ASTM B80-15

(Specification)Standard Specification for Magnesium-Alloy Sand Castings

Standard Specification for Magnesium-Alloy Sand Castings

ABSTRACT

This specification covers magnesium-alloy sand castings. The castings shall conform to the chemical composition limits specified. The castings may be subjected to such heat treatment as deemed necessary to produce material that will conform to the requirements specified. Heat treatment shall be performed on the whole casting and never on a portion. Foundry control shall consist of examination of the castings by radiographic or other approved methods for determining internal discontinuities until the gating, pouring, and other foundry practices have been established to produce castings meeting the quality standards. The tension test specimens representing the castings shall conform to the requirements.

SCOPE

1.1 This specification covers magnesium-alloy sand castings designated as shown in Table 1. (A) Limits are in weight % max unless shown as a range or stated otherwise.(B) ASTM alloy designations were established in accordance with Practice B951. UNS designations were established in accordance with Practice E527.(C) Includes listed elements for when no specific limit is shown.(D) If iron exceeds 0.005 %, the Iron to Manganese ratio shall not exceed 0.032.(E) Rare earth elements are in the form of Didymium, with not less than 70 % Neodymium, and the remainder substantially Praseodymium.(F) Alloy EV31A is a patented composition, suitable for elevated temperature applications. Interested parties are invited to submit information regarding the identification of alternatives to these compositions to ASTM International. Your comments will receive careful consideration at a meeting of the responsible technical committee, which you may attend. ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned in this specification. Users of this specification are expressly advised that determination of the validity of any such patent rights, and the risk of infringement of such rights, are entirely their own responsibility.(G) Other Rare Earths may also be present to a total maximum of 0.4 %. These Rare Earths shall principally be Cerium, Lanthanum, and Praseodymium.(H) Total Rare Earths (TRE) are principally a mixture of Cerium, Lanthanum, Neodymium and Praseodymium. The Cerium content should not be less than 45% of TRE.(I) Other Rare Earths shall be principally heavy rare earths, such as, Gadolinium, Dysprosium, Erbium, and Ytterbium. Other Rare Earths are derived from the Yttrium, typically 80 % Yttrium, and 20 % heavy rare earths.(J) Zinc + Silver shall not exceed 0.20 % in WE43B.

1.2 The values stated in inch-pound units are to be regarded as the standard. The SI values in parentheses are provided for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B80 − 15

Standard Specification for

1

Magnesium-Alloy Sand Castings

This standard is issued under the fixed designation B80; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope E35 Test Methods for Chemical Analysis of Magnesium and

3

Magnesium Alloys (Withdrawn 2008)

1.1 This specification covers magnesium-alloy sand cast-

E88 Practice for Sampling Nonferrous Metals and Alloys in

ings designated as shown in Table 1.

Cast Form for Determination of Chemical Composition

1.2 The values stated in inch-pound units are to be regarded

E94 Guide for Radiographic Examination

as the standard. The SI values in parentheses are provided for

E155 Reference Radiographs for Inspection of Aluminum

information only.

and Magnesium Castings

1.3 This standard does not purport to address all of the

E165 Practice for Liquid Penetrant Examination for General

safety concerns, if any, associated with its use. It is the Industry

responsibility of the user of this standard to establish appro-

E527 Practice for Numbering Metals and Alloys in the

priate safety and health practices and determine the applica- Unified Numbering System (UNS)

bility of regulatory limitations prior to use.

E716 Practices for Sampling and Sample Preparation of

Aluminum and Aluminum Alloys for Determination of

2. Referenced Documents

Chemical Composition by Spectrochemical Analysis

4

2.3 Federal Standards:

2.1 The following documents of the issue in effect on date

of order acceptance form a part of this specification to the Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

Fed. Std. No. 184 Identification Marking of Aluminum,

extent referenced herein:

2 Magnesium and Titanium

2.2 ASTM Standards:

4

2.4 Military Standards:

B93/B93M Specification for Magnesium Alloys in Ingot

MIL-STD-129 Marking for Shipment and Storage (Military

Form for Sand Castings, Permanent Mold Castings, and

Agencies)

Die Castings

MIL-STD-276 Impregnation of Porous Non-ferrous Metal

B296 Practice for Temper Designations of Magnesium

Castings

Alloys, Cast and Wrought

MIL-I-13857 Impregnation of Metal Castings

B557 Test Methods for Tension Testing Wrought and Cast

MIL-M-46062 Magnesium Alloy Castings, High Strength

Aluminum- and Magnesium-Alloy Products

MIL-M-6857 Heat Treatment of Magnesium Alloy Castings

B660 Practices for Packaging/Packing of Aluminum and

5

Magnesium Products

2.5 ANSI Standard:

B661 Practice for Heat Treatment of Magnesium Alloys

ANSI Z1.4 Sampling Procedures and Tables for Inspection

B951 Practice for Codification of Unalloyed Magnesium and

by Attributes

Magnesium-Alloys, Cast and Wrought

E29 Practice for Using Significant Digits in Test Data to

3. Terminology

Determine Conformance with Specifications

3.1 Definitions:

3.1.1 casting lot, n—unless otherwise agreed, shall consist

of not more than 1000 lb of cleaned castings from the same

1

This specification is under the jurisdiction of ASTM Committee B07 on Light

Metals and Alloys and is the direct responsibility of Subcommittee B07.04 on

Magnesium Alloy Cast and Wrought Products.

