ASTM D5515-97

(Test Method)Standard Test Method for Determination of the Swelling Properties of Bituminous Coal Using a Dilatometer

Standard Test Method for Determination of the Swelling Properties of Bituminous Coal Using a Dilatometer

SCOPE

1.1 This test method specifies a procedure for the measurement of the swelling of bituminous coal using a dilatometer.

1.2 The test method is limited in applicability to those coals which have a free swelling index [>=] 1 as determined in accordance with Test Method D720.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 The values stated in SI units (Practice E380) are to be regarded as standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 5515 – 97

Standard Test Method for

Determination of the Swelling Properties of Bituminous Coal

Using a Dilatometer

This standard is issued under the fixed designation D 5515; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

The principle of this test method is that the final volume of char obtained at the conclusion of a

standard dilatation test is dependent on the mass of coal in the coal pencil and on the radius of the

retort tube. This test method incorporates a procedure which: determines the mass of air-dried coal in

the coal pencil; provides a means to measure the average retort tube radii; and employs a means to

report coal expansion on an air dried coal weight basis.

Other test methods used to determine the swelling properties of bituminous coals include the Ruhr

(ISO 8264) and Audibert-Arnu (ISO 349) International Standard Organization (ISO) test methods.

However these two ISO test methods provide consistently different values for percent dilatation and

percent contraction. Percent contraction and dilatation values obtained using the Audibert-Arnu test

method are higher and lower respectively than those obtained using the Ruhr test method . These

differences have been attributed to trimming the length of the coal pencil from different ends. The

Audibert-Arnu test method specifies that the wider end of the coal pencil be trimmed while the Ruhr

test method specifies that the narrower end of the coal pencil be trimmed.

1. Scope System of Units (SI): The Modern Metric System

2.2 International Standardization Organization (ISO) Stan-

1.1 This test method specifies a procedure for the measure-

dards:

ment of the swelling of bituminous coal using a dilatometer.

ISO 349 Hard Coal-Audibert-Arnu Dilatometer Test

1.2 The test method is limited in applicability to those coals

ISO 8264 Hard Coal—Determination of the Swelling Prop-

which have a free swelling index $1 as determined in

erties Using a Dilatometer

accordance with Test Method D 720.

1.3 This standard does not purport to address all of the

3. Terminology

safety concerns, if any, associated with its use. It is the

3.1 Abbreviations:basement level reference mark height,

responsibility of the user of this standard to establish appro-

BLRM , the char height as measured using the BLRM, after

ht

priate safety and health practices and determine the applica-

removing the piston/retort assembly as a unit after completion

bility of regulatory limitations prior to use.

of the test, expressed in millimetres.

1.4 The values stated in SI units (IEEE/ASTM SI-10) are to

3.2 coal pencil, a 60-mm-long test specimen formed by

be regarded as standard.

compression in a mold from coal which has been pulverized to

2. Referenced Documents pass a 250-μm (No. 60) sieve.

, the calculated mass of the

3.3 dry coal pencil mass,M

2.1 ASTM Standards: dry

trimmed 60-mm-long coal pencil corrected for added water,

D 720 Test Method for Free-Swelling Index of Coal

2 expressed in grams.

D 2013 Method of Preparing Coal Samples for Analysis

3.4 equivalent percent dilatation for 2.50 g of air dried coal,

D 2234 Practice for Collection of a Gross Sample of Coal

%D , the calculated percent expansion for a 2.50-g, unmoist-

IEEE/ASTM SI-10 Standard for Use of the International 2.50

ened, 60-mm-long, coal pencil corrected for average tube radii,

expressed as a percentage.

3.5 maximum contraction temperature, T2, the temperature

This test method is under the jurisdiction of ASTM Committee D-5 on Coal and

at which the coal pencil starts swelling, expressed in Celsius.

Coke and is the direct responsibility of Subcommittee D05.15 on Metalurgical

For coals which exhibit contraction only, T2 is the temperature

Properties of Coal and Coke.

