ASTM F3172-15

(Guide)Standard Guide for Design Verification Device Size and Sample Size Selection for Endovascular Devices

Standard Guide for Design Verification Device Size and Sample Size Selection for Endovascular Devices

SIGNIFICANCE AND USE

4.1 The purpose of this guide is to provide guidance for selecting appropriate device size(s) and determining appropriate sample size(s) for design verification of endovascular devices. The device size(s) and sample size(s) for each design input requirement should be determined before testing. The device size(s) selected for verification testing should establish that the entire device matrix is able to achieve the design input requirements. If testing is not performed on all device sizes, justification should be provided.

4.2 The sample size justification and statistical procedures used to analyze the data should be based on sound scientific principles and should be suitable for reaching a justifiable conclusion. Insufficient sample size may lead to erroneous conclusions more often than desired.

4.3 Guidance regarding methodologies for determining device size selection and appropriate sample size is provided in Sections 5 and 6.

SCOPE

1.1 This guide provides guidance for selecting an appropriate device size(s) and determining an appropriate sample size(s) (that is, number of samples) for design verification testing of endovascular devices. A methodology is presented to determine which device size(s) should be selected for testing to verify the device design adequately for each design input requirement (that is, test characteristic). Additionally, different statistical approaches are presented and discussed to help guide the developer to determine and justify sample size(s) for the design input requirement being verified. Alternate methodologies for determining device size selection and sample size selection may be acceptable for design verification.

1.2 This guide applies to physical design verification testing. This guide addresses in-vitro testing; in-vivo/animal studies are outside the scope of this guide. This guide does not directly address design validation; however, the methodologies presented may be applicable to in-vitro design validation testing. Guidance for sampling related to computational simulation (for example, sensitivity analysis and tolerance analysis) is not provided. Guidance for using models, such as design of experiments (DOE), for design verification testing is not provided. This guide does not address sampling across multiple manufacturing lots as this is typically done as process validation. Special considerations are to be given to certain tests such as fatigue (see Practice E739) and shelf life testing (see Section 8).

1.3 Regulatory guidance may exist for endovascular devices that should be considered for design verification device size and sample size selection.

1.4 Units—The values stated in SI units are to be regarded as the standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F3172 −15

Standard Guide for

Design Verification Device Size and Sample Size Selection

1

for Endovascular Devices

This standard is issued under the fixed designation F3172; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

1.1 This guide provides guidance for selecting an appropri-

bility of regulatory limitations prior to use.

ate device size(s) and determining an appropriate sample

size(s) (that is, number of samples) for design verification

2. Referenced Documents

testing of endovascular devices.Amethodology is presented to

2

determinewhichdevicesize(s)shouldbeselectedfortestingto

2.1 ASTM Standards:

verify the device design adequately for each design input

E739 PracticeforStatisticalAnalysisofLinearorLinearized

requirement (that is, test characteristic).Additionally, different

Stress-Life (S-N) and Strain-Life (ε-N) Fatigue Data

statisticalapproachesarepresentedanddiscussedtohelpguide

F2914 Guide for Identification of Shelf-life Test Attributes

the developer to determine and justify sample size(s) for the

for Endovascular Devices

design input requirement being verified. Alternate methodolo-

3

2.2 ISO Standards:

gies for determining device size selection and sample size

ISO 14971:2012 Medical devices—Application of risk man-

selection may be acceptable for design verification.

agement to medical devices

1.2 This guide applies to physical design verification test-

ing. This guide addresses in-vitro testing; in-vivo/animal stud-

3. Terminology

ies are outside the scope of this guide. This guide does not

3.1 Definitions:

directly address design validation; however, the methodologies

3.1.1 attribute data, n—data that identify the presence or

presented may be applicable to in-vitro design validation

absenceofacharacteristic(forexample,good/badorpass/fail).

testing. Guidance for sampling related to computational simu-

3.1.2 design input requirements, n—physical and perfor-

lation (for example, sensitivity analysis and tolerance analysis)

is not provided. Guidance for using models, such as design of mance requirements of a device that are used as a basis for

device design (typically defined as test characteristics such as

experiments (DOE), for design verification testing is not

provided.Thisguidedoesnotaddresssamplingacrossmultiple balloon burst pressure, shaft tensile strength, and so forth).

manufacturing lots as this is typically done as process valida-

3.1.3 design output, n—features of the device (that is,

tion. Special considerationsaretobegiventocertain testssuch

dimensions, materials, and so forth) that define the design and

asfatigue(seePracticeE739)andshelflifetesting(seeSection

make it capable of achieving design input requirements.

8).

