ASTM F2347-11

(Guide)Standard Guide for Characterization and Testing of Hyaluronan as Starting Materials Intended for Use in Biomedical and Tissue Engineered Medical Product Applications

Standard Guide for Characterization and Testing of Hyaluronan as Starting Materials Intended for Use in Biomedical and Tissue Engineered Medical Product Applications

SIGNIFICANCE AND USE

This guide contains a listing of those characterization parameters that are directly related to the functionality of hyaluronan. This guide can be used as an aid in the selection and characterization of the appropriate hyaluronan for a particular application. This guide is intended to give guidance in the methods and types of testing necessary to properly characterize, assess, and ensure consistency in the performance of a particular hyaluronan. It may have use in the regulation of these devices by appropriate authorities.

The hyaluronan covered by this guide may be gelled, cross-linked, extruded, or otherwise formulated into biomedical devices for use in tissue engineered medical products or drug delivery devices for implantation as determined to be appropriate, based on supporting biocompatibility and physical test data. Recommendations in this guide should not be interpreted as a guarantee of clinical success in any tissue engineered medical product or drug delivery application.

To ensure that the material supplied satisfies requirements for use in TEMPs, several general areas of characterization should be considered. These are: identity of hyaluronan, physical and chemical characterization and testing, impurities profile, and performance-related tests.

SCOPE

1.1 This guide covers the evaluation of hyaluronan suitable for use in biomedical or pharmaceutical applications, or both, including, but not limited to, Tissue Engineered Medical Products (TEMPs).

1.2 This guide addresses key parameters relevant to the characterization and purity of hyaluronan.

1.3 As with any material, some characteristics of hyaluronan may be altered by processing techniques, such as cross-linking and sterilization, required for the production of a specific formulation or device. Therefore, properties of fabricated forms of this polymer should be evaluated using test methods that are appropriate to ensure safety and efficacy and are not addressed in this guide.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2347 − 11

StandardGuide for

Characterization and Testing of Hyaluronan as Starting

Materials Intended for Use in Biomedical and Tissue

1

Engineered Medical Product Applications

This standard is issued under the fixed designation F2347; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Hyaluronan, which in this guide will encompass hyaluronic acid, hyaluronate, and its salt forms, is

the simplest of the glycosaminoglycans. Hyaluronan is soluble in water and forms highly viscous

solutions.Hyaluronanisfoundinubiquitouslyinthebodyaspartoftheextracellularmatrixoftissues,

with high concentrations in the synovial fluid, vitreous humor, and skin, as well as in cartilage.

Hyaluronan has found uses in a variety of products ranging from viscosupplements (treatment of

osteoarthritis), adhesion prevention (prevention of post-surgical adhesions), viscoelastics (ocular

protection), and dermal implants (lip augmentation and wrinkle removal). New applications, such as

scaffolds for tissue engineering, are emerging. The aim of this guide is to identify key parameters

relevant to the characterization of hyaluronan for the development of new commercial applications of

hyaluronan for the biomedical and pharmaceutical industries.

1. Scope priate safety and health practices and determine the applica-

bility of regulatory requirements prior to use.

1.1 This guide covers the evaluation of hyaluronan suitable

for use in biomedical or pharmaceutical applications, or both,

2. Referenced Documents

including, but not limited to, Tissue Engineered Medical

2

2.1 ASTM Standards:

Products (TEMPs).

D2196 Test Methods for Rheological Properties of Non-

1.2 This guide addresses key parameters relevant to the

Newtonian Materials by Rotational (Brookfield type)

characterization and purity of hyaluronan.

Viscometer

1.3 As with any material, some characteristics of hyaluro-

F619 Practice for Extraction of Medical Plastics

nan may be altered by processing techniques, such as cross-

F748 PracticeforSelectingGenericBiologicalTestMethods

linking and sterilization, required for the production of a

for Materials and Devices

specific formulation or device. Therefore, properties of fabri-

F749 Practice for Evaluating Material Extracts by Intracuta-

cated forms of this polymer should be evaluated using test

neous Injection in the Rabbit

methods that are appropriate to ensure safety and efficacy and

F756 Practice for Assessment of Hemolytic Properties of

are not addressed in this guide.

