ASTM D1369-84(2000)

(Practice)Standard Practice for Quantities of Materials for Bituminous Surface Treatments

Standard Practice for Quantities of Materials for Bituminous Surface Treatments

SCOPE

1.1 This practice covers the rates of application of bituminous materials and aggregates and types and grades of bituminous materials for single and multiple bituminous surface treatments as applied to suitably prepared pavements or bases.

1.2 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of whoever uses this standard to consult and establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1369–84 (Reapproved 2000)

Standard Practice for

Quantities of Materials for Bituminous Surface Treatments

This standard is issued under the fixed designation D 1369; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.1.1 The types of surface treatments covered by this

practice are as follows:

1.1 This practice covers the rates of application of bitumi-

3.1.2 multiple-surface treatment—a wearing surface com-

nous materials and aggregates and types and grades of bitumi-

posed of bituminous material and aggregate, in which coarser

nous materials for single and multiple bituminous surface

aggregate is placed uniformly over an initial application of

treatments as applied to suitably prepared pavements or bases.

bituminous material and followed by one or more subsequent

1.2 This standard does not purport to address all of the

applications of bituminous material and smaller aggregate.

safety concerns, if any, associated with its use. It is the

3.1.2.1 Discussion—Generally, the designated maximum

responsibility of the user of this standard to establish appro-

size of the smaller aggregate is one half that of the aggregate

priate safety and health practices and determine the applica-

used in the preceding application. Each application of aggre-

bility of regulatory limitations prior to use.

gate is placed uniformly in a single layer, the thickness of

2. Referenced Documents which approximates the nominal maximum size of the aggre-

gate.

2.1 ASTM Standards:

3.1.3 single-surface treatment—a wearing surface of bitu-

C 29/C29M Test Method for Unit Weight and Voids in

minousmaterialandaggregateinwhichtheaggregateisplaced

Aggregate

uniformly over the applied bituminous material in a single

D 448 Classification for Sizes of Aggregate for Road and

layer, the thickness of which approximates the nominal maxi-

Bridge Construction

mum size of the aggregate used.

D 490 Specification for Road Tar

D 633 Volume Correction Table for Road Tar

4. Significance and Use

D 946 Specification for Penetration-Graded Asphalt Ce-

4.1 This practice is intended to be used as a guide by those

ment for Use in Pavement Construction

3 involved in the design of bituminous surface treatments. It

D 977 Specification for Emulsified Asphalt

covers typical application rates for the various types of surface

D 1139 Specification for Aggregate for Single or Multiple

3 treatments and covers aggregate sizes and covers recom-

Bituminous Surface Treatments

mended grades of asphaltic material for both hot and cool

D 1250 Guide for Petroleum Measurement Tables

weather conditions.

D 2027 Specification for CutbackAsphalt (Medium-Curing

4.2 The typical bituminous material application rates given

Type)

are for normal surfaces and non-porous aggregates. Provision

D 2028 Specification for Cutback Asphalt (Rapid-Curing

is made for rate adjustment when other than normal surfaces or

Type)

3 porous aggregates, or both, are involved.

D 2397 Specification for Cationic Emulsified Asphalt

5. Rates of Application

3. Terminology

5.1 Typical quantities of materials for the several types of

3.1 Definitions:

surface treatments are listed in Table 1 and Table 2.

