ASTM D3751-94(1997)

(Practice)Standard Practice for Evaluation of Furniture Polish

Standard Practice for Evaluation of Furniture Polish

SCOPE

1.1 This practice covers the definition of properties to test and the apparatus to use in evaluating the performance of furniture polishes.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

Designation: D 3751 – 94 (Reapproved 1997)

Standard Practice for

Evaluation of Furniture Polish

This standard is issued under the fixed designation D 3751; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4.3 Polishing Cloth—Materials such as washed cheese

cloth, rumple cloth, flannel, cotton diaper cloth, and nonwoven

1.1 This practice covers the definition of properties to test

fabrics are suitable for this purpose. The same type polishing

and the apparatus to use in evaluating the performance of

cloth should be used with each sample tested. Use separate

furniture polishes.

cloths for each sample. Do not use felt or paper.

1.2 This standard does not purport to address all of the

4.4 Cleaning Solvent, aliphatic, with kauri-butanol values

safety concerns, if any, associated with its use. It is the

less than 38.

responsibility of the user of this standard to establish appro-

4.5 Eye Droppers and Tap Water.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

5. Test Specimen

2. Terminology 5.1 The test specimen shall be the sample of polish to be

tested.

2.1 Definition:

2.1.1 furniture polish—a polish used for cleaning and im-

6. Selection of Testers

proving the appearance of furniture finishes.

6.1 The application and evaluation of the test and control

3. Significance and Use polishes requires four individuals. They shall be capable of

making discriminating judgments of subjective, physical, and

3.1 This practice defines the properties to be tested, the

aesthetic properties. Training and orientation to specific prod-

apparatus to be used, and the comparisons of product perfor-

uct performance characteristics may be required.

mance. It is recognized that considerable discretion exists

6.2 Each person applies the polishes to one of the four test

among formulators and marketers of furniture polish on which

panels. The tester then rates all properties except application

properties or performance characteristics are best for their

properties on the remaining three panels that they did not

products. This practice will be flexible to honor this fact within

polish. The person applying the polishes rates ease of use and

the confines of the furniture polish definition below.

other application properties. This means there will be only four

3.2 The methods of testing are subjective and empirical in

readings on application properties. The three rating the other

order to conform to the basic characteristics of the industry and

polish properties do not observe the application because they

to allow flexibility in testing.

rate properties of each polish “blind.”

4. Apparatus and Materials

7. Procedure

4.1 Control Polish, selected subjectively for comparison to

7.1 Cleaning of Test Substrates—Use an aliphatic solvent

the test polish. It may be a competitive product, a modified

having a kauri-butanol value less than 38, to clean the test

formulation of the test polish, etc. The one stipulation is that

substrate thoroughly. Use new paper towels each time to apply

the control polish be of the same or similar type as the test

the solvent to the surface and to wipe it clean.

polish. For example, if the test polish is an aerosol emulsion

7.2 Application of Polish—Assuming the control polish or

polish, the control shall be an aerosol emulsion polish. It would

the test polish is a commercially available product, follow the

not be meaningful to select a paste or liquid product as a

directions on the container so far as possible. When in doubt on

control for comparison to an aerosol emulsion test polish.

the method of use, follow the directions for similar products.

4.2 Test Substrate for which the test polish is intended. The

Use equal volumes of control and test polish to avoid exces-

test surface shall be in good physical condition, not badly

sively thin or heavy coats of polish. Use one or two applica-

cracked, scratched, or otherwise damaged so as to interfere

tions depending on the substrate and the discretion of the tester.

with evaluation of polish properties. The minimum test surface

2 2

Use the same number of coats for both the test polish and the

area for each sample shall be 200 in. (1290 cm ).

control polish.

