ASTM D7842/D7842M-12

(Test Method)Standard Test Method for Holding Strength of Tack and Prong Fastener Attached Buttons

Standard Test Method for Holding Strength of Tack and Prong Fastener Attached Buttons

SIGNIFICANCE AND USE

5.1 This test method may be used for acceptance testing of commercial shipments of garments with attached buttons.

5.2 This test method may be used to determine the compatibility of tack attached buttons or prong fastener attached buttons to fabrics used in apparel. In which case, the buttons are attached to the fabric in the manner in which they will be used and the combined units tested.

SCOPE

1.1 This test method covers the determination of the holding strength of a tack and prong fastener attached button using a tensile testing machine.

1.2 This test method is applicable to attached buttons in garments or to be attached to fabrics intended for use in apparel (see Annex A1).

1.3 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7842/D7842M − 12

StandardTest Method for

Holding Strength of Tack and Prong Fastener Attached

Buttons

This standard is issued under the fixed designation D7842/D7842M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 force, n—a physical influence exerted by one body on

another which produces acceleration of bodies that are free to

1.1 Thistestmethodcoversthedeterminationoftheholding

move and deformation of bodies that are not free to move.

strength of a tack and prong fastener attached button using a

3.1.2 holding strength, n—in buttons, the force required to

tensile testing machine.

separate the button from its attached mating part or separate

1.2 This test method is applicable to attached buttons in

from the fabric it is attached to, whichever shall fail first.

garmentsortobeattachedtofabricsintendedforuseinapparel

3.1.3 tack attached button, n—any button that is attached by

(see Annex A1).

a single post product (most commonly used to attach a non

1.3 Units—The values stated in either SI units or inch-

metal colleted button). (See Fig. 1.)

pound units are to be regarded separately as standard. The

3.1.4 prong fastener attached button, n—any button that is

values stated in each system may not be exact equivalents;

attached by a product with 2 or more prongs (most commonly

therefore, each system shall be used independently of the other.

used to attach a metal colleted button). (See Fig. 2.)

Combining values from the two systems may result in non-

conformance with the standard.

3.1.5 For definitions of other textile terms used in this

standard, refer to Terminology D123.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Summary of Test Method

responsibility of the user of this standard to establish appro-

4.1 A specimen, consisting of a button and tack or prong

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. fastener attached to a fabric, is mounted in a special test fixture

on a tensile testing machine.Aforce is applied perpendicularly

2. Referenced Documents

untilthebuttonseparatesfromthetackorprongfastener,orthe

fabric is torn. The peak force at separation is reported as the

2.1 ASTM Standards:

holding strength. If the fabric tears, the peak force at fabric

D76 Specification for Tensile Testing Machines for Textiles

failure is recorded and the data is reported and considered as a

D123 Terminology Relating to Textiles

different category to be reported separately from the holding

D1776 Practice for Conditioning and Testing Textiles

strength of the fasteners.

2.2 Federal Document:

16 CFR Parts 1500.48-1500.53 and 1501.4 Engineering Test

5. Significance and Use

Manual for Children’s Toys

5.1 This test method may be used for acceptance testing of

commercial shipments of garments with attached buttons.

3. Terminology

5.2 This test method may be used to determine the compat-

3.1 Definitions:

ibility of tack attached buttons or prong fastener attached

buttons to fabrics used in apparel. In which case, the buttons

are attached to the fabric in the manner in which they will be

This test method is under the jurisdiction ofASTM Committee D13 on Textiles

used and the combined units tested.

and is the direct responsibility of Subcommittee D13.54 on Subassemblies.

Current edition approved Dec. 1, 2012. Published December 2012. DOI:

10.1520/D7842-12.