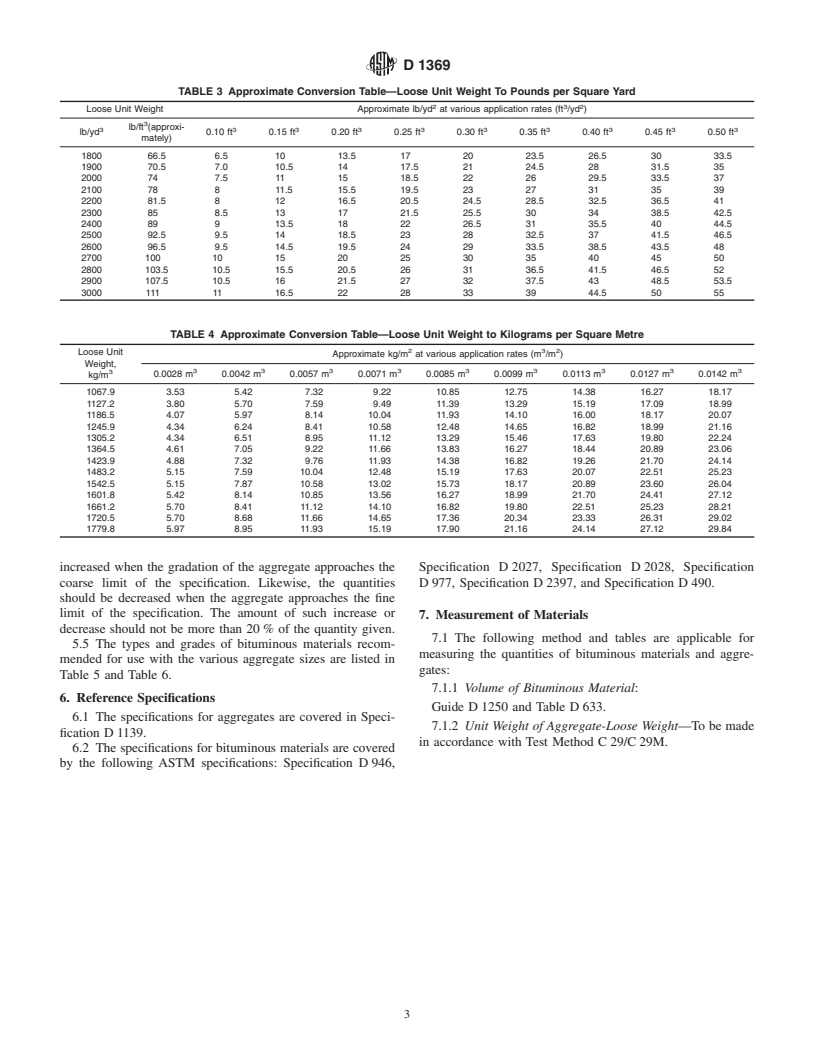

5.2 The quantities of the various gradations are normally

This practice is under the jurisdiction of ASTM Committee D04 on Road and

sufficient to provide a uniform cover over the area specified.

Paving Materials and is the direct responsibility of Subcommittee D04.24 on

Thequantitiesofaggregateareshownbyvolumemeasurement

Bituminous Surface Treatments.

in order to minimize the effect of variations due to specific

CurrenteditionapprovedMarch30,1984.PublishedSeptember1984.Originally

gravity, particle shape, surface texture, and porosity. For job

issued 1955. Last previous edition D 1369 – 84.

Annual Book of ASTM Standards, Vol 04.02.

control, the quantity of aggregate by volume may be converted

Annual Book of ASTM Standards, Vol 04.03.

to a weight figure by determining the loose unit weight of the

Annual Book of ASTM Standards,Vol 05.01 (Description only; tables published

separately in twelve volumes).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

