ASTM F1861-21

(Specification)Standard Specification for Resilient Wall Base

Standard Specification for Resilient Wall Base

ABSTRACT

This specification covers resilient wall base. These products are manufactured from rubber or thermoplastic materials, or a combination thereof. Wall base is used to provide a functional, as well as decorative border, between walls and floors. This specification does not include rigid products. Wall base shall be of the following types, as specified: type TS - rubber, vulcanized thermoset, type TP - rubber, thermoplastic, and type TV - vinyl, thermoplastic. Wall base shall be one of the following groups, as specified: group 1 - solid, and group 2 - layered. Wall base shall be of the following styles as specified: style A - straight, style B - cove, style C - butt-to, style D - sculptured. The wear layer thickness, flexibility, adjacent surface straining induced by wall base, light resistance, chemical resistance, dimensional stability, height, thickness, and length shall be tested to meet the requirements prescribed.

SCOPE

1.1 This specification covers resilient wall base. These products are manufactured from rubber or thermoplastic materials, or a combination thereof. Wall base is used to provide a functional, as well as decorative border, between walls and floors. This specification does not include rigid products.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following safety caveat pertains to the test methods portion, Section 12, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F1861 −21

Standard Specification for

1

Resilient Wall Base

This standard is issued under the fixed designation F1861; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope terials with Cylindrical Mandrel Apparatus

F141 Terminology Relating to Resilient Floor Coverings

1.1 This specification covers resilient wall base. These

F386 Test Method for Thickness of Resilient Flooring Ma-

products are manufactured from rubber or thermoplastic

terials Having Flat Surfaces

materials, or a combination thereof. Wall base is used to

F410 Test Method for Wear Layer Thickness of Resilient

provide a functional, as well as decorative border, between

Floor Coverings by Optical Measurement

walls and floors. This specification does not include rigid

F925 Test Method for Resistance to Chemicals of Resilient

products.

Flooring

1.2 The values stated in inch-pound units are to be regarded

F1515 Test Method for Measuring Light Stability of Resil-

as the standard. The values given in parentheses are for

ient Flooring by Color Change

information only.

2.3 Other Standards:

1.3 The following safety caveat pertains to the test methods

ANSI/ASQC Z1.4 Sampling Procedures and Tables for In-

portion, Section 12, of this specification: This standard does 3

spection by Attributes

not purport to address all of the safety concerns, if any,

associated with its use. It is the responsibility of the user of this

3. Terminology

standard to establish appropriate safety, health, and environ-

3.1 Definitions—For definitions of other terms used in this

mental practices and determine the applicability of regulatory

standard, see Terminology F141.

limitations prior to use.

1.4 This international standard was developed in accor-

4. Classification

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

4.1 Types—Wall base shall be of the following types, as

Development of International Standards, Guides and Recom-

specified (see 5.1.2, 6.1, and 7.1).

mendations issued by the World Trade Organization Technical

4.1.1 Type TS—rubber, vulcanized thermoset.

Barriers to Trade (TBT) Committee.

4.1.2 Type TP—rubber, thermoplastic.

4.1.3 Type TV—vinyl, thermoplastic.

2. Referenced Documents

4.2 Groups—Wallbaseshallbeoneofthefollowinggroups,

2.1 The following documents of the issue in effect on the

as specified (see 5.1.2, 6.2.1, and 6.2.2):

dateofthematerialpurchaseformapartofthisspecificationto

the extent referenced herein: 4.2.1 Group 1—solid (homogeneous).

2

4.2.2 Group 2—layered (multiple layers/heterogeneous).

2.2 ASTM Standards:

4.2.3 Either group may be specified with any of the types

D883 Terminology Relating to Plastics

above. It is not necessary to specify group when either is

D1566 Terminology Relating to Rubber

acceptable.

