ASTM D4374-00

(Test Method)Standard Test Methods for Cyanides in Water--Automated Methods for Total Cyanide, Acid dissociable Cyanide, and Thiocyanate

Standard Test Methods for Cyanides in Water--Automated Methods for Total Cyanide, Acid dissociable Cyanide, and Thiocyanate

SCOPE

1.1 These test methods cover the determination of different species of cyanides and thiocyanate in water and waste water, namely dissociable cyanide, total cyanide, and thiocyanate (1)

1.1.1 Total Cyanide--This test method determines all the dissociable cyanides and the strong metal-cyano-complexes, such as ferrocyanide [Fe(CN)6]4-, ferricyanide [Fe(CN)6]3-, hexacyanocolbaltate [Co(CN)6]3-, and those of gold and platinum.

1.1.2 Dissociable Cyanide --This test method basically determines free cyanides, as CN- and HCN, and weak metal-cyano-complexes such as [Cd(CN)4]2- and [Mn(CN)6]3-. Iron complexes are not included.

1.1.3 Cyanide complexes, strong complexes like those of iron, cobalt, etc., can be determined by difference, that is, cyanide complexes = total cyanides - dissociable cyanides.

1.1.4 Thiocyanate --This test method determines the thiocyanate as the difference between another measurement that includes total cyanide plus thiocyanate and the value of total cyanide, that is, thiocyanate = total cyanide plus thiocyanate - total cyanide.

1.2 Cyanates and cyanogen halides are not detected. Cyanogen chloride hydrolyzes to cyanate at the pH of sample preservation ([>=]12).

1.3 Most of the organo-cyano-complexes are not measured, with the exception of the weak cyanohydrins.

1.4 These test methods apply to different types of water, waste water (raw sewage, sludge, and effluent), sludge, some industrial waste, and sediments. Sample matrixes should be evaluated by the user. The reported precision and bias (see Section 16) may not apply to all samples.

1.5 The values stated in SI units are to be regarded as the standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see Section 9.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation: D 4374 – 00

Standard Test Methods for

Cyanides in Water—Automated Methods for Total Cyanide,

Acid dissociable Cyanide, and Thiocyanate

This standard is issued under the fixed designation D 4374; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope evaluated by the user. The reported precision and bias (see

Section 16) may not apply to all samples.

1.1 These test methods cover the determination of different

1.5 The values stated in SI units are to be regarded as the

species of cyanides and thiocyanate in water and waste water,

standard.

namelyaciddissociablecyanide,totalcyanide,andthiocyanate

1.6 This standard does not purport to address all of the

(1).

safety concerns, if any, associated with its use. It is the

1.1.1 Total Cyanide— This test method determines all the

responsibility of the user of this standard to establish appro-

acid dissociable cyanides and the strong metal-cyano-

4−

priate safety and health practices and determine the applica-

complexes, such as ferrocyanide [Fe(CN) ] , ferricyanide

3− 3−

bility of regulatory limitations prior to use. For specific

[Fe(CN) ] , hexacyanocolbaltate [Co(CN) ] , and those of

6 6

precautionary statements, see Section 9.

gold and platinum.

1.1.2 AcidDissociableCyanide—Thistestmethodbasically

2. Referenced Documents

−

determines free cyanides, as CN and HCN, and weak

2−

2.1 ASTM Standards:

metal-cyano-complexes such as [Cd(CN) ] and [Mn(CN) ]

4 6

D 1129 Terminology Relating to Water

3−. Iron complexes are not included.

D 1193 Specification for Reagent Water

1.1.3 Cyanide complexes, strong complexes like those of

D 2036 Test Methods for Cyanides in Water

iron, cobalt, etc., can be determined by difference, that is,

D 3370 Practices for Sampling Water from Closed Con-

cyanide complexes=total cyanides−acid dissociable cya-

duits

nides.

D3856 Guide for Good Laboratory Practices in Laborato-

1.1.4 Thiocyanate— This test method determines the thio-

ries Engaged in Sampling and Analysis of Water

cyanate as the difference between another measurement that

D 3864 Guide for Continual On-Line Monitoring Systems

includes total cyanide plus thiocyanate and the value of total

for Water Analysis

cyanide, that is, thiocyanate = total cyanide plus

D 4193 Test Method for Thiocyanate in Water

thiocyanate−total cyanide.

