ASTM D1975-95(2010)

(Test Method)Standard Test Method for Environmental Stress Crack Resistance of Plastic Injection Molded Open Head Pails

Standard Test Method for Environmental Stress Crack Resistance of Plastic Injection Molded Open Head Pails

SIGNIFICANCE AND USE

These procedures provide an indication of the environmental stress-crack resistance of injection molded open head pails, covers, and components from a selected group or lot. Provided the thermal history of each container is constant, this test method may be used for determining the applicability of various plastic resins and mold designs for injection molding of open head pails and covers.

The environmental stress-crack that occurs is indicative of what results when a container is exposed to agents such as soaps, organics, or any surface active solutions while under environmental conditions of stress.

Environmental stress-cracking is the mechanism of chemical attack that is highly dependent upon the test reagent, resin, container molding history, exposure temperature, applied stress, and other factors. The combination of these factors may result in eventual stress-crack failure.

Procedure A minimizes the potential for test variability by providing the user with rigidly defined test conditions. This test method may be used for production quality control of injection molded open head containers.

Procedure B allows the user to select and evaluate extreme individual elements or the interaction of several test levels on container performance. These conditions are established based on laboratory experience and available knowledge of the distribution environment. This test method may be used for identifying critical stresses which could aid in container design or help in minimizing the occurrence of these stresses during distribution.

This test method is intended only as a pass/fail procedure in accordance with the user's specification, or as agreed upon between the user and the supplier. It is not intended as a predictor or indicator of field performance regarding time to failure.

SCOPE

1.1 This test method provides procedures for an indication of the environmental stress crack resistance of plastic injection molded open head pails, covers, and components as a summation of the effects of container design, resin, manufacturing conditions, field performance, and other factors.

1.2 This test method may be used to evaluate a container's resistance to mechanical failure by cracking when in the presence of chemical and physical stresses.

1.3 Two procedures are provided as follows:

1.3.1 Procedure A, Specified Stress-Crack Resistance Test Method—This procedure is particularly useful for quality control since the conditions of the test are specified.

1.3.2 Procedure B, User Selected Stress-Crack Resistance Test Method—This procedure allows individual selection of test levels and is particularly useful as a design and development tool.

1.4 These procedures are not designed to test the ability of the cover gasketing material or closure to retain the test reagent. Loss or leakage of the reagent through these openings does not constitute container failure. However, this may indicate an internal pressure loss that might affect test results.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific warning statements are given in 6.2, 10.2.3, 10.2.4, 10.2.6, and 10.2.8.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1975 − 95(Reapproved 2010)

Standard Test Method for

Environmental Stress Crack Resistance of Plastic Injection

Molded Open Head Pails

This standard is issued under the fixed designation D1975; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This test method provides procedures for an indication

D996 Terminology of Packaging and Distribution Environ-

of the environmental stress crack resistance of plastic injection

ments

molded open head pails, covers, and components as a summa-

D4332 Practice for Conditioning Containers, Packages, or

tion of the effects of container design, resin, manufacturing

Packaging Components for Testing

conditions, field performance, and other factors.

E122 Practice for Calculating Sample Size to Estimate,With

1.2 This test method may be used to evaluate a container’s

Specified Precision, the Average for a Characteristic of a

resistance to mechanical failure by cracking when in the

Lot or Process

presence of chemical and physical stresses.

3. Terminology

1.3 Two procedures are provided as follows:

3.1 Definitions—Reference Terminology D996 for defini-

1.3.1 Procedure A, Specified Stress-Crack Resistance Test

tions applicable to this test method.

Method—This procedure is particularly useful for quality

3.2 Definitions of Terms Specific to This Standard:

control since the conditions of the test are specified.