7.3 Placement of Polishes:

This practice is under the jurisdiction of ASTM Committee D-21 on Polishes,

7.3.1 Alternative A—A controlled randomized method of

and is the direct responsibility of Subcommittee D21.04 on Performance Tests.

laying out the test (X) and control (C) polishes is represented

Current edition approved Nov. 15, 1994. Published January 1995. Originally

published as D 3751 – 79. Last previous edition D 3751 – 89a. as follows:

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 3751

8.1.2.8 Water Spotting—At least 2 h after application of the

Test Panel Left Center Right

polishes, place at random on the polished surfaces several spots

1C X C

of water about the size of a penny. Allow the water to remain

2C C X

on the surface for 5 min, 15 min, 30 min, and 1 h. At precise

3X C X

4X X C

intervals, blot the water with a paper towel or other absorbent

material. DO NOT WIPE. Observe the presence and degree of

These four positionings should be written on tags and drawn

film damage. Other materials such as milk, coffee, juice,

randomly by each of the four who apply the polishes.

alcoholic beverages, etc., may be used to supplement the water

7.3.2 Alternative B—A controlled randomized method of

test.

laying out the test (X) and control (C) polishes is represented

8.1.2.9 Gloss Retention—Observe the degree of gloss of a

as follows:

freshly applied polish film compared to that of an aged polish

Test Panel Left Right

film.

1C X

8.1.2.10 Dust Attraction—Measure by carefully wiping the

2X C

test surface to remove all dirt and dust. Place the test substrate

3C X

4X C

in a place to accumulate dust. Check dust build-up on the panel

after 24, 48, and 72 h, and after 1 week.

These four positionings should be written on tags and drawn

randomly by each of the four who apply the polishes.

9. Report

8. Evaluation

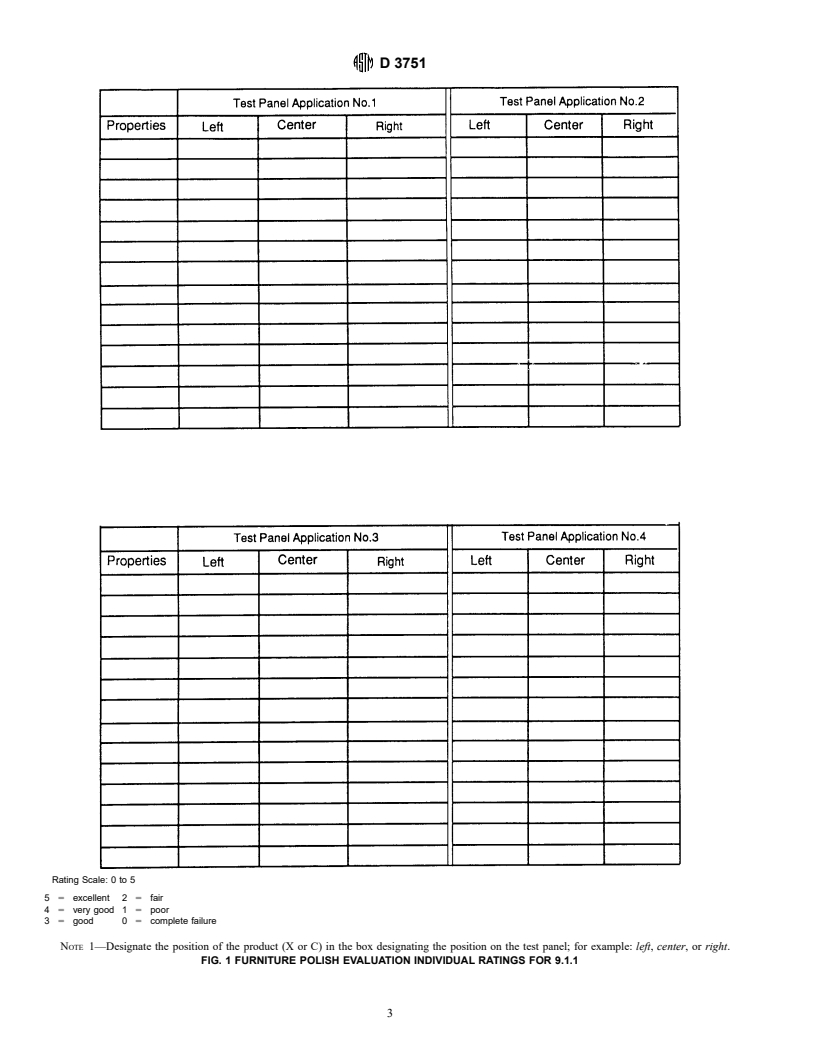

9.1 Alternative A—Using 7.3.1 rate all properties 0 to 5. A

8.1 Compare the test polish and the control as follows: value of 5 equals excellent and 0 equals complete failure.

8.1.1 Application Properties (Ease of Rub-Out to Maximum Values in between are various degrees between these extremes.

Gloss)—During application of the pol

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.