ASTM F925-02(2008)

(Test Method)Standard Test Method for Resistance to Chemicals of Resilient Flooring

Standard Test Method for Resistance to Chemicals of Resilient Flooring

SIGNIFICANCE AND USE

Resilient flooring products are designed and formulated to have good resistance to most common chemicals encountered in typical use. High performance wear layers can also be used to enhance cleanability and chemical resistance. Resilient flooring used in residential and commercial environments may be subjected to a variety of chemicals through accidental spillage or as ingredients used for hygienic purposes. Performance is dependent upon the flooring formulation and that of the maintenance products used on the flooring. This test method provides a means of estimating the relative susceptibility of resilient floor covering to change when exposed to chemical reagents.

SCOPE

1.1 This test method provides a procedure for determining the resistance of resilient floor covering to surface deterioration when exposed to various chemical reagents. This test method is not intended as a staining test nor as a method to judge surface and appearance restoration of the sample after exposure to the chemical reagent.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard information is provided in Section 5 of this test method.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F925 − 02(Reapproved 2008)

Standard Test Method for

Resistance to Chemicals of Resilient Flooring

ThisstandardisissuedunderthefixeddesignationF925;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope tered in typical use. High performance wear layers can also be

used to enhance cleanability and chemical resistance. Resilient

1.1 This test method provides a procedure for determining

flooring used in residential and commercial environments may

theresistanceofresilientfloorcoveringtosurfacedeterioration

be subjected to a variety of chemicals through accidental

whenexposedtovariouschemicalreagents.Thistestmethodis

spillage or as ingredients used for hygienic purposes. Perfor-

not intended as a staining test nor as a method to judge surface

mance is dependent upon the flooring formulation and that of

and appearance restoration of the sample after exposure to the

the maintenance products used on the flooring. This test

chemical reagent.

method provides a means of estimating the relative suscepti-

1.2 The values stated in inch-pound units are to be regarded

bility of resilient floor covering to change when exposed to

as the standard. The values given in parentheses are for

chemical reagents.

information only.

4. Apparatus

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4.1 Gloves, impervious vinyl or rubber,

responsibility of the user of this standard to establish appro-

4.2 Tweezers, or forceps,

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. Specific hazard 4.3 Medicine Dropper, 3 in. straight glass with rubber bulb

information is provided in Section 5 of this test method. or pipette having a point opening diameter not less than ⁄16 in.

(1.6 mm) or greater than ⁄64 in. (1.8 mm),

2. Referenced Documents

4.4 White Facial Tissue.

2.1 ASTM Standards:

4.5 Watch Glass.

D2244 Practice for Calculation of Color Tolerances and

Color Differences from Instrumentally Measured Color

4.6 Timer.

Coordinates

4.7 Filter Paper.

F142 Test Method for Indentation of Resilient Floor Tiles

3 1 1

4.8 Small Laboratory Spatula, approximately ⁄4 – ⁄2 in.-

(McBurney Test) (Withdrawn 2007)

wide blade, rounded bottom, not sharpened,

F386 Test Method for Thickness of Resilient Flooring Ma-

terials Having Flat Surfaces

4.9 SuitableSpectrophotometerorColorimeter,withamini-

F1914 Test Methods for Short-Term Indentation and Re-

mum ⁄4 in. (6.35 mm) diameter opening having a cool white

sidual Indentation of Resilient Floor Covering

fluorescent(CWF)ordaylight(D-65)lightsource,orboth,that

measures color in CIE L*, a*, b* using CIE 10° standard

3. Significance and Use

observer and specular included (see Test Method D2244).

3.1 Resilient flooring products are designed and formulated

4.10 Indentation Tester, see Test Methods F142 and F1914.

to have good resistance to most common chemicals encoun-

4.11 Thickness Tester, see Test Method F386.

ThistestmethodisunderthejurisdictionofASTMCommitteeF06onResilient

4.12 Conditioning Room or Cabinet, equipped with auto-

Floor Coverings and is the direct responsibility of Subcommittee F06.30 on Test

Methods - Performance. matic temperature and humidity controls that will maintain

Current edition approved Jan. 1, 2008. Published March 2008. Originally

73.4 6 3.6°F (23 6 2°C) and 50 6 5 % relative humidity.

approved in 1985. Last previous edition approved in 2002 as F925–02. DOI:

10.1520/F0925-02R08.

