ASTM G109-07(2013)

(Test Method)Standard Test Method for Determining Effects of Chemical Admixtures on Corrosion of Embedded Steel Reinforcement in Concrete Exposed to Chloride Environments

Standard Test Method for Determining Effects of Chemical Admixtures on Corrosion of Embedded Steel Reinforcement in Concrete Exposed to Chloride Environments

SIGNIFICANCE AND USE

3.1 This test method provides a reliable means for predicting the inhibiting or corrosive properties of admixtures to be used in concrete.

3.2 This test method is useful for development studies of corrosion inhibitors to be used in concrete.

3.3 This test method has been used elsewhere with good agreement between corrosion as measured by this test method and corrosion damage on the embedded steel (1-4).5 This test method might not properly rank the performance of different corrosion inhibitors, especially at concrete covers over the steel less than 40 mm (1.5 in.) or water-to-cement ratios above 0.45. The concrete mixture proportions and cover over the steel are chosen to accelerate chloride ingress. Some inhibitors might have an effect on this process, which could lead to results that would differ from what would be expected in actual use (5).

SCOPE

1.1 This test method covers a procedure for determining the effects of chemical admixtures on the corrosion of metals in concrete. This test method can be used to evaluate materials intended to inhibit chloride-induced corrosion of steel in concrete. It can also be used to evaluate the corrosivity of admixtures in a chloride environment.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G109 − 07 (Reapproved 2013)

Standard Test Method for

Determining Effects of Chemical Admixtures on Corrosion

of Embedded Steel Reinforcement in Concrete Exposed to

1

Chloride Environments

This standard is issued under the fixed designation G109; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C511Specification for Mixing Rooms, Moist Cabinets,

Moist Rooms, and Water Storage Tanks Used in the

1.1 Thistestmethodcoversaprocedurefordeterminingthe

Testing of Hydraulic Cements and Concretes

effects of chemical admixtures on the corrosion of metals in

C876Test Method for Corrosion Potentials of Uncoated

concrete. This test method can be used to evaluate materials

Reinforcing Steel in Concrete

intended to inhibit chloride-induced corrosion of steel in

C881/C881MSpecification for Epoxy-Resin-Base Bonding

concrete. It can also be used to evaluate the corrosivity of

Systems for Concrete

admixtures in a chloride environment.

C1152/C1152MTest Method for Acid-Soluble Chloride in

1.2 The values stated in SI units are to be regarded as

Mortar and Concrete

standard. The values given in parentheses are for information

D448Classification for Sizes of Aggregate for Road and

only.

Bridge Construction

1.3 This standard does not purport to address all of the D632Specification for Sodium Chloride

safety concerns, if any, associated with its use. It is the

E177Practice for Use of the Terms Precision and Bias in

responsibility of the user of this standard to establish appro- ASTM Test Methods

priate safety and health practices and determine the applica-

E691Practice for Conducting an Interlaboratory Study to

bility of regulatory limitations prior to use. Determine the Precision of a Test Method

G3Practice for Conventions Applicable to Electrochemical

2. Referenced Documents

Measurements in Corrosion Testing

2

G15TerminologyRelatingtoCorrosionandCorrosionTest-

2.1 ASTM Standards:

3

ing (Withdrawn 2010)

A615/A615MSpecificationforDeformedandPlainCarbon-

G33Practice for Recording Data from Atmospheric Corro-

Steel Bars for Concrete Reinforcement

sion Tests of Metallic-Coated Steel Specimens

C33Specification for Concrete Aggregates

G46Guide for Examination and Evaluation of Pitting Cor-

C143/C143MTest Method for Slump of Hydraulic-Cement

rosion

Concrete

4

2.2 NACE Standards:

C150Specification for Portland Cement

SSPC-SP 5/NACE No. 1White Metal Blast Cleaning

C173/C173MTestMethodforAirContentofFreshlyMixed

Concrete by the Volumetric Method

3. Significance and Use

C192/C192MPracticeforMakingandCuringConcreteTest

Specimens in the Laboratory

3.1 This test method provides a reliable means for predict-

C231Test Method for Air Content of Freshly Mixed Con-

ing the inhibiting or corrosive properties of admixtures to be

crete by the Pressure Method

used in concrete.

3.2 This test method is useful for development studies of

corrosion inhibitors to be used in concrete.

1

This test method is under the jurisdiction of ASTM Committee G01 on

3.3 This test method has been used elsewhere with good

Corrosion of Metals and is the direct responsibility of Subcommittee G01.14 on

Corrosion of Metals in Construction Materials.

agreement between corrosion as measured by this test method

CurrenteditionapprovedMay1,2013.PublishedJuly2013.Originallyapproved

in1992.Lastpreviouseditionapprovedin2007asG109–07.DOI:10.1520/G0109-

07R13.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The last approved version of this historical standard is referenced on

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.astm.org.

