ASTM F1853-98

(Test Method)Standard Test Method for Measuring Sleeping Bag Packing Volume

Standard Test Method for Measuring Sleeping Bag Packing Volume

SCOPE

1.1 This test method covers the quantitative volume of a sleeping bag in a cylinder under a standardized load.

1.2 This test method uses a physical volumetric measurement applicable in the laboratory or in the field.

1.3 The volumes stated in SI units are to be regarded as standard. The inch-pound units given in parentheses are provided for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: F 1853 – 98

Standard Test Method for

Measuring Sleeping Bag Packing Volume

This standard is issued under the fixed designation F 1853; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope loading force. Small ventilation holes are also acceptable to

allow air to escape. See Annex A1 for specifications on a

1.1 This test method covers the quantitative volume of a

typical design.

sleeping bag in a cylinder under a standardized load.

4.3 Measuring Scale—A scale accurate to 1 mm (1/16 in.)

1.2 This test method uses a physical volumetric measure-

and having a capacity to measure the height of the loading

ment applicable in the laboratory or in the field.

system in the measuring cylinder. For convenience, multiple

1.3 The values stated in SI units are to be regarded as

scales can be placed around (and can be affixed to) the

standard. The inch-pound units given in parentheses are

measuring cylinder so opposing height readings can be taken

provided for information only.

directly. Additionally, scale markings can be customized to

1.4 This standard does not purport to address all of the

read packing volume directly since the cross-sectional area of

safety concerns, if any, associated with its use. It is the

the cylinder is constant.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5. Procedure

bility of regulatory limitations prior to use.

5.1 Perform tests at ambient temperatures between 10 and

2. Terminology 25°C (55 and 80°F).

5.2 Zip up the sleeping bag and place feet end first into the

2.1 Definitions:

measuring cylinder. The bag should be packed down slightly to

2.1.1 sleeping bag, n—a structure made of down, synthetic

make its distribution in the measuring cylinder as uniform as

fiberfill, shell fabrics, or other materials, or both, that is

possible. Sleeping bags with low air permeability outer shells

designed for people to use for thermal protection when

may be turned inside out to minimize the settling time

sleeping (for example, outdoors, tent, cabin).

(entrained air release) when the load is applied.

3. Significance and Use 5.3 Apply the loading system to the sleeping bag in the

measuring cylinder and allow to settle. The system is deemed

3.1 This test method can be used to quantify and compare

settled when the change in measured height is less that 1 mm

packing volumes of sleeping bags. It defines the volume

in a 1 min interval.

occupied by a sleeping bag under a standardized load (see 4.2).

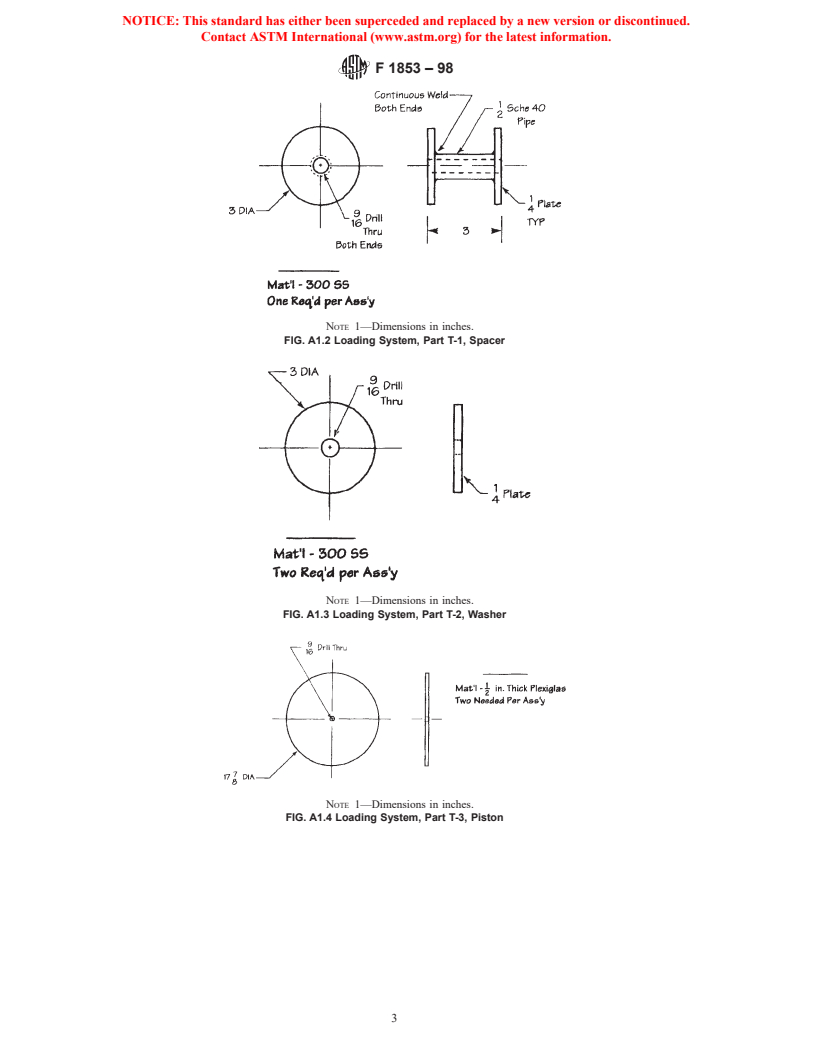

5.3.1 Using the typical design shown in Annex A1, place the

4. Apparatus

6.12 kg (13.5 lb) piston assembly into the measuring cylinder

with the first round disk contacting the surface of the bag.

4.1 Measuring Cylinder—A circularly round container,

Stack five 9.07 kg (20 lb) weights and one 4.54 kg (10 lb)

measuring in diameter 45 6 3cm(18 6 1 in.), suitable to

weight on top of the second disk of the piston assembly for a

contain the sleeping bag being measured, and capable of not

total of 56.02 kg (123.5 lb).

deforming when the loading system is applied. See Annex A1

5.4 Take two height readings to the nearest 1 mm (1/16 in.),

for specifications on a typical design.

one opposite the other, of the height of the compressed bag in

4.2 Loading System—A circular plate or piston structure

the measuring cylinder.

that closely matches the diameter of the measuring cylinder,

5.4.1 Using the typical design shown in the annex, take two

with weights, that provides a 3.45 6 0.07 kPa (0.50 6 0.01 psi)

height readings, one opposite the other, at the top of the second

load. The diameter of the plate or piston structure should be

disk of the piston assembly. Areas where the bag material

slightly undersized, compared to the measuring cylinder, to

creeps up past the loading system or where an air pocket forms

allow air to escape as the bag under test is subject to the

should not be used for the measurement. A flashlight can be

held inside the semi-transparent measuring cylinder so that the

This test method is under the jurisdiction of ASTM Committee F-8 on Sports

location of the top disk can be accurately determined. Subtract

Equipment and Facilitiesand is the direct responsibility of Subcommittee F08.22on

the distance between the top disk and bottom disk (in contact

Sleeping Bags.

with the bag) from the measurement and use as the bag height

Current edition approved Feb. 10, 1998. Publis

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.