ASTM D7467-08

(Specification)Standard Specification for Diesel Fuel Oil, Biodiesel Blend (B6 to B20)

Standard Specification for Diesel Fuel Oil, Biodiesel Blend (B6 to B20)

SCOPE

1.1 This specification covers fuel blend grades of 6 to 20 volume percent (%) biodiesel with the remainder being a light middle or middle distillate diesel fuel, collectively designated as B6 to B20. These grades are suitable for various types of diesel engines.

1.1.1 The biodiesel component of the blend shall conform to the requirements of Specification D 6751. The remainder of the fuel shall be a light middle or middle distillate grade diesel fuel conforming to Specification D 975 grades No. 1-D and No. 2-D of any sulfur level specified with the following exceptions. The light middle or middle distillate grade diesel fuel whose sulfur level, aromatic level, cetane, or lubricity falls outside of Specification D 975 may be blended with biodiesel meeting Specification D 6751, provided the finished mixtures meets this specification.

1.1.2 The fuel sulfur grades are described as follows:

1.1.2.1 Grade B6 to B20 S15—A fuel with a maximum of 15 ppm sulfur.

1.1.2.2 Grade B6 to B20 S500—A fuel with a maximum of 500 ppm sulfur.

1.1.2.3 Grade B6 to B20 S5000—A fuel with a maximum of 5000 ppm sulfur.

1.2 This specification prescribes the required properties of B6 to B20 biodiesel blends at the time and place of delivery. The specification requirements may be applied at other points in the production and distribution system when provided by agreement between the purchaser and the supplier.

1.2.1 Nothing in this specification shall preclude observance of federal, state, or local regulations that may be more restrictive.

Note 1—The generation and dissipation of static electricity can create problems in the handling of distillate diesel fuel oils. For more information on this subject, see Guide D 4865.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 7467 – 08

Standard Specification for

Diesel Fuel Oil, Biodiesel Blend (B6 to B20)

This standard is issued under the fixed designation D 7467; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This specification covers fuel blend grades of 6 to 20 2.1 ASTM Standards:

volume percent (%) biodiesel with the remainder being a light D56 Test Method for Flash Point byTag Closed CupTester

middle or middle distillate diesel fuel, collectively designated D86 Test Method for Distillation of Petroleum Products at

as B6 to B20. These grades are suitable for various types of Atmospheric Pressure

diesel engines. D93 Test Methods for Flash Point by Pensky-Martens

1.1.1 Thebiodieselcomponentoftheblendshallconformto Closed Cup Tester

therequirementsofSpecificationD 6751.Theremainderofthe D 129 Test Method for Sulfur in Petroleum Products (Gen-

fuelshallbealightmiddleormiddledistillategradedieselfuel eral Bomb Method)

conforming to Specification D 975 grades No. 1-D and No. D 130 Test Method for Corrosiveness to Copper from

2-Dofanysulfurlevelspecifiedwiththefollowingexceptions. Petroleum Products by Copper Strip Test

The light middle or middle distillate grade diesel fuel whose D 445 Test Method for Kinematic Viscosity of Transparent

sulfur level, aromatic level, cetane, or lubricity falls outside of and Opaque Liquids (and Calculation of Dynamic Viscos-

Specification D 975 may be blended with biodiesel meeting ity)

SpecificationD 6751,providedthefinishedmixturesmeetsthis D 482 Test Method for Ash from Petroleum Products

specification. D 524 Test Method for Ramsbottom Carbon Residue of

1.1.2 The fuel sulfur grades are described as follows: Petroleum Products

1.1.2.1 Grade B6 to B20 S15—A fuel with a maximum of D 613 Test Method for Cetane Number of Diesel Fuel Oil

15 ppm sulfur. D 664 TestMethodforAcidNumberofPetroleumProducts

1.1.2.2 Grade B6 to B20 S500—Afuel with a maximum of by Potentiometric Titration

500 ppm sulfur. D 975 Specification for Diesel Fuel Oils

1.1.2.3 Grade B6 to B20 S5000—Afuelwithamaximumof D 976 Test Method for Calculated Cetane Index of Distil-

5000 ppm sulfur. late Fuels

1.2 This specification prescribes the required properties of D 1266 Test Method for Sulfur in Petroleum Products

B6 to B20 biodiesel blends at the time and place of delivery. (Lamp Method)