4

Standards volume information, refer to the standard’s Document Summary page on Available from The Society for Protective Coatings (SSPC), 40 24th St., 6th

the ASTM website. Floor, Pittsburgh, PA 15222-4656.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

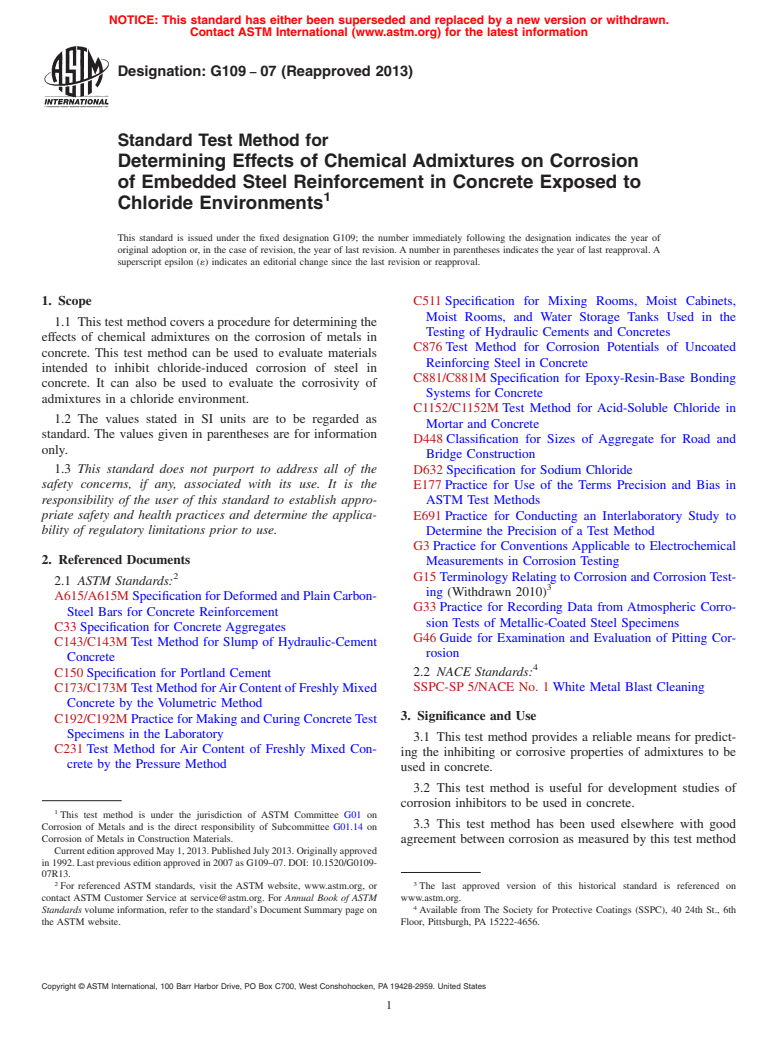

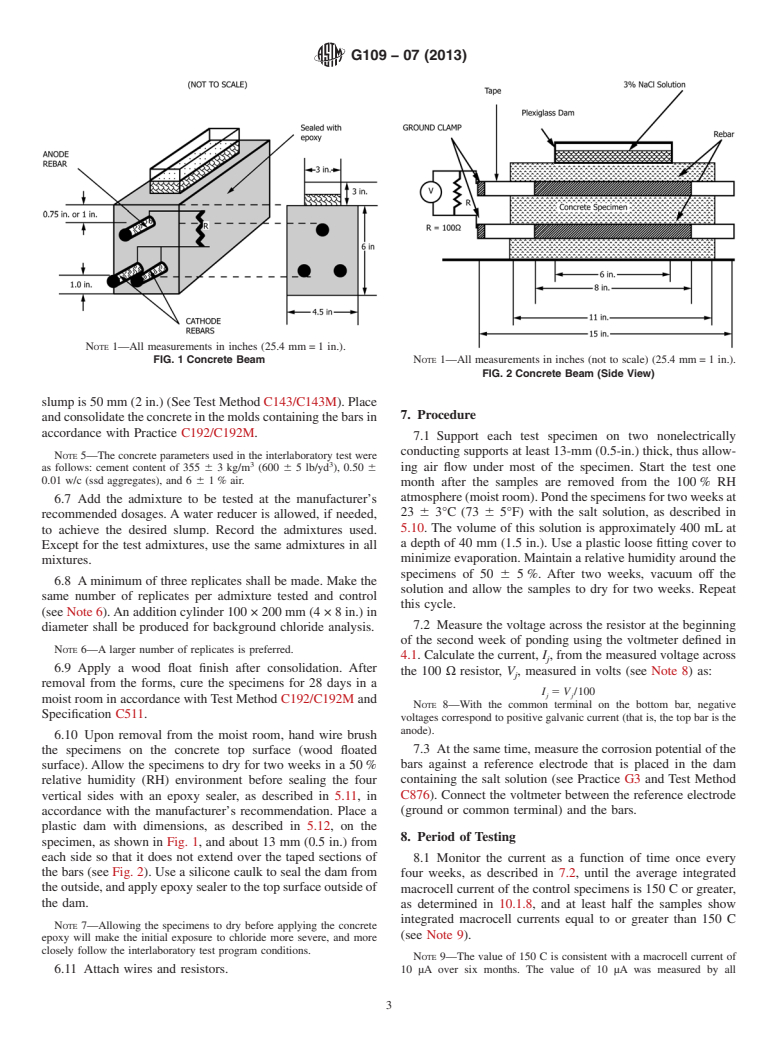

G109 − 07 (2013)

5

and corrosion damage on the embedded steel (1-4). This test 5.11 EpoxySealer,forapplicationtotheconcretespecimens

method might not properly rank the performance of different after manufacture. This sealer shall be of Type III, Grade 1,

7,9

corrosioninhibitors,especiallyatconcretecoversoverthesteel Class C in accordance with Specification C881/C881M.

lessthan40mm(1.5in.)orwater-to-cementratiosabove0.45.

5.12 Plastic Dams, 75-mm (3-in.) wide and 150-mm (6-in.)

The concrete mixture proportions and cover over the steel are

longwithaminimumheightof75mm(3in.)forplacementon

chosen to accelerate ch

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.