D 4210 Practice for Intralaboratory Quality Control Proce-

1.2 Cyanatesandcyanogenhalidesarenotdetected.Cyano-

dures and a Discussion on Reporting Low-Level Data

gen chloride hydrolyzes to cyanate at the pH of sample

D5788 GuideforSpikingOrganicsIntoAqueousSamples

preservation ($12).

D5789 Practice forWriting Quality ControLSpecifications

1.3 Most of the organo-cyano-complexes are not measured,

for Standard Test Methods for Organic Constituents

with the exception of the weak cyanohydrins.

1.4 These test methods apply to different types of water,

3. Terminology

waste water (raw sewage, sludge, and effluent), sludge, some

3.1 Definitions—For definition of terms relating to water,

industrial waste, and sediments. Sample matrixes should be

refer to Terminology D1129.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 distillation ratio,%=

These test methods are under the jurisdiction of ASTM Committee D19 on

volumeofdistilledportionofsample

Water and are the direct responsibility of Subcommittee D19.06 on Methods for

totalvolumeofacidifiedsample

Analysis for Organic Substances in Water.

Current edition approved June 10, 2000. Published September 2000. Originally

published as D4374–84. Last previous edition D4374–98.

2 3

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof Annual Book of ASTM Standards, Vol 11.01.

the text. Annual Book of ASTM Standards, Vol 11.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

D 4374 – 00

4. Summary of Test Method

4.1 Some automated continuous flow modules are used (see

Guide D3864) in addition to the newly developed on-line thin

film distillation (2) and ultraviolet (UV) irradiation (3).

4.2 Threefactorscontroltheseparationofcyanidesfromthe

samples, namely (a) UV irradiation, (b) pH and acidification,

and (c) temperature and time of distillation (see 7.4, 7.5, and

7.3).

4.3 Acidification is made to pH < 1, but the sample

exposure to heat treatment in the continuous thin film distilla-

tion is very short (few seconds).Thus the liberation of HCN is

only from the free cyanides and the weak cyanide complexes,

that is, the acid dissociable cyanides, and not from the strong

complexes. (Acidification to pH 4.5 gives the same acid

dissociable cyanide results.)

