ASTM G185-06

(Practice)Standard Practice for Evaluating and Qualifying Oil Field and Refinery Corrosion Inhibitors Using the Rotating Cylinder Electrode

Standard Practice for Evaluating and Qualifying Oil Field and Refinery Corrosion Inhibitors Using the Rotating Cylinder Electrode

SIGNIFICANCE AND USE

Selection of corrosion inhibitor for oil field and refinery applications involves qualification of corrosion inhibitors in the laboratory (see Guide G 170). Field conditions should be simulated in the laboratory in a fast and cost-effective manner (1).3

Oil field corrosion inhibitors should provide protection over a range of flow conditions from stagnant to that found during typical production conditions. Not all inhibitors are equally effective over this range of conditions so that is important for a proper evaluation of inhibitors to test the inhibitors using a range of flow conditions.

The RCE is a compact and relatively inexpensive approach to obtaining varying hydrodynamic conditions in a laboratory apparatus. It allows electrochemical methods of estimating corrosion rates on the specimen and produces a uniform hydrodynamic state across the metal test surface. (2-21)

In this practice, a general procedure is presented to obtain reproducible results using RCE to simulate the effects of different types of coupon materials, inhibitor concentrations, oil, gas and brine compositions, temperature, pressure, and flow. Oil field fluids may often contain sand. This practice does not cover erosive effects that occur when sand is present.

SCOPE

1.1 This practice covers a generally accepted procedure to use the rotating cylinder electrode (RCE) for evaluating corrosion inhibitors for oil field and refinery applications in defined flow conditions.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:G185 −06

StandardPractice for

Evaluating and Qualifying Oil Field and Refinery Corrosion

Inhibitors Using the Rotating Cylinder Electrode

This standard is issued under the fixed designation G185; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope G46 Guide for Examination and Evaluation of Pitting Cor-

rosion

1.1 This practice covers a generally accepted procedure to

G59 Test Method for Conducting Potentiodynamic Polariza-

use the rotating cylinder electrode (RCE) for evaluating

tion Resistance Measurements

corrosion inhibitors for oil field and refinery applications in

G96 Guide for Online Monitoring of Corrosion in Plant

defined flow conditions.

Equipment (Electrical and Electrochemical Methods)

1.2 The values stated in SI units are to be regarded as

G102 Practice for Calculation of Corrosion Rates and Re-

standard. The values given in parentheses are for information

lated Information from Electrochemical Measurements

only.

G106 Practice for Verification of Algorithm and Equipment

1.3 This standard does not purport to address all of the for Electrochemical Impedance Measurements

safety concerns, if any, associated with its use. It is the

G111 Guide for Corrosion Tests in High Temperature or

responsibility of the user of this standard to establish appro- High Pressure Environment, or Both

priate safety and health practices and determine the applica-

G170 Guide for Evaluating and Qualifying Oilfield and

bility of regulatory limitations prior to use. Refinery Corrosion Inhibitors in the Laboratory

2. Referenced Documents

3. Terminology

2.1 ASTM Standards:

3.1 The terminology used throughout shall be in accordance

D1141 Practice for the Preparation of Substitute Ocean

with Terminologies G15 and D4410 and Guide G170.

Water

D4410 Terminology for Fluvial Sediment 4. Summary of Practice

G1 Practice for Preparing, Cleaning, and Evaluating Corro-

4.1 This practice provides a method of evaluating corrosion

sion Test Specimens

inhibitor efficiency in a RCE apparatus. The method uses a

G3 Practice for Conventions Applicable to Electrochemical

well-defined rotating specimen set up and mass loss or elec-

Measurements in Corrosion Testing

trochemical measurements to determine corrosion rates in a

G5 Reference Test Method for Making Potentiostatic and

laboratory apparatus. Measurements are made at a number of

Potentiodynamic Anodic Polarization Measurements

rotating rates to evaluate the inhibitor performance under

G15 Terminology Relating to Corrosion and CorrosionTest-

increasingly severe hydrodynamic conditions.

ing (Withdrawn 2010)

G16 Guide for Applying Statistics to Analysis of Corrosion

5. Significance and Use

Data

5.1 Selection of corrosion inhibitor for oil field and refinery

G31 PracticeforLaboratoryImmersionCorrosionTestingof

applicationsinvolvesqualificationofcorrosioninhibitorsinthe

Metals

laboratory (see Guide G170). Field conditions should be

simulated in the laboratory in a fast and cost-effective manner

(1).

