ASTM C170/C170M-14a

(Test Method)Standard Test Method for Compressive Strength of Dimension Stone

Standard Test Method for Compressive Strength of Dimension Stone

SIGNIFICANCE AND USE

4.1 This test method is useful in indicating the differences in compressive strength between the various dimension stones. This test method also provides one element in comparing stones of the same type.

SCOPE

1.1 This test method covers the sampling, preparation of specimens, and determination of the compressive strength of dimension stone.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C170/C170M − 14a

StandardTest Method for

Compressive Strength of Dimension Stone

This standard is issued under the fixed designation C170/C170M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 4. Significance and Use

1.1 This test method covers the sampling, preparation of 4.1 This test method is useful in indicating the differences in

specimens, and determination of the compressive strength of compressive strength between the various dimension stones.

dimension stone. This test method also provides one element in comparing

stones of the same type.

1.2 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. The values stated in

5. Apparatus

each system may not be exact equivalents; therefore, each

5.1 The testing machine used shall conform to the require-

system shall be used independently of the other. Combining

ments of Test Method C39, Section 5, including the calibration

values from the two systems may result in non-conformance

requirements of Practices E4.

with the standard.

5.2 The testing machine used shall be capable of applying

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the the required load at a uniform rate as prescribed in Section 9

and applying load in a steady manner as to avoid sudden or

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- rapid load changes.

bility of regulatory limitations prior to use.

5.3 The spherical bearing block of the testing machine shall

be suspended from the upper head so that the contact plate

2. Referenced Documents

remains in a central position (spherical surfaces in full contact)

2.1 ASTM Standards:

when not loaded. The spherical surfaces shall be well

C39 Test Method for Compressive Strength of Cylindrical

lubricated, and the center of curvature shall be aligned within

Concrete Specimens

the surface of contact with the specimen.

C119 Terminology Relating to Dimension Stone

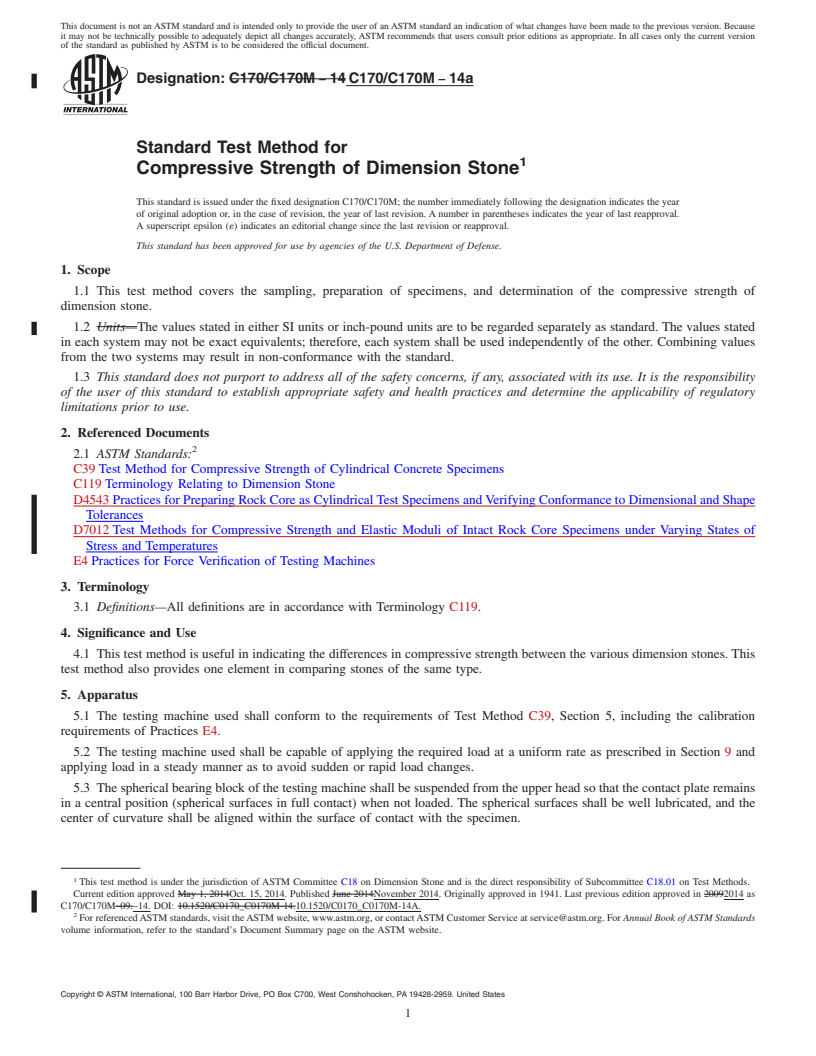

5.4 Fig.1illustratesthecorrectalignmentofaspecimenand

D4543 PracticesforPreparingRockCoreasCylindricalTest

the typical components of a testing machine conforming to

Specimens and Verifying Conformance to Dimensional

these requirements.