6. Apparatus

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

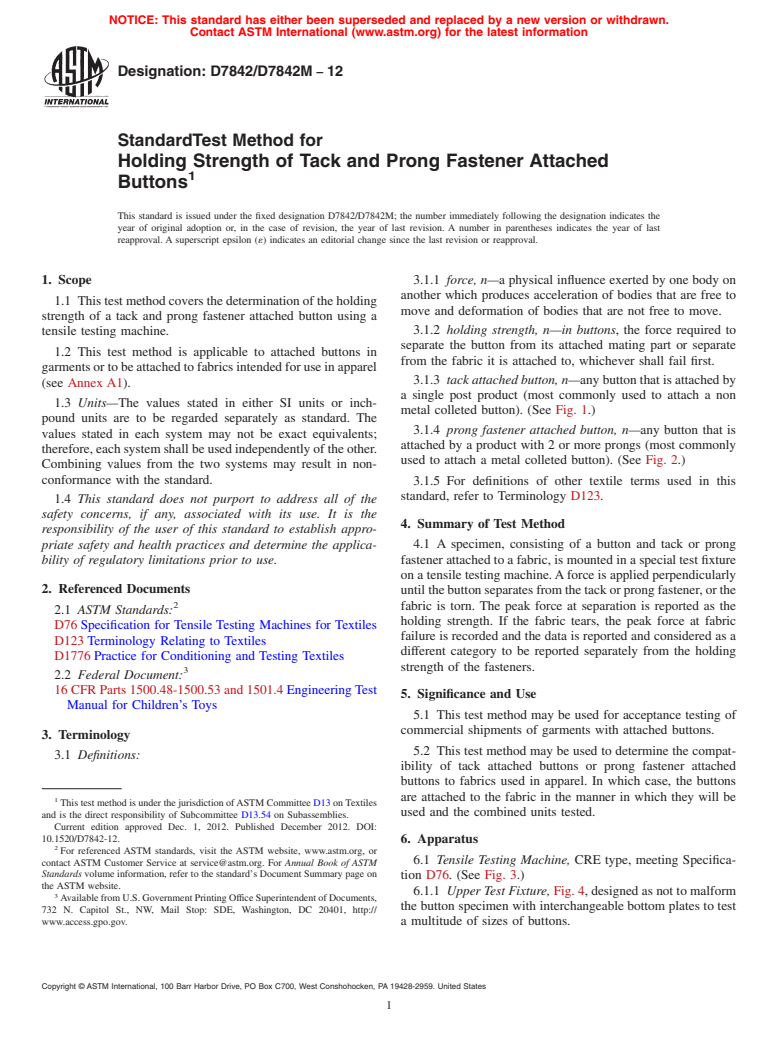

6.1 Tensile Testing Machine, CRE type, meeting Specifica-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

tion D76. (See Fig. 3.)

the ASTM website.

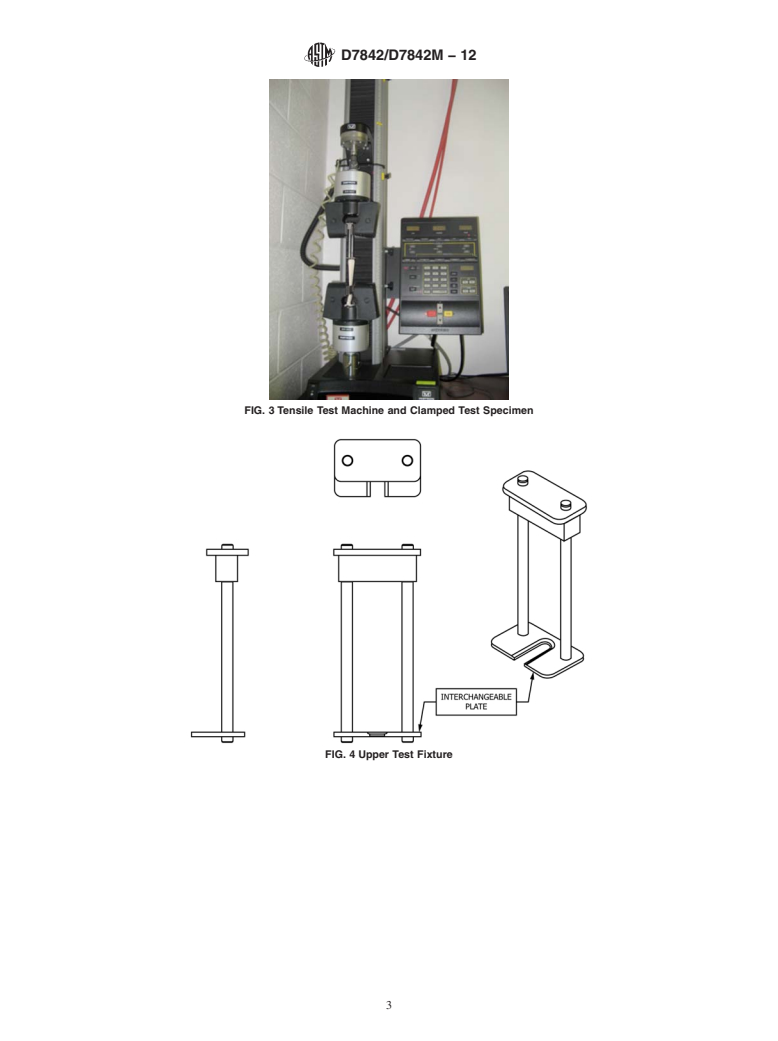

6.1.1 Upper Test Fixture, Fig. 4, designed as not to malform

Available from U.S. Government Printing Office Superintendent of Documents,

the button specimen with interchangeable bottom plates to test

732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

www.access.gpo.gov. a multitude of sizes of buttons.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7842/D7842M − 12

9. Calibration and Standardization

9.1 Testing equipment should be calibrated on a regular

basis as recommended by manufacturer’s instructions.

10. Conditioning

10.1 Condition the specimens by bringing them from the

dry side to approximate moisture equilibrium for testing in the

standard atmosphere for testing textiles as directed in Practice

FIG. 1 Tack Attached

D1776.

11. Procedure

11.1 The attached button is placed in the test fixture. The

test fixture is clamped to the top jaws of the Tensile Testing

machineandthefabricisclampedtothebottomjaws.(SeeFig.

5.)

11.2 Initiate the test by applying force to the machine until

the button disengages from the fastener or the fabric tears.

FIG. 2 Prong Fastener Attached

11.3 Record the force to disengage the button from the

fastener as the holding force to the nearest 0.1 N [0.5 lbf].

7. Sampling, Test Specimens, and Test Units

12. Calculation or Interpretation of Results

7.1 Lot Sample:

7.1.1 For acceptance testing, randomly select the number of

12.1 If the fabric tears before the fastener and button

shipping cartons or other containers of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.