Materials

F763 Practice for Short-Term Screening of Implant Materi-

1.4 The values stated in SI units are to be regarded as

als

standard. No other units of measurement are included in this

F813 Practice for Direct Contact Cell Culture Evaluation of

standard.

Materials for Medical Devices

1.5 This standard does not purport to address all of the

F895 TestMethodforAgarDiffusionCellCultureScreening

safety concerns, if any, associated with its use. It is the

for Cytotoxicity

responsibility of the user of this standard to establish appro-

F981 Practice for Assessment of Compatibility of Biomate-

rials for Surgical Implants with Respect to Effect of

1

This guide is under the jurisdiction of ASTM Committee F04 on Medical and

Surgical Materials and Devicesand is the direct responsibility of Subcommittee

2

F04.42 on Biomaterials and Biomolecules for TEMPs. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved March 1, 2011. Published March 2011. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2003. Last previous edition approved in 2003 as F2347 – 03. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F2347-11. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2347 − 11

Materials on Muscle and Bone ISO EN 12442-1 Animal Tissues and Their Derivative

F1251 Terminology Relating to Polymeric Biomaterials in Utilized in the Manufacture of Medical Devices—Part 1:

3 6

Medical and Surgical Devices (Withdrawn 2012) Analysis and Management of Risk

F1439 Guide for Performance of Lifetime Bioassay for the ISO EN 12442-3 Animal Tissues and Their Derivative

Tumorigenic Potential of Implant Materials Utilized in the Manufacture of Medical Devices—Part 3:

F1903 Practice for Testing For Biological Responses to Validation of the Elimination and/or inactivation of Virus

6

Particles In Vitro and Tran

...