5. Hazards

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.1 A new medicine dropper or pipette should be used for

Standards volume information, refer to the standard’s Document Summary page on

each test reagent. If the same reagent dispenser apparatus is to

the ASTM website.

bereused,itshallbethoroughlycleanedinhotsoapywaterand

The last approved version of this historical standard is referenced on

www.astm.org. alcohol, or both, prior to applying each different test reagent.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

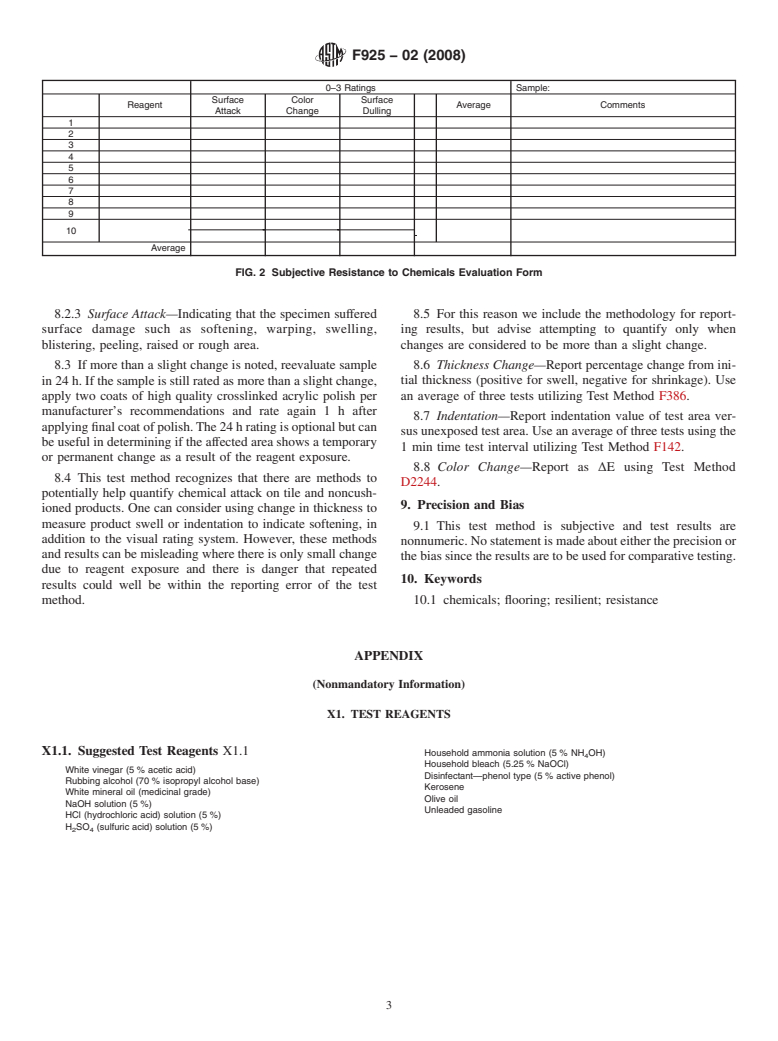

F925 − 02 (2008)

5.2 Check to be sure the colorimeter is properly warmed up 7.6 For testing liquid reagents, center a piece of filter paper

and calibrated prior to use. within the test square, using a medicine dropper or pipette,

deposit 6–8 drops of test reagent or a sufficient amount to

5.3 Be sure specimens are held flat when measuring color.

thoroughly wet the filter paper.

5.4 Be sure each specimen is marked in the corner on the

7.7 If the test reagent is a paste, apply a thin layer

back for easy identification.

(approximately ⁄16 in. (1.6 mm) thick) directly to the test area.

5.5 Dispose of chemical test reagents properly. Refer to

Use a spatula or other convenient means.

Material Safety Data Sheets (MSDS) or precautions on the

7.8 Place a watch glass cover over the reagent and allow the

label for proper disposal. (Warning—Observe all necessary

test reagent to remain in contact with the test area for 60 6 1

precautions when handling test reagents known to be flam-

min.

mable or potentially hazardous.)

7.9 Remove filter paper with tweezers. Blot (do not rub)

6. Test Specimen

residual liquid with a dry facial tissue. For paste reagents,

6.1 The specimen shall consist of a portion of the test unit at lightly scrape surface with the spatula to remove reagent and

least 6 by 6 in. (153.4 by 153.4 mm) for each reagent

wipe area with dry facial tissue. Particular care must be taken

(chemical) to be tested. during scraping and blotting so as not to disturb the exposed

surface more than necessary.

6.2 Specimens shall be selected with minimal changes in

surface texture.

7.10 If residual reagent remains on the surface, lightly clean

the exposed area with water or mild solvent, such as isopro-

6.3 Specimens should be of a color to show potential effect

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:F925–97 Designation: F 925 – 02 (Reapproved 2008)

Standard Test Method for

Resistance to Chemicals of Resilient Flooring

This standard is issued under the fixed designation F 925; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 Thistestmethodprovidesaprocedurefordeterminingtheresistanceofresilientfloorcoveringtosurfacedeteriorationwhen

exposed to various chemical reagents. This test method is not intended as a staining test nor as a method to judge surface and

appearance restoration of the sample after exposure to the chemical reagent.