The specification requirements may be applied at other points D 1319 Test Method for Hydrocarbon Types in Liquid

in the production and distribution system when provided by Petroleum Products by Fluorescent Indicator Adsorption

agreement between the purchaser and the supplier. D 1552 Test Method for Sulfur in Petroleum Products

1.2.1 Nothinginthisspecificationshallprecludeobservance (High-Temperature Method)

of federal, state, or local regulations that may be more D 2500 Test Method for Cloud Point of Petroleum Products

restrictive. D 2622 Test Method for Sulfur in Petroleum Products by

Wavelength Dispersive X-ray Fluorescence Spectrometry

NOTE 1—The generation and dissipation of static electricity can create

D 2709 Test Method for Water and Sediment in Middle

problems in the handling of distillate diesel fuel oils. For more informa-

Distillate Fuels by Centrifuge

tion on this subject, see Guide D 4865.

D 2880 Specification for Gas Turbine Fuel Oils

1.3 The values stated in SI units are to be regarded as

D3117 Test Method forWaxAppearance Point of Distillate

standard. No other units of measurement are included in this

Fuels

standard.

1 2

This specification is under the jurisdiction of ASTM Committee D02 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

D02.E0 on Burner, Diesel, Non-Aviation Gas Turbine, and Marine Fuels. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Oct. 1, 2008. Published October 2008. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7467–08

D 3120 Test Method for Trace Quantities of Sulfur in Light EN 14112 Fat and oil derivatives - Fatty acid methyl esters

Liquid Petroleum Hydrocarbons by Oxidative Microcou- (FAME) - Determination of oxidation stability (Acceler-

lometry ated oxidation test)

D 3828 TestMethodsforFlashPointbySmallScaleClosed

3. Terminology

Cup Tester

3.1 Definitions:

D 4057 Practice for Manual Sampling of Petroleum and

3.2 biodiesel, n—fuel comprised of mono-alkyl esters of

Petroleum Products

long chain fatty acids derived from vegetable oils or animal

D 4294 Test Method for Sulfur in Petroleum and Petroleum

fats, designated B100.

Products by Energy Dispersive X-ray Fluorescence Spec-

3.3 B6 to B20, n—fuel blend consisting of 6 to 20 volume

trometry

percent biodiesel conforming to the requirements of Specifi-

D 4539 Test Method for Filterability of Diesel Fuels by

cation D 6751 with the remainder being a light middle or

Low-Temperature Flow Test (LTFT)

middledistillategradedieselfuelandmeetingtherequirements

D 4737 Test Method for Calculated Cetane Index by Four

of this specification.

Variable Equation

3.3.1 Discussion—The abbreviation BXX represents a spe-

D 4865 Guide for Generation and Dissipation of Static

cific blend concentration in the range B6 to B20, where XX is

Electricity in Petroleum Fuel Systems

the percent volume of biodiesel in the fuel blend.

D 5453 Test Method for Determination of Total Sulfur in

3.4 S(numerical specification maximum)—indicates the

Light Hydrocarbons, Spark Ignition Engine Fuel, Diesel

maximumsulfurcontent,inweightppm(µg/g),allowedbythis

Engine Fuel, and Engine Oil by Ultraviolet Fluorescence

specification.

D 5771 Test Method for Cloud Point of Petroleum Products

4. Test Methods

(Optical Detection Stepped Cooling Method)

D 5772 Test Method for Cloud Point of Petroleum Products 4.1 The requirements enumerated in this specification shall

(Linear Cooling Rate Method) be determined in accordance with the following methods:

D 5773 Test Method for Cloud Point of Petroleum Products 4.1.1 Acid Number—Test Method D 664.