and Shape Tolerances

D7012 Test Methods for Compressive Strength and Elastic

6. Sampling

Moduli of Intact Rock Core Specimens under Varying

6.1 The sample shall be selected to represent a true average

States of Stress and Temperatures

of the type or grade of stone under consideration and shall be

E4 Practices for Force Verification of Testing Machines

of the quality supplied to the market in finished form under the

type designation to be tested. The sample may be selected by

3. Terminology

the purchaser or his authorized representative from quarried

3.1 Definitions—All definitions are in accordance with Ter-

stone or taken from the natural ledge and shall be of adequate

minology C119.

size to permit the preparation of the desired number of test

specimens. When perceptible variations occur, the purchaser

1 may select as many samples as are necessary for determining

This test method is under the jurisdiction of ASTM Committee C18 on

Dimension Stone and is the direct responsibility of Subcommittee C18.01 on Test

the variation in compressive strength.

Methods.

Current edition approved Oct. 15, 2014. Published November 2014. Originally

7. Test Specimens

approved in 1941. Last previous edition approved in 2014 as C170/C170M–14.

DOI: 10.1520/C0170_C0170M-14A.

7.1 The test specimens may be cubes or right cylinders and

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

shall be cut from the sample with saws or core drills. The

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

diameter or lateral dimension (distance between opposite

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. vertical surfaces) shall be not less than 2 in. [50 mm]

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C170/C170M − 14a

7.6 The load-bearing surfaces and the direction of rift shall

be marked on each specimen.

7.7 Use of capping materials or end surfacing treatments

other than grinding shall not be permitted.

8. Conditioning

8.1 Before testing the specimens in a dry condition, dry

them for 48 h at 140 6 4°F [60 6 2°C].At the 46th, 47th, and

48th h, weigh the specimens to ensure that the weight is the

same. If the weight continues to drop, continue to dry the

specimens until there are 3 successive hourly readings with the

same weight. After removing the specimens from the oven,

cool them to room temperature in a desiccator before testing

them.

FIG. 1 Diagram of a Specimen Properly Aligned within a Testing

8.2 Before testing the specimens in a wet condition, im-

Apparatus Suitable for Compressive Strength Testing

merse them in water for 48 h at 72 6 4°F [22 6 2°C]. Test

them immediately upon removal from the bath, wiping the

dimensional to accommodate variations in the grain size or

specimens free of surface water.

composition of the sample (Explanatory Note 1).

9. Procedure

7.2 The ratio of height (the distance between the surfaces in

9.1 The load-bearing area of each specimen shall be calcu-

contact with the testing apparatus) to the diameter or lateral

lated from measurements taken midway between the surfaces

dimension shall be between 0.9:1.0 and 1.1:1.0 (Explanatory

in contact with the testing apparatus and calculated to the

Note 2).

2 2

nearest 0.1 in. [60 mm ]. An alternate approach for determin-

7.3 The sides of the specimen shall be smooth and straight

ing the load-bearing area is to calculate the areas of the top and

towithin0.02in.[0.5mm]overthefullheightofthespecimen.

2 2

bottom bearing surfaces to the nearest 0.1 in. [60 mm ] and

7.4 The two surfaces in contact with the testing apparatus

average these values.

shall have a fine abrasive finish, and the other surfaces shall

9.2 Center the specimens in the testing machine and apply

have a fine sawn finish (Explanatory Note 5). The surfaces in

an initial seating load that will hold the specimen in place but

contact with the testing apparatus shall be ground or lapped to

still permit hand adjustment of the contact plate on the

a flatness tolerance of plus or minus 0.005 in. [0.1 mm], and

specimen. Rotate the contact plate back and forth through an

shall not depart from perpendicular to the longitudinal axis of

angle of approximately 30 deg. to properly seat the spherical

the specimen by more than 0.25 deg.

block,butdonotmovethespecimenoutofthecentralposition.

7.5 At least five specimens shall be prepared for each test

9.3 Apply load at a uniform rate not exceeding 100 psi/s

condition. Final test conditions are determined by the project

[0.5 MPa/s].

conditions and specified with the testing request. Typically,

9.4 Apply the load until specimen failure. Failure of the

testing includes wet and dry conditions both perpendicular and

specimen is defined as the inability of the specimen to resist

parallel to

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C170/C170M − 14 C170/C170M − 14a

Standard Test Method for

Compressive Strength of Dimension Stone

This standard is issued under the fixed designation C170/C170M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This test method covers the sampling, preparation of specimens, and determination of the compressive strength of

dimension stone.