This practice is under the jurisdiction of ASTM Committee G01 on Corrosion

of Metals and is the direct responsibility of Subcommittee G01.05 on Laboratory

5.2 Oil field corrosion inhibitors should provide protection

Corrosion Tests.

over a range of flow conditions from stagnant to that found

Current edition approved Jan. 15, 2006. Published February 2006. DOI:

during typical production conditions. Not all inhibitors are

10.1520/G0185-06.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

equally effective over this range of conditions so that is

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

The last approved version of this historical standard is referenced on The boldface numbers in parentheses refer to the list of references at the end of

www.astm.org. this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

G185−06

important for a proper evaluation of inhibitors to test the electrode can be attached. The other end of the rod is attached

inhibitors using a range of flow conditions. directly to the rotating unit, through which the electrical

connection is made.

5.3 The RCE is a compact and relatively inexpensive

approach to obtaining varying hydrodynamic conditions in a 6.6 After attaching the specimen to the shaft, the system

laboratory apparatus. It allows electrochemical methods of should be checked for eccentricity and wobble. This can be

estimating corrosion rates on the specimen and produces a accomplished by installing a dial micrometer so as to monitor

uniform hydrodynamic state across the metal test surface. the location of the top of the rotating cylinder and rotating the

(2-21) shaft slowly through one complete turn. The micrometer

should then be moved to monitor the center of the specimen,

5.4 In this practice, a general procedure is presented to

and the process repeated. Finally the micrometer should be

obtainreproducibleresultsusingRCEtosimulatetheeffectsof

moved to the bottom of the specimen and the process repeated.

different types of coupon materials, inhibitor concentrations,

The assembly should also be rotated at its maximum rotation

oil, gas and brine compositions, temperature, pressure, and

rate and the specimen wobble checked again using, for

flow.Oilfieldfluidsmayoftencontainsand.Thispracticedoes

example, a laser indicator or vibration monitor.

not cover erosive effects that occur when sand is present.