3

Current edition approved May 1, 2015. Published June 2015. Originally The last approved version of this historical standard is referenced on

approved in 1930. Last previous edition approved in 2009 as B80 – 09. DOI: www.astm.org.

4

10.1520/B0080-15. Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.dodssp.daps.mil.

5

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B80 − 15

2

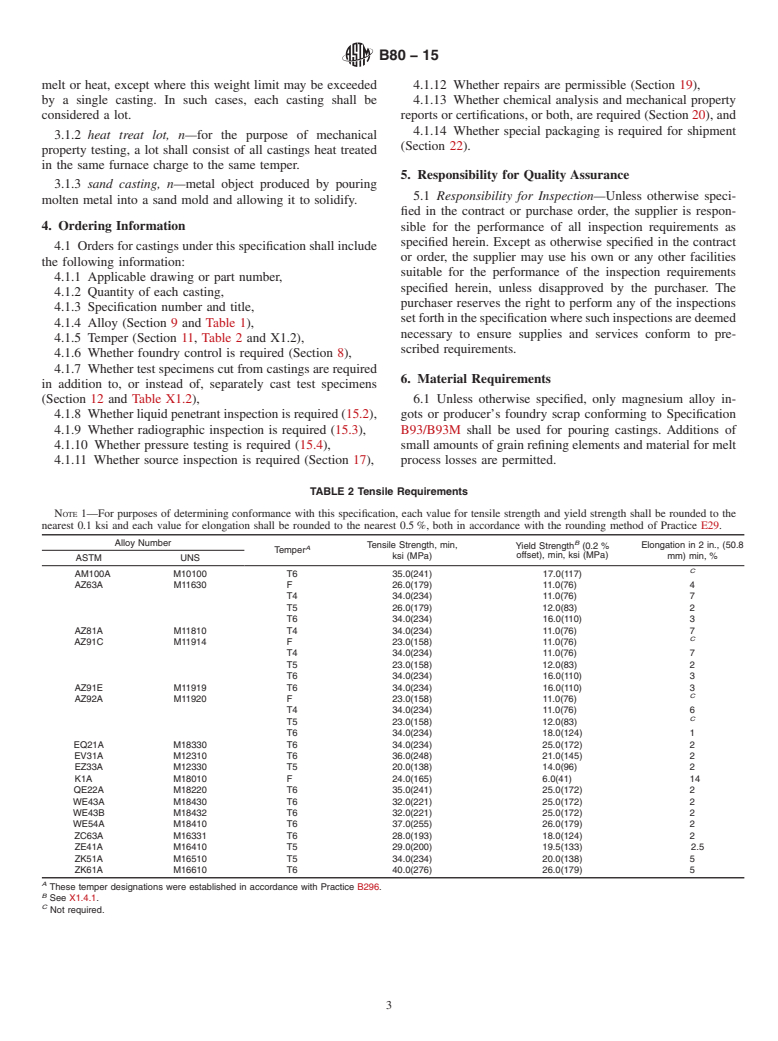

A

TABLE 1 Chemical Requirements

NOTE 1—Analysis shall regularly be made only for the elements specifically mentioned in this table. If, however, the presence of other elements is suspected or indicated in amounts greater than

the specified limits, further analysis shall be made to determine that these elements are not present in excess of the specified limits.

NOTE 2—The following applies to all specified limits in this table: For purposes of acceptance and rejection, an obs

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B80 − 09 B80 − 15

Standard Specification for

1

Magnesium-Alloy Sand Castings

This standard is issued under the fixed designation B80; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

Note—Sections 12.6 and X1.1.15, and Tables 1, 2, X1.1 and X1.3 were corrected editorially and the year date changed on Dec. 7, 2009.