4.1.2 Flash Point—Test Method D93, except where other

(Constant Cooling Rate Method)

methods are prescribed by law. Test Method D 3828 may be

D 6079 Test Method for Evaluating Lubricity of Diesel

used as an alternate with the same limits. Test Method D56

Fuels by the High-Frequency Reciprocating Rig (HFRR)

may be used as an alternate with the same limits, provided the

D 6217 Test Method for Particulate Contamination in

flash point is below 93°C. This test method will give slightly

Middle Distillate Fuels by Laboratory Filtration

lower values. In cases of dispute, Test MethodD93 shall be

D 6371 Test Method for Cold Filter Plugging Point of

used as the referee method.

Diesel and Heating Fuels

4.1.3 Cloud Point—Test Method D 2500. For all B6 to B20

D 6468 Test Method for High Temperature Stability of

grades in Table 1 the automatic Test Methods D 5771, D 5772,

Middle Distillate Fuels

or D 5773 can be used as alternates with the same limits. Test

D 6469 Guide for Microbial Contamination in Fuels and

MethodD3117 can also be used since it is closely related to

Fuel Systems

Test Method D 2500. In case of dispute, Test Method D 2500

D 6751 Specification for Biodiesel Fuel Blend Stock

shall be the referee test method.

(B100) for Middle Distillate Fuels

4.1.4 Cold Filter Plugging Point (CFPP)—Test Method

D 6890 Test Method for Determination of Ignition Delay

D 6371.

andDerivedCetaneNumber(DCN)ofDieselFuelOilsby

4.1.5 Low Temperature Flow Test (LTFT)—Test Method

Combustion in a Constant Volume Chamber

D 4539.

D 7371 Test Method for Determination of Biodiesel (Fatty

4.1.6 Water and Sediment—Test Method D 2709.

Acid Methyl Esters) Content in Diesel Fuel Oil Using Mid

4.1.7 Carbon Residue—Test Method D 524.

Infrared Spectroscopy (FTIR-ATR-PLS Method)

4.1.8 Ash—Test Method D 482.

E29 Practice for Using Significant Digits in Test Data to

4.1.9 Distillation—Test MethodD86.

Determine Conformance with Specifications

4.1.10 Viscosity—Test Method D 445.

2.2 Other Standards:

4.1.11 Sulfur—Table 2 shows the referee test methods and

26 CFR Part 48 Manufacturers and Retailers Excise Taxes

alternatetestmethodsforsulfur,therangeoverwhicheachtest

40 CFR Part 80 Regulation of Fuels and Fuel Additives

method applies and the corresponding fuel grades.

EN 14078 Liquid petroleum products - Determination of

4.1.12 Aromaticity—Test Method D 1319. This test method

fatty acid methyl ester (FAME) content in middle distil-

provides an indication of the aromatic content of fuels. For

lates - Infrared spectrometry method

fuels with a maximum final boiling point of 315°C, this test

method is a measurement of the aromatic content of the fuel.

Grade S5000 does not have an aromatics content.

4.1.13 Cetane Index—Test Method D 976.

AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

4.1.14 Lubricity—Test Method D 6079.

732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401.

4.1.15 Copper Corrosion—Test Method D 130, 3 h test at

Available from the National CEN members listed on the CEN website

(www.cenorm.be.) or from the CEN/TC 19 Secretariat (astm@nen.nl). 50°C minimum.