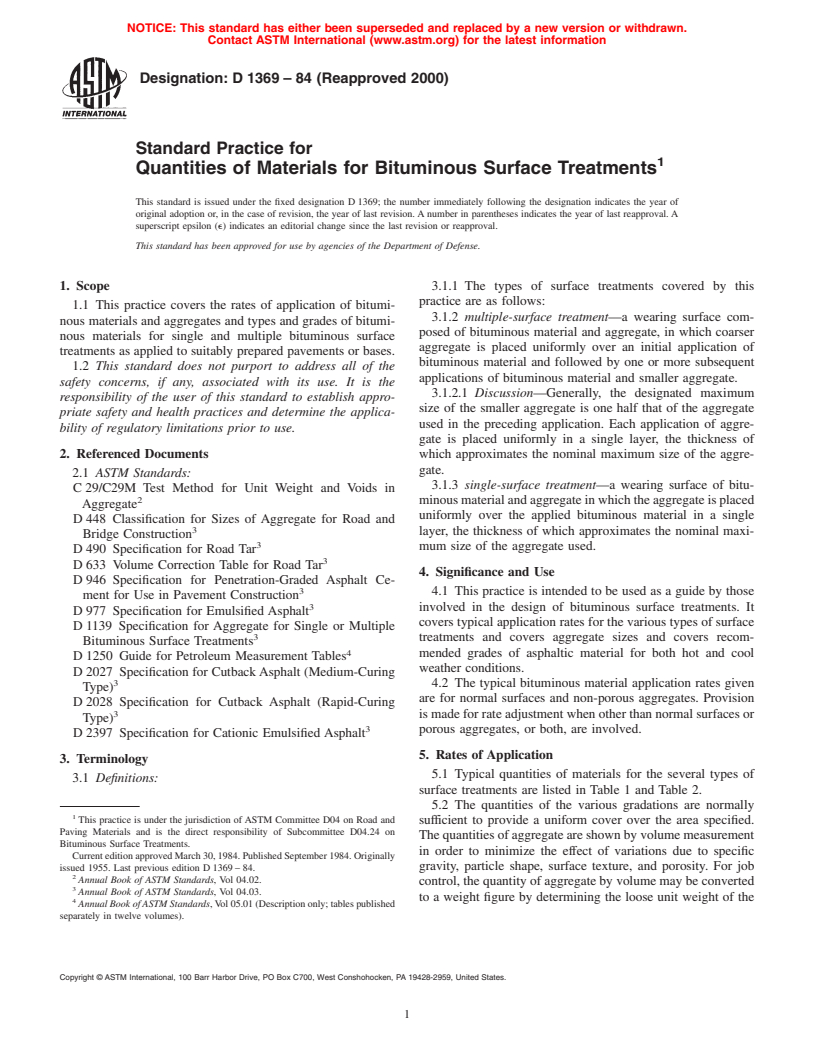

D1369

TABLE 1 Quantities of Materials for Bituminous Surface Treatments (U.S. Customary Units)

NOTE 1—The values are typical design or target values and are not necessarily obtainable to the precision indicated.

Bituminous Mate-

Surface Treatment Aggregate

A

rial

Nominal Size Typical Rate of Ap- Typical Rate of Ap-

B

Type Application Size No.

3 2 2

(Square Openings) plication, ft /yd plication, gal/yd

Single initial 5 1 in. to ⁄2 in. 0.50 0.42

3 3

6 ⁄4in. to ⁄8in. 0.36 0.37

7 ⁄2in. to No. 4 0.23 0.23

8 ⁄8in. to No. 8 0.17 0.19

9 No. 4 to No. 16 0.11 0.13

Double initial 5 1 in. to ⁄2 in. 0.50 0.42

second 7 ⁄2 in. to No. 4 0.25 0.26

3 3

Double initial 6 ⁄4 in. to ⁄8 in. 0.36 0.37

second 8 ⁄8 in. to No. 8 0.18 0.20

Triple initial 5 1 in. to ⁄2 in. 0.50 0.42

second 7 ⁄2 in. to No. 4 0.25 0.26

third 9 No. 4 to No. 16 0.13 0.14

3 3

Triple initial 6 ⁄4 in. to ⁄8 in. 0.36 0.37

second 8 ⁄8 in. to No. 8 0.18 0.20

third 9 No. 4 to No. 16 0.13 0.14

A

Experience has shown that these quantities should be increased slightly (5 to 10 %) when the bituminous material to be used was manufactured for application with

little or no heating.

B

According to Classification D 448.

TABLE 2 Quantities of Materials for Bituminous Surface Treatments (Metric Units)

NOTE 1—The values are typical design or target values and are not necessarily obtainable to the precision indicated.

A

Surface Treatment Aggregate Bituminous Material

Typical Rate of

Nominal Size Typical Rate of Ap-

B

Type Application Size No. Application,

(Square Openings, mm) plication, litre/m

3 2

m /m

Single initial 5 25.0 to 12.5 0.017 1.90

6 19.0 to 9.5 0.012 1.68

7 12.5 to 4.75 0.008 1.04

8 9.5 to 2.36 0.006 0.86

9 4.8 to 1.2 0.004 0.59

Double initial 5 25.0 to 12.5 0.017 1.90

second 7 2.5 to 4.75 0.008 1.18

Double initial 6 19.0 to 9.5 0.012 1.68

second 8 9.5 to 2.36 0.006 0.91

Triple initial 5 25.0 to 12.5 0.017 1.90

second 7 12.5 to 4.75 0.008 1.18

third 9 4.75 to 1.18 0.004 0.63

Triple initial 6 19.0 to 9.5 0.012 1.68

second 8 9.5 to 2.36 0.006 0.91

third 9 4.75 to 1.18 0.004 0.63

A

Experience has shown that these quantities should be increased slightly (5 to 10 %) when the bituminous material to be used was manufactured for application with

little or no heating.

B

According to Classification D 448.

aggregate and calculating or

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.