4.4 For total cyanides the breakdown of the strong metal

cyanide complexes, prior to the thin film distillation, is

achievedbyUVirradiation(4).Quartzistransparenttothefull

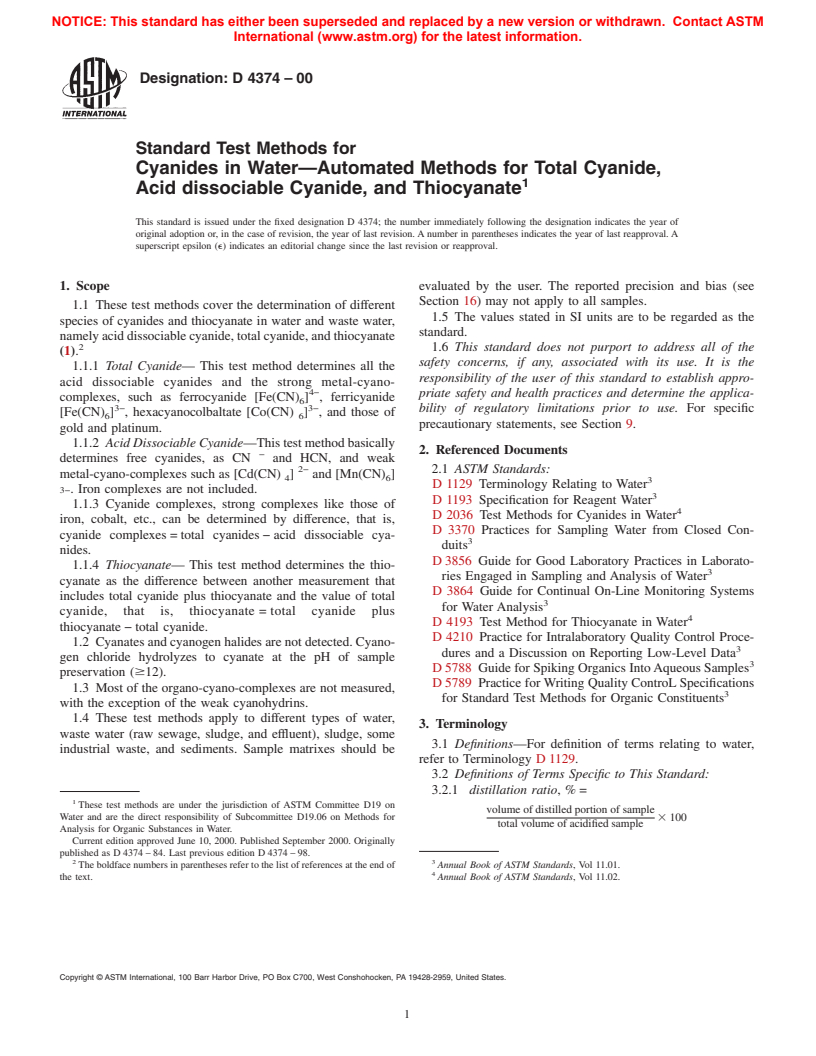

FIG. 1 Flow Diagram for Cyanide Measurements

range of UV wavelengths, 200 to 400 nm, and allows for the

breakdown of the strong metal cyanide complexes as well as

substances are removed automatically through the thin film

thiocyanate. On the other hand, borosilicate glass filters out a

distillation step prior to color development.

major portion of the UV irradiation and transmits only the

6.3 Sulfides—Sulfides may cause direct or indirect interfer-

wavelengthslongerthan300nm,whichwithlongerirradiation

ences, or both, with cyanide measurements.

time at alkaline pH can break down all the strong Co and Fe

6.3.1 Direct Sulfide Interference—Sulfide competes with

cyanide complexes, but not the thiocyanate (1).

cyanide in the reaction with the colorimetric reagents. The

4.5 AbsorptionoftheliberatedHCNgasiscarriedoutusing

degree of sulfide interference depends on the concentrations of

a glass coil and 0.02 M sodium hydroxide solution (see 7.5).

sulfide, cyanide, and chloramine-T solution. At the specified

4.6 Colorimetric determination of the recovered cyanides is

conditions, the cyanide automated system can tolerate the

made by pyridine-barbituric acid reagent. The color is devel-

presence of sulfides up to about 10 mg/L without significant

oped at pH 5.5 to 6.0 and is measured at 578 nm (or use a 580

interference.

nm filter).

6.3.2 Indirect Sulfide Interference—Sulfide may react with

4.7 The lower limit of detection for these automated meth-

cyanide and form thiocyanate.The reaction kinetics depend on

odsis#0.5µg/L(whenusinga50mmflowcellanddepending

theconcentrationofsulfideandcyanideionsaswellasthepH.

on the working range).

Higher pH values accelerate the reaction.

6.3.3 Treatment for Sulfides—Sulfide-containing samples

5. Significance and Use

should be treated as follows. Treatment by dilution is recom-

5.1 Cyanides are known to be toxic to man, but more so to

mended when samples are to be analyzed rapidly, whereas

fish and other aquatic life. The complexity of the chemistry of

treatment with lead or cadmium carbonate should be done

cyanides has led to the coexistence of several cyanide species

before storage.

in the environment. The presence of cyanides in industrial,

6.3.3.1 Treatment by Dilution—Dilute the sample with dis-

domestic, and surface water is cause for concern. Several

tilledwater(withinthedetectionlimitsofthetestmethod)until

regulations and standards require continuous monitoring of

the lead acetate paper test becomes negative (the sensitivity of

cyanidesindifferenttypesofwaterandwastes.Theautomated

thistestisabout5mg/Lsulfide).Thusthesulfideconcentration

test methods presented offer useful tools for such monitoring.

will be below the interfering level. Proceed with the analysis

(See also Practice D4193.)

taking into account the dilution factor.

6.3.3.2 Treatment with Lead or Cadmium Carbonate—This

6. Interferences and Treatment

treatment is recommended to be made before preservation if

6.1 Several interferences are encountered with cyanide

possible: Add small amounts of powdered carbonate to the

analysis (see Test Methods D2036). The known interferents

stabilized sample. Repeat addition until no further dark lead

with the automated system are turbidity and color-contributing

sulfide or yellow cadmium sulfide precipitates, and the lead

substances, sulfides, oxidizing materials, nitrate-nitrite, some

acetate paper test becomes negative. Avoid large excess of

metal cations, aldehydes, fatty acids, and some potential

carbonate and long contact time to minimize cyanide losses.

cyanide-forming materials. Many of these interferences could

6.3.4 For more information refer to Appendix X1 .

be treated, however care should be taken to reduce the time of

6.4 Oxidizing Materials:

sample handling and minimize exposure to UV light (5, 6).

