ASTM D5575-07

(Specification)Standard Classification System for Copolymers of Vinylidene Fluoride (VDF) with Other Fluorinated Monomers

Standard Classification System for Copolymers of Vinylidene Fluoride (VDF) with Other Fluorinated Monomers

ABSTRACT

This classification system covers both developing property designations and specifications for thermoplastic compositions consisting of vinylidene fluoride (VDF) polymers modified with other fluoromonomers and property-enhancing additives. Four property codes are presented: code 1 - melt temperature, code 2 - melt-flow rate or melt viscosity, or both, code 3 - tensile strength and modulus, and code 5 - density. The melt temperatures, melt-flow rate, melt viscosity, tensile properties, specific gravity, volume resistivity, dielectric constant, dissipation factor, and limiting oxygen index shall be tested to meet the requirements prescribed.

SCOPE

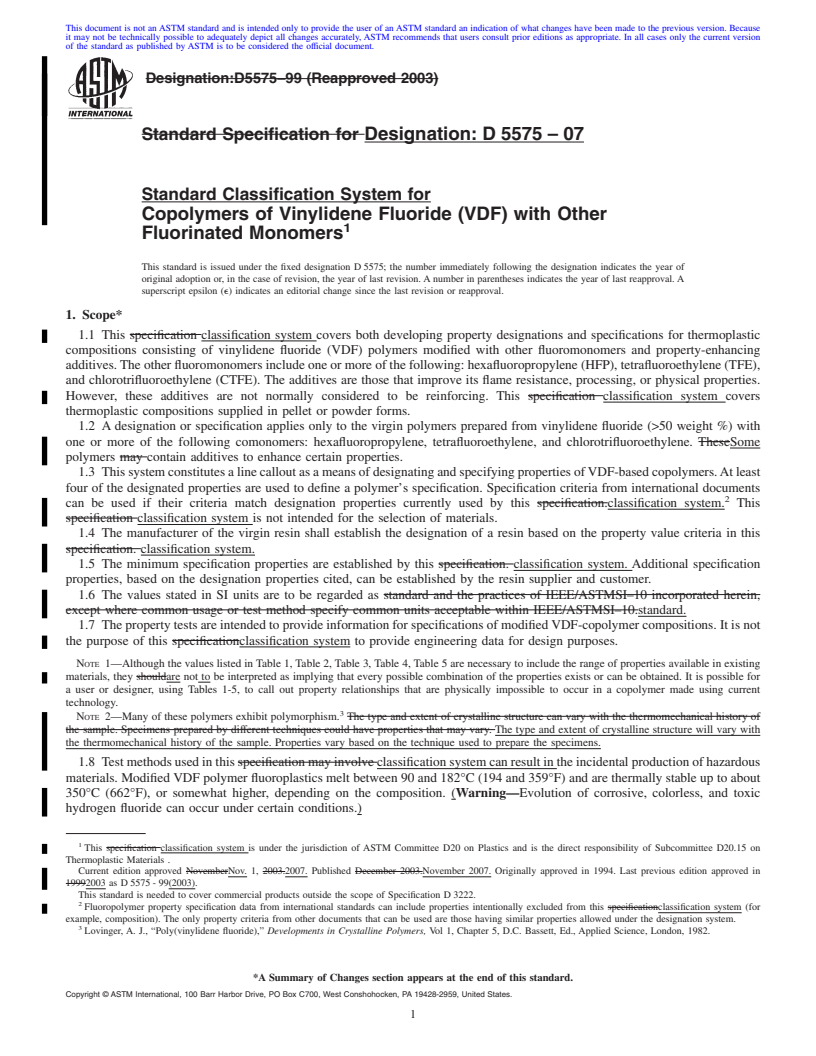

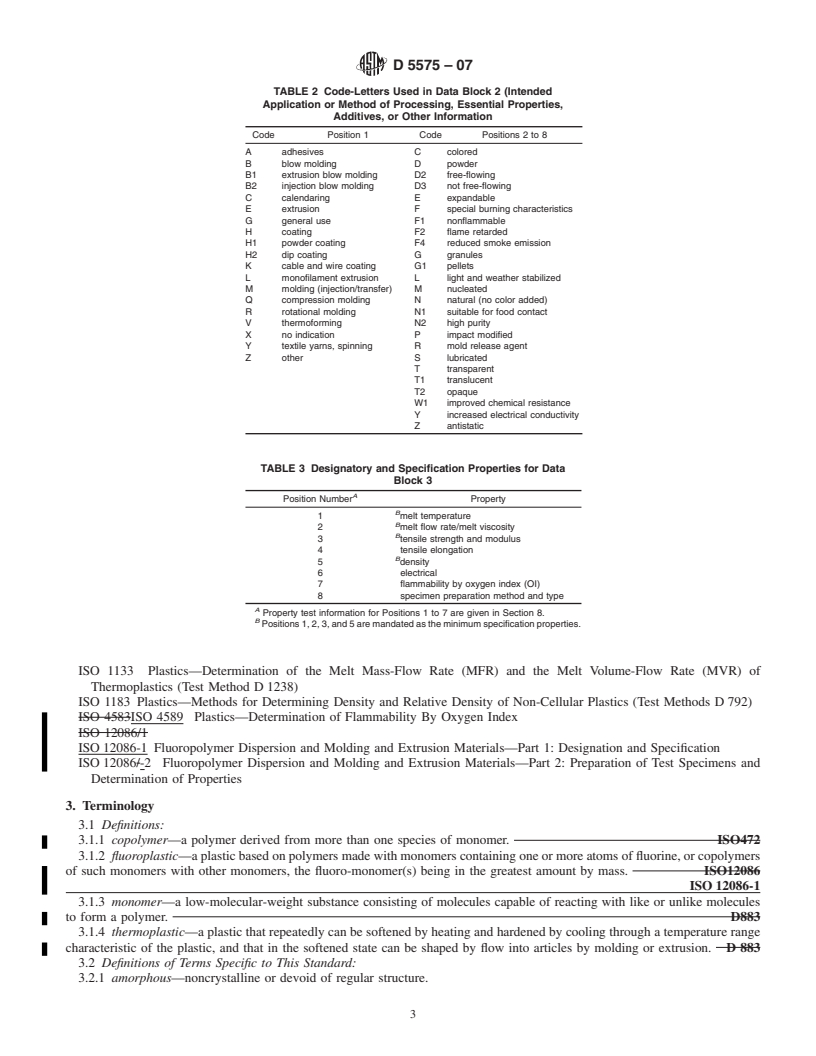

1.1 This classification system covers both developing property designations and specifications for thermoplastic compositions consisting of vinylidene fluoride (VDF) polymers modified with other fluoromonomers and property-enhancing additives. The other fluoromonomers include one or more of the following: hexafluoropropylene (HFP), tetrafluoroethylene (TFE), and chlorotrifluoroethylene (CTFE). The additives are those that improve its flame resistance, processing, or physical properties. However, these additives are not normally considered to be reinforcing. This classification system covers thermoplastic compositions supplied in pellet or powder forms.

1.2 A designation or specification applies only to the virgin polymers prepared from vinylidene fluoride (>50 weight %) with one or more of the following comonomers: hexafluoropropylene, tetrafluoroethylene, and chlorotrifluoroethylene. Some polymers contain additives to enhance certain properties.

1.3 This system constitutes a line callout as a means of designating and specifying properties of VDF-based copolymers. At least four of the designated properties are used to define a polymer's specification. Specification criteria from international documents can be used if their criteria match designation properties currently used by this classification system. This classification system is not intended for the selection of materials.

1.4 The manufacturer of the virgin resin shall establish the designation of a resin based on the property value criteria in this classification system.

1.5 The minimum specification properties are established by this classification system. Additional specification properties, based on the designation properties cited, can be established by the resin supplier and customer.

1.6 The values stated in SI units are to be regarded as standard.

1.7 The property tests are intended to provide information for specifications of modified VDF-copolymer compositions. It is not the purpose of this classification system to provide engineering data for design purposes.Note 1