1.2 Thevaluesstatedininch-poundunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformation

only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Specific precautionary statements are provided in Section 6 Specific hazard information is provided in

Section 5 of this test method.

2. Referenced Documents

2.1 ASTM Standards:

D 2244Method Practice for Calculation of Color Tolerances and Color Differences from Instrumentally Measured Color

Coordinates

F 142 Test Method for Indentation of Resilient Floor Tiles (McBurney Test)

F 386Test Method for Thickness of Resilient Flooring Material Having Flat Surfaces

2.2 Federal Standard:

Test Method for Indentation of Resilient Floor Tiles, Utilizing Apparatus and Specimen Sizes from Method3221of Federal

Standard501a Test Method for Thickness of Resilient Flooring Materials Having Flat Surfaces

F 1914 Test Methods for Short-Term Indentation and Residual Indentation of Resilient Floor Covering

3. Significance and Use

3.1 Resilient flooring products are designed and formulated to have good resistance to most common chemicals encountered in

typicaluse.Highperformancewearlayerscanalsobeusedtoenhancecleanabilityandchemicalresistance.Resilientflooringused

inresidentialandcommercialenvironmentsmaybesubjectedtoavarietyofchemicalsthroughaccidentalspillageorasingredients

used for hygienic purposes. Performance is dependent upon the flooring formulation and that of the maintenance products used

on the flooring. This test method provides a means of estimating the relative susceptibility of resilient floor covering to change

when exposed to chemical reagents.

4. Specimen

4.1The specimen shall consist of a portion of the test unit at least 6 by 6 in. (153.4 by 153.4 mm) for each reagent (chemical)

to be tested.

4.2Specimens shall be selected with minimal changes in surface texture.

4.3Specimens should be of a color to show potential effect of reagent.

This practice is under the jurisdiction ofASTM Committee F-6 on Resilient Floor Coverings and is the direct responsibility of Subcommittee F06.30 on Physical Service

Properties.

Current edition approved Sept. 10, 1997. Published June 1998. Originally published as F925–85. Last previous edition F925–96.

ThistestmethodisunderthejurisdictionofASTMCommitteeF06onResilientFloorCoveringsandisthedirectresponsibilityofSubcommitteeF06.30onTestMethods

- Performance.

Current edition approved Jan. 1, 2008. Published March 2008. Originally approved in 1985. Last previous edition approved in 2002 as F 925–02.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. ForAnnualBookofASTMStandards

, Vol 06.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 925 – 02 (2008)

5.Apparatus

5.1

4.1 Gloves—impervious vinyl or rubber,

5.2, impervious vinyl or rubber,

4.2 Tweezers, or forceps,

5.3

4.3 Medicine Dropper—, 3 in. straight glass with rubber bulb or pipette having a point opening diameter not less than ⁄16 in.

(1.6 mm) or greater than ⁄64 in. (1.8 mm),

5.4

4.4 White Facial Tissue,

5.5.

4.5 Watch Glass,

5.6.

4.6 Timer,

5.7.

4.7 Filter Paper,

5.8.

1 1 1

4.8 Small Laboratory Spatula—approximately ⁄4 , approximately ⁄4 – ⁄2 in.-wide blade, rounded bottom, not sharpened,

5.9

4.9 Suitable Spectrophotometer or Colorimeter, with a minimum ⁄4 in. (6.35 mm) diameter opening having a cool white

fluorescent (CWF) or daylight (D-65) light source, or both, that measures color in CIE L*, a*, b* using CIE 10° standard observer

and specular included (see Test Method D 2244).

5.10

4.10 Indentation Tester(see Test Method F142 and Fed. Std. 501a),

5.11, see Test Methods F 142 and F 1914.

4.11 Thickness Tester (see Test Method F386),

5.12Conditioning Room or Cabinet—equipped with automatic temperature and humidity controls that will maintain 73.4+3.6°F

(23 6 2°C) and 506 5% relative humidity.

6., see Test Method F 386.

4.12 Conditioning Room or Cabinet , equipped with automatic temperature and humidity controls that will maintain 73.4 6

3.6°F (23 6 2°C) and 50 6 5 % relative humidity.

5. Hazards

6.1A new medicine dropper or pipette should be used for each test reagent. If the same reagent dispenser apparatus is to be

reused, it shall be thoroughly cleaned in hot soapy water and alcohol, or both, prior to applying each different test reagent.

6.2Check to be sure the colorimeter is properly warmed up and calibrated prior to use.

6.3Be sure specimens are held flat when measuring color.