(Fig. 1 is a flow diagram for cyanide measurements.)

6.2 Turbidity and Color Contributing Substances—These

PermissionhasbeengrantedbytheMetropolitanWaterReclamationDistrictof

mayinterferewithcolormeasurement.However,mostofthese Greater Chicago (MWRDGC) to include additional data on interferences.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

D 4374 – 00

6.4.1 Oxygen, ozone, chlorine, and other oxidants may

oxidize the free and some weak complex cyanides to cyanate

and results in lower cyanide values. It should be realized that

treatment with reducing agents is to prevent further oxidation

but cannot recover what has been already oxidized. Several

reducing agents, such as ascorbic acid (C H O ), sodium

6 8 6

hydrogen sulfite (NaHSO ), sodium thiosulfate (Na S O ),

3 2 2 3

stannous chloride (Sn Cl ), and hypophosphorous acid

(H PO ), were evaluated and found not satisfactory. They

3 3

either cause interferences themselves or did not demonstrate

efficient reduction. On the other hand, oxalic acid [(COOH) ],

sodium arsenite [(NaAsO )], and sodium borohydride [NaBH

4] were found to be effective in many cases.

6.4.2 Oxalic acid, about 2 g/L, can reduce up to 50 mg

chlorine per litre. The reaction is satisfactory, though some-

what slow and requires acidic or neutral pH. Therefore, treat

with oxalic acid and close the sample container. Wait 15 min,

then preserve with sodium hydroxide.