D7467–08

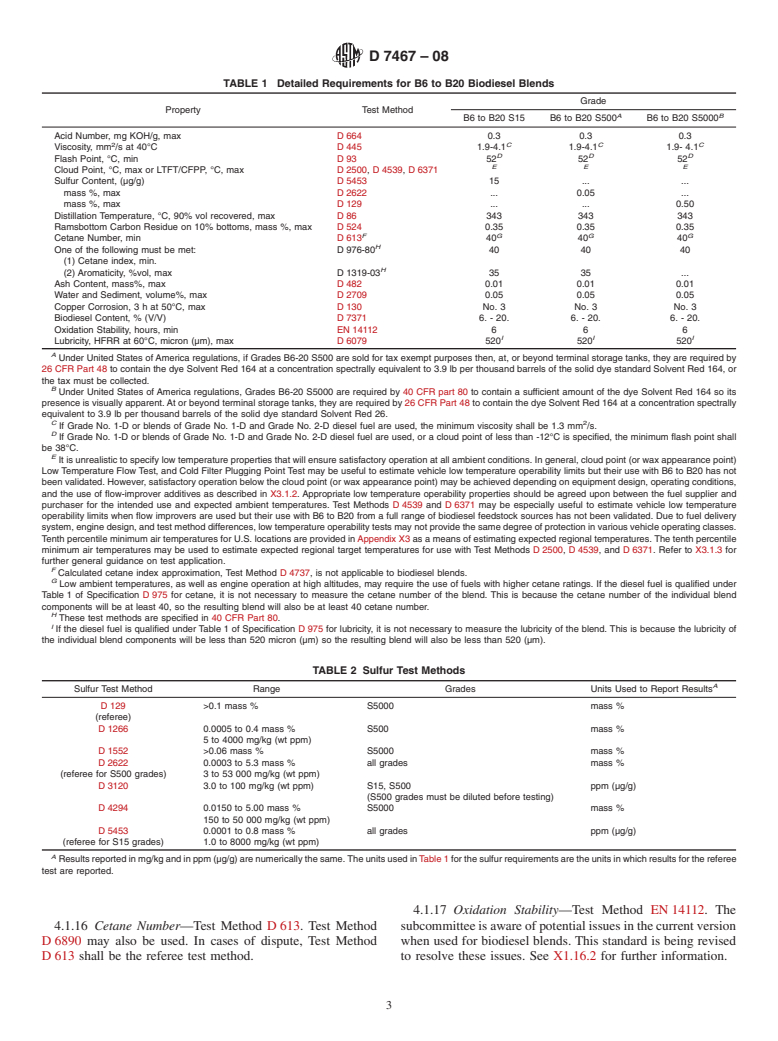

TABLE 1 Detailed Requirements for B6 to B20 Biodiesel Blends

Grade

Property Test Method

A B

B6 to B20 S15 B6 to B20 S500 B6 to B20 S5000

Acid Number, mg KOH/g, max D 664 0.3 0.3 0.3

2 C C C

Viscosity, mm /s at 40°C D 445 1.9-4.1 1.9-4.1 1.9- 4.1

D D D

Flash Point, °C, min D93 52 52 52

EE E

Cloud Point, °C, max or LTFT/CFPP, °C, max D 2500, D 4539, D 6371

Sulfur Content, (µg/g) D 5453 15 . .

mass %, max D 2622 . 0.05 .

mass %, max D 129 . . 0.50

Distillation Temperature, °C, 90% vol recovered, max D86 343 343 343

Ramsbottom Carbon Residue on 10% bottoms, mass %, max D 524 0.35 0.35 0.35

F G G G

Cetane Number, min D 613 40 40 40

H

One of the following must be met: D 976-80 40 40 40

(1) Cetane index, min.

H

(2) Aromaticity, %vol, max D 1319-03 35 35 .

Ash Content, mass%, max D 482 0.01 0.01 0.01

Water and Sediment, volume%, max D 2709 0.05 0.05 0.05

Copper Corrosion, 3 h at 50°C, max D 130 No. 3 No. 3 No. 3

Biodiesel Content, % (V/V) D 7371 6. - 20. 6. - 20. 6. - 20.

