mass-Flow

rable method is listed after each citation in parentheses.

Rate (MFR) and the Melt Volume-Flow Rate (MVR) of

D150Test Methods forAC Loss Characteristics and Permit-

Thermoplastics (Test Method D1238)

tivity (Dielectric Constant) of Solid Electrical Insulation

ISO 1183Plastics—Methods for Determining Density and

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

D5575−07 (2013)

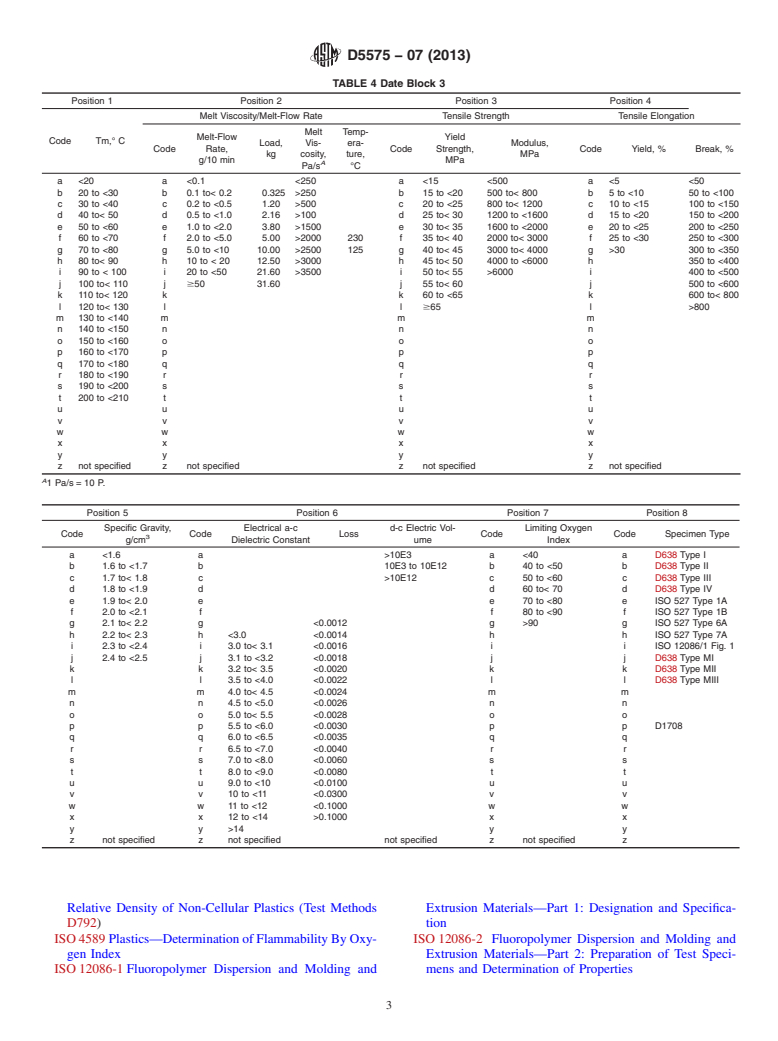

TABLE 4 Date Block 3

Position 1 Position 2 Position 3 Position 4

Melt Viscosity/Melt-Flow Rate Tensile Strength Tensile Elongation

Melt Temp-

Melt-Flow Yield

Code Tm,° C

Load, Vis- era- Modulus,

Code Rate, Code Strength, Code Yield, % Break, %

kg cosity, ture, MPa

g/10 min MPa

A

Pa/s °C

a <20 a <0.1 <250 a <15 <500 a <5 <50

b 20 to <30 b 0.1 to< 0.2 0.325 >250 b 15 to <20 500 to< 800 b 5 to <10 50 to <100

c 30 to <40 c 0.2 to <0.5 1.20 >500 c 20 to <25 800 to< 1200 c 10 to <15 100 to <150

d 40 to< 50 d 0.5 to <1.0 2.16 >100 d 25 to< 30 1200 to <1600 d 15 to <20 150 to <200

e 50 to <60 e 1.0 to <2.0 3.80 >1500 e 30 to< 35 1600 to <2000 e 20 to <25 200 to <250

f 60 to <70 f 2.0 to <5.0 5.00 >2000 230 f 35 to< 40 2000 to< 3000 f 25 to <30 250 to <300

g 70 to <80 g 5.0 to <10 10.00 >2500 125 g 40 to< 45 3000 to< 4000 g >30 300 to <350