6.7 Appropriate cylinder specimen (such as, carbon steel) is

6. Apparatus machined and snugly fitted into the PTFE or any other suitable

specimen holder (Fig. 2). The presence of gap between

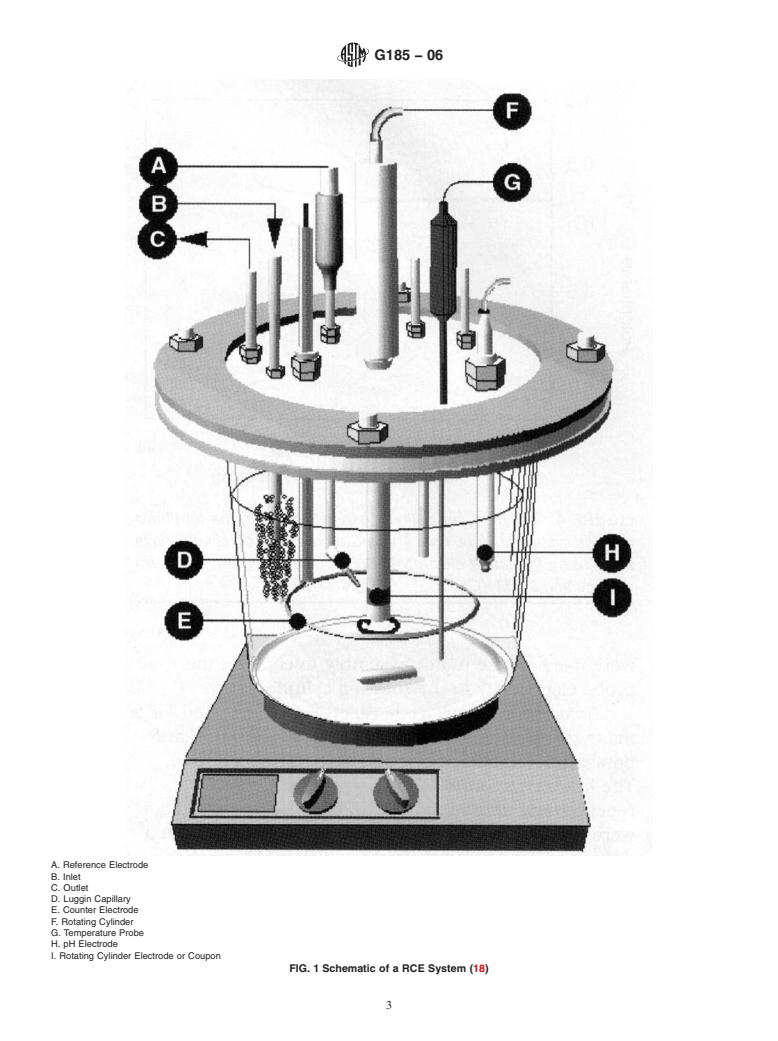

6.1 Fig. 1 shows a schematic diagram of the RCE system.

specimen and holder will create crevice corrosion as well as

The RCE apparatus consists of a rotating unit driven by a

change the flow pattern. If necessary, apply a very small

motorthatisattachedtoasampleholder.Asystemwitharange

amount of epoxy to fit the specimen into the holder. Tightly

of rotational speeds from 100 to 10 000 rpm with an accuracy

attach or screw an end-cap so that only the outer cylindrical

of 62 rpm is typical. It is essential to be able to rotate the

area of known length is exposed to the solution. The specimen

electrodeatbothlowandhighspeedsandtobeabletomeasure

holder is then attached to the rotating unit. Specimen, holder,

the speed and maintain it at a constant. The accuracy of the

and end-cap should all have the same diameter.

rotation rate should be checked. At the side of the sample

holder where it is outside the cell, electrical connections to the 6.8 The rotating unit is attached into the experimental

electrodes are made by a brush contact. It is important for the vessel, ensuring that there is no leakage through the rotating

connection to be as noise free as possible. shaft and the holder and that the rotating shaft is vertically

positioned. Even a very slight inclination could drastically

6.2 The cylinder geometry is usually defined in terms of the

change the flow pattern.

length-to-diameter ratio. Both low and high ratios are used,

with ratios varying between 0.3 and 3.0. The rotating cylinder 6.9 A versatile and convenient apparatus, consisting of a

can also be used as a mass loss coupon when the mass loss is kettle or flask (Fig. 1) of suitable size (usually 500 to

sufficiently large to be accurately measured using a conven- 5000 mL),inletandoutletportsfordeaeration,thermowelland

tional balance (with accuracy of 0.1 mg). temperature-regulating device, a heating device (mantle, hot

plate, or bath), and a specimen support system, should be used.

6.3 The RCE geometry may have an inner cylinder and an

The volume (of the solution) to surface area (of the specimen)

outer cylinder. The geometry is usually defined in terms of the

ratio has some effect on the corrosion rate and hence inhibitor

radiusoftheinnercylinderandtheradiusoftheoutercylinder.

efficiencies. A larger volume/surface area (minimum 40 mL/

When the outer diameter is several times the diameter of the

cm ) should be preferred.

innerelectrodethehydrodynamicsareessentiallycontrolledby

the diameter of the inner rotating cylinder (2). The outer 6.10 In some cases a wide-mouth jar with a suitable closure

cylinder may act as counter electrode. An RCE with only an can be used, but open-beaker tests should not be used because

inner cylinder may also be used. of evaporation and contamination. Do not conduct the open-

beaker test when H S (hydrogen sulfide) is used. In more

6.4 A saturated calomel electrode (SCE) with a controlled

complex tests, provisions might be needed for continuous flow

rate of leakage or a saturated calomel electrode utilizing a

or replenishment of the corrosive liquid, while simultaneously

semipermeable membrane or porous plug tip or silver/silver

maintaining a controlled atmosphere.

chloride or any other suitable electrode should be used as

reference electrode. The potential of the reference electrode 6.11 For experiments above atmospheric pressure, a high-

should be checked at periodic intervals to ensure the accuracy temperature, high-pressure rotating cylinder electrode (HTH-

of the electrode. For experiments at higher-temperature, a PRCE) system with an electrically isolated electrode system,

higher-pressure,referenceelectrodearrangementthatcanwith- an electrically isolated motor for rotating the electrode, and a

stand higher temperature and pressure should be used (22). vessel that can withstand high pressure without leakage should

This may require special care. be used.