D1755 Specification for Poly(Vinyl Chloride) Resins

F137 Test Method for Flexibility of Resilient Flooring Ma-

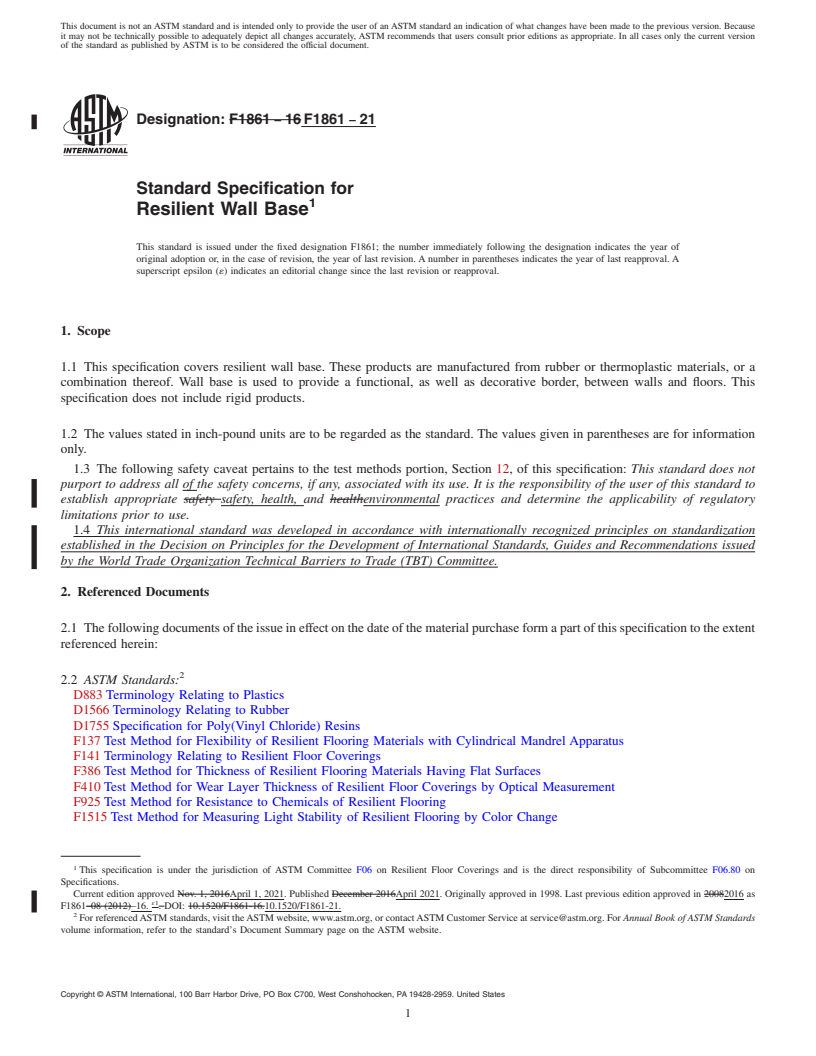

4.3 Styles—Wall base shall be of the following styles as

specified (see 5.1.2, 6.3, and Fig. 1):

4.3.1 Style A—straight.

1

This specification is under the jurisdiction of ASTM Committee F06 on

4.3.2 Style B—cove.

Resilient Floor Coverings and is the direct responsibility of Subcommittee F06.80

on Specifications.

4.3.3 Style C—butt-to.

Current edition approved April 1, 2021. Published April 2021. Originally

4.3.4 Style D—sculptured.

approved in 1998. Last previous edition approved in 2016 as F1861–16. DOI:

10.1520/F1861-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1861−21

FIG. 1Typical Profiles of Wall Base

4.4 Corners—Where specified, both inside and outside 90° 6. Materials and Manufacture

factory-made corners should be specified by style. Corners

6.1 Materials—Any polymeric material or combination of

must meet the same height and thickness requirements as wall

polymeric materials is acceptable if, in combination with

base (see Section 9).

processing chemicals, fillers, and colorants, the material can b

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F1861 − 16 F1861 − 21

Standard Specification for

1

Resilient Wall Base

This standard is issued under the fixed designation F1861; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers resilient wall base. These products are manufactured from rubber or thermoplastic materials, or a

combination thereof. Wall base is used to provide a functional, as well as decorative border, between walls and floors. This

specification does not include rigid products.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information

only.

1.3 The following safety caveat pertains to the test methods portion, Section 12, of this specification: This standard does not

purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to

establish appropriate safety safety, health, and healthenvironmental practices and determine the applicability of regulatory

limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 The following documents of the issue in effect on the date of the material purchase form a part of this specification to the extent

referenced herein:

2

2.2 ASTM Standards:

D883 Terminology Relating to Plastics

D1566 Terminology Relating to Rubber

D1755 Specification for Poly(Vinyl Chloride) Resins

F137 Test Method for Flexibility of Resilient Flooring Materials with Cylindrical Mandrel Apparatus

F141 Terminology Relating to Resilient Floor Coverings

F386 Test Method for Thickness of Resilient Flooring Materials Having Flat Surfaces

F410 Test Method for Wear Layer Thickness of Resilient Floor Coverings by Optical Measurement

F925 Test Method for Resistance to Chemicals of Resilient Flooring

F1515 Test Method for Measuring Light Stability of Resilient Flooring by Color Change

1

This specification is under the jurisdiction of ASTM Committee F06 on Resilient Floor Coverings and is the direct responsibility of Subcommittee F06.80 on

Specifications.

Current edition approved Nov. 1, 2016April 1, 2021. Published December 2016April 2021. Originally approved in 1998. Last previous edition approved in 20082016 as

ɛ1

F1861–08 (2012)–16. . DOI: 10.1520/F1861-16.10.1520/F1861-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1861 − 21

2.3 Other Standards:

3

ANSI/ASQC Z1.4–2003(R2013)Z1.4 Sampling Procedures and Tables for Inspection by Attributes

3. Terminology

3.1 Definitions—For definitions of other terms used in this standard, see Terminology F141.

4. Classification

4.1 Types—Wall base shall be of the following types, as specified (see 5.1.2, 6.1, and 7.1).

4.1.1 Type TS—rubber, vulcanized thermoset.

4.1.2 Type TP—rubber, thermoplastic.

4.1.3 Type TV—vinyl, thermoplastic.

4.2 Groups—Wall base shall be one of the following groups, as specified (see 5.1.2, 6.2.1, and 6.2.2):

4.2.1 Group 1—solid (homogeneous).

4.2.2 Group 2—layered (multiple layers/heterogeneous).

4.2.3 Either group may be specified with any of the types above. It is not necessary to specify group when either is acceptable.

4.3 Styles—Wall base shall be of the following styles as specified (see 5.1.2, 6.3, and Fig. 1):

4.3.1 Style A—straight.

4.3.2 Style B—cove.

4.3.3 Style C—butt-to.

FIG. 1 Typical Profiles of Wall Base

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

2

---------------------- Page: 2 ----------------------

F1861 − 21

4.3.4 Style D—sculptured.

4.4 Corners—Where specified, both inside and outside 90° factory-made corners should be specified by

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.