1. Scope

1.1 This specification covers magnesium-alloy sand castings designated as shown in Table 1.

1.2 The values stated in inch-pound units are to be regarded as the standard. The SI values in parentheses are provided for

information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 The following documents of the issue in effect on date of order acceptance form a part of this specification to the extent

referenced herein:

2

2.2 ASTM Standards:

B93/B93M Specification for Magnesium Alloys in Ingot Form for Sand Castings, Permanent Mold Castings, and Die Castings

B296 Practice for Temper Designations of Magnesium Alloys, Cast and Wrought

B557 Test Methods for Tension Testing Wrought and Cast Aluminum- and Magnesium-Alloy Products

B660 Practices for Packaging/Packing of Aluminum and Magnesium Products

B661 Practice for Heat Treatment of Magnesium Alloys

B951 Practice for Codification of Unalloyed Magnesium and Magnesium-Alloys, Cast and Wrought

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

3

E35 Test Methods for Chemical Analysis of Magnesium and Magnesium Alloys (Withdrawn 2008)

E88 Practice for Sampling Nonferrous Metals and Alloys in Cast Form for Determination of Chemical Composition

E94 Guide for Radiographic Examination

E155 Reference Radiographs for Inspection of Aluminum and Magnesium Castings

E165 Practice for Liquid Penetrant Examination for General Industry

E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

E716 Practices for Sampling and Sample Preparation of Aluminum and Aluminum Alloys for Determination of Chemical

Composition by Spectrochemical Analysis

4

2.3 Federal Standards:

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

Fed. Std. No. 184 Identification Marking of Aluminum, Magnesium and Titanium

4

2.4 Military Standards:

MIL-STD-129 Marking for Shipment and Storage (Military Agencies)

MIL-STD-276 Impregnation of Porous Non-ferrous Metal Castings

1

This specification is under the jurisdiction of ASTM Committee B07 on Light Metals and Alloys and is the direct responsibility of Subcommittee B07.04 on Magnesium

Alloy Cast and Wrought Products.

Current edition approved Dec. 7, 2009May 1, 2015. Published February 2010June 2015. Originally approved in 1930. Last previous edition approved in 20072009 as

B80 – 07.B80 – 09. DOI: 10.1520/B0080-09.10.1520/B0080-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

4

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://www.dodssp.daps.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

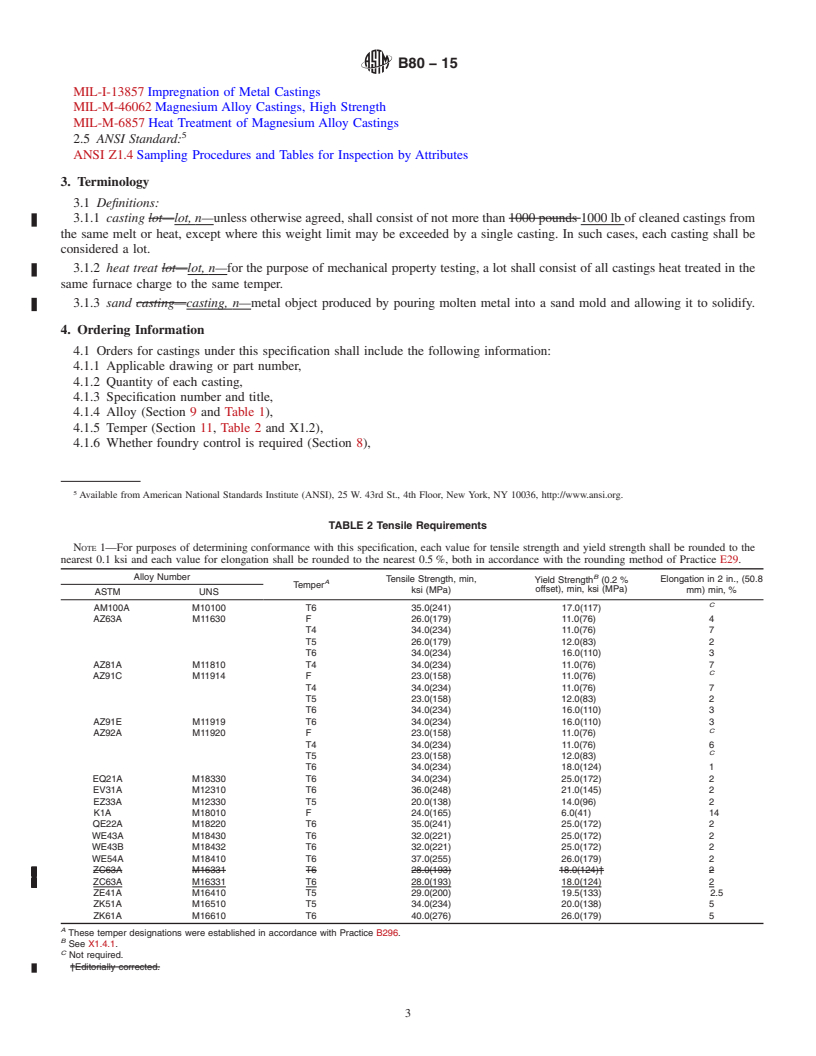

B80 − 15

2

A

TABLE 1 Chemical Requirements

NOTE 1—Analysis shall regularly be made only for the elements specifically mentioned in this table. If, however, the presence of other elements is suspected or indicated in amounts greater than

the specified limits, further analysis shall be made to determine that these elements are not present in excess of the specified limits.

NOTE 2—The following applies to all specified limits in this table: For purposes of acceptance and rejection, an observed value or a calculated value obtained from analysis shall be ro

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.