Current edition approved June 10, 1997. Published May 1998. Originally

published as D 5515 – 94. Last previous edition D 5515 – 94.

2 3

Annual Book of ASTM Standards, Vol 05.05. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 5515

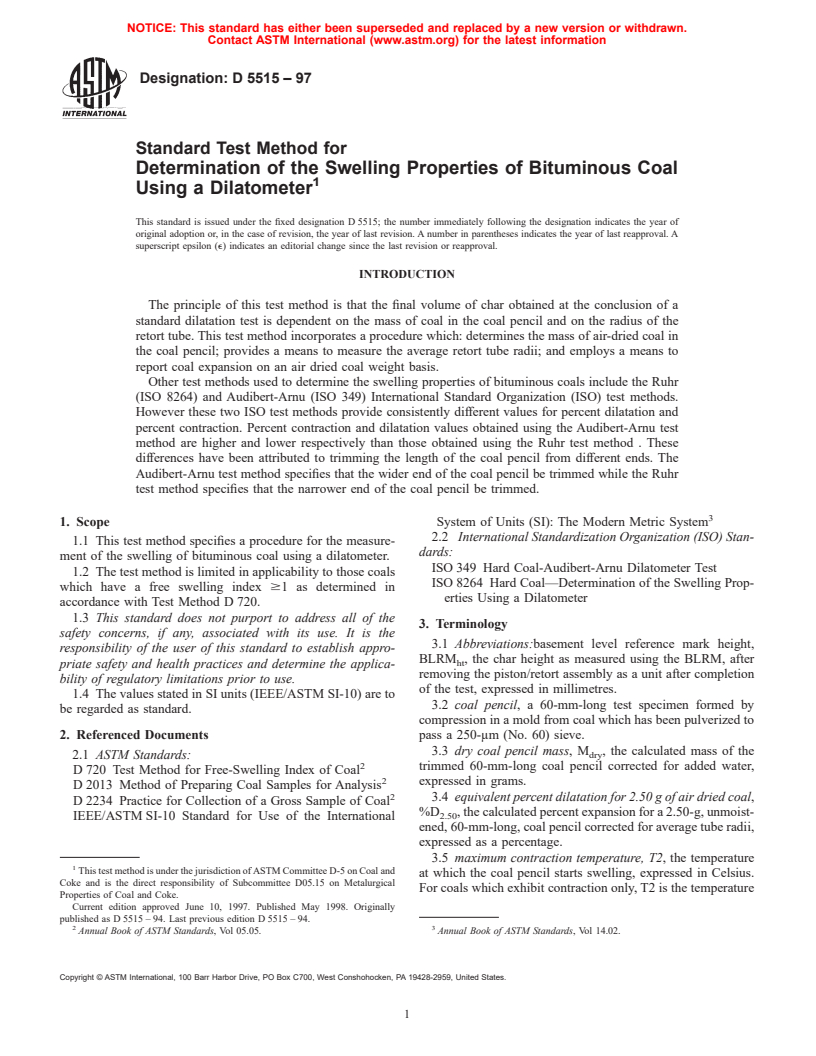

at which the coal pencil reaches its minimum (see Fig. 1). For 6. Apparatus

coals that exhibit contraction only and are still contracting at

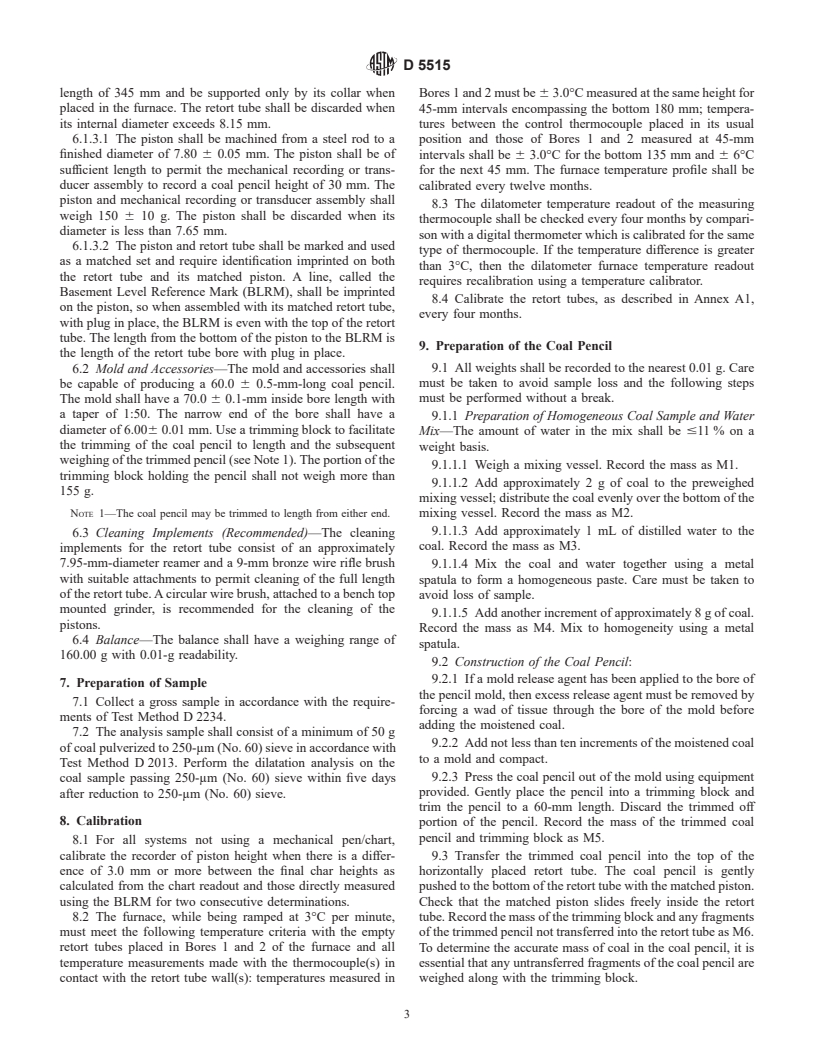

6.1 Dilatometer apparatus, a typical arrangement of the

500°C, T2 will be reported as taken at 500°C (see Fig. 1d).

dilatometer apparatus is shown in Fig. 2. The apparatus

3.6 maximum dilatation temperature, T3, the temperature at

consists of the following:

which the coal pencil first reaches a maximum height after

6.1.1 Electric Furnace—The dilatometer furnace has a core

swelling, expressed in Celsius (see Fig. 1).

consisting of a 65-mm-diameter cylindrical block of aluminum

bronze, resistant to oxidation and having a sufficiently high

3.7 percent contraction, %C, the minimum recorded height

melting point. The length of the furnace core can vary from 400

of char expressed as a percentage, based on an initial coal

to 460 mm depending on the length of the retort tubes used.

pencil height of 60 mm (see Fig. 1).

The block has three symmetrically placed 15-mm-diameter

3.8 percent dilatation, %D, the maximum recorded height

bored holes capable of accepting three retort tubes. The core is

of char expressed as a percentage, based on an initial coal

heated electrically by insulated resistance windings capable of

pencil height of 60 mm (see Fig. 1).

being controlled at a temperature ramp rate of 3.0 6 0.1°C per

3.9 softening temperature, T1, the temperature at which the

minute from within 7 min of the time a test is started to a final

height of the coal pencil contracts 1.0 % (0.6 mm) from the

temperature of 520°C. The furnace shall perform in accordance

highest recorded initial pencil height, expressed in Celsius (see

with the specifications outlined in 8.2. The thermocouple used

Fig. 1).

for temperature control is situated in a retort tube placed in the

3.10 wet coal pencil mass, M , the measured mass of a

wet

third role of the core. The thermocouple tip is placed in contact

trimmed 60-mm-long coal pencil weight, expressed in grams.

with the retort tube wall 60 mm above the bottom of the retort

tube plug.

