ASTM D2668-02e1

(Test Method)Standard Test Method for 2,6-di-tert-Butyl- p-Cresol and 2,6-di-tert-Butyl Phenol in Electrical Insulating Oil by Infrared Absorption

Standard Test Method for 2,6-<i>di-tert</i>-Butyl-<i> p</i>-Cresol and 2,6-<ital>di-tert</ital>-Butyl Phenol in Electrical Insulating Oil by Infrared Absorption

SCOPE

1.1 This test method covers the determination of the weight percent of 2,6-ditertiary-butyl paracresol and 2,6-ditertiary-butyl phenol in new or used electrical insulating oil in concentrations up to 0.5 % by measuring its absorbance at the specified wavelengths in the infrared spectrum.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation:D 2668–02

Standard Test Method for

2,6-di-tert-Butyl-p-Cresol and 2,6-di-tert-Butyl Phenol in Electrical

1

Insulating Oil by Infrared Absorption

This standard is issued under the fixed designation D 2668; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1 −1 −1

e NOTE—TheabsorbanceofDBPCandDBPwascorrectedfrom3680cm to3650cm in3.2editoriallyinNovember2005.

1. Scope* an increase in absorbance of the spectrum at several wave-

lengths (or wavenumbers). 2,6 ditertiary-butyl paracresol pro-

1.1 This test method covers the determination of the weight

duces pronounced increases in absorbance at 2.72 µm (3650

percent of 2,6-ditertiary-butyl paracresol and 2,6-ditertiary-

−1 −1

cm ), and 11.63 µm (860 cm ). 2,6 ditertiary-butyl phenol

butyl phenol in new or used electrical insulating oil in

producespronouncedincreasesinabsorbanceat2.72µm(3650

concentrations up to 0.5% by measuring its absorbance at the

−1 −1

cm ) and 13.33 µm (750 cm ).

specified wavelengths in the infrared spectrum.

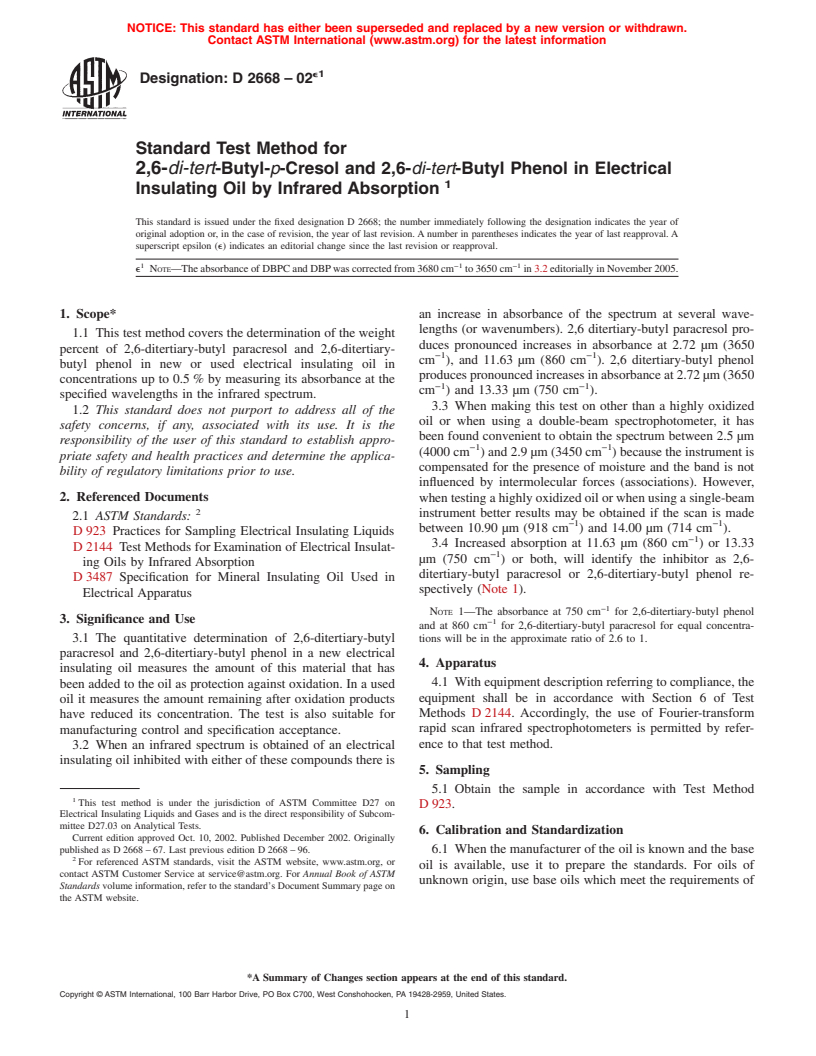

3.3 When making this test on other than a highly oxidized

1.2 This standard does not purport to address all of the

oil or when using a double-beam spectrophotometer, it has

safety concerns, if any, associated with its use. It is the

been found convenient to obtain the spectrum between 2.5 µm

responsibility of the user of this standard to establish appro-

−1 −1

(4000cm )and2.9µm(3450cm )becausetheinstrumentis

priate safety and health practices and determine the applica-

compensated for the presence of moisture and the band is not

bility of regulatory limitations prior to use.

influenced by intermolecular forces (associations). However,

2. Referenced Documents

whentestingahighlyoxidizedoilorwhenusingasingle-beam

2

instrument better results may be obtained if the scan is made

2.1 ASTM Standards:

−1 −1

between 10.90 µm (918 cm ) and 14.00 µm (714 cm ).