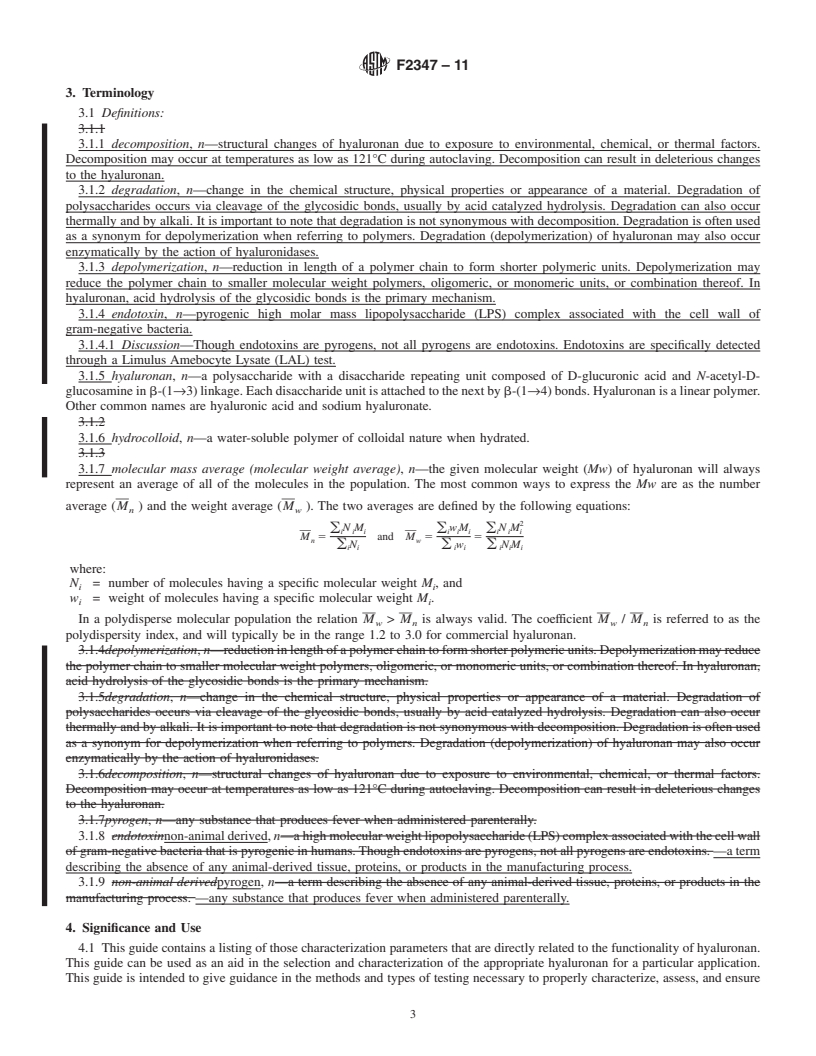

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:F2347–03 Designation: F2347 – 11

Standard Guide for

Characterization and Testing of Hyaluronan as Starting

Materials Intended for Use in Biomedical and Tissue

1

Engineered Medical Product Applications

This standard is issued under the fixed designation F2347; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Hyaluronan, which in this guide will encompass hyaluronic acid, hyaluronate, and its salt forms, is

the simplest of the glycosaminoglycans. Hyaluronan is soluble in water and forms highly viscous

solutions.Hyaluronanisfoundinubiquitouslyinthebodyaspartoftheextracellularmatrixoftissues,

with high concentrations in the synovial fluid, vitreous humor, and skin, as well as in cartilage.

Hyaluronan has found uses in a variety of products ranging from viscosupplements (treatment of

osteoarthritis), adhesion prevention (prevention of post-surgical adhesions), viscoelastics (ocular

protection), and dermal implants (lip augmentation and wrinkle removal). New applications, such as

scaffolds for tissue engineering, are emerging. The aim of this guide is to identify key parameters

relevant to the characterization of hyaluronan for the development of new commercial applications of

hyaluronan for the biomedical and pharmaceutical industries.

1. Scope

1.1 This guide covers the evaluation of hyaluronan suitable for use in biomedical or pharmaceutical applications, or both,

including, but not limited to, Tissue Engineered Medical Products (TEMPs).

1.2 This guide addresses key parameters relevant to the characterization and purity of hyaluronan.

1.3 Aswithanymaterial,somecharacteristicsofhyaluronanmaybealteredbyprocessingtechniques,suchascross-linkingand

sterilization, required for the production of a specific formulation or device. Therefore, properties of fabricated forms of this

polymer should be evaluated using test methods that are appropriate to ensure safety and efficacy and are not addressed in this

guide.

1.4

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

requirements prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D2196 Test Methods for Rheological Properties of Non-Newtonian Materials by Rotational (Brookfield type) Viscometer

F619 Practice for Extraction of Medical Plastics

F748 Practice for Selecting Generic Biological Test Methods for Materials and Devices

F749 Practice for Evaluating Material Extracts by Intracutaneous Injection in the Rabbit

F756 Practice for Assessment of Hemolytic Properties of Materials

F763 Practice for Short-Term Screening of Implant Materials

F813 Practice for Direct Contact Cell Culture Evaluation of Materials for Medical Devices

1

This guide is under the jurisdiction of ASTM Committee F04 on Medical and Surgical Materials and Devices and is the direct responsibility of Subcommittee F04.42

on Biomaterials and Biomolecules for TEMPs.

Current edition approved Nov. 1, 2003. Published December 2003. DOI: 10.1520/F2347-03.

Current edition approved March 1, 2011. Published March 2011. Originally approved in 2003. Last previous edition approved in 2003 as F2347 – 03. DOI:

10.1520/F2347-11.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F2347 – 11

F895 Test Method for Agar Diffusion Cell Culture Screening for Cytotoxicity

F981 Practice for Assessment of Compatibility of Biomaterials for Surgical Implants with Respect to Effect of Materials on

Muscle and Bone

F1251 Terminology Relating to Polymeric Biomaterials in Medical and Surgical Devices

F1439 Guide for Performance of Lifetime Bioassay for the Tumorigenic Potential of Implant Materials

F1903 Practice for Testing For Biologic

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.