Oxidation Stability, hours, min EN 14112 66 6

I I I

Lubricity, HFRR at 60°C, micron (µm), max D 6079 520 520 520

A

Under United States of America regulations, if Grades B6-20 S500 are sold for tax exempt purposes then, at, or beyond terminal storage tanks, they are required by

26 CFR Part 48 to contain the dye Solvent Red 164 at a concentration spectrally equivalent to 3.9 lb per thousand barrels of the solid dye standard Solvent Red 164, or

the tax must be collected.

B

Under United States of America regulations, Grades B6-20 S5000 are required by 40 CFR part 80 to contain a sufficient amount of the dye Solvent Red 164 so its

presence is visually apparent. At or beyond terminal storage tanks, they are required by 26 CFR Part 48 to contain the dye Solvent Red 164 at a concentration spectrally

equivalent to 3.9 lb per thousand barrels of the solid dye standard Solvent Red 26.

C 2

If Grade No. 1-D or blends of Grade No. 1-D and Grade No. 2-D diesel fuel are used, the minimum viscosity shall be 1.3 mm /s.

D

If Grade No. 1-D or blends of Grade No. 1-D and Grade No. 2-D diesel fuel are used, or a cloud point of less than -12°C is specified, the minimum flash point shall

be 38°C.

E

It is unrealistic to specify low temperature properties that will ensure satisfactory operation at all ambient conditions. In general, cloud point (or wax appearance point)

Low Temperature Flow Test, and Cold Filter Plugging Point Test may be useful to estimate vehicle low temperature operability limits but their use with B6 to B20 has not

been validated. However, satisfactory operation below the cloud point (or wax appearance point) may be achieved depending on equipment design, operating conditions,

and the use of flow-improver additives as described in X3.1.2. Appropriate low temperature operability properties should be agreed upon between the fuel supplier and

purchaser for the intended use and expected ambient temperatures. Test Methods D 4539 and D 6371 may be especially useful to estimate vehicle low temperature

operability limits when flow improvers are used but their use with B6 to B20 from a full range of biodiesel feedstock sources has not been validated. Due to fuel delivery

system, engine design, and test method differences, low temperature operability tests may not provide the same degree of protection in various vehicle operating classes.

Tenth percentile minimum air temperatures for U.S. locations are provided in Appendix X3 as a means of estimating expected regional temperatures. The tenth percentile

minimum air temperatures may be used to estimate expected regional target temperatures for use with Test Methods D 2500, D 4539, and D 6371. Refer to X3.1.3 for

further general guidance on test application.

F

Calculated cetane index approximation, Test Method D 4737, is not applicable to biodiesel blends.

G

Low ambient temperatures, as well as engine operation at high altitudes, may require the use of fuels with higher cetane ratings. If the diesel fuel is qualified under

Table 1 of Specification D 975 for cetane, it is not necessary to measure the cetane number of the blend. This is because the cetane number of the individual blend

components will be at least 40, so the resulting blend will also be at least 40 cetane number.

H

These test methods are specified in 40 CFR Part 80.

I

If the diesel fuel is qualified under Table 1 of Specification D 975 for lubricity, it is not necessary to measure the lubricity of the blend. This is because the lubricity of

the individual blend components will be less than 520 micron (µm) so the resulting blend will also be less than 520 (µm).

TABLE 2 Sulfur Test Methods

A

Sulfur Test Method Range Grades Units Used to Report Results

D 129 >0.1 mass % S5000 mass %

(referee)

D 1266 0.0005 to 0.4 mass % S500 mass %

5 to 4000 mg/kg (wt ppm)

D 1552 >0.06 mass % S5000 mass %

D 2622 0.0003 to 5.3 mass % all grades mass %

(referee for S500 grades) 3 to 53 000 mg/kg (wt ppm)

D 3120 3.0 to 100 mg/kg (wt ppm) S15, S500 ppm (µg/g)

(S500 grades must be diluted before testing)

D 4294 0.0150 to 5.00 mass % S5000 mass %

150 to 50 000 mg/kg (wt ppm)

D

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.