D923 Practices for Sampling Electrical Insulating Liquids

−1

3.4 Increased absorption at 11.63 µm (860 cm ) or 13.33

D2144 Test Methods for Examination of Electrical Insulat-

−1

µm (750 cm ) or both, will identify the inhibitor as 2,6-

ing Oils by Infrared Absorption

ditertiary-butyl paracresol or 2,6-ditertiary-butyl phenol re-

D3487 Specification for Mineral Insulating Oil Used in

spectively (Note 1).

Electrical Apparatus

−1

NOTE 1—The absorbance at 750 cm for 2,6-ditertiary-butyl phenol

3. Significance and Use

−1

and at 860 cm for 2,6-ditertiary-butyl paracresol for equal concentra-

3.1 The quantitative determination of 2,6-ditertiary-butyl tions will be in the approximate ratio of 2.6 to 1.

paracresol and 2,6-ditertiary-butyl phenol in a new electrical

4. Apparatus

insulating oil measures the amount of this material that has

4.1 Withequipmentdescriptionreferringtocompliance,the

been added to the oil as protection against oxidation. In a used

equipment shall be in accordance with Section 6 of Test

oil it measures the amount remaining after oxidation products

Methods D2144. Accordingly, the use of Fourier-transform

have reduced its concentration. The test is also suitable for

rapid scan infrared spectrophotometers is permitted by refer-

manufacturing control and specification acceptance.

ence to that test method.

3.2 When an infrared spectrum is obtained of an electrical

insulating oil inhibited with either of these compounds there is

5. Sampling

5.1 Obtain the sample in accordance with Test Method

1

This test method is under the jurisdiction of ASTM Committee D27 on

D923.

Electrical Insulating Liquids and Gases and is the direct responsibility of Subcom-

mittee D27.03 on Analytical Tests.

6. Calibration and Standardization

Current edition approved Oct. 10, 2002. Published December 2002. Originally

published as D2668–67. Last previous edition D2668–96. 6.1 Whenthemanufactureroftheoilisknownandthebase

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

oil is available, use it to prepare the standards. For oils of

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

unknown origin, use base oils which meet the requirements of

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

e1

D 2668–02

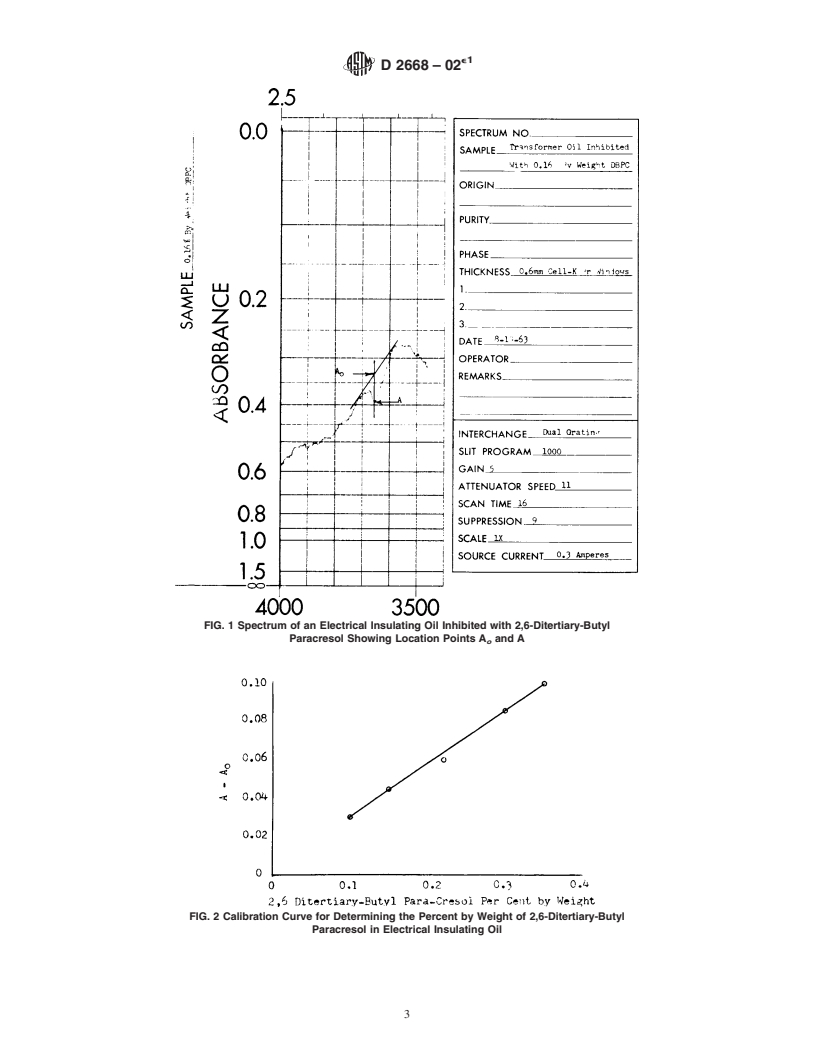

Specification D3487. Some base oils may provide a better test specimen may be determined. One such calibration curve

match than others and therefore it is desirable

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.