6.5 Fig. 2 shows a typical rotating electrode unit.Arotating 6.12 A design of the vessel that can be used in elevated

shaft can be modified by drilling a hole in the shaft into which pressure conditions (23, 24) include a standard autoclave (Fig.

a polytetrafluoroethylene (PTFE) insulator is inserted. Inside 3) modified by lining on the inside with PTFE.The stirring rod

the PTFE insulator, a metal rod should be introduced (Fig. 2). can be modified by drilling a hole into that a PTFE insulator is

One end of the metal rod is threaded so that the cylindrical inserted. Inside the PTFE insulator, a metal rod is introduced.

G185−06

A. Reference Electrode

B. Inlet

C. Outlet

D. Luggin Capillary

E. Counter Electrode

F. Rotating Cylinder

G. Temperature Probe

H. pH Electrode

I. Rotating Cylinder Electrode or Coupon

FIG. 1Schematic of a RCE System (18)

G185−06

A. Outside View

B. Cross-Sectional View

FIG. 2Schematic Representation of a RCE with its Components (adapted from Ref 18)

Three O-rings are used to secure and to prevent leakage. One 7.3 Thespecimensarerinsedwithdistilledwater,degreased

end of the metal rod is threaded so that cylindrical (Fig. 3) by immersing in acetone (or any suitable alcohol), ultrasoni-

electrode can be attached. The other end of the rod, projecting cally cleaned for 1 minute, and dried. The surface of the

slightly above the motor unit, is attached directly the rotating specimens should not be touched with bare hands. The speci-

unit, through which the electrical connection is made. The rod mens are weighed to the nearest 0.1 mg (for mass loss

is rotated by a motor connected to the rod using a belt. The measurements), the dimensions are measured to the nearest 0.1

counter and reference electrodes are inserted inside the auto- mm, and the surface area is calculated.

clave.

7.4 Freshly prepared specimens are installed in the RCE

6.13 The suggested components can be modified, holder. If the test is not commenced within 4 h, the prepared

simplified, or made more sophisticated to fit the needs of a coupons shall be stored in a desiccator to avoid pre-rusting.

particular investigation.

8. Test Solutions

7. Materials

8.1 All solutions (oil and aqueous) should be obtained from

7.1 Methods for preparing specimens for tests and for the field for which the inhibitor is being evaluated. These are

removing specimens after the test are described in Practice G1. known as live solutions. It is important that live solutions do

Standardlaboratoryglasswareshouldbeusedforweighingand not already contain corrosion inhibitor. In the absence of live

measuring reagent volumes. solutions, synthetic solutions should be used, the composition

of which should be based on field water analysis. The compo-

7.2 The specimen shall be made of the material (such as,

sition of the solution should be determined and reported.

carbon steel) for which the inhibitor is being evaluated. The

Alternatively, standard brine (such as per Practice D1141)

specimen should have same metallographic structure as that

should be employed. The solutions should be prepared using

used in the service components. The specimens should be

analytical grade reagents and deionized water.

ground to a specified surface finish (such as, 150-grit). The

grinding should produce a reproducible surface finish, with no 8.2 The solutions should be deoxygenated by passing nitro-

rust deposits, pits, or deep scratches. All sharp edges on the gen or any other inert gas for sufficient time to reduce the

specimen should be ground. All loose dirt particles should be oxygen content below 5 ppb and preferably below 1 ppb in

removed. solution. The solution must be kept under deoxygenated

G185−06

1. Electrical Contact Unit

2. Techometer (Rotation Speed Display)

3. Rotation Controller

4. Electrochemical Instruments

5. Working Electrode

6. Reference Electrode

7. Water Cooler Coil

8. Gas Inlet

9. Thermocouple

10. Gas Outlet

11. Counter Electrode

12. Autoclave Body

13. Solution

14. PTFE Liner

FIG. 3Schematic Diagram of HTHPRCE System (20,21)

conditions. The oxygen concentration in solution depends on shall be kept as low as possible with guidelines of below 5 ppb

the quality of gases used to purge the solution. Any leaks

and preferably under 1 ppb oxygen in solution.

through vessel, tubing, and joints shall be avoided.

8.4 The solution pH before and after testing shall be

8.3 The appropriate composition of gases is determined by

measured, recorded, and reported. The solution pH should be

the composition of gases in the field for which the inhibitor is

monitored regularly (at least once a day) during the test.

evaluated. Hydrogen sulfide (H S) and carbon dioxide (CO )

2 2

8.5 Inhibi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.