4. Summary of Test Method

6.1.2 System for Measuring Piston Movement and

Temperature—The system shall be capable of measuring the

4.1 The test involves preparing a coal pencil and determin-

linear displacement of the piston to the nearest 1.0 mm and

ing the changes of the coal pencil height in a retort tube during

providing a correlation of displacement with temperature.

a prescribed heating cycle.

6.1.3 Retort Tube and Pistons—The retort tube consists of a

seamless tube of steel, with an internal diameter of 8.00 6 0.05

5. Significance and Use

mm and an external diameter of 14.50 6 0.05 mm. It shall have

5.1 Values of the dilatation properties of coals may be used

a support collar at the top and be threaded to accept a gastight,

to predict or explain the behavior of a coal or blends during

threaded plug at its base. The retort tube shall have a minimum

carbonization or in other processes such as gasification, lique-

faction, and combustion.

FIG. 1 Types of Dilatation Curves FIG. 2 Typical Dilatometer Apparatus

D 5515

length of 345 mm and be supported only by its collar when Bores 1 and 2 must be 6 3.0°C measured at the same height for

placed in the furnace. The retort tube shall be discarded when 45-mm intervals encompassing the bottom 180 mm; tempera-

its internal diameter exceeds 8.15 mm. tures between the control thermocouple placed in its usual

6.1.3.1 The piston shall be machined from a steel rod to a position and those of Bores 1 and 2 measured at 45-mm

finished diameter of 7.80 6 0.05 mm. The piston shall be of

intervals shall be 6 3.0°C for the bottom 135 mm and 6 6°C

sufficient length to permit the mechanical recording or trans- for the next 45 mm. The furnace temperature profile shall be

ducer assembly to record a coal pencil height of 30 mm. The

calibrated every twelve months.

piston and mechanical recording or transducer assembly shall

8.3 The dilatometer temperature readout of the measuring

weigh 150 6 10 g. The piston shall be discarded when its

thermocouple shall be checked every four months by compari-

diameter is less than 7.65 mm.

son with a digital thermometer which is calibrated for the same

6.1.3.2 The piston and retort tube shall be marked and used

type of thermocouple. If the temperature difference is greater

as a matched set and require identification imprinted on both

than 3°C, then the dilatometer furnace temperature readout

the retort tube and its matched piston. A line, called the

requires recalibration using a temperature calibrator.

Basement Level Reference Mark (BLRM), shall be imprinted

8.4 Calibrate the retort tubes, as described in Annex A1,

on the piston, so when assembled with its matched retort tube,

every four months.

with plug in place, the BLRM is even with the top of the retort

tube. The length from the bottom of the piston to the BLRM is

9. Preparation of the Coal Pencil

the length of the retort tube bore with plug in place.

9.1 All weights shall be recorded to the nearest 0.01 g. Care

6.2 Mold and Accessories—The mold and accessories shall

be capable of producing a 60.0 6 0.5-mm-long coal pencil. must be taken to avoid sample loss and the following steps

must be performed without a break.

The mold shall have a 70.0 6 0.1-mm inside bore length with

a taper of 1:50. The narrow end of the bore shall have a

9.1.1 Preparation of Homogeneous Coal Sample and Water

diameter of 6.006 0.01 mm. Use a trimming block to facilitate

Mix—The amount of water in the mix shall be #11%ona

the trimming of the coal pencil to length and the subsequent

weight basis.

weighing of the trimmed pencil (see Note 1). The portion of the

9.1.1.1 Weigh a mixing vessel. Record the mass as M1.

trimming block holding the pencil shall not weigh more than

9.1.1.2 Add approximately2gof coal to the preweighed

155 g.

mixing vessel; distribute the coal evenly over the bottom of the

NOTE 1—The coal pencil may be trimmed to length from either end. mixing vessel. Record the mass as M2.