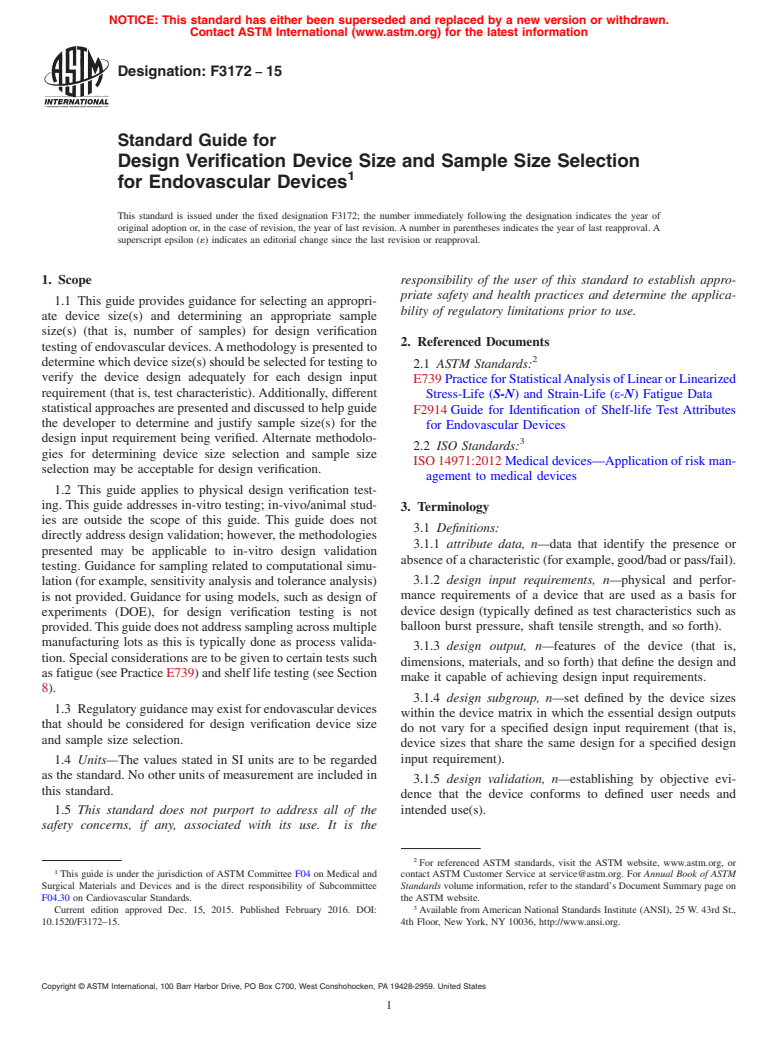

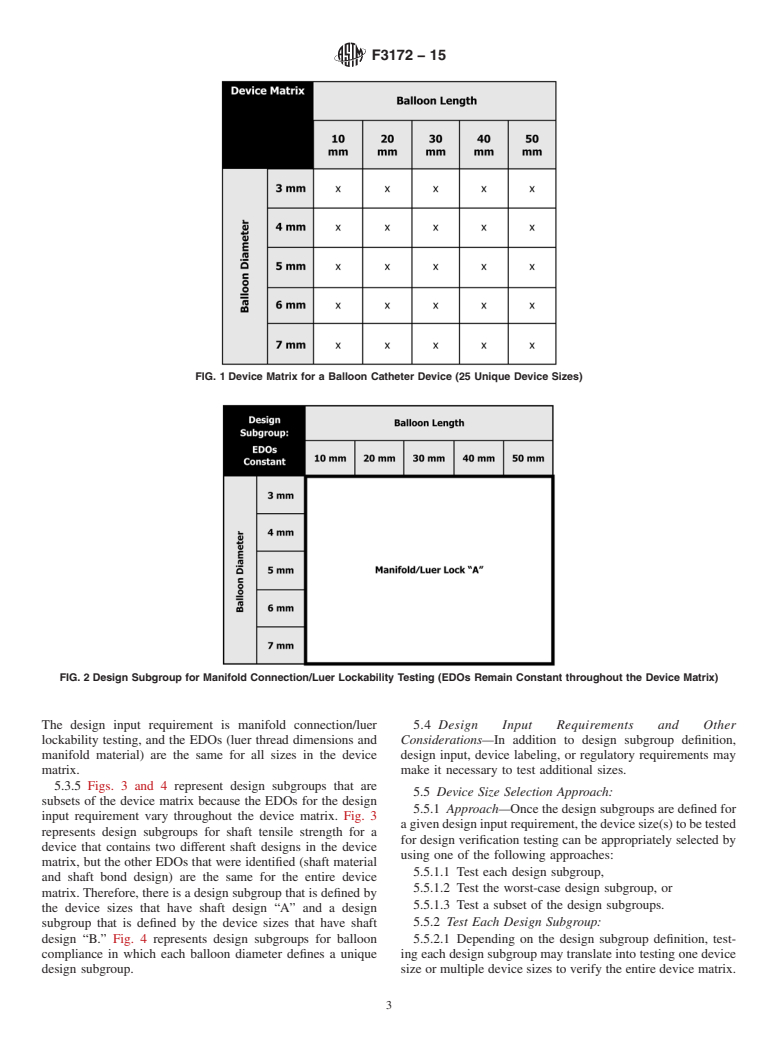

3.1.4 design subgroup, n—set defined by the device sizes

1.3 Regulatoryguidancemayexistforendovasculardevices

within the device matrix in which the essential design outputs

that should be considered for design verification device size

do not vary for a specified design input requirement (that is,

and sample size selection.

device sizes that share the same design for a specified design

input requirement).

1.4 Units—The values stated in SI units are to be regarded

as the standard. No other units of measurement are included in

3.1.5 design validation, n—establishing by objective evi-

this standard.

dence that the device conforms to defined user needs and

intended use(s).

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

This guide is under the jurisdiction of ASTM Committee F04 on Medical and contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Surgical Materials and Devices and is the direct responsibility of Subcommittee Standards volume information, refer to the standard’s Document Summary page on

F04.30 on Cardiovascular Standards. the ASTM website.

3

Current edition approved Dec. 15, 2015. Published February 2016. DOI: Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

10.1520/F3172–15. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F3172−15

3.1.6 design verification, n—confirmation by examination design throughout the device matrix will drive which device

and provis

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.