3.2.1 environmental stress crack—an external or internal

1.3.2 Procedure B, User Selected Stress-Crack Resistance

crack that develops when a container is exposed to chemical or

Test Method—This procedure allows individual selection of

physical stresses, or both.

test levels and is particularly useful as a design and develop-

ment tool. 3.2.2 stress crack failure—any environmental stress crack

that causes a loss or leakage of the test reagent shall be

1.4 These procedures are not designed to test the ability of

interpreted as container failure.

the cover gasketing material or closure to retain the test

reagent. Loss or leakage of the reagent through these openings

4. Summary of Test Method

does not constitute container failure. However, this may

4.1 The environmental stress-crack resistance is determined

indicate an internal pressure loss that might affect test results.

by subjecting an injection molded open head pail and cover

1.5 The values stated in inch-pound units are to be regarded that is filled and sealed with a stress-crack reagent to a

mechanical top load at elevated temperatures. The time to

as standard. The values given in parentheses are mathematical

stress-crack failure is observed.

conversions to SI units that are provided for information only

4.1.1 ProcedureAexposesaminimumofthreecontainersto

and are not considered standard.

specified levels of chemical and physical stresses.

1.6 This standard does not purport to address all of the

4.1.2 Procedure B exposes containers to varying chemical

safety problems, if any, associated with its use. It is the

and physical stresses based on the user’s knowledge and

responsibility of the user of this standard to establish appro-

objectives.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. Specific warning

5. Significance and Use

statements are given in 6.2, 10.2.3, 10.2.4, 10.2.6, and 10.2.8.

5.1 These procedures provide an indication of the environ-

mental stress-crack resistance of injection molded open head

pails, covers, and components from a selected group or lot.

This test method is under the jurisdiction of ASTM Committee D10 on

Packaging and is the direct responsibility of Subcommittee D10.21 on Shipping

Containers and Systems - Application of Performance Test Methods. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2010. Published November 2010. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1991. Last previous edition approved in 2006 as D1975 – 95 (2006). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D1975-95R10. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1975 − 95 (2010)