6.4Be sure each specimen is marked in the corner on the back for easy identification.

6.5Dispose of chemical test reagents properly. Refer to Material Safety Data Sheets (MSDS) or precautions on the label for

proper disposal.

NOTE1—Warning:Observe all necessary precautions when handling test reagents known to be flammable or potentially hazardous.

5.1 A new medicine dropper or pipette should be used for each test reagent. If the same reagent dispenser apparatus is to be

reused, it shall be thoroughly cleaned in hot soapy water and alcohol, or both, prior to applying each different test reagent.

5.2 Check to be sure the colorimeter is properly warmed up and calibrated prior to use.

5.3 Be sure specimens are held flat when measuring color.

5.4 Be sure each specimen is marked in the corner on the back for easy identification.

5.5 Dispose of chemical test reagents properly. Refer to Material Safety Data Sheets (MSDS) or precautions on the label for

proper disposal. (Warning—Observe all necessary precautions when handling test reagents known to be flammable or potentially

hazardous.)

6. Test Specimen

6.1 The specimen shall consist of a portion of the test unit at least 6 by 6 in. (153.4 by 153.4 mm) for each reagent (chemical)

to be tested.

6.2 Specimens shall be selected with minimal changes in surface texture.

6.3 Specimens should be of a color to show potential effect of reagent.

7. Procedure

7.1 Unless otherwise specified, condition the specimens and the test reagents (chemicals) for at least 24 h prior to testing. The

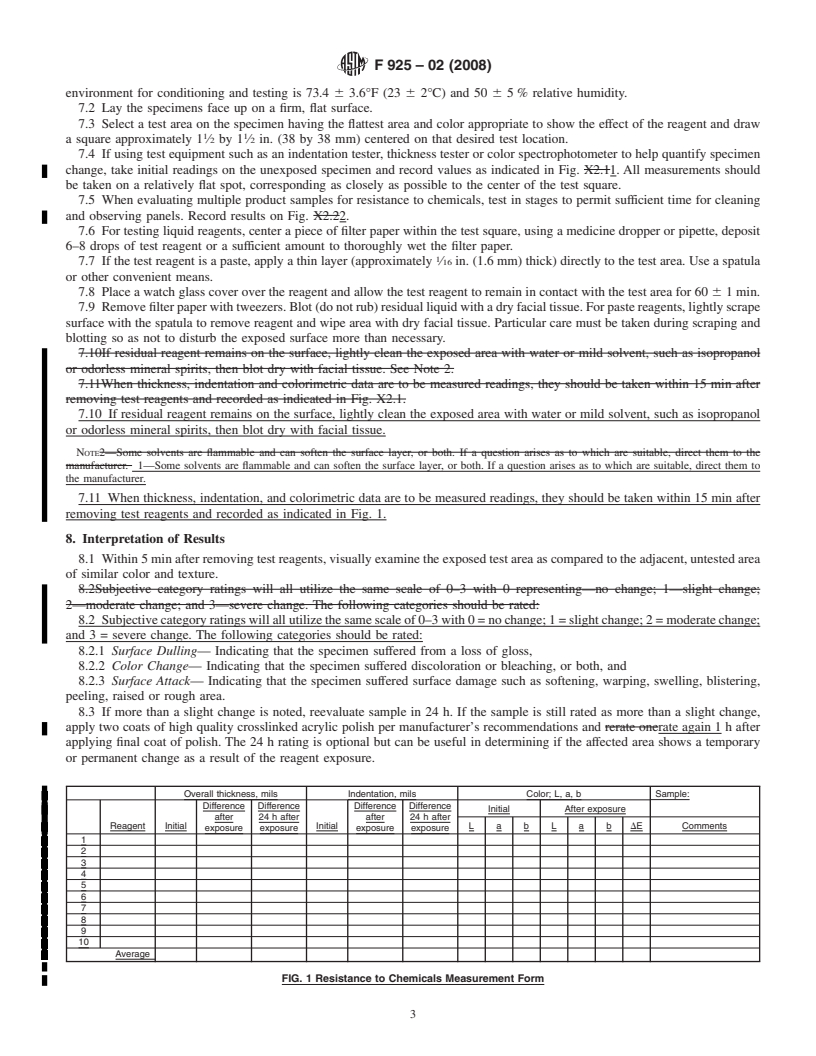

F 925 – 02 (2008)

environment for conditioning and testing is 73.4 6 3.6°F (23 6 2°C) and 50 6 5 % relative humidity.

7.2 Lay the specimens face up on a firm, flat surface.

7.3 Select a test area on the specimen having the flattest area and color appropriate to show the effect of the reagent and draw

1 1

a square approximately 1 ⁄2 by 1 ⁄2 in. (38 by 38 mm) centered o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.