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated

in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values

from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C39 Test Method for Compressive Strength of Cylindrical Concrete Specimens

C119 Terminology Relating to Dimension Stone

D4543 Practices for Preparing Rock Core as Cylindrical Test Specimens and Verifying Conformance to Dimensional and Shape

Tolerances

D7012 Test Methods for Compressive Strength and Elastic Moduli of Intact Rock Core Specimens under Varying States of

Stress and Temperatures

E4 Practices for Force Verification of Testing Machines

3. Terminology

3.1 Definitions—All definitions are in accordance with Terminology C119.

4. Significance and Use

4.1 This test method is useful in indicating the differences in compressive strength between the various dimension stones. This

test method also provides one element in comparing stones of the same type.

5. Apparatus

5.1 The testing machine used shall conform to the requirements of Test Method C39, Section 5, including the calibration

requirements of Practices E4.

5.2 The testing machine used shall be capable of applying the required load at a uniform rate as prescribed in Section 9 and

applying load in a steady manner as to avoid sudden or rapid load changes.

5.3 The spherical bearing block of the testing machine shall be suspended from the upper head so that the contact plate remains

in a central position (spherical surfaces in full contact) when not loaded. The spherical surfaces shall be well lubricated, and the

center of curvature shall be aligned within the surface of contact with the specimen.

This test method is under the jurisdiction of ASTM Committee C18 on Dimension Stone and is the direct responsibility of Subcommittee C18.01 on Test Methods.

Current edition approved May 1, 2014Oct. 15, 2014. Published June 2014November 2014. Originally approved in 1941. Last previous edition approved in 20092014 as

C170/C170M–09.–14. DOI: 10.1520/C0170_C0170M-14.10.1520/C0170_C0170M-14A.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C170/C170M − 14a

5.4 Fig. 1 illustrates the correct alignment of a specimen and the typical components of a testing machine conforming to these

requirements.

6. Sampling

6.1 The sample shall be selected to represent a true average of the type or grade of stone under consideration and shall be of

the quality supplied to the market in finished form under the type designation to be tested. The sample may be selected by the

purchaser or his authorized representative from quarried stone or taken from the natural ledge and shall be of adequate size to

permit the preparation of the desired number of test specimens. When perceptible variations occur, the purchaser may select as

many samples as are necessary for determining the variation in compressive strength.

7. Test Specimens

7.1 The test specimens may be cubes or right cylinders and shall be cut from the sample with saws or core drills. The diameter

or lateral dimension (distance between opposite vertical surfaces) shall be not less than 2 in. [50 mm] dimensional to accommodate

variations in the grain size or composition of the sample (Explanatory Note 1).

7.2 The ratio of height (the distance between the surfaces in contact with the testing apparatus) to the diameter or lateral

dimension shall be between 0.9:1.0 and 1.1:1.0 (Explanatory Note 2).

7.3 The sides of the specimen shall be smooth and straight to within 0.02 in. [0.5 mm] over the full height of the specimen.

7.4 The two surfaces in contact with the testing apparatus shall have a fine abrasive finish, and the other surfaces shall have a

fine sawn finish (Explanatory Note 5). The surfaces in contact with the testing apparatus shall be ground or lapped to a flatness

tolerance of plus or minus 0.005 in. [0.1 mm], and shall not depart from perpendicular to the longitudinal axis of the specimen

by more than 0.25 deg.

7.5 The test specimens may be cubes or cylinders and shall be cut from the sample with saws or core drills. The diameter or

lateral dimension (distance between opposite vertical faces) shall be not less than 2 in. [50 mm] (Explanatory Note 1), and the ratio

of height (Explanatory Note 2) to diameter or lateral dimension shall be 1:1. At least five specimens shall be prepared for each

condition of the test; that is, when the compressive strength is desired for the test condition. Final test conditions are determined

by the project conditions and specified with the testing request. Typically, testing includes wet and dry conditions but in only one