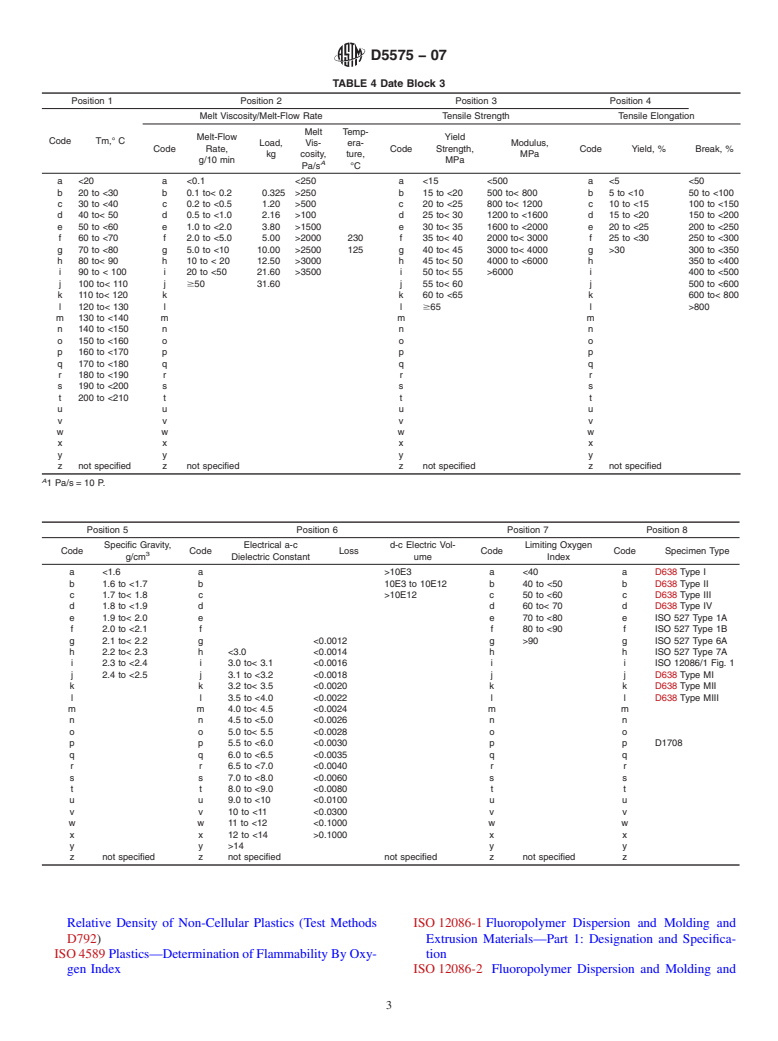

Although the values listed in Table 1, Table 2, Table 3, Table 4, Table 5 are necessary to include the range of properties available in existing materials, they are not to be interpreted as implying that every possible combination of the properties exists or can be obtained. It is possible for a user or designer, using , to call out property relationships that are physically impossible to occur in a copolymer made using current technology.Note 2

Many of these polymers exhibit polymorphism. The type and extent of crystalline structure will vary with the thermomechanical history of the sample. Properties vary based on the technique used to prepare the specimens.

1.8 Test methods used in this classification system can result in the incidental production of hazardous materials. Modified VDF polymer fluoroplastics melt between 90 and 182°C (194 and 359°F) and are thermally stable up to about 350&%176;C (662°F), or somewhat higher, depending on the composition. (Evolution of corrosive, colorless, and toxic hydrogen fluoride can occur under certain conditions.)

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish ap...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5575 −07

StandardClassification System for

Copolymers of Vinylidene Fluoride (VDF) with Other

1

Fluorinated Monomers

This standard is issued under the fixed designation D5575; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 1.5 Theminimumspecificationpropertiesareestablishedby

this classification system. Additional specification properties,

1.1 This classification system covers both developing prop-

basedonthedesignationpropertiescited,canbeestablishedby

erty designations and specifications for thermoplastic compo-

the resin supplier and customer.

sitions consisting of vinylidene fluoride (VDF) polymers

modified with other fluoromonomers and property-enhancing 1.6 The values stated in SI units are to be regarded as

additives. The other fluoromonomers include one or more of standard.

the following: hexafluoropropylene (HFP), tetrafluoroethylene

1.7 The property tests are intended to provide information

(TFE), and chlorotrifluoroethylene (CTFE). The additives are

forspecificationsofmodifiedVDF-copolymercompositions.It

those that improve its flame resistance, processing, or physical

is not the purpose of this classification system to provide

properties. However, these additives are not normally consid-

engineering data for design purposes.

ered to be reinforcing. This classification system covers ther-

NOTE 1—Although the values listed in Table 1, Table 2, Table 3, Table

moplastic compositions supplied in pellet or powder forms.

4, and Table are necessary to include the range of properties available in

1.2 Adesignation or specification applies only to the virgin

existing materials, they are not to be interpreted as implying that every

possible combination of the properties exists or can be obtained. It is

polymers prepared from vinylidene fluoride (>50 weight %)

possible for a user or designer, using Tables 1-, to call out property

with one or more of the following comonomers:

relationships that are physically impossible to occur in a copolymer made

hexafluoropropylene, tetrafluoroethylene, and chlorotrifluoro-

using current technology.

ethylene. Some polymers contain additives to enhance certain 3

NOTE2—Manyofthesepolymersexhibitpolymorphism. Thetypeand

properties.

extentofcrystallinestructurewillvarywiththethermomechanicalhistory

of the sample. Properties vary based on the technique used to prepare the

1.3 This system constitutes a line callout as a means of

specimens.

designating and specifying properties of VDF-based copoly-

1.8 Testmethodsusedinthisclassificationsystemcanresult

mers. At least four of the designated properties are used to

in the incidental production of hazardous materials. Modified

define a polymer’s specification. Specification criteria from

VDF polymer fluoroplastics melt between 90 and 182°C (194

international documents can be used if their criteria match

and359°F)andarethermallystableuptoabout350°C(662°F),

designation properties currently used by this classification

2

or somewhat higher, depending on the composition.

system. This classification system is not intended for the

(Warning— Evolution of corrosive, colorless, and toxic hy-

selection of materials.

drogen fluoride can occur under certain conditions.)