9.1.1.3 Add approximately 1 mL of distilled water to the

6.3 Cleaning Implements (Recommended)—The cleaning

coal. Record the mass as M3.

implements for the retort tube consist of an approximately

7.95-mm-diameter reamer and a 9-mm bronze wire rifle brush

9.1.1.4 Mix the coal and water together using a metal

with suitable attachments to permit cleaning of the full length spatula to form a homogeneous paste. Care must be taken to

of the retort tube. A circular wire brush, attached to a bench top

avoid loss of sample.

mounted grinder, is recommended for the cleaning of the

9.1.1.5 Add another increment of approximately8gof coal.

pistons.

Record the mass as M4. Mix to homogeneity using a metal

6.4 Balance—The balance shall have a weighing range of

spatula.

160.00 g with 0.01-g readability.

9.2 Construction of the Coal Pencil:

9.2.1 If a mold release agent has been applied to the bore of

7. Preparation of Sample

the pencil mold, then excess release agent must be removed by

7.1 Collect a gross sample in accordance with the require-

forcing a wad of tissue through the bore of the mold before

ments of Test Method D 2234.

adding the moistened coal.

7.2 The analysis sample shall consist of a minimum of 50 g

9.2.2 Add not less than ten increments of the moistened coal

of coal pulverized to 250-μm (No. 60) sieve in accordance with

to a mold and compact.

Test Method D 2013. Perform the dilatation analysis on the

9.2.3 Press the coal pencil out of the mold using equipment

coal sample passing 250-μm (No. 60) sieve within five days

provided. Gently place the pencil into a trimming block and

after reduction to 250-μm (No. 60) sieve.

trim the pencil to a 60-mm length. Discard the trimmed off

8. Calibration

portion of the pencil. Record the mass of the trimmed coal

pencil and trimming block as M5.

8.1 For all systems not using a mechanical pen/chart,

calibrate the recorder of piston height when there is a differ- 9.3 Transfer the trimmed coal pencil into the top of the

ence of 3.0 mm or more between the final char heights as horizontally placed retort tube. The coal pencil is gently

calculated from the chart readout and those directly measured pushed to the bottom of the retort tube with the matched piston.

using the BLRM for two consecutive determinations. Check that the matched piston slides freely inside the retort

8.2 The furnace, while being ramped at 3°C per minute, tube. Record the mass of the trimming block and any fragments

must meet the following temperature criteria with the empty of the trimmed pencil not transferred into the retort tube as M6.

retort tubes placed in Bores 1 and 2 of the furnace and all To determine the accurate mass of coal in the coal pencil, it is

temperature measurements made with the thermocouple(s) in essential that any untransferred fragments of the coal pencil are

contact with the retort tube wall(s): temperatures measured in weighed along with the trimming block.

D 5515

10. Procedure

M = mass of the prepared coal pencil calculated in

wet

12.2; and

10.1 Clean the dilatometer retort and piston assembly.

% = amount of water added to the coal calculated in

Firmly attach the retort tube plugs to the retort tubes. Check

H2O

12.1.

that the matched piston slides freely in the retort tube.

10.2 Prepare the coal pencils and load them into the retort

12.4 Calculate the char height, H , as follows:

c

tubes as described in Section 9.

H 5 %D 3 0.6 1 60 (3)

c

10.3 Load both retort tube and piston assemblies, charged

with trimmed coal pencils, into the dilatometer furnace which where:

H = calculated char height, mm;

is thermally stabilized at its 315°C setpoint. Start the tempera-

c

%D = dilatation for a 60-mm-long trimmed coal pencil, %;

ture control program immediately after loading is completed.

0.6 = the factor used to convert %D to a height, mm/%;

10.4 Attach the mechanism used to measure piston height

and

and adjust the piston height reading to 0 6 5 %D.

60 = the baseline height of the coal pencil, mm.

10.5 Terminate the test when no movement of the piston can

12.5 Calculate the char height for 2.50 g of air-dried coal,

be detected for 5 min after completion of the dilatation process.

In the instance of no dilatation, terminate the test when the H , as follows:

2.50

furnace temperature reaches 500°C. Reset

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.