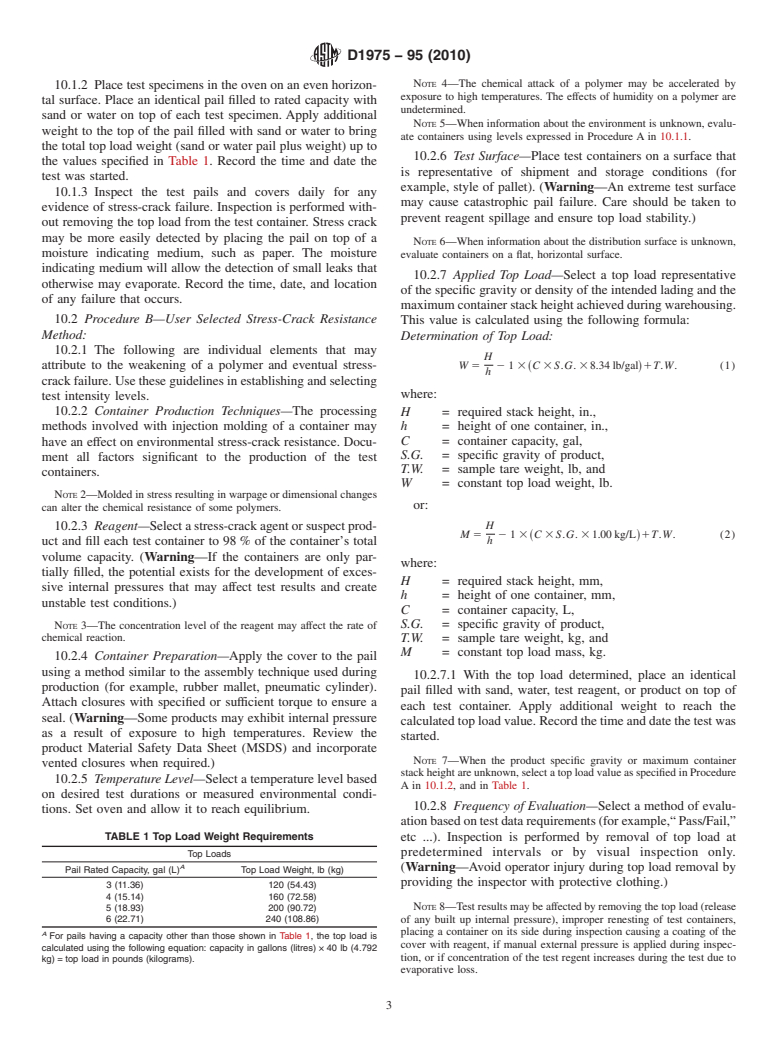

Provided the thermal history of each container is constant, this 7. Reagents

test method may be used for determining the applicability of

7.1 ProcedureA; Nonyl Phenoxypoly (Ethyleneoxy) Ethanol

variousplasticresinsandmolddesignsforinjectionmoldingof

Solution—Prepare a 10 % solution, by volume, of the stress-

open head pails and covers.

cracking agent and water.

5.2 The environmental stress-crack that occurs is indicative

NOTE 1—Due to the viscosity of the stress-cracking agent, it is helpful

of what results when a container is exposed to agents such as

to prepare the solution at an elevated temperature. A maximum tempera-

soaps, organics, or any surface active solutions while under

ture of 122°F (50°C) is an acceptable level provided caution is used to

environmental conditions of stress.

avoid prolonged heating and eventual volume losses.

5.3 Environmental stress-cracking is the mechanism of

7.2 Procedure B—Any reagent or proprietary product (liq-

chemical attack that is highly dependent upon the test reagent,

uid, solid, etc.) that is potentially a stress-cracking agent.

resin,containermoldinghistory,exposuretemperature,applied

stress, and other factors. The combination of these factors may

8. Sampling

result in eventual stress-crack failure.

5.4 Procedure A minimizes the potential for test variability

8.1 Aminimum of three containers are required for this test

by providing the user with rigidly defined test conditions. This

method. When possible for direct comparison, the test contain-

test method may be used for production quality control of

ers should be produced in the same mold and molding

injection molded open head containers.

conditions. It is suggested that test container resin, machine,

mold, and molding conditions be thoroughly documented to

5.5 Procedure B allows the user to select and evaluate

improve statistical reliability of the test data. (Practice E122.)

extreme individual elements or the interaction of several test

levels on container performance. These conditions are estab-

lished based on laboratory experience and available knowledge 9. Conditioning

of the distribution environment. This test method may be used

9.1 Condition empty test containers at 73 6 2°F (23 6

for identifying critical stresses which could aid in container

1.3°C) 50 6 3 % relative humidity for 48 h prior to testing (see

design or help in minimizing the occurrence of these stresses

Practice D4332).

during distribution.

5.6 This test method is intended only as a pass/fail proce-

10. Procedure

dure in accordance with the user’s specification, or as agreed

10.1 Procedure A—Specified Stress-Crack Resistance

upon between the user and the supplier. It is not intended as a

Method:

predictor or indicator of field performance regarding time to

failure.

10.1.1 Place the oven set point control at 122 6 2°F (50 6

1.3°C) and allow it to reach equilibrium. Fill each test

6. Apparatus

specimen to 98 % of the container’s total volumetric capacity

6.1 Oven—The oven should be capable of maintaining a

with the test reagent. Apply the cover to the pail firmly and

temperature control of 62.5°F (61.4°C) of set point. For best

evenly using a method similar to the assembly technique used

circulation and a constant temperature throughout, a forced air

during actual production.

system is recommended.

6.2 Top Load—Requires a pail identical to the test pail be

filled to rated capacity or weight and then nested above the test

pail. Free weights are then placed above in amounts necessary

to equal the specified top load. A calibrated pneumatic or

hydraulic cylinder may be substituted for the additional free

The sole source of supply of the stress-cracking agent (nonyl phenoxypoly

weights. (Warning—The potential exists for catastrophic

(ethyleneoxy) ethanol solution, known as IIgepal CO-630 (Antanox CO-630))

stress-crack failure causing an instability of the applied top

known to the committee at this time is Rhodia, Inc. Home, Personal Care and

Industrial Ingredients, CN 7500, 259 Prospect Plains Road, Cranbury, NJ

load. Precautionary steps should be taken (that is,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.