1.4 The manufacturer of the virgin resin shall establish the

1.9 This standard does not purport to address all of the

designation of a resin based on the property value criteria in

safety concerns, if any, associated with its use. It is the

this classification system.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

1

ThisclassificationsystemisunderthejurisdictionofASTMCommitteeD20on

bility of regulatory limitations prior to use.SeeWarning in1.8

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic

Materials.

and Section 10 for specific hazards statements.

Current edition approved Nov. 1, 2007. Published November 2007. Originally

NOTE 3—Many, but not all of the codes and specifications found in this

approved in 1994. Last previous edition approved in 2003 as D5575-99(2003).

This standard is needed to cover commercial products outside the scope of classification system are also in ISO12086-1 and ISO12086-2.

Specification D3222. DOI: 10.1520/D5575-07.

2

Fluoropolymer property specification data from international standards can

include properties intentionally excluded from this classification system (for

3

example,composition).Theonlypropertycriteriafromotherdocumentsthatcanbe Lovinger, A. J., “Poly(vinylidene fluoride),” Developments in Crystalline

used are those having similar properties a

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D5575–99 (Reapproved 2003)

Standard Specification for Designation: D 5575 – 07

Standard Classification System for

Copolymers of Vinylidene Fluoride (VDF) with Other

1

Fluorinated Monomers

This standard is issued under the fixed designation D5575; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification classification system covers both developing property designations and specifications for thermoplastic

compositions consisting of vinylidene fluoride (VDF) polymers modified with other fluoromonomers and property-enhancing

additives.Theotherfluoromonomersincludeoneormoreofthefollowing:hexafluoropropylene(HFP),tetrafluoroethylene(TFE),

and chlorotrifluoroethylene (CTFE). The additives are those that improve its flame resistance, processing, or physical properties.

However, these additives are not normally considered to be reinforcing. This specification classification system covers

thermoplastic compositions supplied in pellet or powder forms.

1.2 Adesignation or specification applies only to the virgin polymers prepared from vinylidene fluoride (>50 weight %) with

one or more of the following comonomers: hexafluoropropylene, tetrafluoroethylene, and chlorotrifluoroethylene. TheseSome

polymers may contain additives to enhance certain properties.

1.3 ThissystemconstitutesalinecalloutasameansofdesignatingandspecifyingpropertiesofVDF-basedcopolymers.Atleast

four of the designated properties are used to define a polymer’s specification. Specification criteria from international documents

2

can be used if their criteria match designation properties currently used by this specification.classification system. This

specification classification system is not intended for the selection of materials.

1.4 The manufacturer of the virgin resin shall establish the designation of a resin based on the property value criteria in this

specification. classification system.

1.5 The minimum specification properties are established by this specification. classification system. Additional specification

properties, based on the designation properties cited, can be established by the resin supplier and customer.

1.6 The values stated in SI units are to be regarded as standard and the practices of IEEE/ASTMSI–10 incorporated herein,

except where common usage or test method specify common units acceptable within IEEE/ASTMSI–10.standard.

1.7 ThepropertytestsareintendedtoprovideinformationforspecificationsofmodifiedVDF-copolymercompositions.Itisnot

the purpose of this specificationclassification system to provide engineering data for design purposes.

NOTE 1—Although the values listed inTable 1,Table 2,Table 3,Table 4,Table 5 are necessary to include the range of properties available in existing

materials, they shouldare not to be interpreted as implying that every possible combination of the properties exists or can be obtained. It is possible for

a user or designer, using Tables 1-5, to call out property relationships that are physically impossible to occur in a copolymer made using current

technology.

3

NOTE 2—Many of these polymers exhibit polymorphism. The type and extent of crystalline structure can vary with the thermomechanical history of

the sample. Specimens prepared by different techniques could have properties that may vary. The type and extent of crystalline structure will vary with

the thermomechanical history of the sample. Properties vary based on the technique used to prepare the specimens.

1.8 Testmethodsusedinthisspecificationmayinvolveclassificationsystemcanresultintheincidentalproductionofhazardous

materials.ModifiedVDFpolymerfluoroplasticsmeltbetween90and182°C(194and359°F)andarethermallystableuptoabout

350°C (662°F), or somewhat higher, depending on the composition. (Warning—Evolution of corrosive, colorless, and toxic

hydrogen fluoride can occur under certain conditions.)

1

This specification classification system is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.15 on

Thermoplastic Materials .

Current edition approved NovemberNov. 1, 2003.2007. Published December 2003.November 2007. Originally approved in 1994. Last previous edition approved in

19992003 as D5575-99(2003).

This standard is needed to cover commercial products outside the scope of Specification D3222.

2

Fluoropolymer prop

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.