6.4.3 Sodium arsenite was found to be very efficient in

reduction. Only 0.1 g/L is required to reduce 50 mg chlorine

per litre. The reaction is fast and the arsenite could be added

before or after sodium hydroxide. However, in some cases

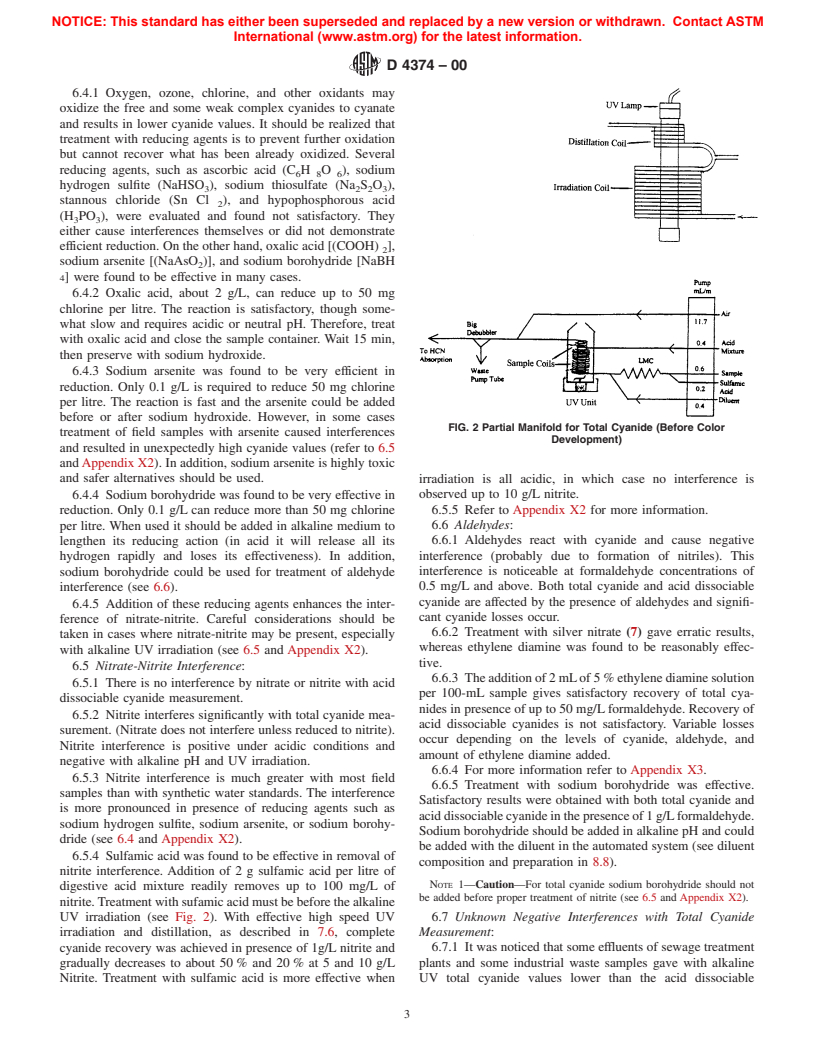

FIG. 2 Partial Manifold for Total Cyanide (Before Color

treatment of field samples with arsenite caused interferences

Development)

and resulted in unexpectedly high cyanide values (refer to 6.5

andAppendix X2). In addition, sodium arsenite is highly toxic

and safer alternatives should be used.

irradiation is all acidic, in which case no interference is

observed up to 10 g/L nitrite.

6.4.4 Sodium borohydride was found to be very effective in

reduction. Only 0.1 g/L can reduce more than 50 mg chlorine 6.5.5 Refer to Appendix X2 for more information.

6.6 Aldehydes:

per litre. When used it should be added in alkaline medium to

lengthen its reducing action (in acid it will release all its 6.6.1 Aldehydes react with cyanide and cause negative

interference (probably due to formation of nitriles). This

hydrogen rapidly and loses its effectiveness). In addition,

sodium borohydride could be used for treatment of aldehyde interference is noticeable at formaldehyde concentrations of

0.5 mg/L and above. Both total cyanide and acid dissociable

interference (see 6.6).

cyanide are affected by the presence of aldehydes and signifi-

6.4.5 Addition of these reducing agents enhances the inter-

cant cyanide losses occur.

ference of nitrate-nitrite. Careful considerations should be

6.6.2 Treatment with silver nitrate (7) gave erratic results,

taken in cases where nitrate-nitrite may be present, especially

whereas ethylene diamine was found to be reasonably effec-

with alkaline UV irradiation (see 6.5 and Appendix X2).

tive.

6.5 Nitrate-Nitrite Interference:

6.6.3 Theadditionof2mLof5%ethylenediaminesolution

6.5.1 There is no interference by nitrate or nitrite with acid

per 100-mL sample gives satisfactory recovery of total cya-

dissociable cyanide measurement.

nides in presence of up to 50 mg/Lformaldehyde. Recovery of

6.5.2 Nitrite interferes significantly with total cyanide mea-

acid dissociable cyanides is not satisfactory. Variable losses

surement. (Nitrate does not interfere unless reduced to nitrite).

occur depending on the levels of cyanide, aldehyde, and

Nitrite interference is positive under acidic conditions and

amount of ethylene diamine added.

negative with alkaline pH and UV irradiation.

6.6.4 For more information refer to Appendix X3.

6.5.3 Nitrite interference is much greater with most field

6.6.5 Treatment with sodium borohydride was effective.

samples than with synthetic water standards. The interference

Satisfactory results were obtained with both total cyanide and

is more pronounced in presence of reducing agents such as

aciddissociablecyanideinthepresenceof1g/Lformaldehyde.

sodium hydrogen sulfite, sodium arsenite, or sodium borohy-

Sodium borohydride should be added in alkaline pH and could

dride (see 6.4 and Appendix X2).

be added with the diluent in the automated system (see diluent

6.5.4 Sulfamic acid was found to be effective in removal of

composition and preparation in 8.8).

nitrite interference. Addition of 2 g sulfamic acid per litre of

NOTE 1—Caution—For total cyanide sodium borohydride should not

digestive acid mixture readily removes up to 100 mg/L of

be added before proper treatment of nitrite (see 6.5 and Appendix X2).

nitrite.Treatmentwithsufamicacidmustbebeforethealkaline

UV irradiation (see Fig. 2). With effective high speed UV 6.7 Unknown Negative Interferences with Total Cyanide

irradiation and distillation, as described in 7.6, complete Measurement:

cyanide recovery was achieved in presence of 1g/L nitrite and 6.7.1 It was noticed that some effluents of sewage treatment

gradually decreases to about 50% and 20% at 5 and 10 g/L plants and some industrial waste samples gave with alkaline

Nitrite. Treatment with sulfamic acid is more effective when UV total cyanide values lower than the acid dissociable

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.