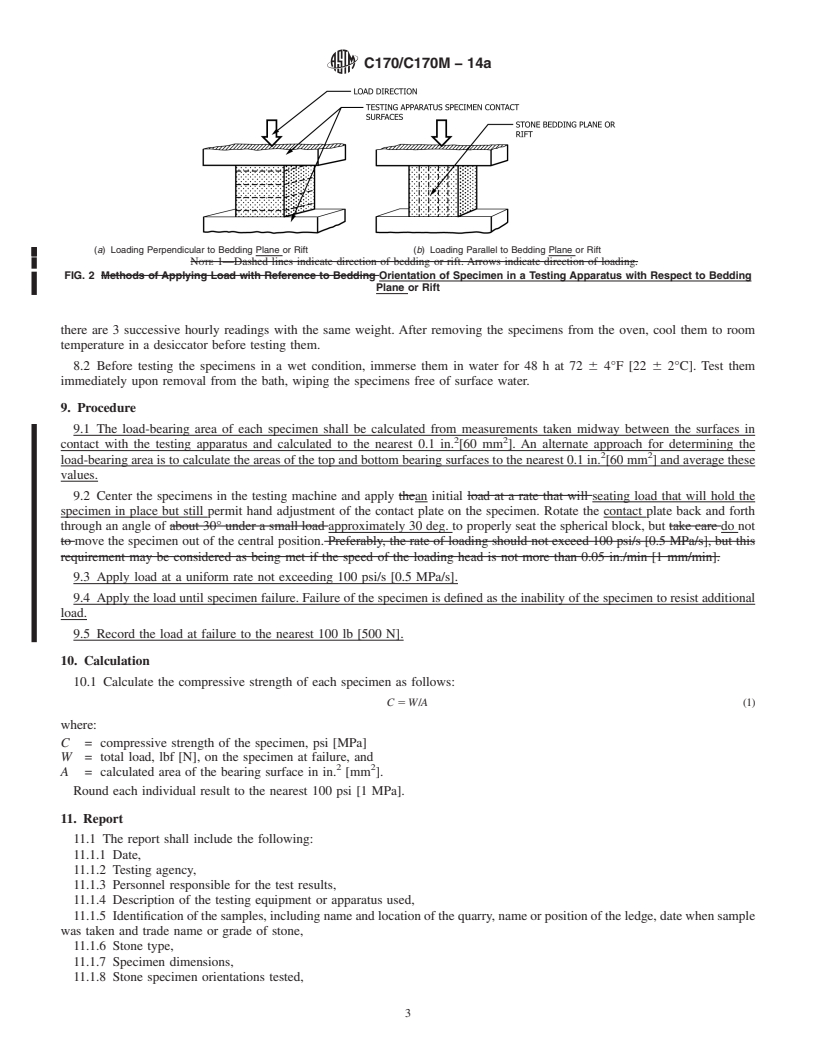

direction, such as perpendicular to the bed (or rift) (seeboth perpendicular and parallel to the stone rift (plane of Fig. 2(easiesta)),

ten specimens will be required. For wet splitting, typically consistent with the bedding plane orientation), requiring a minimum

of 20 specimens. Fig. 2a and Fig. 2dry strength tests both perpendicular and parallel to the bed (or rift) (seeb illustrate the proper

placement of test specimens within a testing apparatus for Fig. 2(thea) and ( two mostb)), twenty specimens are required

(Explanatory common rift orientations. Note 3). The load-bearing facessurfaces shall be finished by grinding to as nearly true and

parallel planes (Explanatory Note 45) as practicable.

7.6 The load-bearing surfaces and the direction of bedding (or rift) rift shall be marked on each specimen after

finishing.specimen.

7.7 The load-bearing areas of the specimen shall be calculated from measurements taken midway between the load-bearing

surfaces. The dimensions of the specimens shall be measured to the nearest 0.02 in. (0.5 mm) and the load-bearing areas calculated

2 2

to the nearest 0.04 in.Use of capping materials or end surfacing treatments other than grinding shall not be permitted. [0.10 mm ].

8. Conditioning

8.1 Before testing the specimens in a dry condition, dry them for 48 h at 140 6 4°F [60 6 2°C]. At the 46th, 47th, and 48th

h, weigh the specimens to ensure that the weight is the same. If the weight continues to drop, continue to dry the specimens until

FIG. 1 Diagram of a Specimen Properly Aligned within a Testing Apparatus Suitable for Compressive Strength Testing

C170/C170M − 14a

(a) Loading Perpendicular to Bedding Plane or Rift (b) Loading Parallel to Bedding Plane or Rift

NOTE 1—Dashed lines indicate direction of bedding or rift. Arrows indicate direction of loading.

FIG. 2 Methods of Applying Load with Reference to Bedding Orientation of Specimen in a Testing Apparatus with Respect to Bedding

Plane or Rift

there are 3 successive hourly readings with the same weight. After removing the specimens from the oven, cool them to room

temperature in a desiccator before testing them.

8.2 Before testing the specimens in a wet condition, immerse them in water for 48 h at 72 6 4°F [22 6 2°C]. Test th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.