h 80 to< 90 h 10 to < 20 12.50 >3000 h 45 to< 50 4000 to <6000 h 350 to <400

i 90 to < 100 i 20 to <50 21.60 >3500 i 50 to< 55 >6000 i 400 to <500

j 100 to< 110 j $50 31.60 j 55 to< 60 j 500 to <600

k 110 to< 120 k k 60 to <65 k 600 to< 800

l 120 to< 130 l l $65 l >800

m 130 to <140 m m m

n 140 to <150 n n n

o 150 to <160 o o o

p 160 to <170 p p p

q 170 to <180 q q q

r 180 to <190 r r r

s 190 to <200 s s s

t 200 to <210 t t t

uu u u

vv v v

ww w w

xx x x

yy y y

z not specified z not specified z not specified z not specified

A

1 Pa/s = 10 P.

Position 5 Position 6 Position 7 Position 8

Specific Gravity, Electrical a-c d-c Electric Vol- Limiting Oxygen

Code Code Loss Code Code Specimen Type

g/cm Dielectric Constant ume Index

a <1.6 a >10E3 a <40 a D638 Type I

b 1.6 to <1.7 b 10E3 to 10E12 b 40 to <50 b D638 Type II

c 1.7 to< 1.8 c >10E12 c 50 to <60 c D638 Type III

d 1.8 to <1.9 d d 60 to< 70 d D638 Type IV

e 1.9 to< 2.0 e e 70 to <80 e ISO 527 Type 1A

f 2.0 to <2.1 f f 80 to <90 f ISO 527 Type 1B

g 2.1 to< 2.2 g <0.0012 g >90 g ISO 527 Type 6A

h 2.2 to< 2.3 h <3.0 <0.0014 h h ISO 527 Type 7A

i 2.3 to <2.4 i 3.0 to< 3.1 <0.0016 i i ISO 12086/1 Fig. 1

j 2.4 to <2.5 j 3.1 to <3.2 <0.0018 j j D638 Type MI

k k 3.2 to< 3.5 <0.0020 k k D638 Type MII

l l 3.5 to <4.0 <0.0022 l l D638 Type MIII

m m 4.0 to< 4.5 <0.0024 m m

n n 4.5 to <5.0 <0.0026 n n

o o 5.0 to< 5.5 <0.0028 o o

p p 5.5 to <6.0 <0.0030 p p D1708

q q 6.0 to <6.5 <0.0035 q q

r r 6.5 to <7.0 <0.0040 r r

s s 7.0 to <8.0 <0.0060 s s

t t 8.0 to <9.0 <0.0080 t t

u u 9.0 to <10 <0.0100 u u

v v 10 to <11 <0.0300 v v

w w 11 to <12 <0.1000 w w

x x 12 to <14 >0.1000 x x

y y >14 y y

z not specified z not specified not specified z not specified z

Relative Density of Non-Cellular Plastics (Test Methods Extrusion Materials—Part 1: Designation and Specifica-

D792) tion

ISO4589Plastics—DeterminationofFlammabilityByOxy- ISO12086-2 Fluoropolymer Dispersion and Molding and

gen Index Extrusion Materials—Part 2: Preparation of Test Speci-

ISO12086-1Fluoropolymer Dispersion and Molding and mens and Determination of Properties

D5575−07 (2013)

TABLE 5 Codes for Filler and Physical Form of Materials for Use

3.3.4 HFP—hexafluoropropylene (1,1,2,3,3,3-hexaflu-

in Data Block 4

oropropylene).

Code Material Code Form/Structure

3.3.5 MFR—melt-flow rate.

B boron B beads, spheres, balls

C carbon C chips, cuttings

3.3.6 MV—melt viscosity.

CG graphite D powder

3.3.7 PVDF—poly(vinylidene fluoride).

E clay F fiber

G glass G ground

3.3.8 TFE—tetrafluoroethylene (1,1,2,2-tetrafluoro-

K calcium carbonate H whisker

M mineral, metal K knitted fabric ethylene). D1600

Ma aluminum oxide L layer

3.3.9 VDF—vinylidene fluoride (1,1,-difluoroethylene).

Mb bronze M mat (thick)

MC calcium fluoride N nonwoven (fabric)

3.3.10 VDF/CTFE—vinylidene fluoride/chlorotriflu-

Md molybdenum disulfide P paper

oroethylene copolymer.

Me stainless steel S roving

P mica T scale, flake

3.3.11 VDF/HFP—vinylidene fluoride/hexafluoropro-

Q silica V cord

penecopolymer.

R aramid W veneer

S synthetic, organic X not specified

3.3.12 VDF/TFE—vinylidene fluoride/tetrafluoroethylene

T talcum Y yarn

copolymer.

X not specified Z others

Z none

3.3.13 VDF/TFE/HFP—vinylidene fluoride/tetrafluoro-

ethylene/hexafluoropropene copolymer.

4. Classification and Designation

3. Terminology

4.1 The classification and designation system of the poly-

3.1 Definitions:

mersisbasedonthefollowingstandardizedpatterntakenfrom

3.1.1 copolymer—a polymer derived from more than one

ISO12086-1:

species of monomer.

3.1.2 fluoroplastic—a plastic based on polymers made with

Designation and Classification System

monomers containing one or more atoms of fluorine, or

Description Block

| Identity Block |

copolymers of such monomers with other monomers, the

| Individual Item Block |

fluoro-monomer(s) being in the greatest amount by mass.

Data Data Data Data Data

ISO 12086-1

Block 1 Block 2 Block 3 Block 4 Block 5

3.1.3 monomer—alow-molecular-weightsubstanceconsist-

4.1.1 The designation system consists of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.